How To Make (almost) Anything

mechanical machine design

CHOCOLATE EXTRUDING MACHINE

inspiration:

TASK

As a group, design a machine that includes mechanism+actuation+automation

COLLABORATION

We broke into groups to handle machine design & hardware vs electronics vs software vs extruder. I worked on the team that handled machine design. We met for a marathon day of designing. This day’s heros were Erik Strand and Lizbeth Delatorre, with several others of us providing as much help as we could.

MACHINE DESIGN

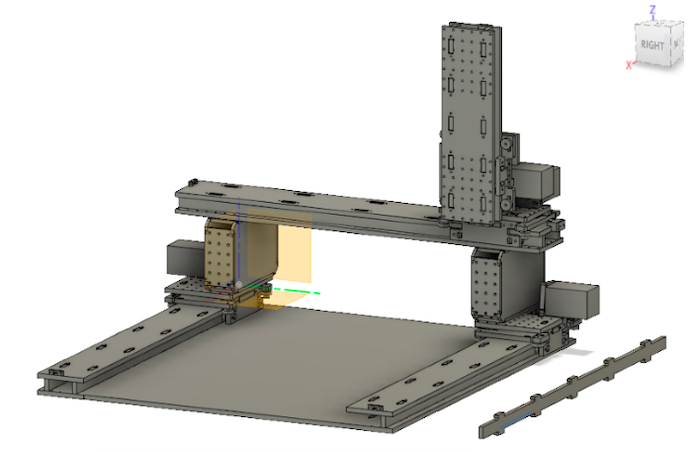

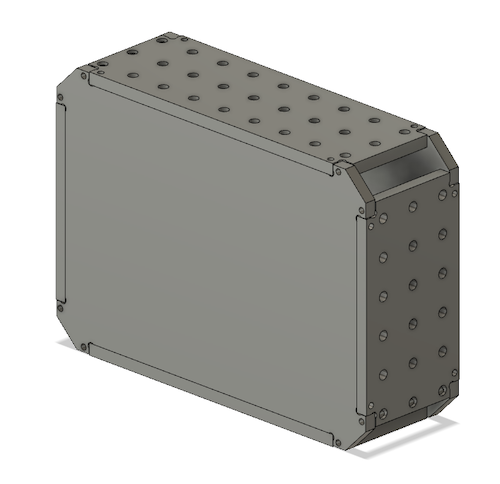

A chocolate extruding machine.

Machine body material: HDPE

CAD software: Fusion 360

STARTING DESIGN

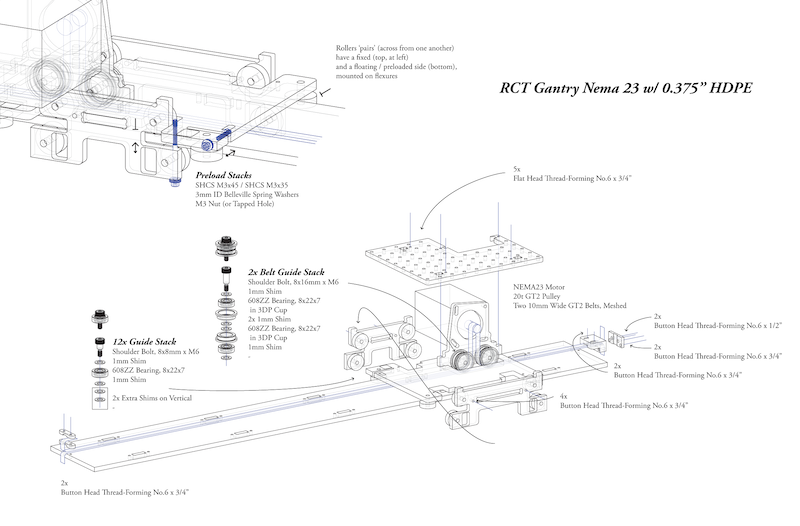

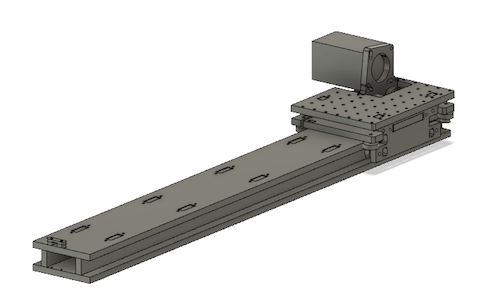

We started with RCTN23-0375HDPE Fusion CAD File from the machine-week rct gantries repo: https://gitlab.cba.mit.edu/jakeread/rctgantries#rctn23-0375hdpe-fusion-cad-file

MODIFICATIONS TO STARTING DESIGN

Design considerations

Our machine bears weight at its extruder

- It is holding chocolate which may be heavy

- Implication: We want our x-axis to be shorter to make it sturdier

Protecting our motors from chocolate

- We do not want our motors to come close to the chocolate that has been extruded, as that would damage the motors (and make our chocolate less delicious)

- Our machine will not have automatic collision detection (we are not that advanced) so we must design the machine so that the motors are safely positioned away from potential chocolate

We started by using the provided RCT gantry as the X, Y, and Z axes, and worked on how to compose the axes.

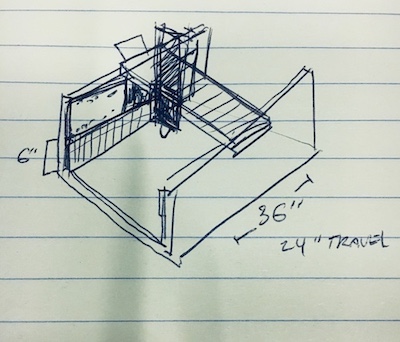

Original plan:

- Use 2 lengthened Y-axes and position them vertically

- Put a shortened X-axes on top of the Y-axes, so that the extruder can travel between these gantries

We thought this would establish the best stability for chocolate extrusion.

ISSUES WITH ORIGINAL PLAN

We encountered parametric issues when attempting to shorten the x-axis from the original design -- we were unable to simply shorten the part, or lessen the number of tabs.

The issues with the parametric settings caused us to reconsider our design.

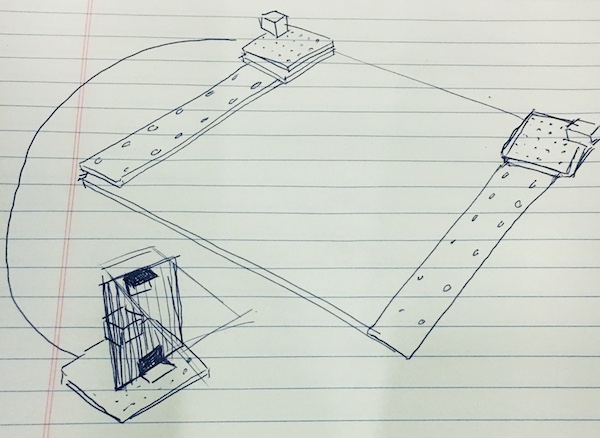

NEW PLAN

to work with the parametric issues & constraints imposed by the original design:

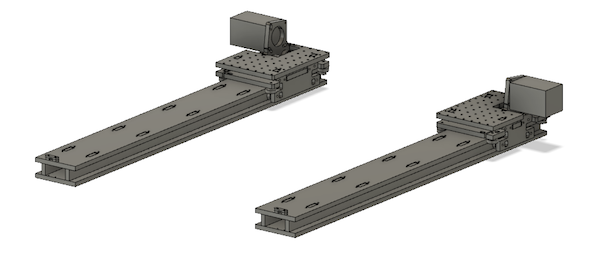

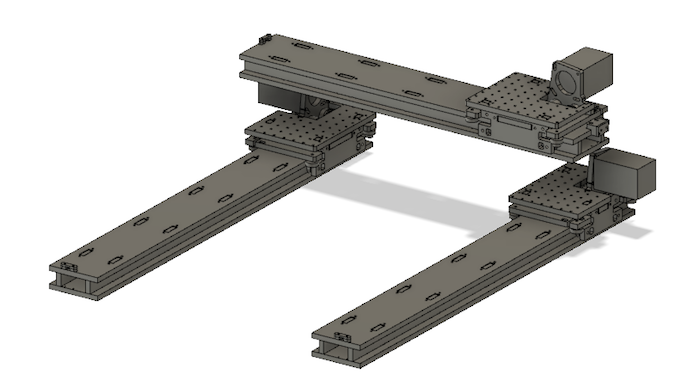

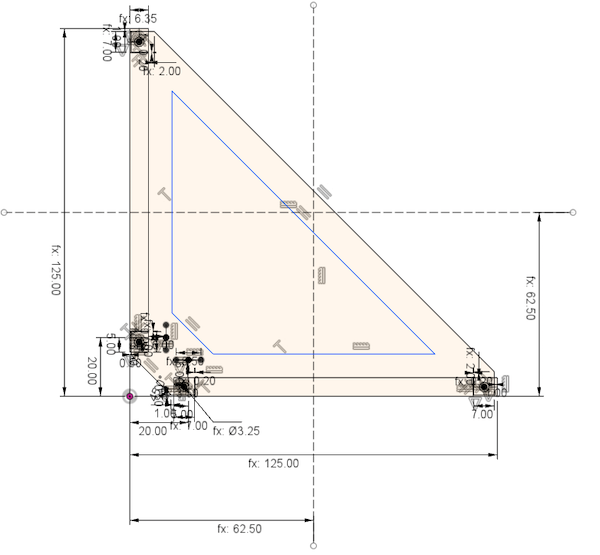

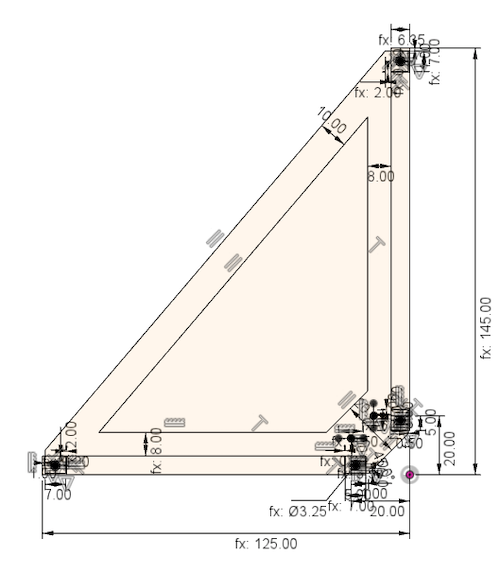

- 2 mirrored Y-axes positioned horizontally (laying on their sides)

- Each y-axis has a motor

- Brackets extend above the y-axes to elevate the x-axis that sits between them

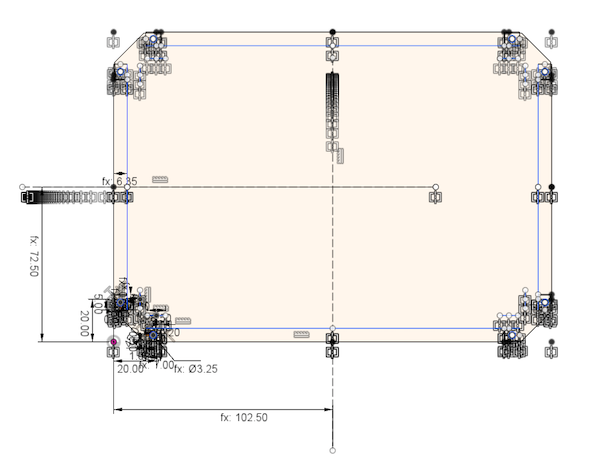

- 1 extended (wider) bottom plate between the Y-axes to accommodate the horizontal positioning of the Y-axes

- Z-axis fits on top of X-axis

TASKS

- shorten the z-axis without working with parametric settings (note broken parametric settings)

- This is necessary so that the z-axis can bear the weight of the chocolate in the extruder.

- We chose to do this by using boolean logic to slice the starting axis design.

- Design the base plate that sits between the y-axes

- Design brackets that elevate x-axis above y-axes

- Compose the parts

STEPS

We mirrored our y-axis component to create its mate

Challenge:

Connect y-axes with a base plate. The problem was that two separate components cannot be connected by one body (a base plate).

Solution:

We deleted the base plates of the y-axis components and put them into a new “base plate” component, which we then joined into one base plate. We reconnected this base plate to our y-axes.

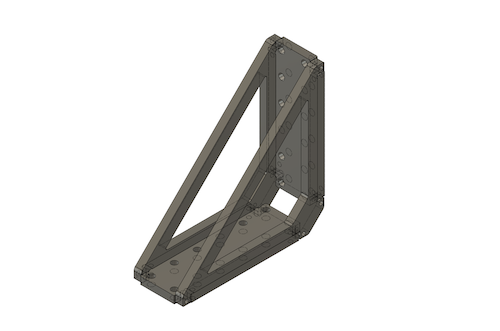

Connecting the y-axes and x-axis with brackets:

We started with the design for the provided 90 Degree Block for 1/4" Aluminum: RCTBLK-90-025ALU Fusion CAD File

We went into the part’s creation history timeline in fusion to modify it in the following ways:

- Transform its triangular shape to a rectangle. We modified the underlying sketch for the component

- Make it solid without cutouts. The bracket was originally designed for aluminum, which is a more rigid material than our HDPE material. We removed the cutouts to provide more support for our HDPE brackets.

To save ourselves time, made the decision to not include all of the fillet’s from Jake’s original design. We did this knowing we ran the risk of imprecision at the time of cutting the parts.

Throughout this process, much of time went to measuring parts and determining how large parts should be, how many holes they should have, etc.

Assembly continued, and we finally handed our design off for fabrication.