Wildcard Week: Machine Knitting

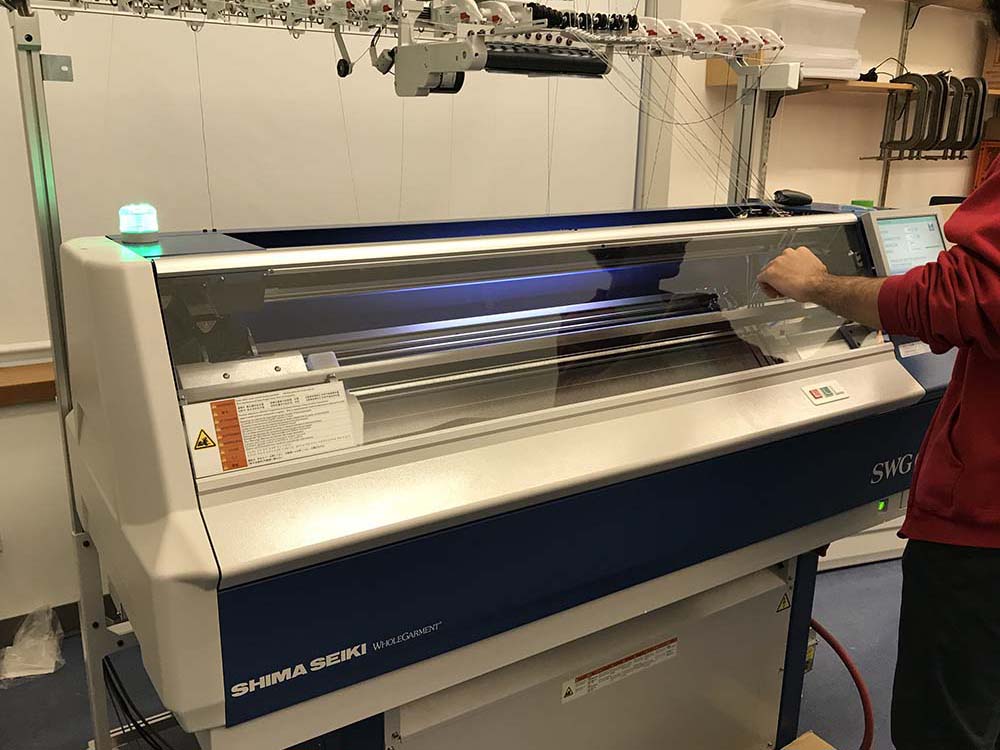

This week, I joined Alexandre Kaspar's machine knitting class. I knit as a hobby and have a fascination with textiles in general, so I was excited to see what a knitting machine could do. I visited Hong Kong Polytechnic Institute's textile lab this summer and got to see machine knitting and looming. I had heard that the machine we would get to use, a Shima Seiki, was very complex but extremely versatile.

In the first intro session, Alexandre showed us the basics of how the machine worked, how it processed different types of knitting instructions, and how we could create our own designs. What was really interesting to me was how much was like hand knitting--different stitch types and knitting processes--but also completely different. The programming of the knit patterns and some of the terminology were completely foreign to me.

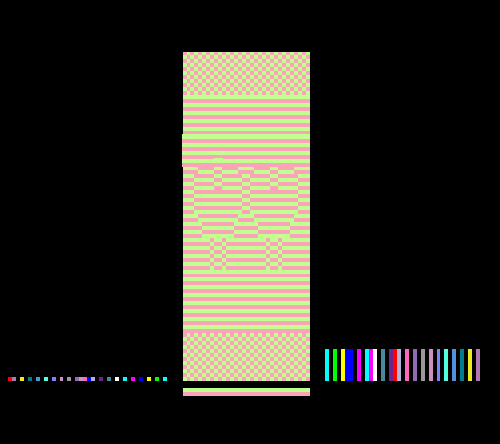

We were advised to keep it simple, so I decided to take one of Alexandre's demo patterns and modify it. We could either try to use Javascript to write a pattern or modify an image that the Shima Seiki program would read. I didn't feel comfortable writing a program, so I went straight to modifying the image.

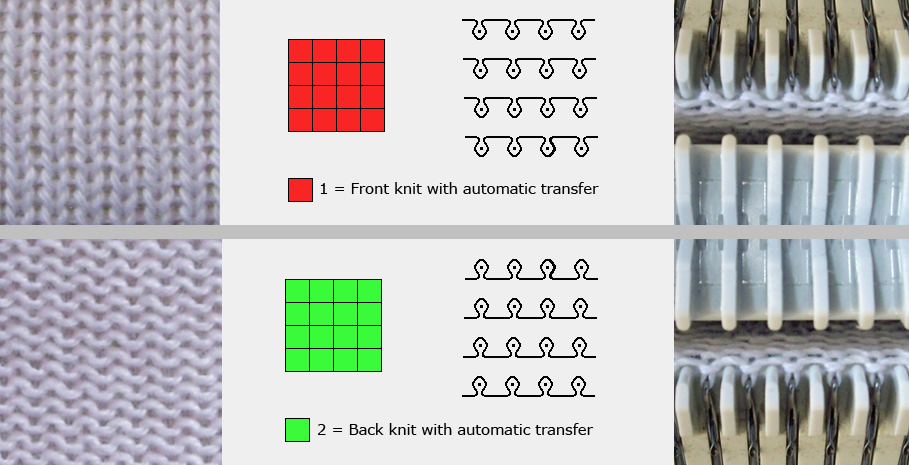

The knitting machine program uses a color-coded image to interface with the designer. Each pixel in the image represents a set of instructions. In the main body of the image, each pixel correlates with a stitch instruction. The color can mean one of many different types of stitches.

I had no idea what I was doing, so I created a very basic pattern based on a hand knitting pattern I saw online of multicolored sheep. Alexandre had advised us that the machine had been having trouble with multiple colors, so I decided to modify the pattern into a single-color tube construction with the sheep in a different stitch type. However, when it came time for us to process the pattern, I hadn't made it correctly. First, the different stitch types I had chosen couldn't be made in a tube form. Second, I was switching between an interlocking rib stitch at the bottom and top of the design, and a tube construction in the middle, which didn't really make sense.

Alexandre was really helpful in spending time to revise my pattern into something that the machine could work with. The program found so many errors that had to be laboriously fixed. When everything was finally fixed and checked, we could then send it to the machine.

The first knit/print was incredibly fast. I hadn't realized just how tiny my design was! However, the knit material came out with little holes where it looked like the machine had dropped a stitch or broken the yarn.

Alexandre loosened the tension on the machine and we tried again. This time, the result held together without any holes. It's a bit bigger than the first run because of the looser tension.