My final project idea was originally to build a ceramic 3D printer. I enjoy making ceramics as a hobby, so I wanted to explore the medium in a digital context. Based on conversations with the architecture section TAs, a more reasonable goal might be to focus on just the ceramic extruder. However, I wasn't really happy with just making an extruder, which seemed a bit useless. Near the end of the class, I decided to modify the design into an automatic toothpaste dispensor.

Originally, I was inspired by the different textures and patterns you can produce from 3d printed ceramics. After a bit of research, it was clear that there are a variety of techniques to 3D printing clay, as with the other materials we have explored in class. It was clear that the extruder mechanism would be the most challenging piece.

As I researched clay 3D printers, I found a lot of resources online of communities where people had either adapted an existing 3D printer with a clay extruder head or built what's called a delta 3D printer from scratch. A delta printer has three rods holding up a frame with a stepper motor controlling one arm of the printer head on each rod. For a hot second, I considered building the delta printer myself since I'd found some resources online to do it. However, I didn't feel comfortable figuring out the stepper motors in the amount of time I had left.

In my research, I also found a couple sites online describing the different ways clay could be extruded. This one seems to juse a basic stepper motor and auger to extrude.

After moving away from the clay printer extruder, which I do eventually want to try making when I have more time, I was inspired by the extruding mechanisms I'd been researching. What if instead of extruding clay, it extruded something else in a slightly more useful context? That's how the automatic toothpaste extruder idea was born.

A toothbrush would trigger a PIR sensor that would cause a stepper motor to turn a key attached to a tube of toothpaste, squeezing out a bit of toothpaste onto the toothbrush. I think this would be pretty simple to do, combining the PIR input and stepper motor output boards that already exist.

Luckily, I found someone who had made PIR motion sensor triggered bipolar stepper motor board. This was really helpful in figuring out what might work when designing my board: Seunghwan Ji's final project.

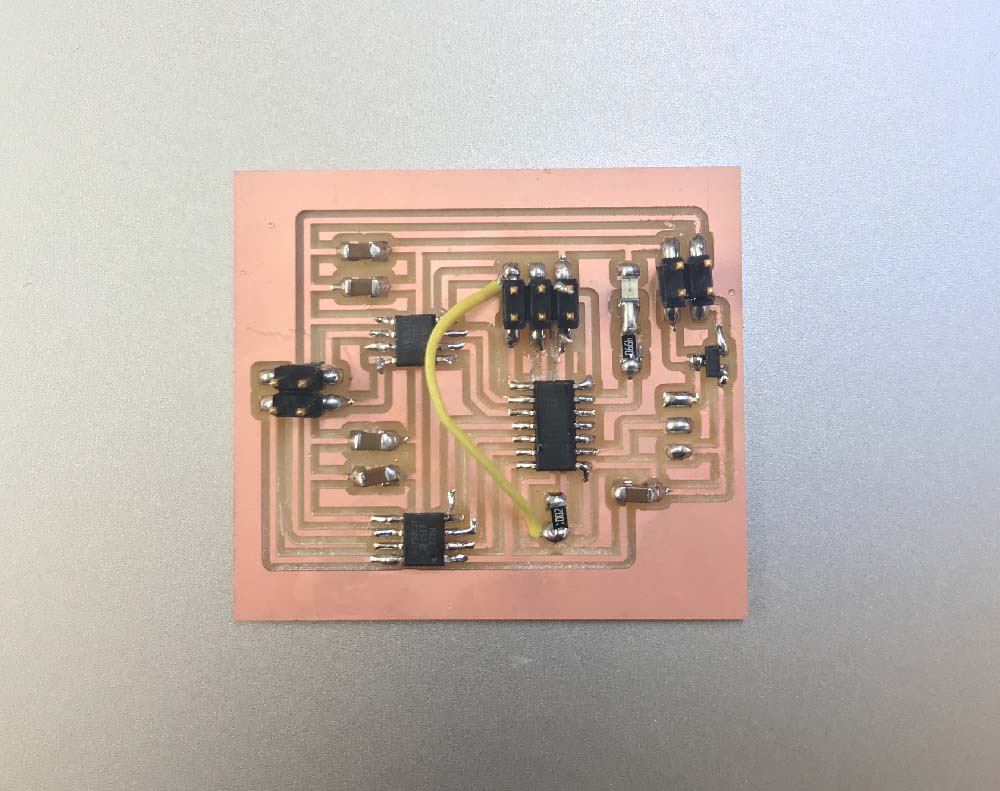

Using these hints, I drew the schematic and board in Eagle, exported to png, milled and stuffed the board.

This is where things got difficult. I tested the board with a multimeter, checking for shorts, and everything seemed fine. I then attached the board to the Atmel programmer we have in the architecture shop in order to try and program it using Arudino IDE. After flipping an LED on my board around, it seemed responsive, blinking when powered up.

Unfortunately, this is about as far as I got with programming the board. Despite following all the instructions on the high-low tech page and connecting it to the USBtinyISP, Arduino IDE just wasn't able to recognize the ATtiny44. I tried different computers and different wires, but it kept throwing the error.

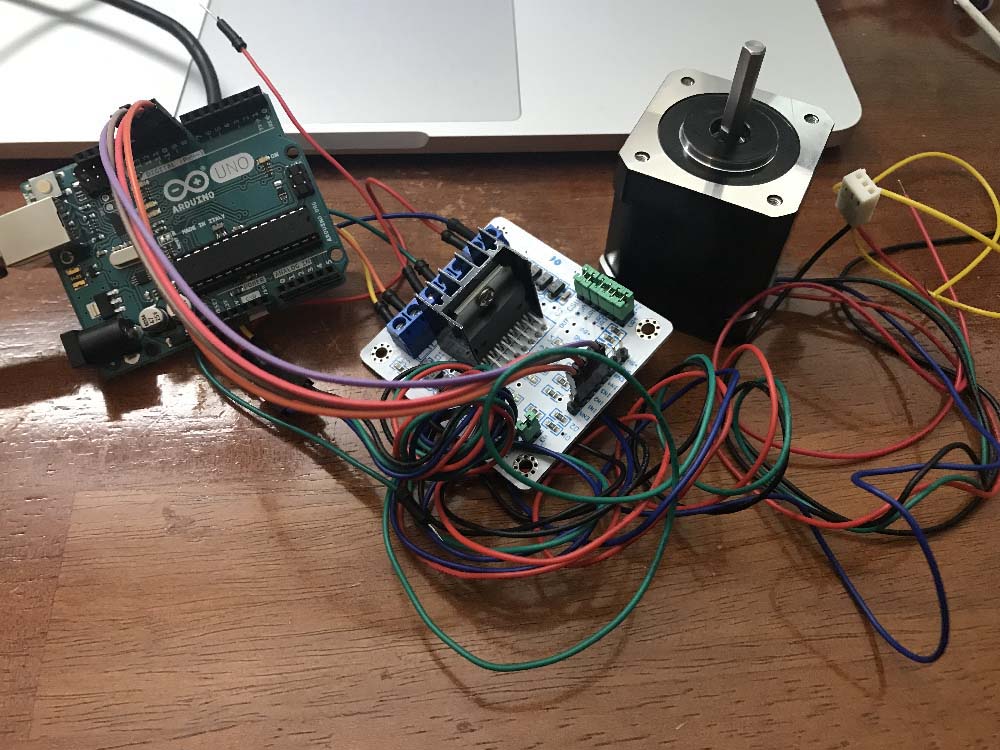

I got some help working on getting the Arduino working on the board, and in the meantime had the code for the stepper motor and PIR sensor. It seemed to work using an Arduino Uno and shield, but I still struggled to get it to work on my board.

After getting the stepper motor and PIR sensor working, I would have built a box to hide the wires with the toothpaste tube strapped on top. The stepper motor would be held by a 3D printed carriage that would slide on a horizontal metal rod. As the PIR sensor gets triggered, the motor would turn, moving the carriage along a track and turning the key attached to the toothpaste. The turning key would cause the tube to roll up at the end, squeezing out toothpaste.

Board traces and outline for milling

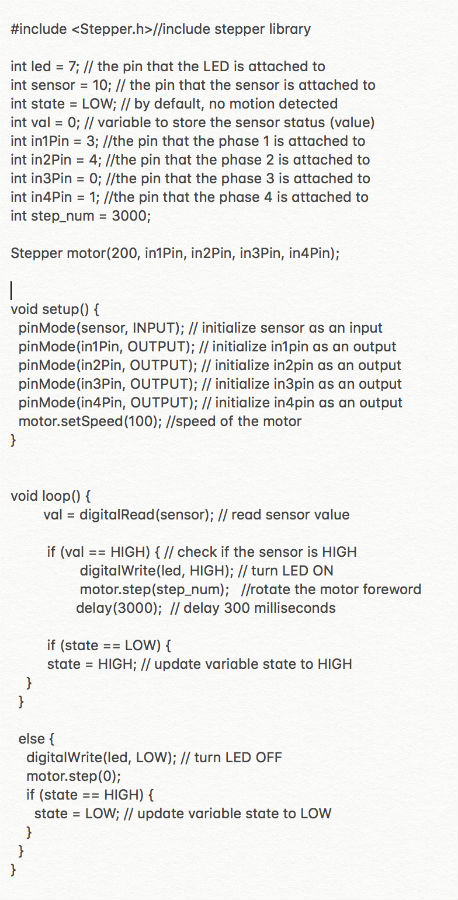

Arduino code