During this week, I learned to CNC mill wood boards for the first time, and this experience gave me some understanding with milling and thin materials.

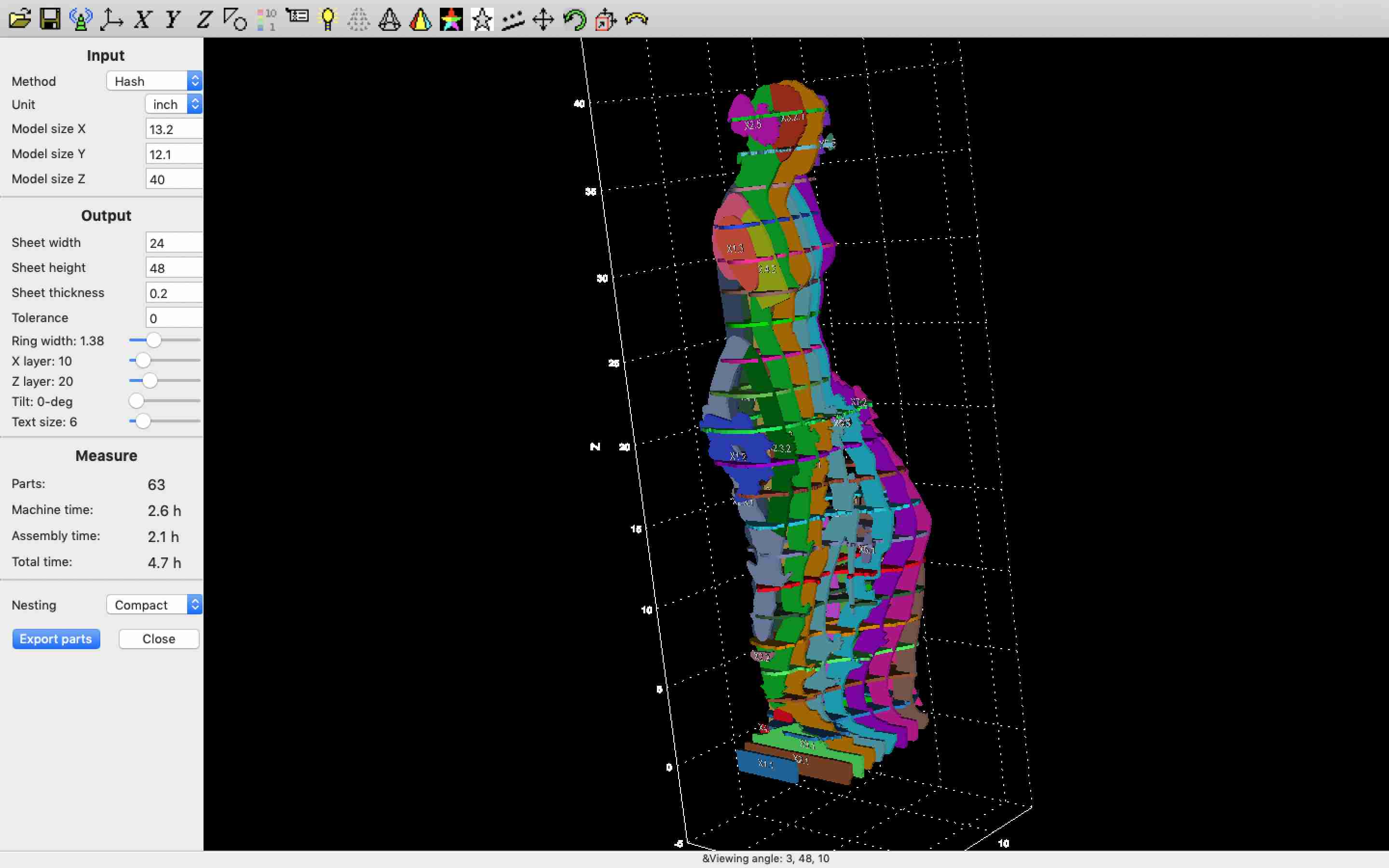

We are learning to use the software Luban in another CAD class to create volumes piecing together from laser cutting plates. Thus, I want to further explore the software, and then create a bigger volume, as what we did in the other class is only 3 inch tall letters. As I also wanted to test the limit of the curves to work in Luban, I decided to fabricate a 40-inch-tall Venus sculpture with the hash structure.

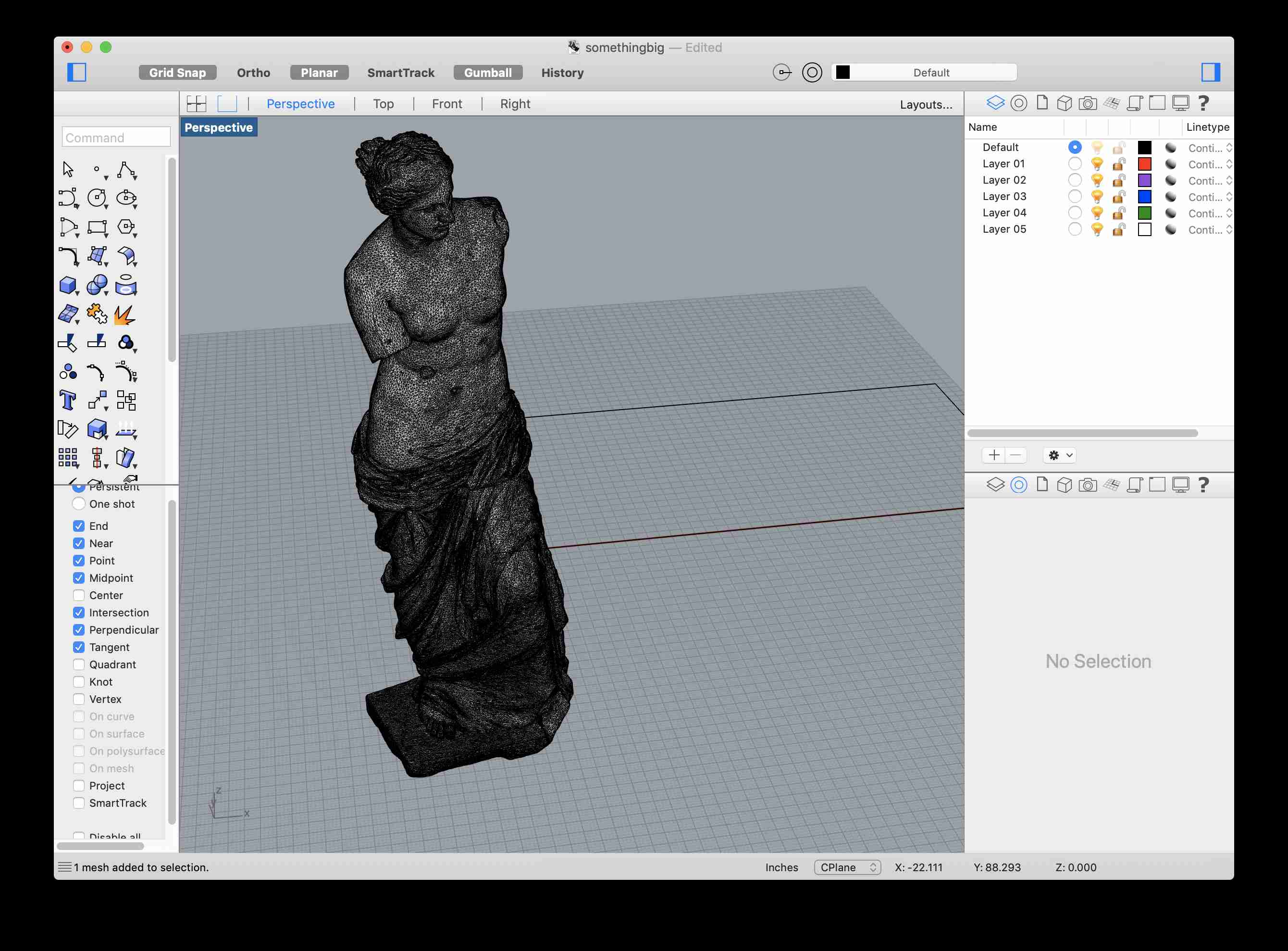

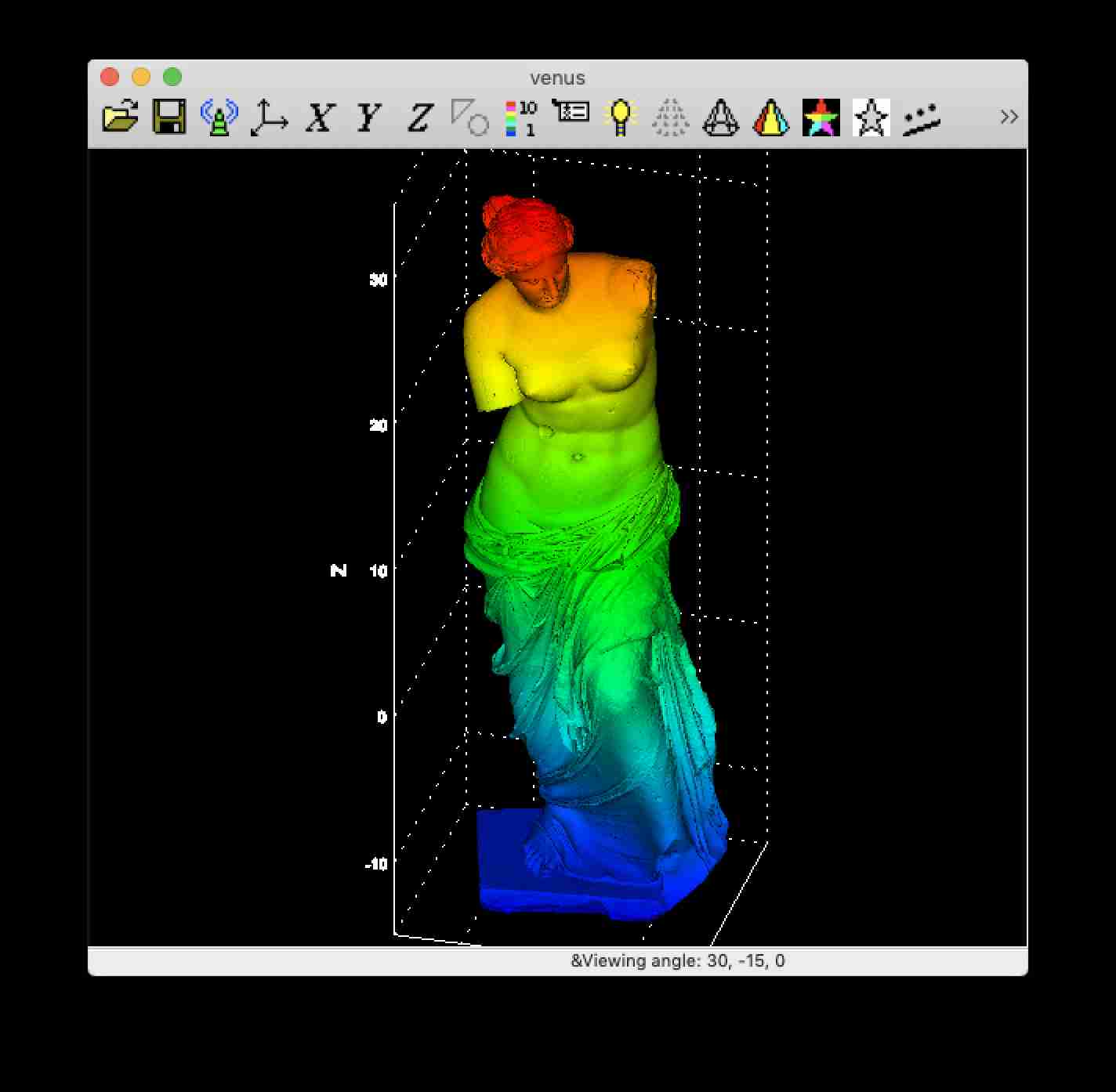

I actually found the obj.txt file online, provided by Denmark National Museum. I then converted it to obj and then imported into Rhino. The mesh imported was extremely detailed, that it has the flaws on the original sculpture. I then scaled it to 40 inches tall and exported as a stl file

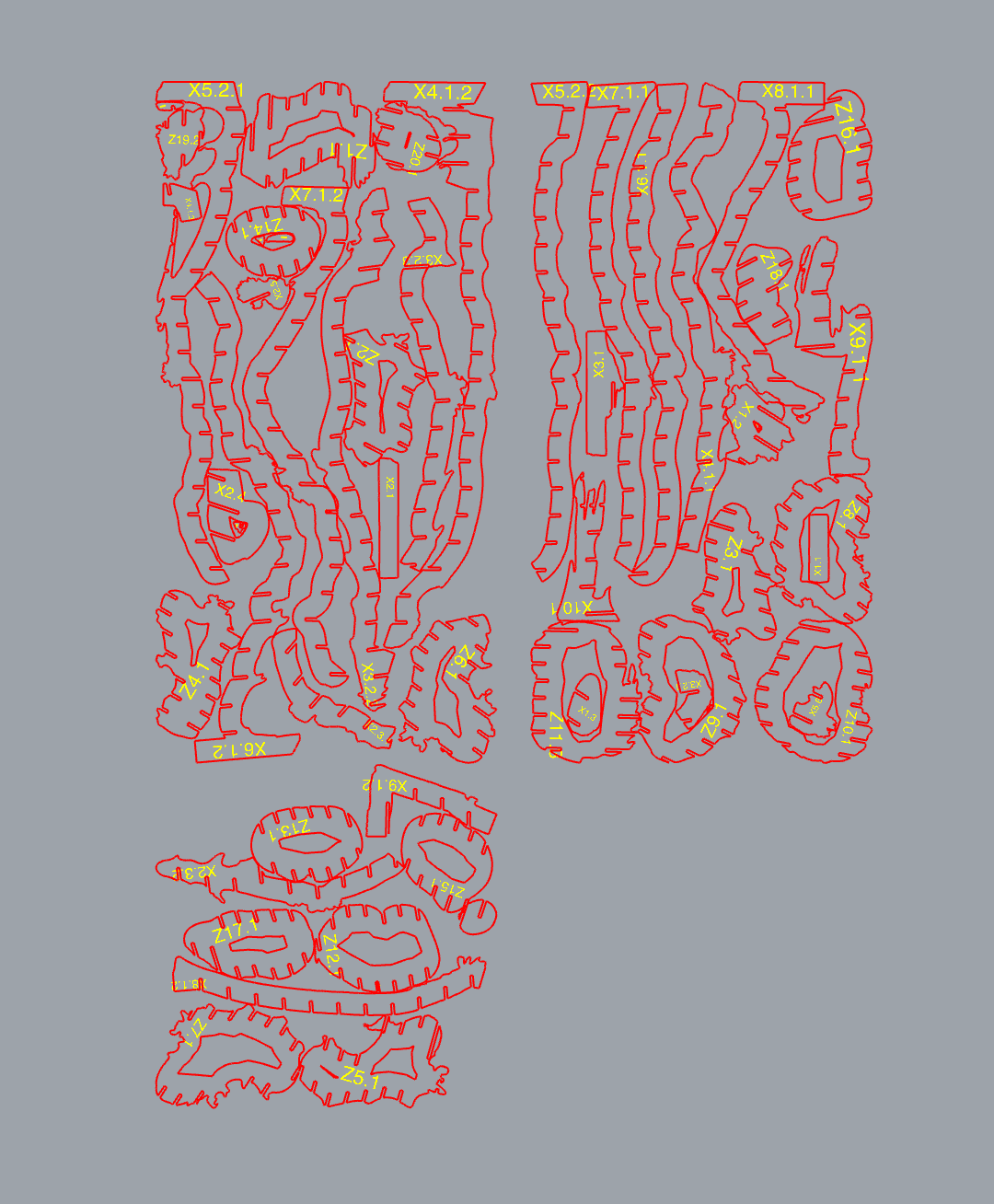

After imported into Luban, and then I played around with the settings. They have different layering techniques, including hashing, stacking, and plates. I chose the hashing style, and then set the thickness, and sheet size. Playing with x-layers, z-layers, ring width and plate rotation is super fun. As the screenshot shown, this is my finally design. It also tells me the time to build it.

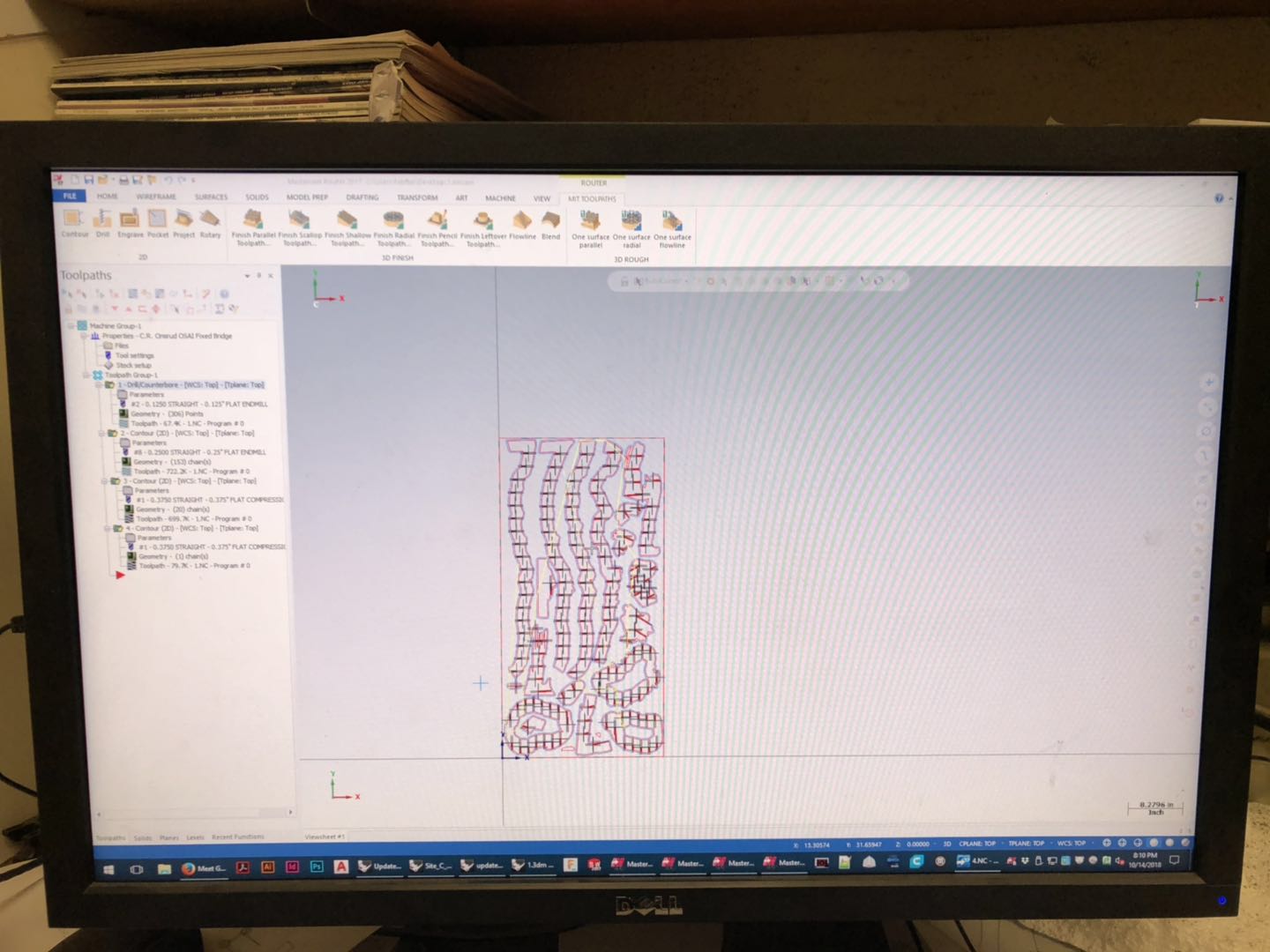

Setting up in this software was the most time consuming part for the first sheet, that I needed to choose all of the point of the pockets, and then setting up the geometry of every shape. Setting up the drilling point was also something I did not enjoy doing. And because my wood is really thin, I later realized that I did not have to use the drill points. The compensation is something that I am still confused about, that when do we need it and when do we not.

Because fo the thin wood, we were using the 1/8 endmill for this job. During the milling of the first sheet, because I drew something in the loose part to cut, and because the wood is too thing, the machine pulled the sheet up and broke the cut piece. So we had to redo some parts of it. Also, the setting of the first sheet was not perfectly right.

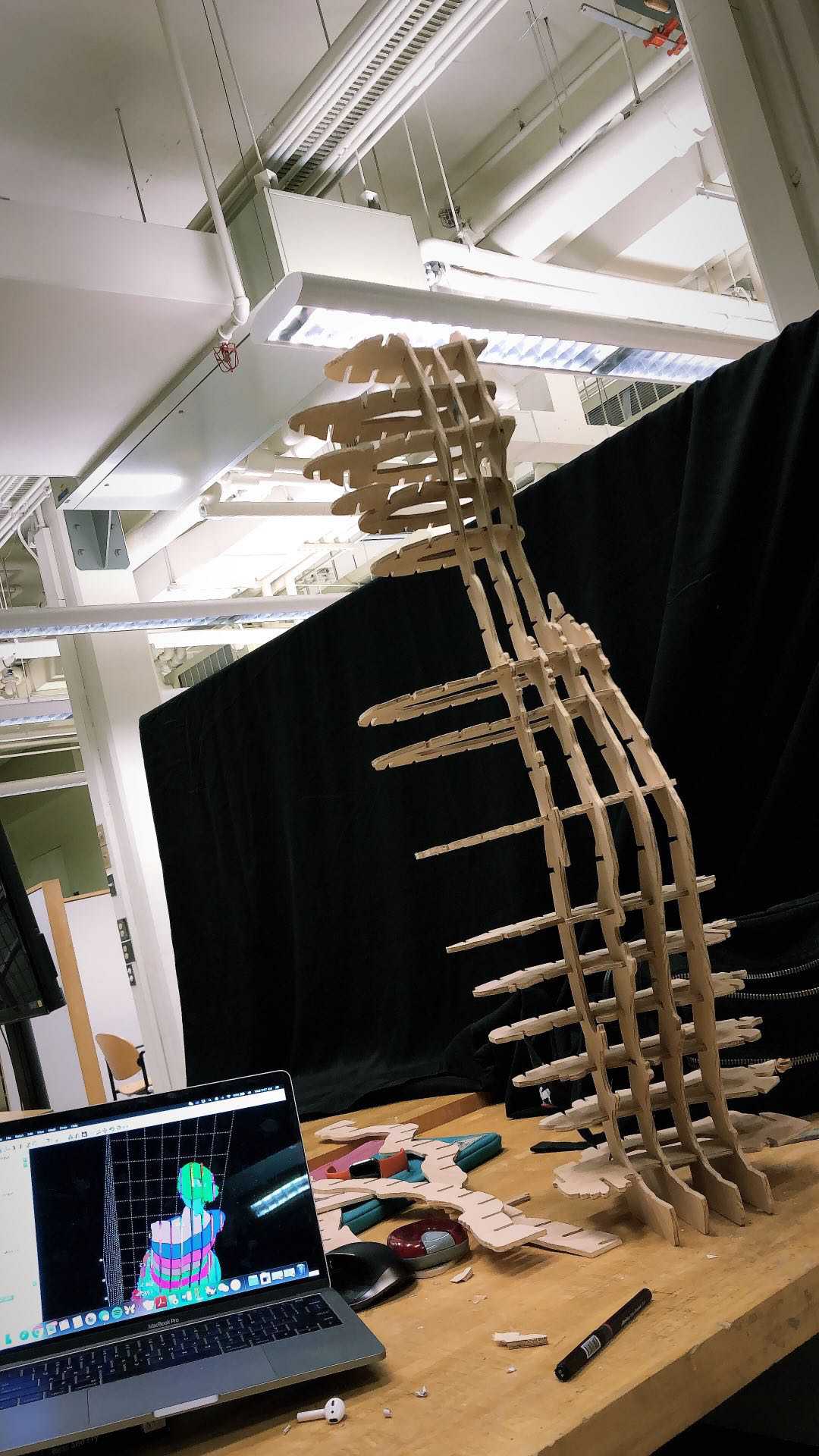

The sanding also took forever, that every piece’s edge was smoothen and then tested for the jointing.

Finding the pieces actually took way more time than I expected, as I had in total 63 pieces. Plus some of them are really similar, so I had to distinguish and label them.

Then I realized the order of the assembly is really important, that some parts I could not get between the parts.

In addition, there are certain parts of the model cannot be installed, due to the wrong geometry the software produced.