How To Make (almost) Anything

final project | mas.863 | mit

AR ENHANCED WALL PLANTS

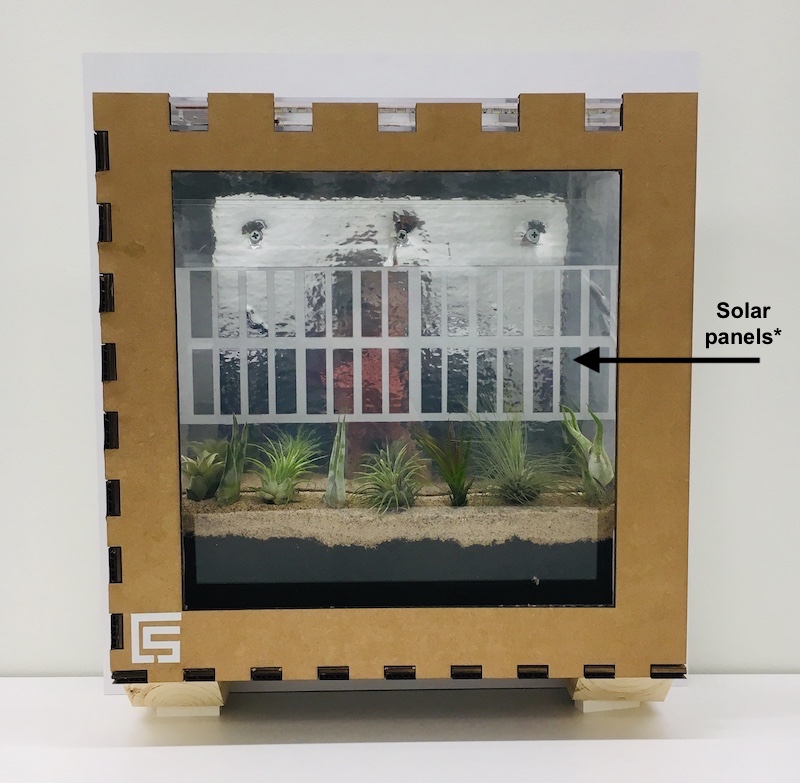

An environment of plants and mirrors that extends beyond the terrarium walls.

The terrarium is wired with a light source for its plants

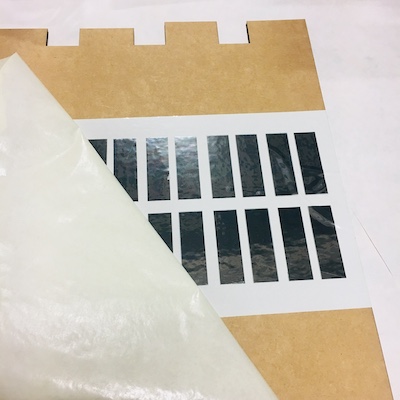

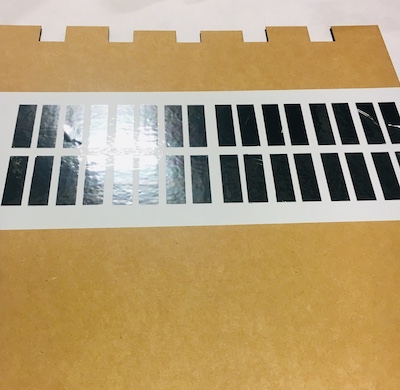

It is lined with interior mirrors to amplify that light, as well as reflect its plants and create an illusion where they occupy more space.

Interior solar panels also absorb the light to drive power back into the wired system.*

An augmented reality view further mirrors the contents of the terrarium, and expands the small box of wall plants into a desert landscape.

The result is an energy efficient environment that transforms a small wall space into a larger expanse of plants.

The lights for the plants are on a 14hr on/10hr off cycle.

Small LEDs indicate which hour of the cycle the lights are in. One line of LEDs counts through the hours on, and another line of LEDs counts the hours off (in binary).

WHERE

In the MIT Media Lab’s City Science group, there is an escape pod.

The escape pod is an exploratory platform for researchers to experiment with how the small spaces that will be increasingly common in dense future cities, can be transformed.

The terrarium lives on a wall of the escape pod.

It is an experiment in transforming a wall panel of a small, enclosed room into an environment that extends beyond its physical walls.

WHY CARDBOARD

Increasingly more consumer goods are shipped to our homes in cardboard boxes with packaging that then goes to landfill.

How can we change this cycle in our future cities? Can materials be reused and transformed to create new life closer to home? Can we reduce their use by making small things feel like more?

HOW IT WAS DESIGNED AND MADE

Terrarium and Shelf

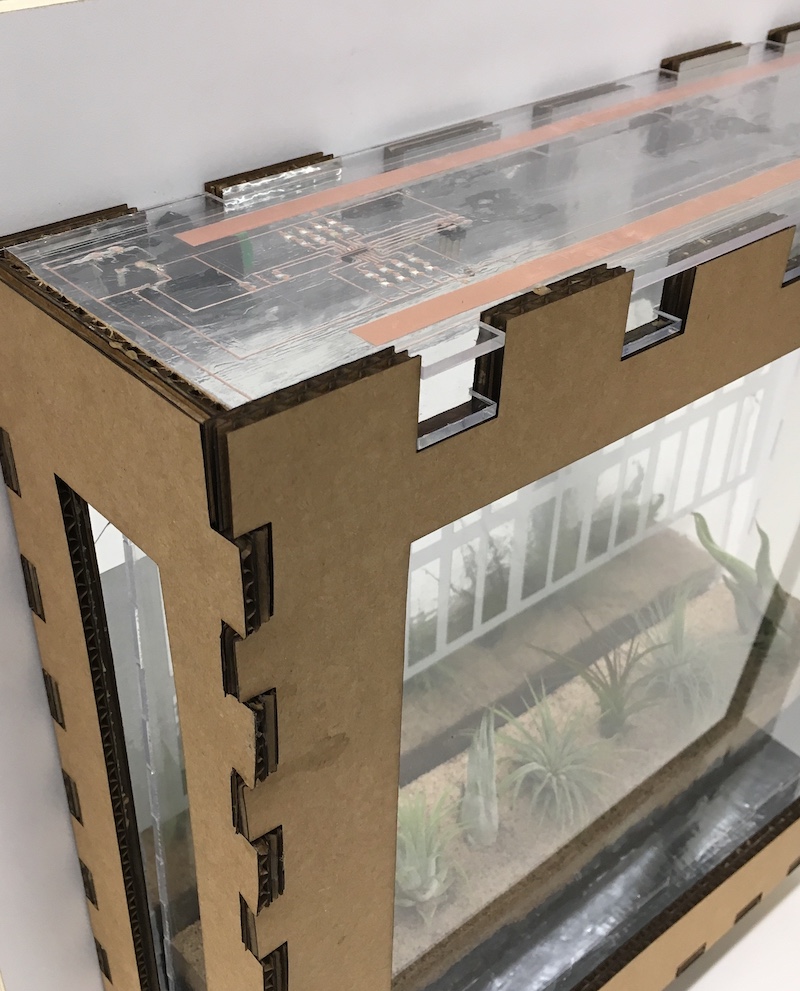

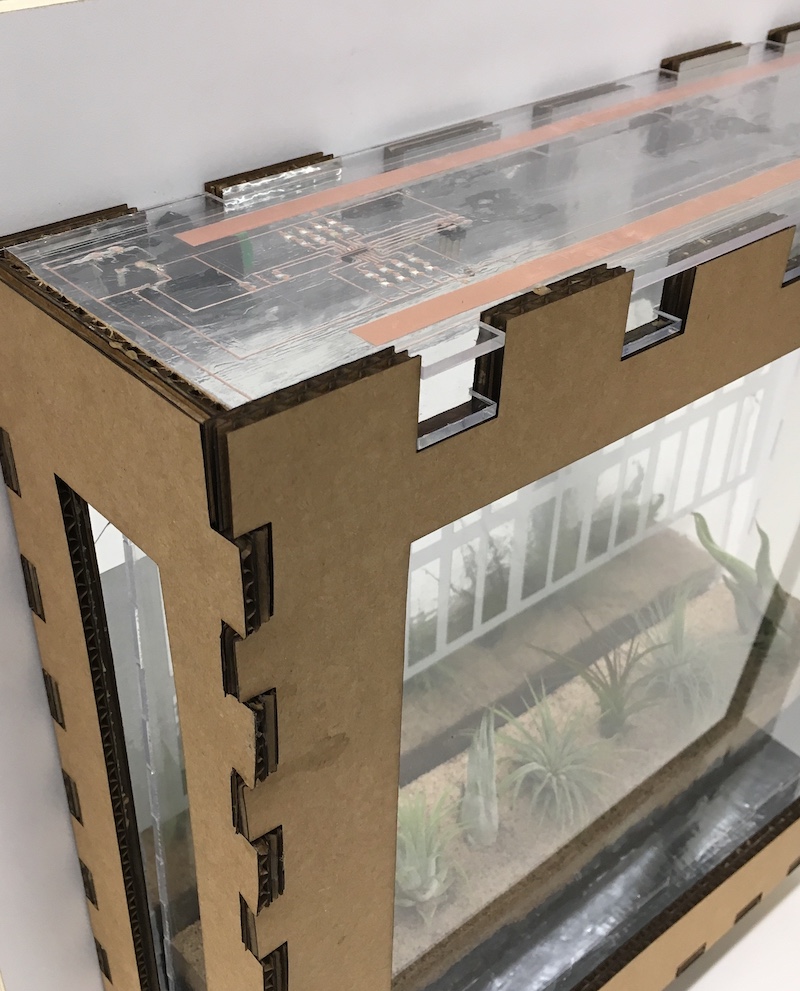

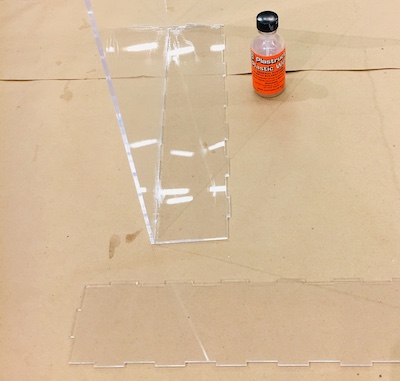

A clear terrarium with an open top contains the plants. It slides into a shelving unit that attaches to the wall panel. The circuitry and mirrors are attached to the shelving so that the terrarium can simply function as a container for plants.

CAD

Fusion360 was used to model both the shelving and the clear plant container. They were modeled as separate components. Parametric modeling was employed so that the thickness of materials used, or the size of the components, could be adjusted and the entire models could then update accordingly*.

STL files:

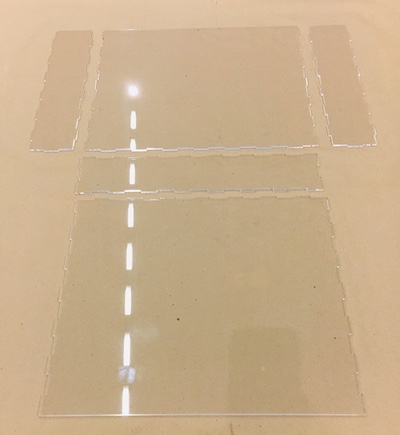

*Taking the time to create a proper parametric model ended up being very helpful. When it came time to laser cut the plant container’s faces, I was using acrylic with a different thickness than I had originally expected. I was able to simply update the parameter for the acrylic material’s thickness in Fusion360 and the entire model was recompiled within a minute, so that I could export new files of the proper dimensions for cutting.

MATERIALS

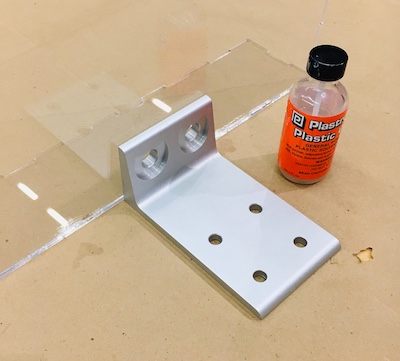

Plant container: ⅛” clear acrylic

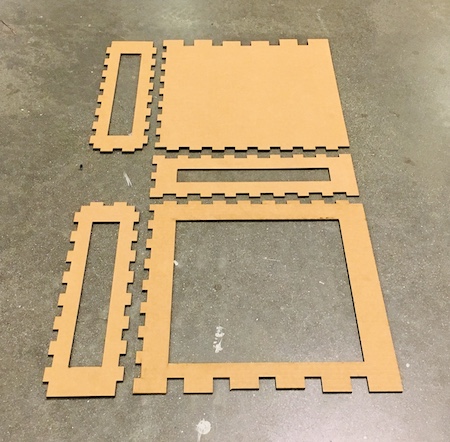

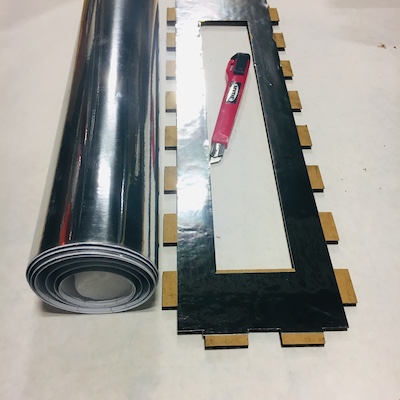

Shelving unit: Two pieces of 3/16” cardboard are composed with perpendicular orientations to create each wall of the shelving unit. The perpendicular directions of perforations create a stronger resistance to bending.

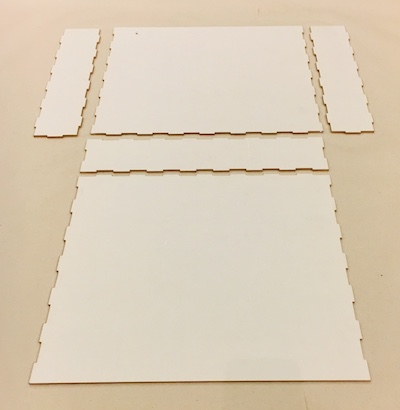

LASER CUTTING

An Epilog Legend laser cutter (120 watts) was used to cut the pieces of the shelving unit and plant container.

Each face of the shelf and plant container components was exported as a .dxf file from Fusion360. These faces were then imported into the CorelDraw software and laid out to cut on the laser cutter.

Laser cutter settings:

Cardboard - Freq: 1000; Speed: 15; Power: 85

Acrylic -Speed: 8; Power: 80; Freq: 2500

ASSEMBLY

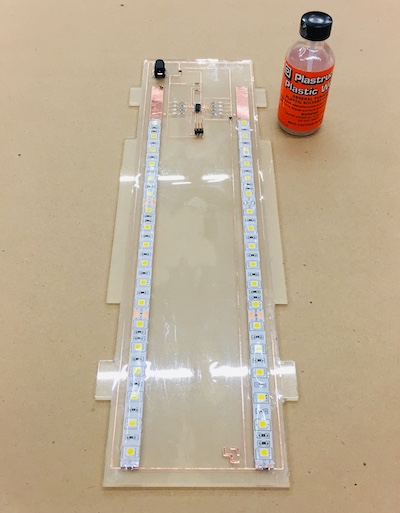

Plastic cement was used as the adhesive for the acrylic panels.

Wood glue was used as the adhesive for the cardboard box panels.

CIRCUIT

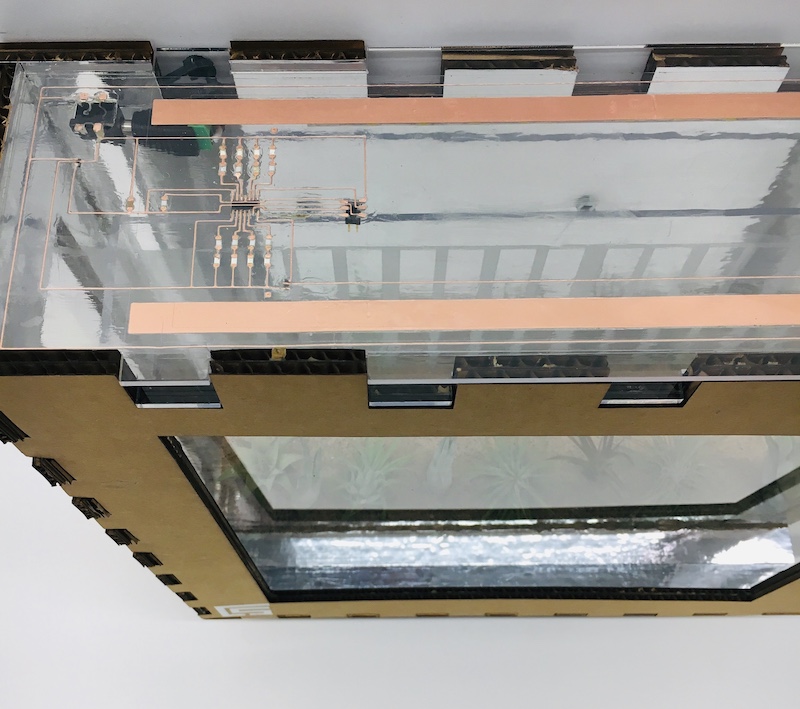

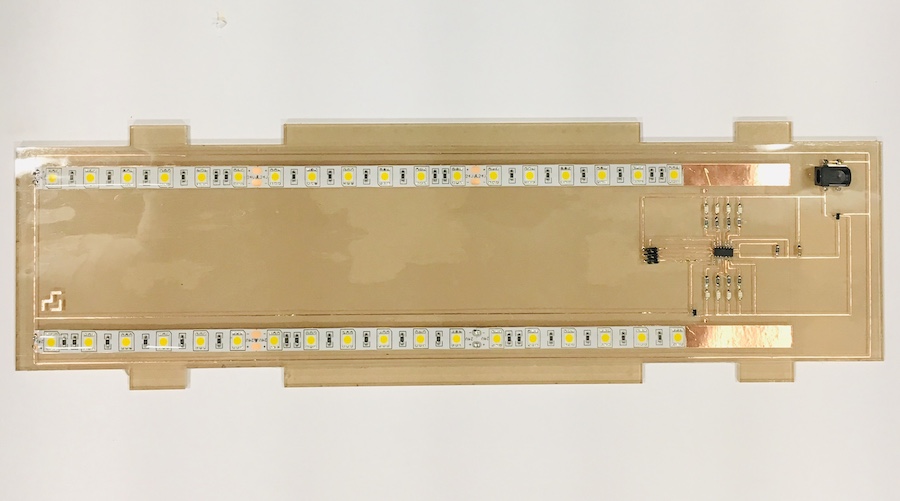

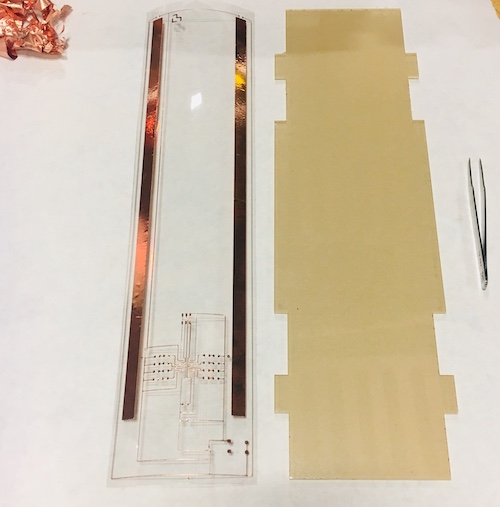

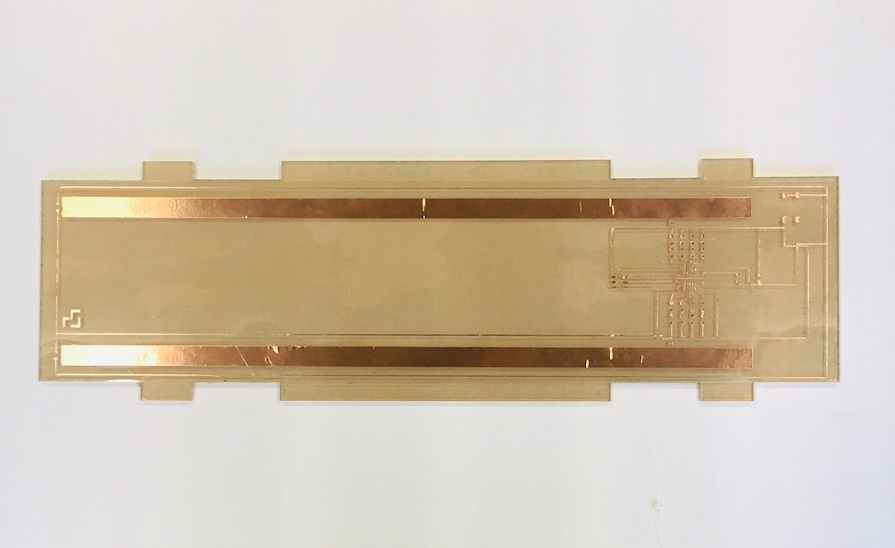

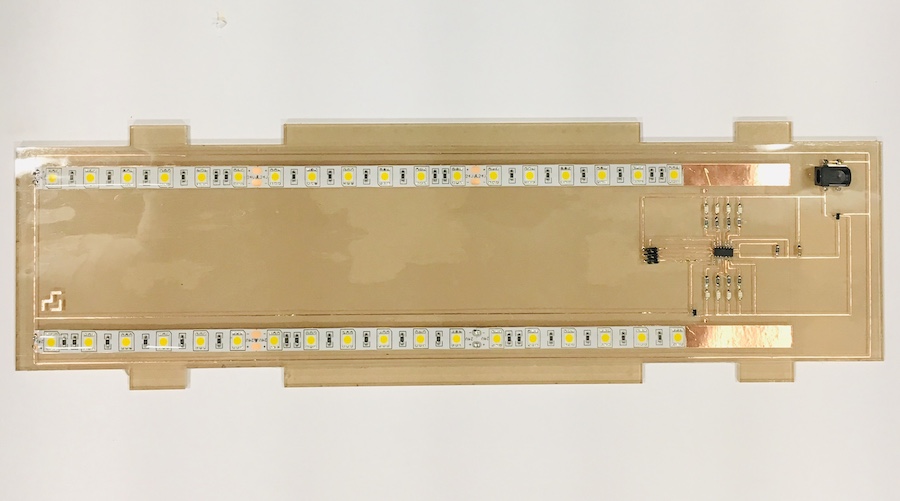

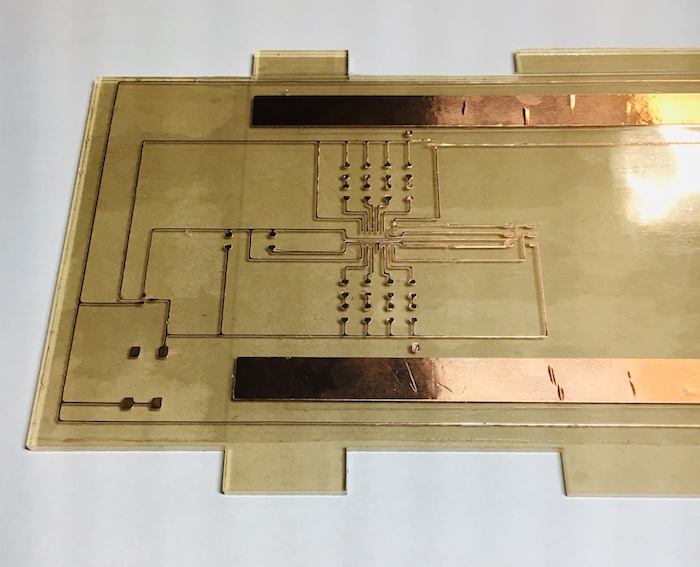

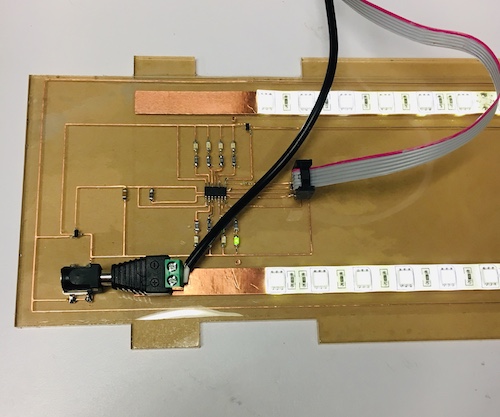

The logic for the circuit sits on top of the box on a clear acrylic panel.

The circuit was first reasoned out and routed on paper.

Major Components:

- 24V LED strips - produce light source for the plants.

- ATTiny44 - controls when the lights are on vs off on a timed cycle.

- 8 LEDs - used to indicate the current hour in the light cycle.

- 24V power source + power jack - provides enough power for lights as well as ATTiny to operate.

- Regulator - takes 24V in, puts 5V out so that power source can be safely used with the ATTiny.

- MOSFET (N-CH) - used as a logical switch to allow the ATTiny to control whether the lights are on vs off while operating at a different voltage level from them.

Supporting components: Resistors and capacitor

Eagle was then used, and traces were exported as a monochrome PNG file to cut out.

CIRCUIT MATERIALS

The circuit was cut out as copper sticker upon a clear acetate, by using a vinyl cutter.

VINYL CUTTER

A vinyl cutter was used to cut the traces. The unneeded material was then removed by weeding it with tweezers.

The vinyl cutter was also used to cut the outlines of the mirrors and fake solar panels that line the shelving unit walls.

CIRCUIT SOLDERING

The circuit components were soldered to the copper traces.

Solder was also used to repair the traces, as they had some holes left from an imperfect vinyl cutting and weeding process.

Once the circuit was programmed and confirmed to work, it was covered in a layer of plastic cement to help keep the soldered connections from ripping up.

CIRCUIT CODE

The circuit logic was written in C.

Code: lights.c | lights.make

To compile the code and program the ATtiny:

make -f lights.make

make -f lights.make program-avrisp2

AUGMENTED REALITY APPLICATION

Code: https://github.com/aberke/ar-terrarium

The augmented reality application was developed for iOS with XCode and ARKit.

The AR target is a logo for City Science located in the bottom left corner of the shelf. The logo was cut out using the vinyl cutter.

The augmented reality view is then overlaid with planes to cover the terrarium window and reflect that window out to its sides. These view planes are positioned relative to the found AR target.

I tried a variety of strategies to make it look like the interior of the box was reflected outside its exterior.

- Using ARKit’s metal materials to make the exterior surfaces shiny enough to look like a mirror. I manually configured the space that the mirrors were reflecting so that they would reflect what was inside the box rather than how a true front-facing mirror would reflect what was in front of it.

- Taking a real time snapshot of what was in the phone’s camera view inside the box to then place on the planes on the exterior of the box.

I had limited success with both of these experiments.

My final solution was a simpler hybrid: I took photos of the terrarium window and preloaded them into the app code. The photo that best matches the light settings of the environment is then what shows on the window and mirror panels of the AR terrarium. The photo is used to create a “material” to apply to the planes. The material also uses physically based metallic properties to reflect light from the real-time captured terrarium surroundings on to the planes, to make the visual effect more realistic.

notes from final project planning