While waiting for samples to arrive, I tried some regular black vinyl just to see how it would hold up - it basically disintegrated and was difficult to remove, despite barely sticking to the rusty metal. This is with some unspecified ((probably 80 grit (unlabeled inherited bag)) abrasive at about 80 psi. I held the nozzle well away from the material to try not to obliterate the vinyl immediately.

Then a few samples from Beacon Graphics arrived - all 3 were Hartco brand. Each sheet was only about 4x6 inches, so I did not have a lot of wiggle room.

One was 35 mil high tack heavy duty - rolls are $100 and up, and overkill for most of our work, I think.

The next was a thinner, low tack 22.5 mil vinyl. The low tack sheets seemed to threaten to detach fairly easily on my 5 in. diameter thermos.

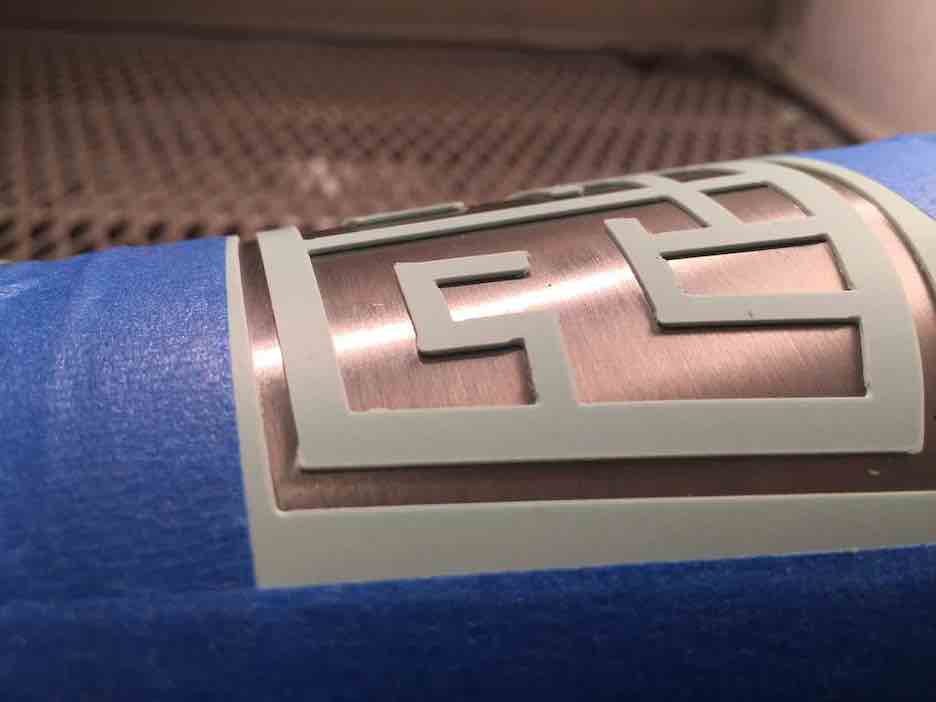

The one I used in the photos was a 25 mil low tack (400 series). It took the highest force setting on the Roland, and 2 passes to cut through to the backing.

After applying to my guinea pig, the favorite coffee thermos, I noticed long extensions wanting to lift up - I squeegeed the life out of it just before blasting to keep them down.

Relevant to our interests: the set of Hartco products has a shelf life listed at only about a year.

Also, its SDS information has eluded me so far (see below)

Then I got a roll of Anchor BlastLite Stencil T-226, 22 mil, Wood & HDU, High Tack

It comes $69.99 from uscutter.com, no shelf life listed, but as an aside, the site says it has acrylic adhesive and is safe to laser cut. The SDS sheet is extremely vague, but does not say anything that would throw up a laser cutting red flag.

This sheet material was reasonably thin relative to some of the Hartco stuff, and the high tack felt much more promising. As it went with the others, though, cutting through required a lot of force. 2 passes were not required with this sheet, however.

One problem with this material is the roll orientation - the curl at the end of the piece wants to trip the light sensor on the vinyl cutter too soon, so I had to hold it down - between that and occasional motor errors (probably too much resistance from the roll dragging during movement) I think it would be easier to cut sheets rather than directly from the roll. If it can be flattened/relaxed by sitting flat after being removed from the roll for a while before using, that would help.

>

>

>

> The thickness of the material makes the corners messy as the knife rotates turning a corner. The defect is sort of small, and would be insignificant visually, proportionally to a larger image. Small, detailed images would look more deformed (you can see the weird corners on the blue vinyl closeups), but would be difficult to transfer as well as cut, as I noticed with the blue Hartco sheet - the closer the thickness comes to the width of a detail, the more impossible it gets to transfer it without shifting it. The deformation at the corners is not a square edge, meaning not perpendicular to the XY of the sheet, so based on the appearance of my thermos at the end, if the sand is blasted at angles and gets under those wonky edges, the shape of the vinyl where the tip of the knife cut is more accurate and so the final results don’t look quite as terrible as the top of the vinyl stencil.

>

>

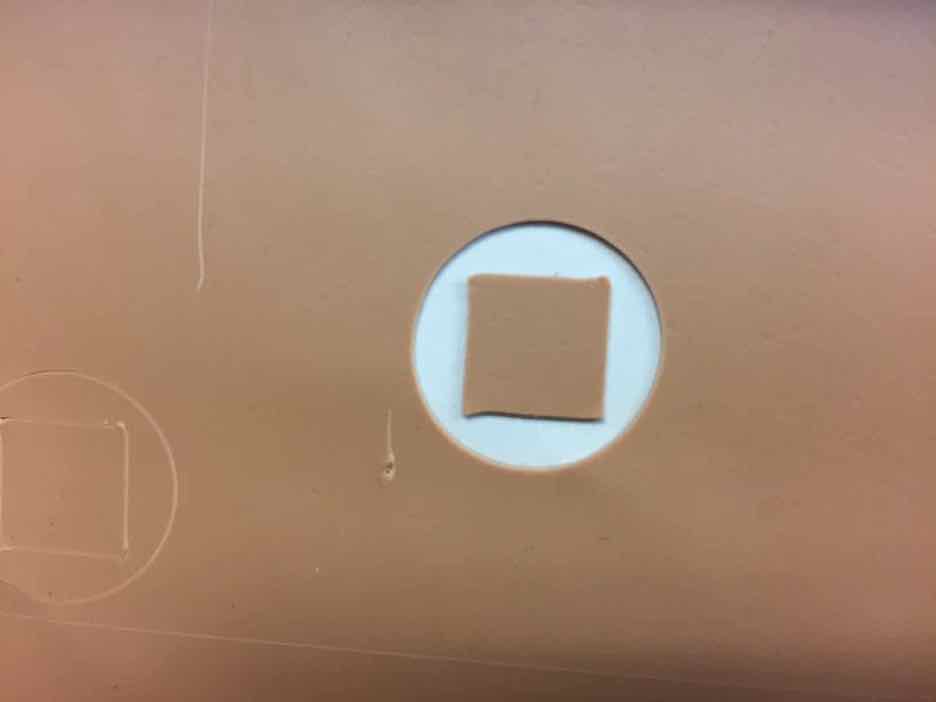

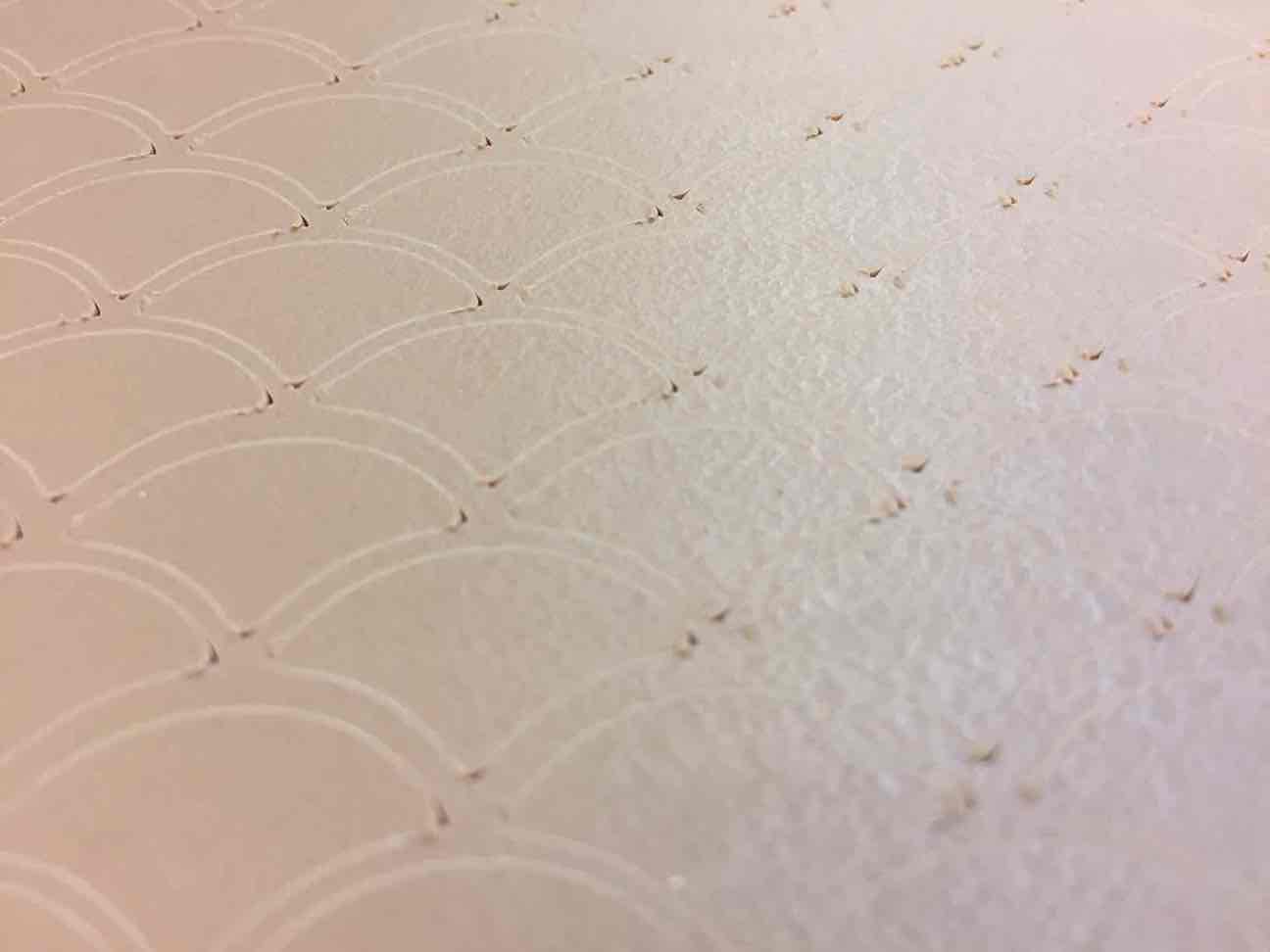

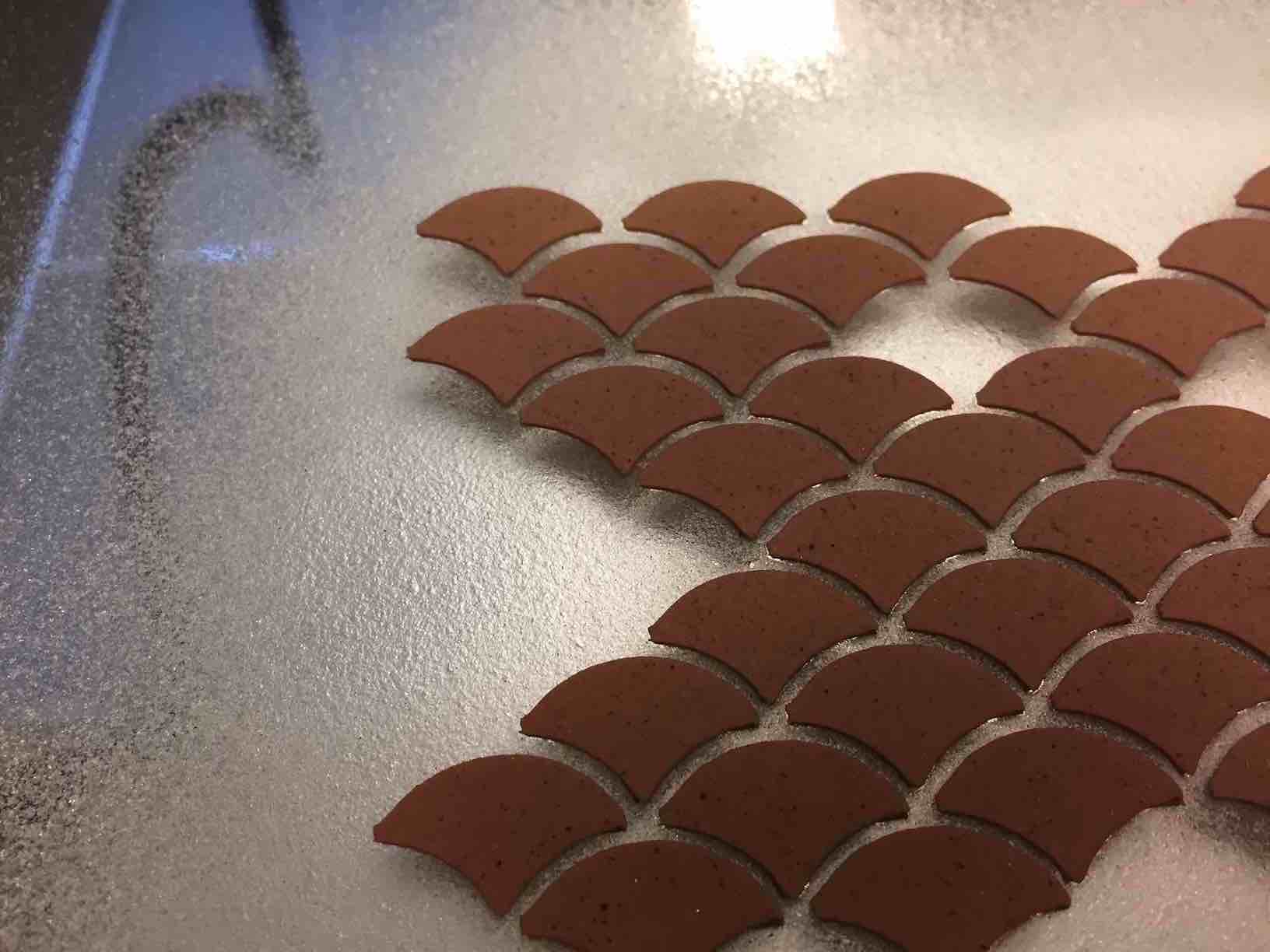

I tested the t-226 material on a spare piece of .25 in. mirror we had lying around in the shop. The results were interesting (and about as tacky as I could possibly have gotten, without using flamingos and palm trees for images). The abrasive is coarse, and left a really pitted-looking surface. The reflection was a detail I wasnt really thinking about when I grabbed it, but hey, bonus? The edges are rough, but these little objects are only .75 inches across.

I still want to try doubling up sheets of the regular vinyl we have in stock to see if it holds up better, but havent gotten around to it yet. I squeegeed 2 sheets together this afternoon, and just doing that without trapping lots of bubbles and/or ruining it entirely was difficult. May or may not end up being worth the effort. I also havent seen yet whether the same type of vinyl simply comes in thicker gauges, without being the soft rubbery type sold specifically for sand blasting stencils.