Week 10

mechanical machine design

Overview

This week, the architecture shop team made a machine for mixing drinks. I was on the Chassis and X-Axis team, and contributed to designing and building the main body for the machine, the x-axis, and cup holder.

Chassis Design

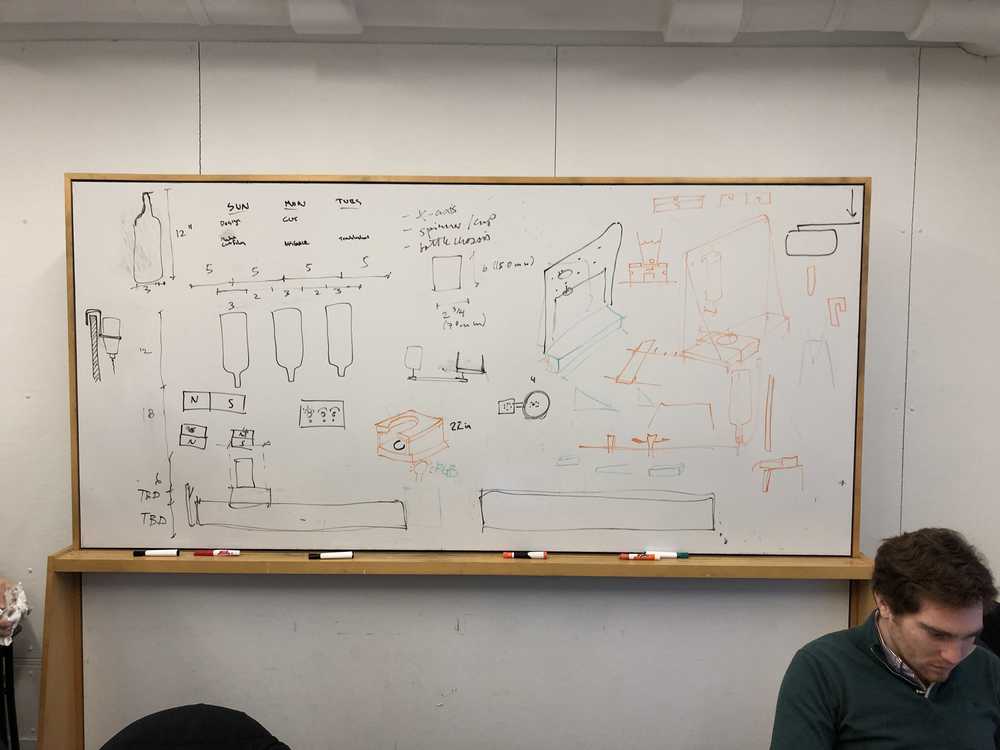

We took one axis from Jake’s fusion file, adjusted the dimensions based on the bottles and cup we would be using. We exported it from fusion to Rhino, where I modeled each of the pieces.

We tested several options for the body, and ultimately decided to have a modular backboard that could allow parallel design processes and on the fly adaptations.

In the future, we would redesign it so the bottles aren’t designed to drip directly onto the electronics below..

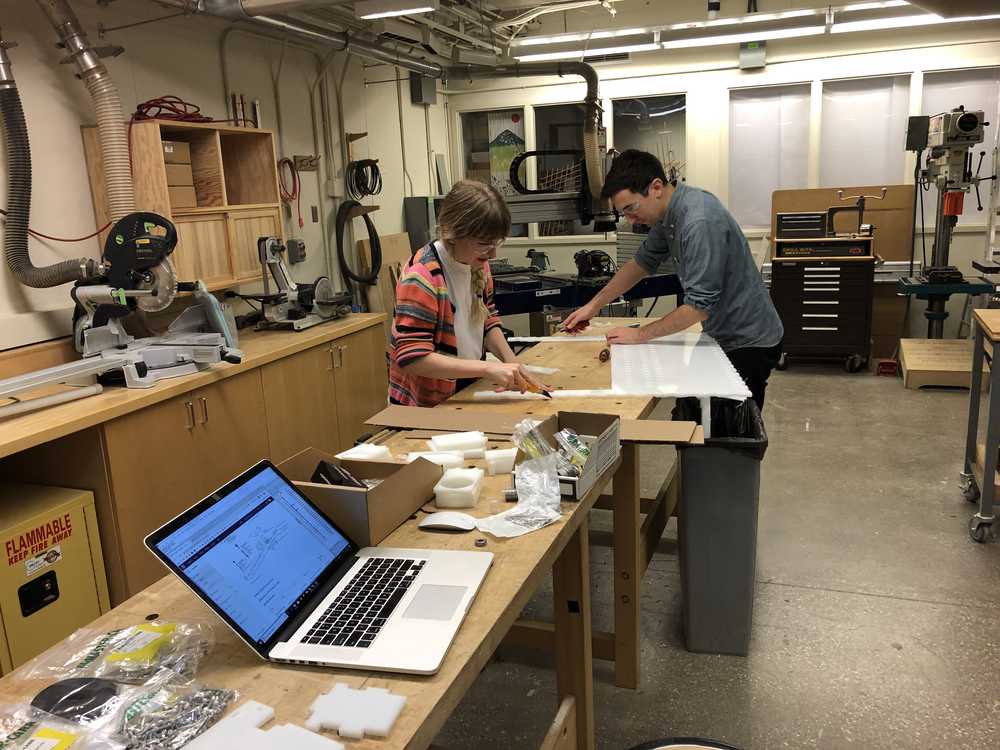

Chassis Fabrication

I passed the rhino files on to the team that prepared the CNC files and returned the milled pieces.

The chassis fabrication went smoothly. The milling team had used an onion skin to keep the pieces down, and we started by removing those with a de-burrer and xacto. In the end, we could use a mallet to get the pieces to go together (and hold together snugly) without this lengthy process.

Although many of the pieces fit together well without any kind of fastener, the servos for the valves were attached using screws. Drilling pilot holes first helped that process go smoothly.

Assembly:

X-Axis Fabrication

We followed Jake’s instructions for assembling the x-axis, 3d printing some pieces and milling others. We forgot to double up the rubber track, but the 3d prints were too delicate to unscrew at the eleventh hour. Luckily the motor got good traction although it did get looser as time went on.

Testing the x-axis after assembly was complete:

Cup Holder Design

We designed and laser cut a platform for the cup to sit on, with a nested platform underneath to hold up the DC motor.

We tested a few different options for attaching magnets to the DC motor and a few different options for which magnets made the best vortex inside the glass when spun.

Testing the magnet:

We ran into some issues with grounding, and ultimately decided to temporarily isolate the DC motor for the magnet from the rest of the machine. I worked with daniel to add a button that was triggered when the cup holder got to the end of the chassis, and would trigger the mixing mechanism.