MAS:863 HOW TO MAKE (ALMOST) ANYTHING 2018

––––––

WEEK 11: mechanical machine design

group assignment: actuate and automate your machine, document the group project and your individual contribution

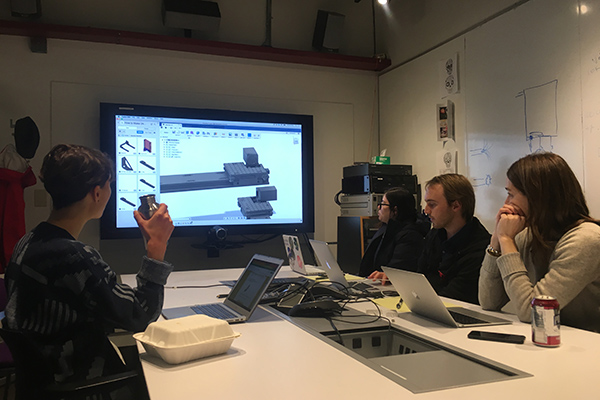

I sat into watch Erik lead design but I worked mostly on the fabrication team.

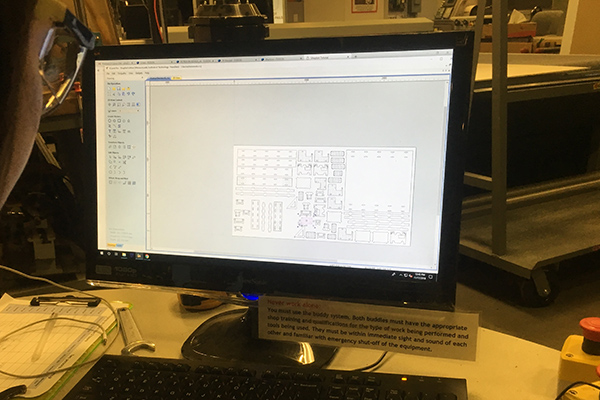

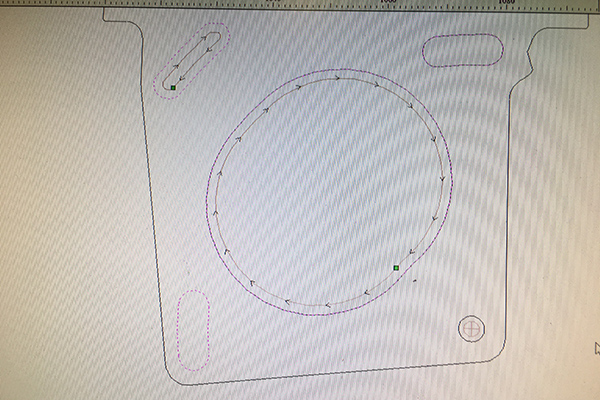

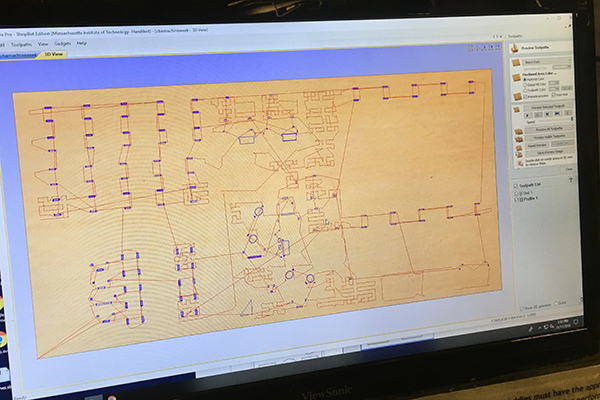

Fabrication team took turns performing the delicate, labor-intensive task of selecting all the pieces for each type of cut; circles, inner, and outer. During this process, we noticed the traces were not actually joined even though we had joined all of the traces and some of the dog bone fillet had not been formed.

For the interior cuts that were not joined we had to select each segment of the cut and join them one by one.

Check the cut path

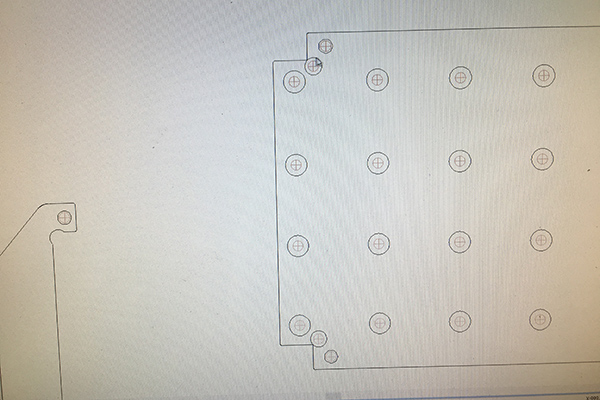

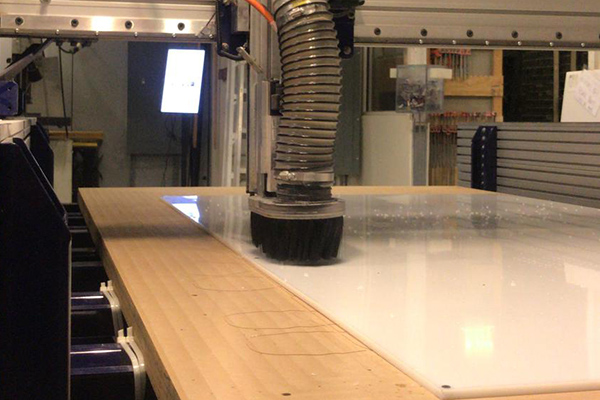

We followed Filppios' CNC settings for the machine and started cutting. It ended up taking 4.5hrs just to do the holes. Our intial setting for the peck depth was .75mm which for a 12mm cut depth was around 16 pecks per hole. We changed this the cut set to be 6mm per peck and that sped thing up tremendously.

Once we started getting into the traces we noticed the pieces started to rattle around. The tab settings of 1mm that we set was too minimal for it to show up. We experimented with the tab thickness and arrived at 4mm. We had also set some of the pieces too close to each other. We decided to re draw some tools paths to correct these errors and cut on the exisitng board.