Week 6

Computer-Controlled maching, Making something big with the Shopbot

Assignment:

1) Make something big

This week, we were given a 4' x 8' piece of OSB plywood (a low-grade plywood), trained on the Shopbot, and told to "make something big." The Shopbot is a computer-controlled cutting machine that can handle large formats, like this week's board.

The board on the Shopbot.

I decided to make something mildly useful, versus something fanciful that would get thrown away at the end of the project. My house has a fireplace and an outdoor wood pile that is not well protected from the rain, so I decided to make a small shelter to keep the firewood dry. A partial woodshed.

I added a decorative element, something whimsical. This also gave me a chance to do a bit more with the shopbut than cut rectangles. I modeled the shed's trim on a swiss chalet, in particular one owned by Charles Dickens (it came up on the first page of my Google search)

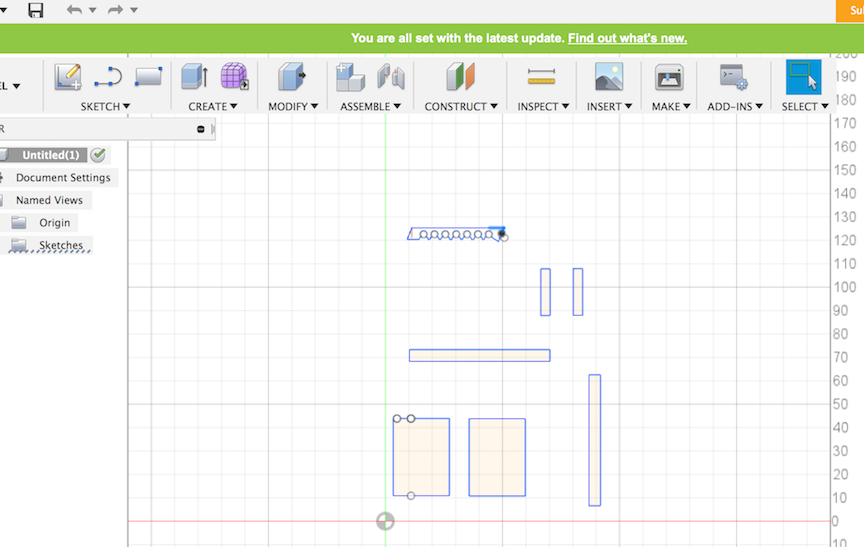

I made my initial design using Fusion360. I wanted to try SolidWorks, which we were introduced to during this week's recitation (which is a supplemental class), but I couldn't get SolidWorks to work on my laptop. Also, my design for this week is relatively simple and can be done eaisly on Fusion360.

Design sketch.

The first step in working on the shopbop is to attach your board firmly to the cutting bed, making sure there are no gaps where the board is lifting up off the surface. I used more than the recommended 4 screws to secure my board, ultimately placing about ten screws on the outer edges, as needed.

Drilling in screws to hold down the board.

Next up, setting the origin x,y to one corner of the board, which is done by using the Shopbot's software to drive the cutting head to the board corner, and then telling the software to consider that spot the origin. For the z-axis, we use the zeroing tool that comes with the machine.

Mistake: The Shopbot software is very particular. One thing it insists on is that the keypad for moving the cutting head can't be open on the screen if you want to do anything else with the software. I made this mistake a few times, which froze the program and required a restart.

Shopbot likes things the way it likes them.

Finally, off and cutting! It looks beautiful....

...Until my first cut starts running off the board and cutting in the air. I stop the machine and reset the origin. It turns out that whoever used the machine before me had left an "offset" in the software settings of about 4 inches. This was telling the machine to start cutting 4 inches away from my x,y origin, thus shifting my entire design 4 inches over and ultimately off the board.

I reset the x,y origin and the z-height, restart the machine, and we're off and running. Everything looks good now. The trim is coming out nicely.

Here's all the cut pieces, straight from the Shopbot.

To make the roof boards fit together at the right angle, I'll need to make some additional cuts with other types of machines. With John's help I cut the roof boards at an angle using the table saw.

I use some scrap wood to make interior supports for the roof, so it has stability. This requires a cutting angle that is bigger (or smaller) than what the saw can do.

I end up drawing the angles I want by hand and then cutting along those lines with the bandsaw. Not easy, and not perfect, but it works well enough. All in all, I ended up spending much more time on these cuts than I did with the Shopbot.

As I soon found out, the screws I used to attach the trim to the roof are too short, and the trim is easily knocked off. I can't screw on the legs right now because then the shed will be too big to fit in a car and drive home. For the legs, I bought 4 3x4's from the ACT program and cut them at the same angle as the roof, 68.2 degrees, using a table saw.

Another thing I learned is that it's very hard to fit a woodshed, even a disassembled one, in a compact Prius.

The trunk wouldn't fully close so it was a long, harrowing, slow-speed drive home with many stressful beeping warning noises coming from the car, and additional stressful beeping angry noises coming from other drivers.

However, I did get it home and into place!

Before I designed my initial sketch, I had taken rough measurements of the woodpile, on a dark, unlit porch at night. I should have measured better. I was worried about making the shed too small, but in adding extra clearance I made it too big. The door to the house will be blocked by the woodshed roof. Options are to cut it smaller (but I don't have saws at home), or put the shed somewhere else. I think I will do this. Once I find my hand drill I can attach the legs and a few other supports I made.

Looking forward to more of these this winter.