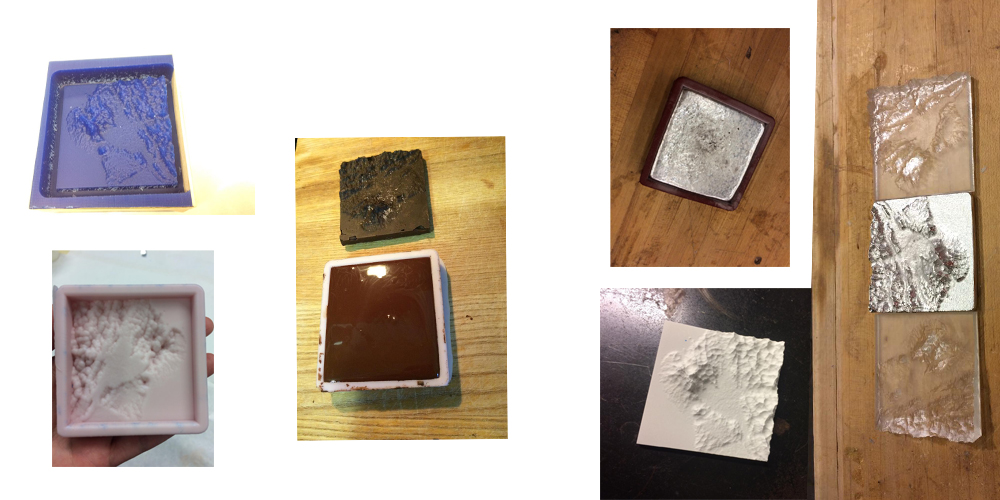

I SAW THAT SAM HAD PREVIOUSLY MILLED A WOOD MOLD FOR BLOCKING GLASS, SO I WANTED TO TRY A TWO PART MOLD FOR BLOWING INTO. I CHOSE TO MAKE A KNEE TO KEEP THINGS CONSISTANT. I ALSO WANTED A ANATOMICALLY CORRECT KNEE SO I GOT A 3D MODEL FROM A CT SCAN, AND SPENT HOURS CLEANING UP THE MODEL TO GET RID OF HOLES AND UNDERCUTS. ALSO TO MILL NEGATIVES INSTEAD OF POSITIVES LIKE THE WAX MOLD I MADE TWO PART NEGATIVE 3D MODELS. THE MILLING WENT GREAT, I USED RED OAK, IT WAS A LITTLE LOUD LIKE TOM SPECULATED BUT NOT HORRIBLE. AFTER MILLING I SECURED HINGES AND HANDLES AND IMMERSED IN WATER FOR THREE DAYS. THIS STEP IS CRUCIAL FOR WORKING WITH GLASS OTHERWISE THE WOOD WOULD JUST BURN.

PETER HOUK WAS KIND ENOUGH TO BLOW INTO THE MOLD DURING HIS SLOT. ITS ADMITTEDLY NOT AN EASY MOLD TO BLOW INTO BECAUSE OF THE IRREGULAR SHAPE AND TIGHT JOINTS. AFTER SEVERAL TRIES WE SUCCEEDED! FROM THE PHOTO ON THE LEFT YOU CAN TELL GLASS WAS PUSHED OUT OF THE MOLD. THE ONE ON THE RIGHT WAS PRETTY CLOSE TO MY MODEL, WITH JUST THE TIP A LITTLE OFF.