"The Gang Makes a Drinking Machine"

Overview

This week we were assigned to make a machine which, defined by Neil Gershenfeld, is just "something that does something." After getting together for some group brain storming, we decided what we all really wanted after weeks of hauntingly persistent rc=-1 messages was a good, stiff drink. And thus, the drink mixing machine was born.

Chasis + X-Axis (Don, Molly, Jim, Rodrigo)

Design

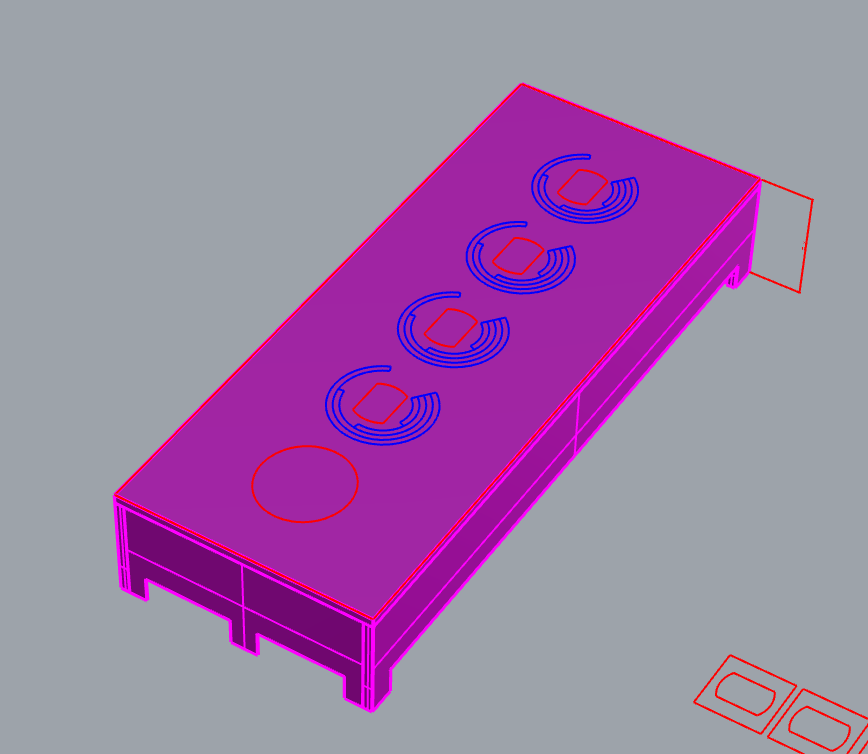

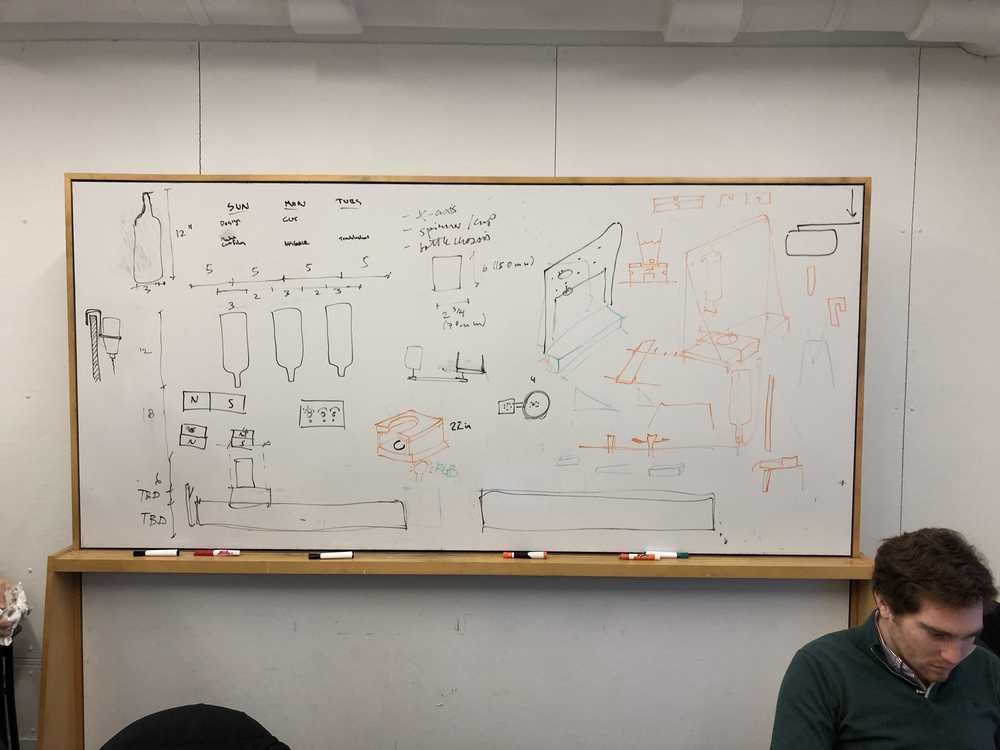

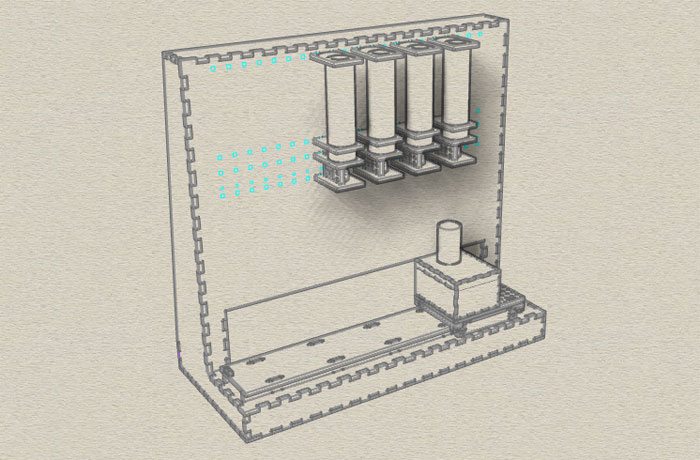

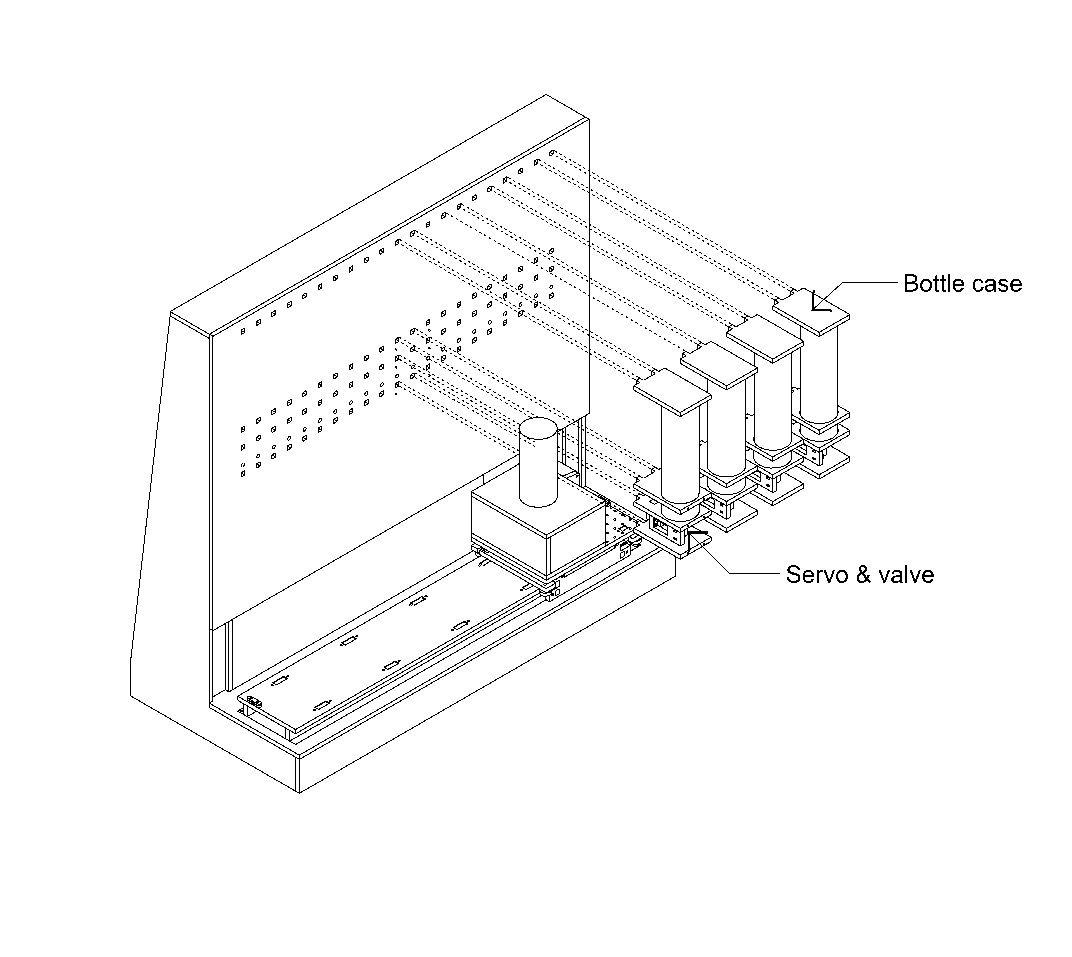

We all agreed upon trying to make a "simple" machine as we suspected even that would be difficult. We settled on a single X-Axis which would move a cup under a series of different bottles which would dispense liquid. And, of course, a magnetic stirrer.

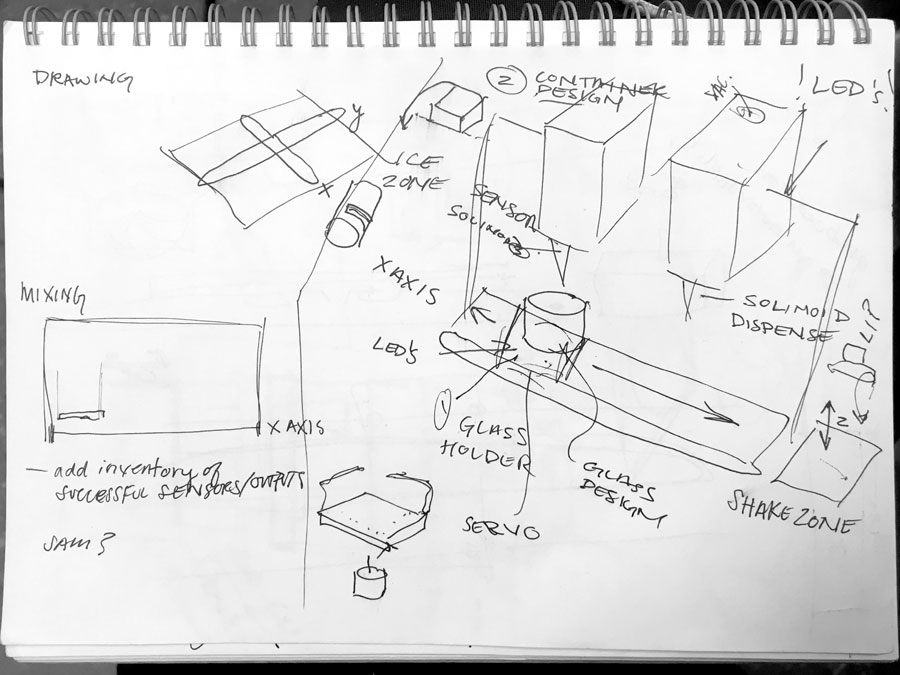

The "Simplest Sketch" first involved an ice bucket and a shake zone.

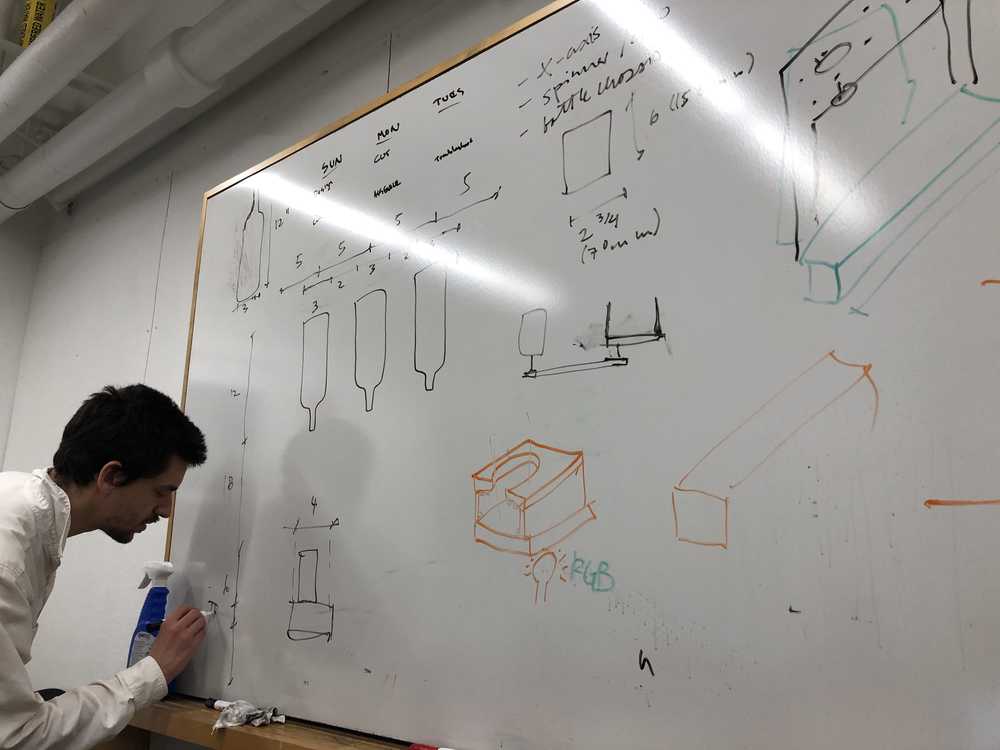

Some design options for the casing:

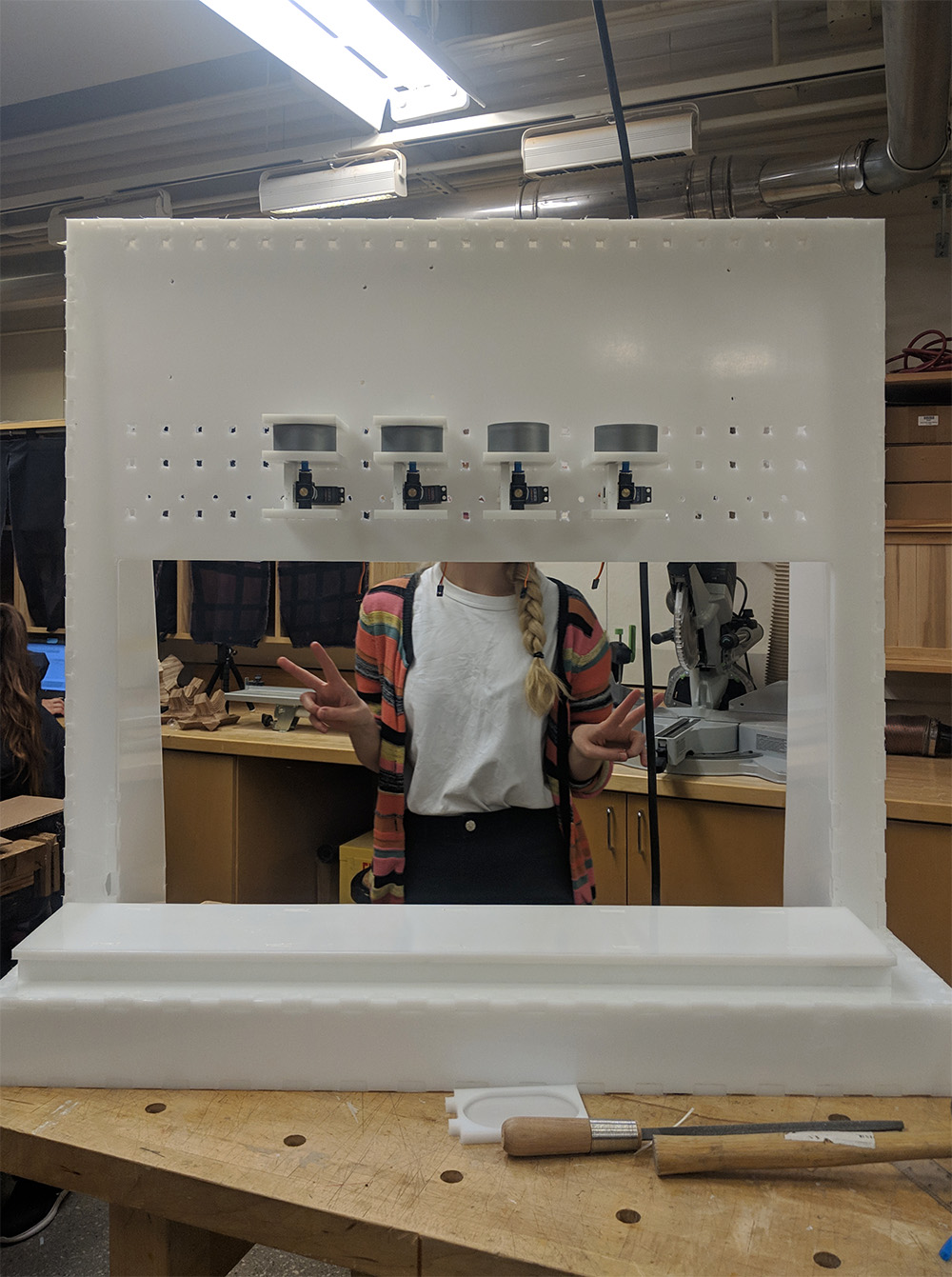

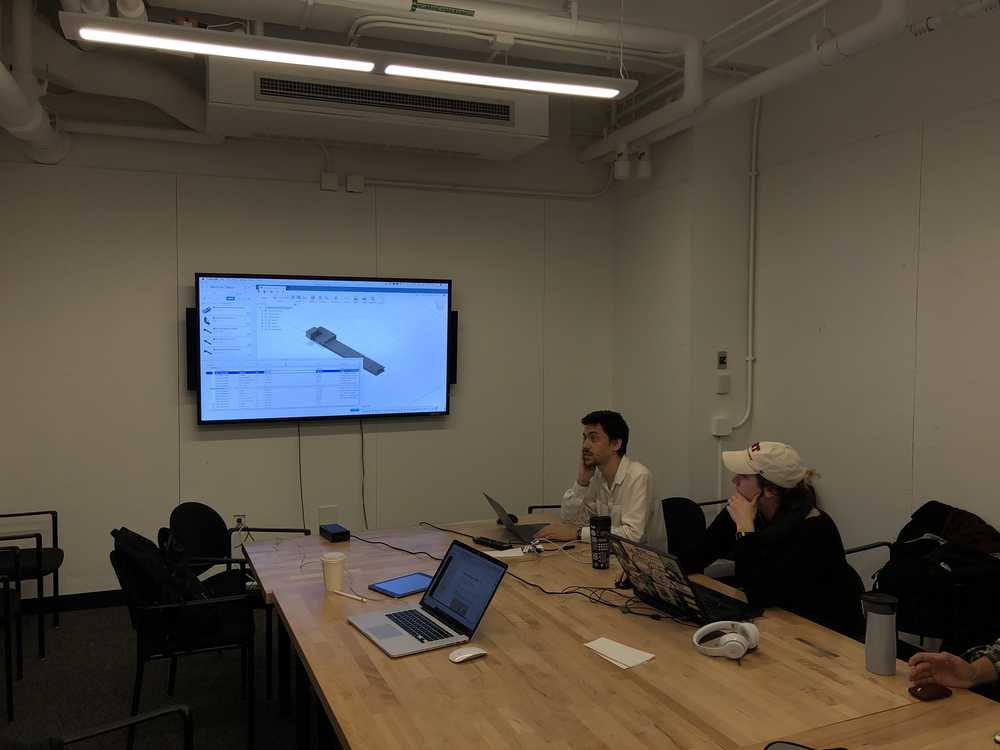

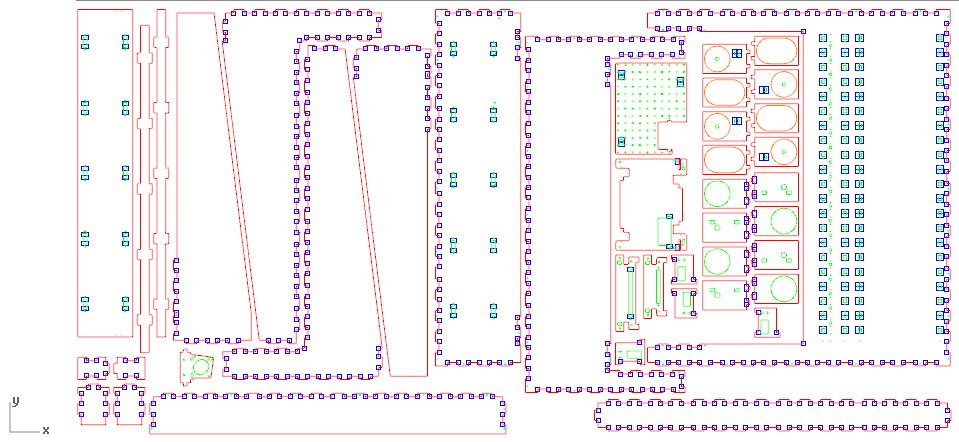

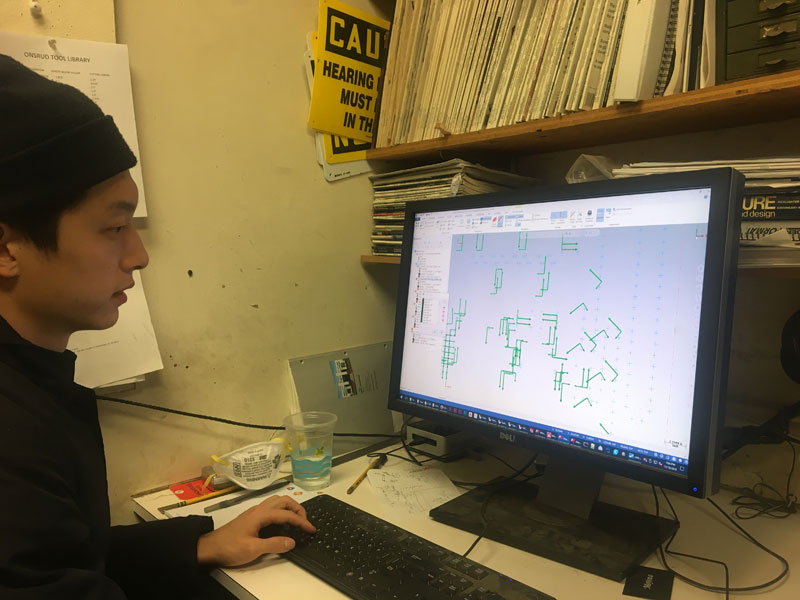

Ultimately, our final design was resized to all fit on one sheet before cutting.

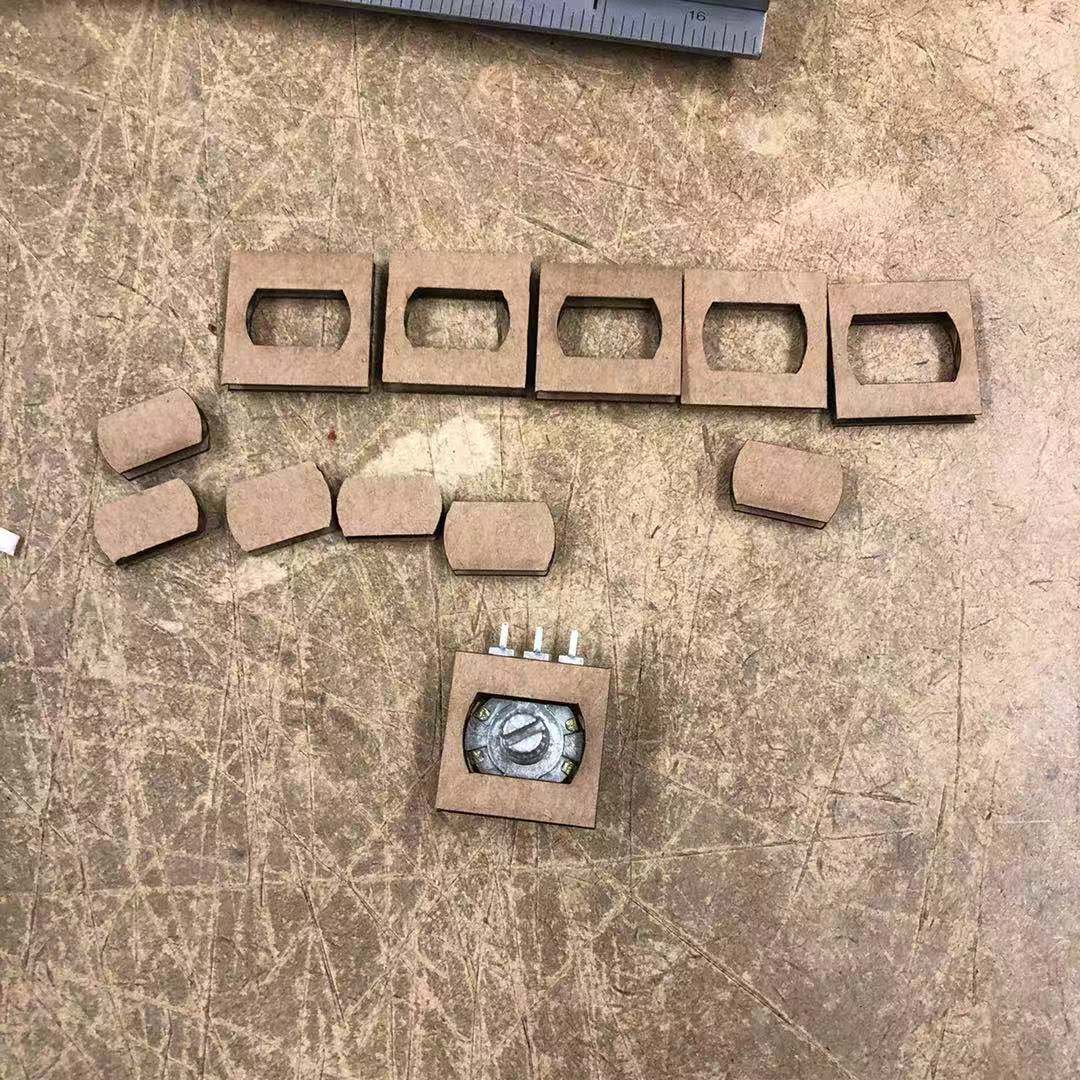

Milling

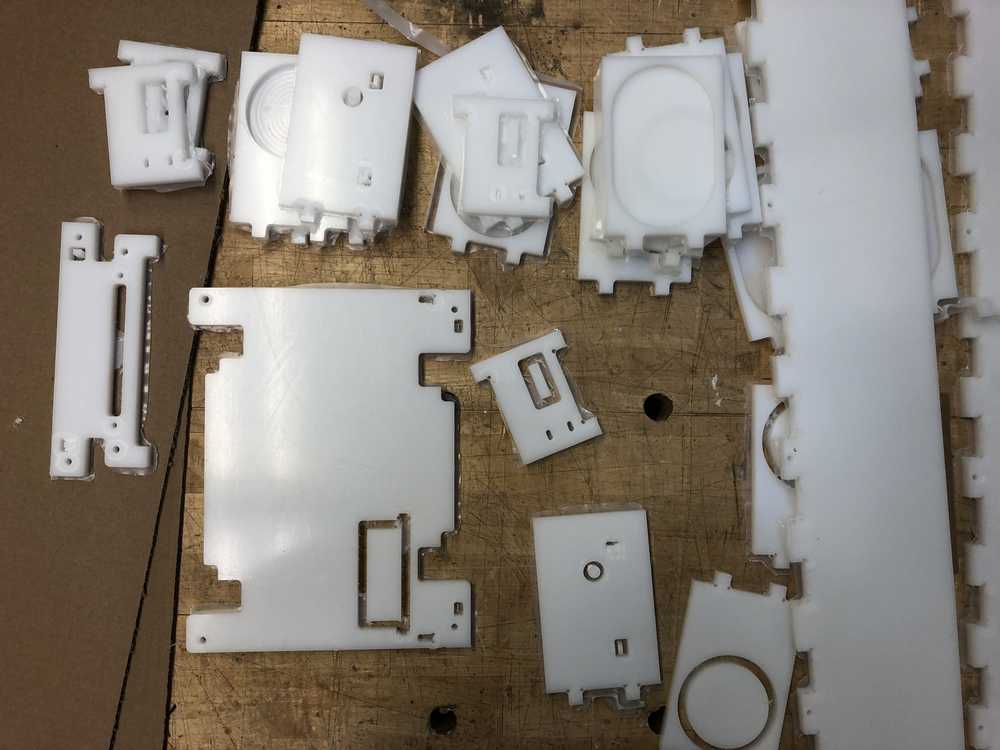

We left an onion skin during the milling process. We filed or trimmed a lot of it off before putting things together, but we found that it wasn't necessary in order to get the pieces to fit together (so long as we had a mallet in hand!), and it actually helped make the fit pretty snug.

Assembly

"MALLETS!"

Pre-drilling some holes on the drink dispensers:

X-Axis

Stirrer

We used a DC motor and magnets to stir our drinks. We attached magnets to the top of the motor head, and concealed it inside a box. The glass sits on top of the box, and we tested a few different magnet stirrers. We tested with magnets we found at the hardware store first:But then ultimately ordered an industrial, pill shaped stirrer. Together with some of the other magnets, we were able to get a pretty good vortex!

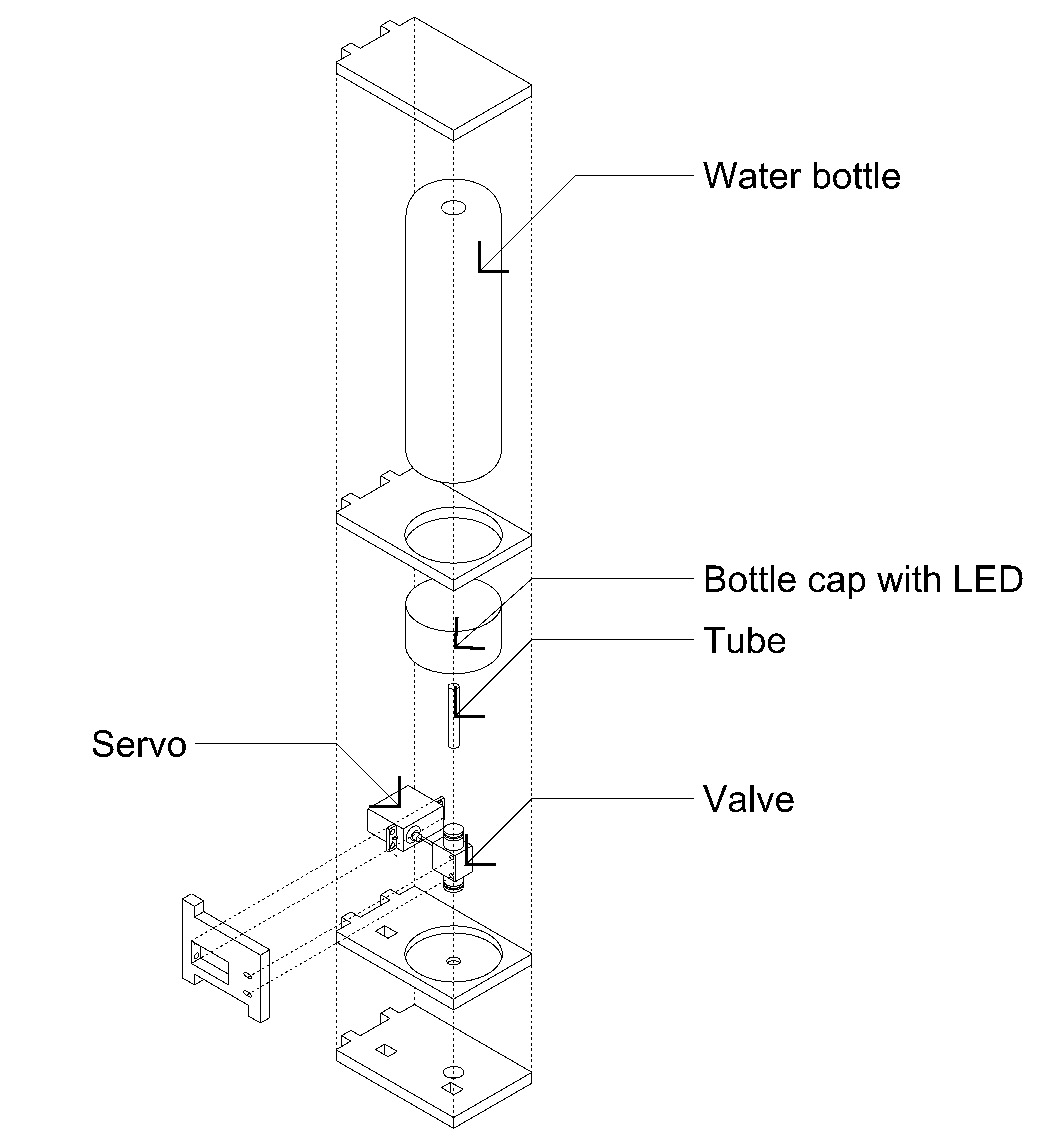

Drink Dispenser (Dalma, Jung, Emily)

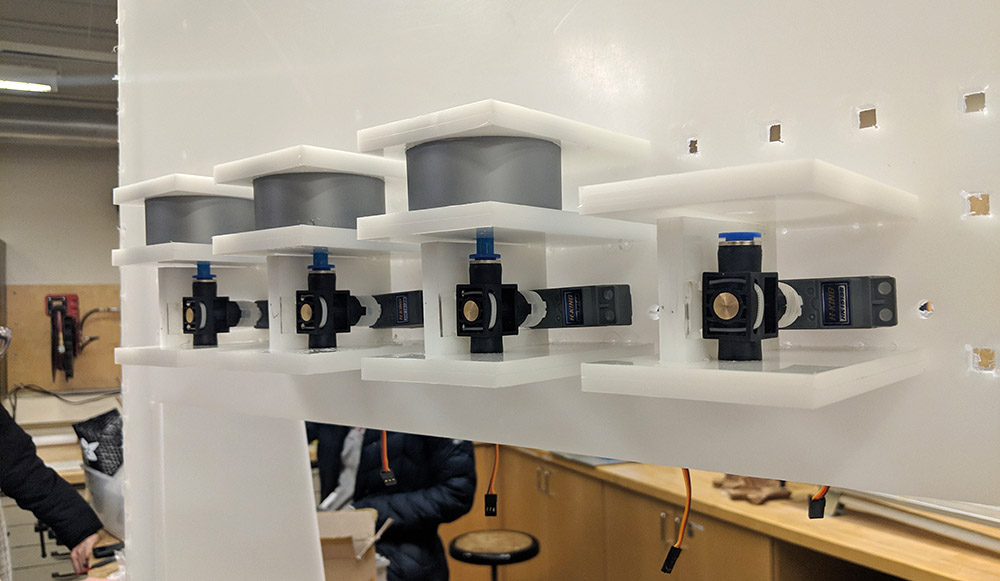

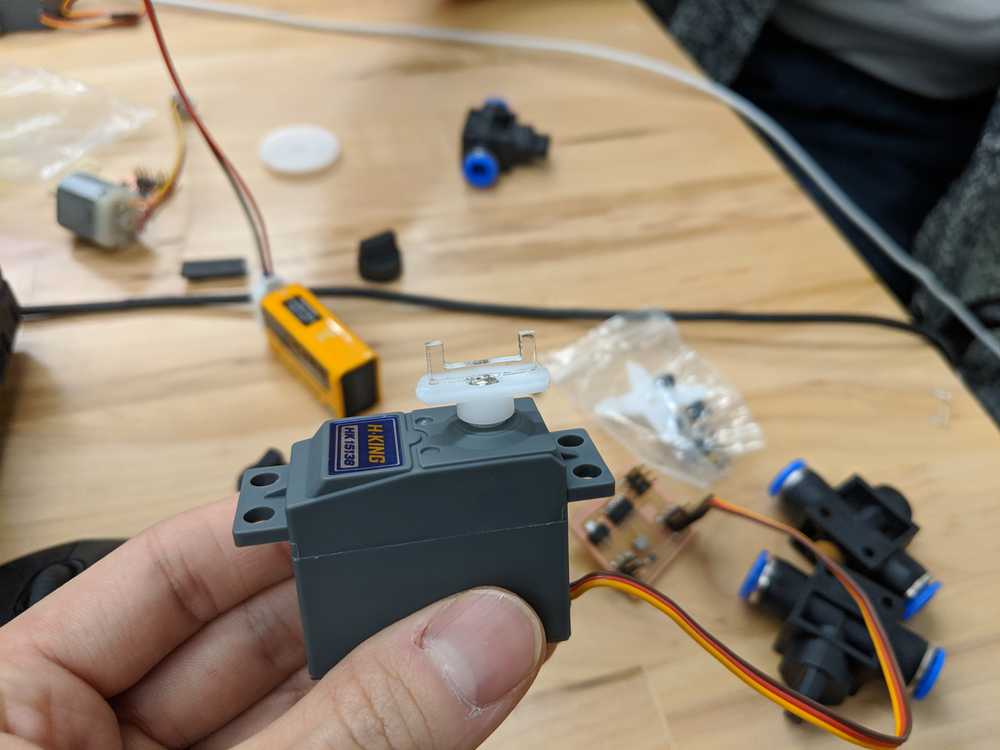

Our group was in charge of designing the mechanism & container for the dispenser. We were choosing between a pressurized solenoid valve and servo-driven options, and we landed on using a simple valve & rotating its handle with a servo so that we could also separate the parts later.

Taking apart the valve to see the rotating mechanism inside.

We then tested several ways of attaching to the servo arms, either by removing the valve cap of by keeping it so that we can reuse the valves later.

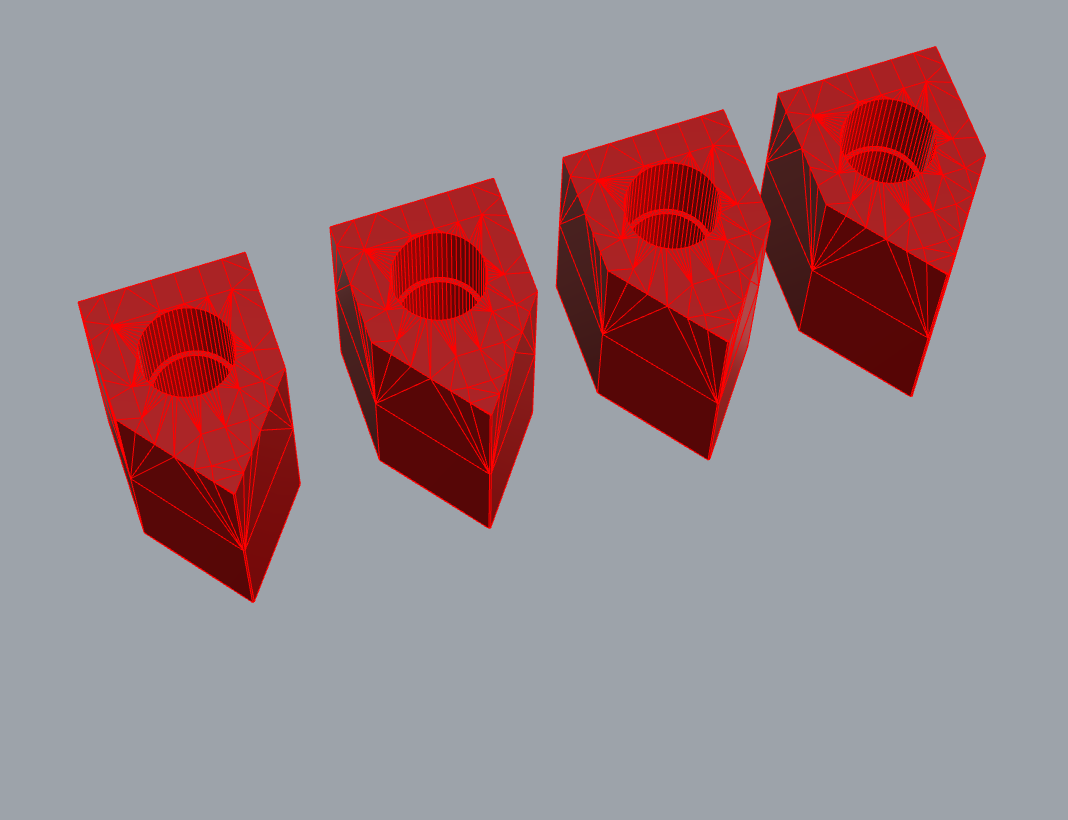

Different connections from valve to servo--we ended up designing a cap for the most robust and least destructive joint.

Laser cut joint prototype from valve to servo arm.

We made several of these tiny acrylic joints that seemed stable and robust enough for the rotation inside the case.

Dry-fit connection to chassis

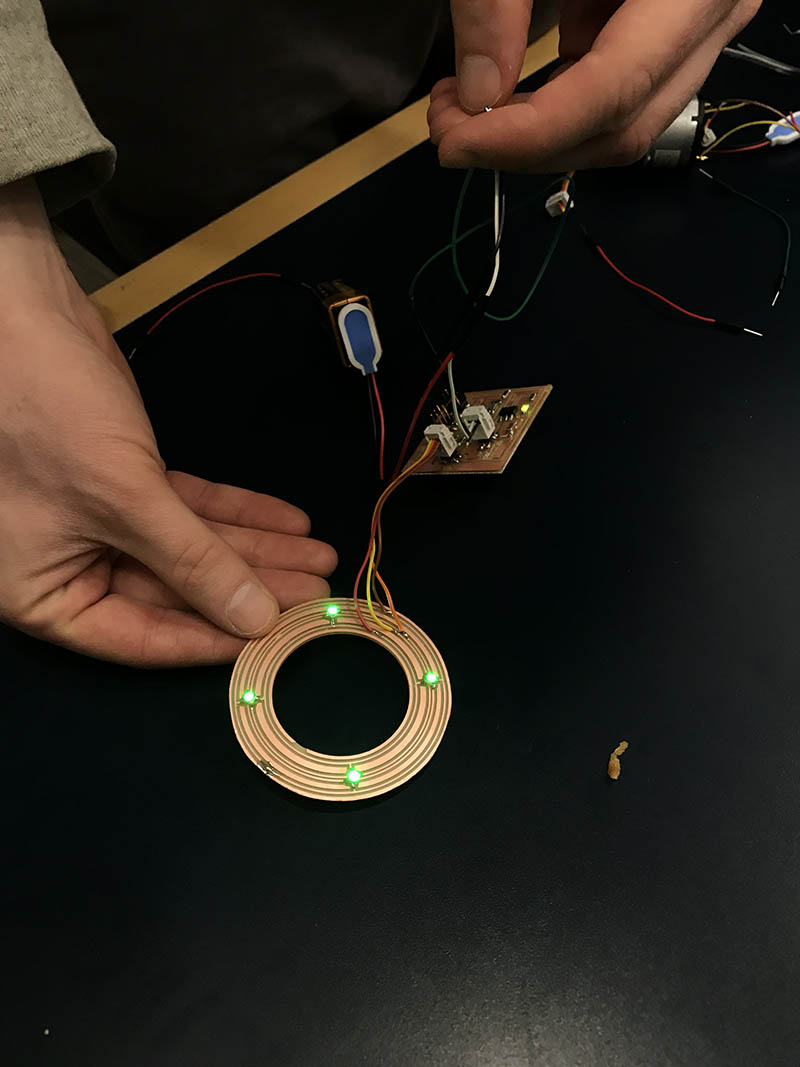

Board for LEDs to sit inside bottle cap.

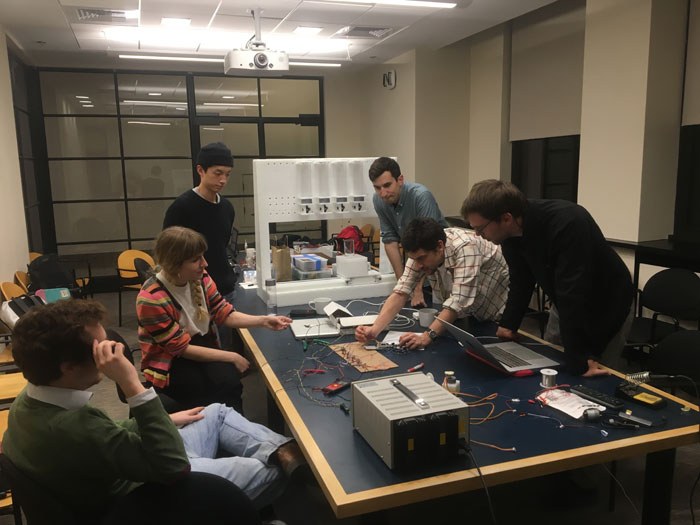

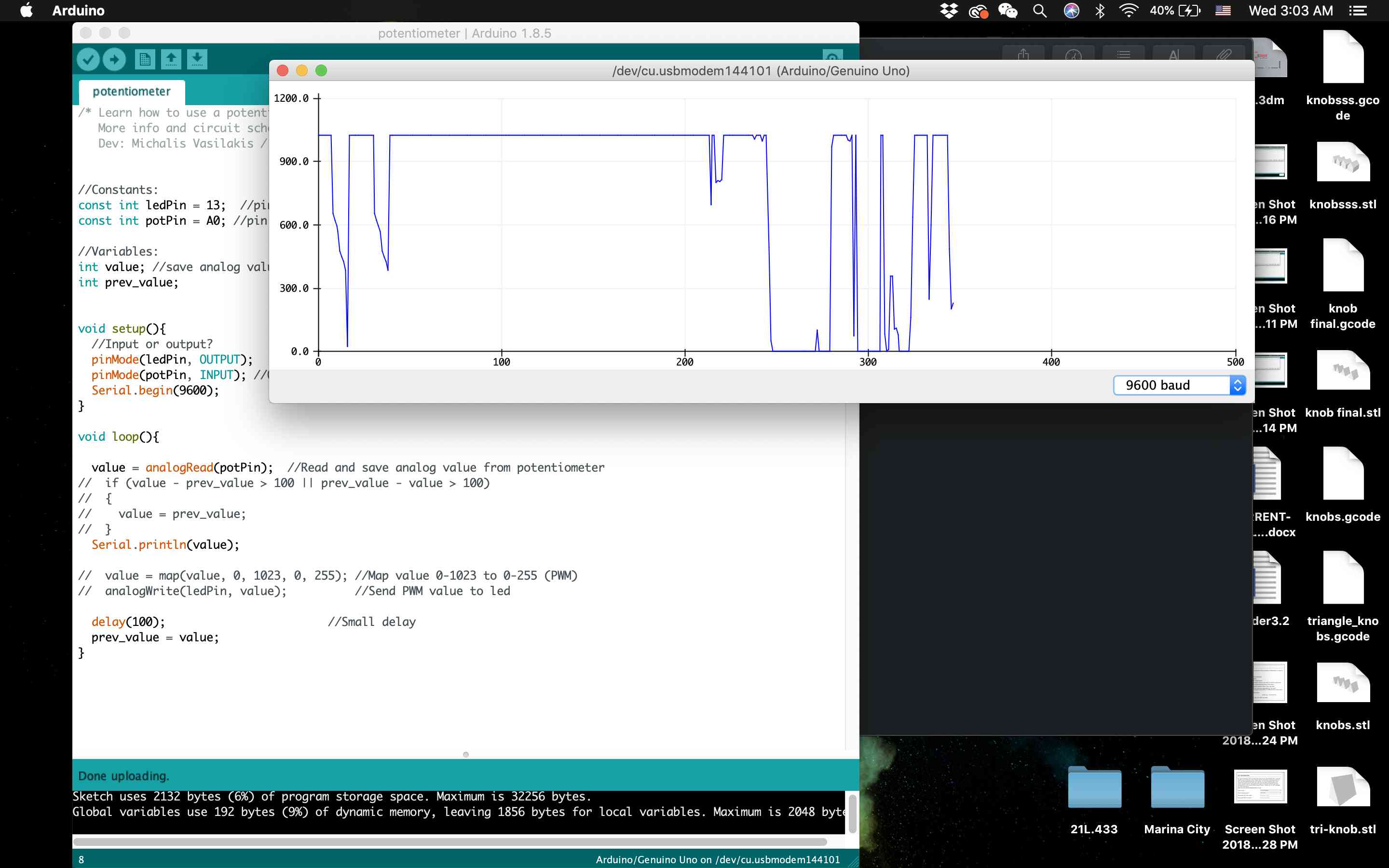

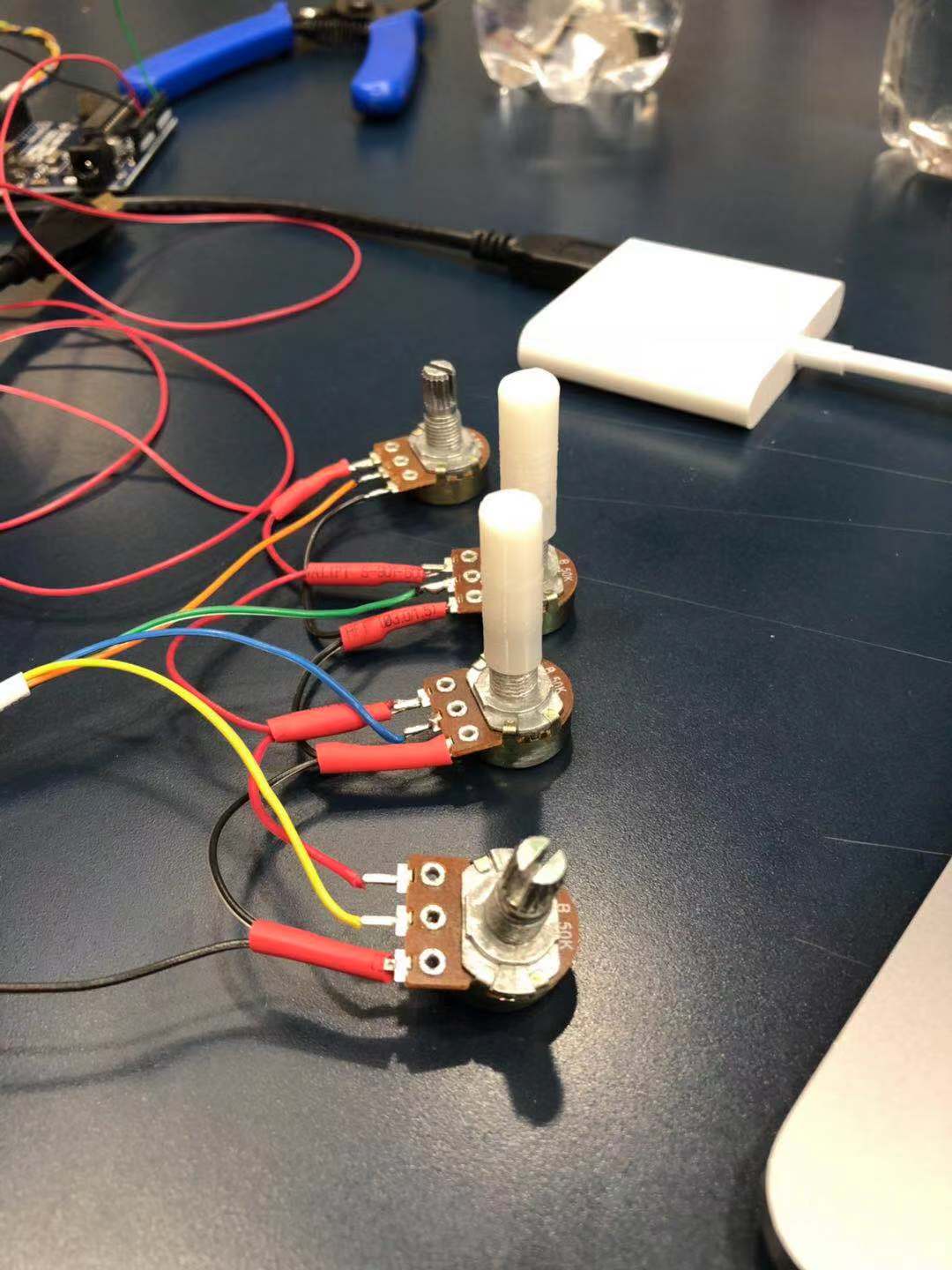

Electronics (Rafa, Lukas, Daniel, Yi)

Design