09

OUTPUT DEVICES

This week we worked on output devices. I learned how to use stepper motors which be used in my final project to rotate the magnetic ball around the table.

| Tools: | Eagle, Roland Mill, Jameco 238538 Stepper Motor |

| Files: | Stepper motor - code |

| Date: | 11.14.2018 |

Ideas

Getting a stepper motor working is by far the most important part of my final project. I started by taking a look at Neil's board design for a unipolar stepper motor. From there I was able to design my own board in a similar way. However my board also has a communication pin header that will allow me to have a main board that then tells this board what to do.

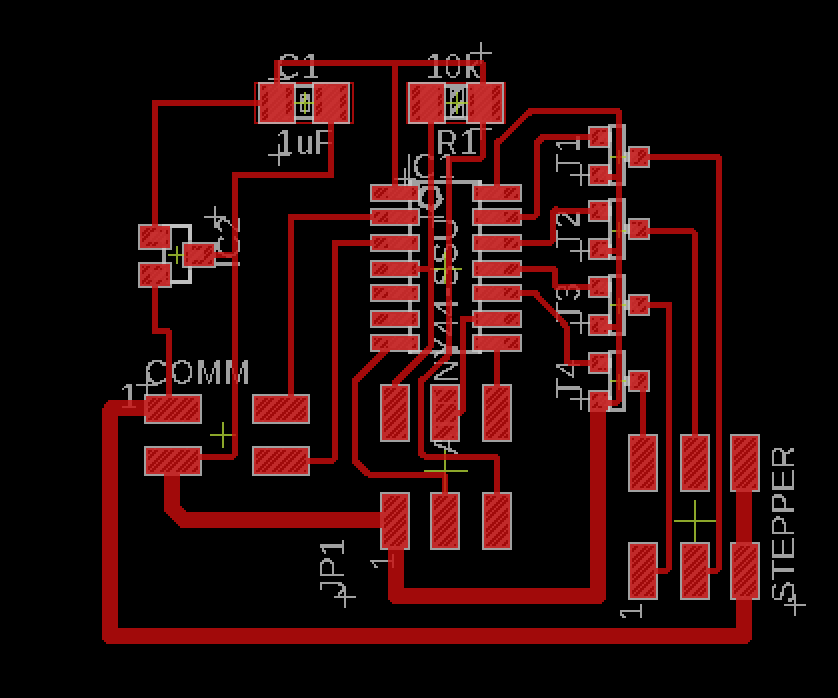

Below you can see the board design for controlling the stepper motor. The H-bridge design that allows the motor to move both forward and backwards is on the right of the board.

Milling

Milling this board took a few hours because I struggled a lot with all of the ticks of the machine and exporting images from EAGLE. Here are the helpful reminders I took away from this week.

- The images exported from EAGLE are twice are large as they should be on Macs with retina display. Double the DPI on Mods to fix this.

- The SRM-20 door is finicky. Make sure you don't touch the door until a few seconds after it's stopped moving so as to not have to restart it.

- Make sure the copper board is completely flat when stuck onto the sacrificial layer. This ensures milling goes all the way through the copper.

- The ATtiny44 has an orientation (duh). Make sure to double check this before soldering on everything.

Soldering

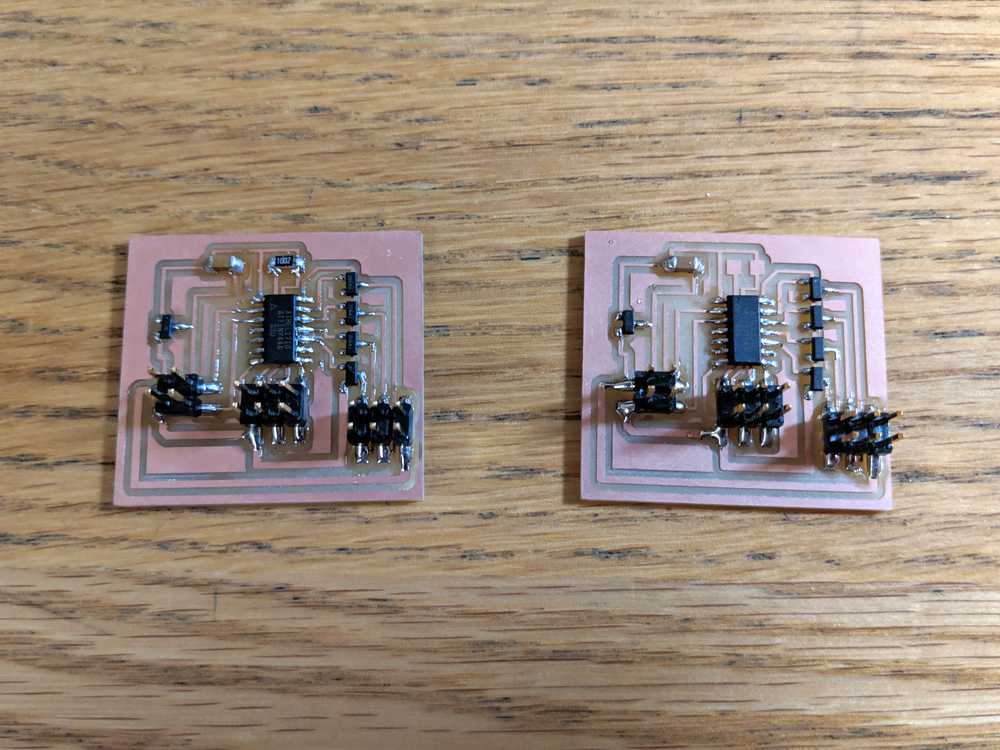

Soldering was fast as always as I've practiced doing it many times through out the semester. I milled two boards, one for each of my two motors.

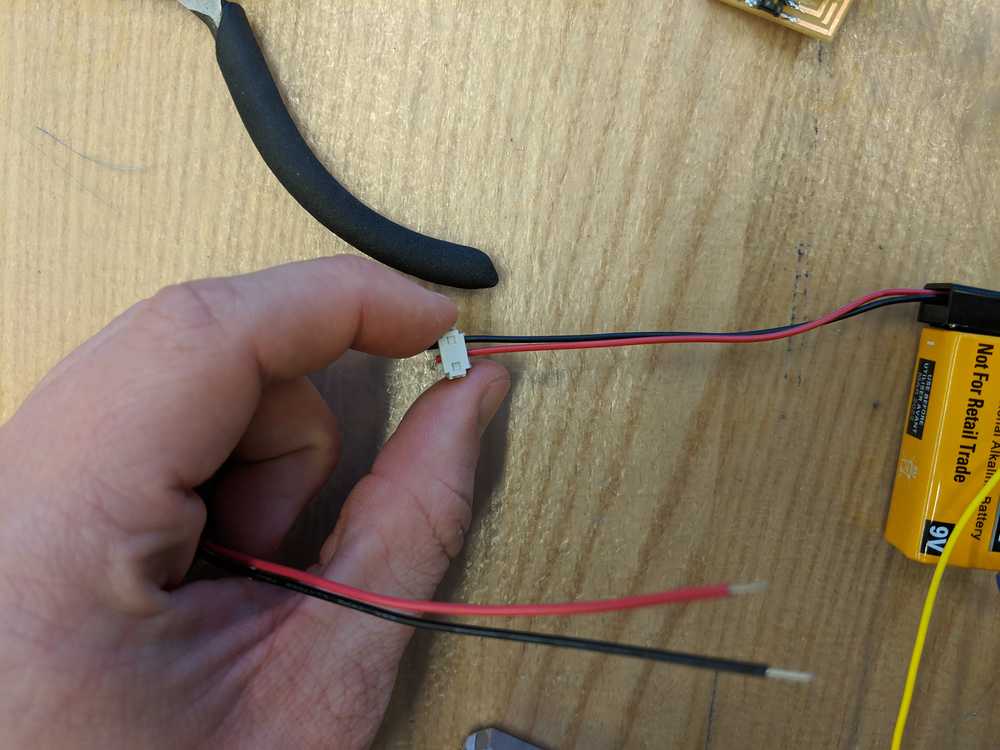

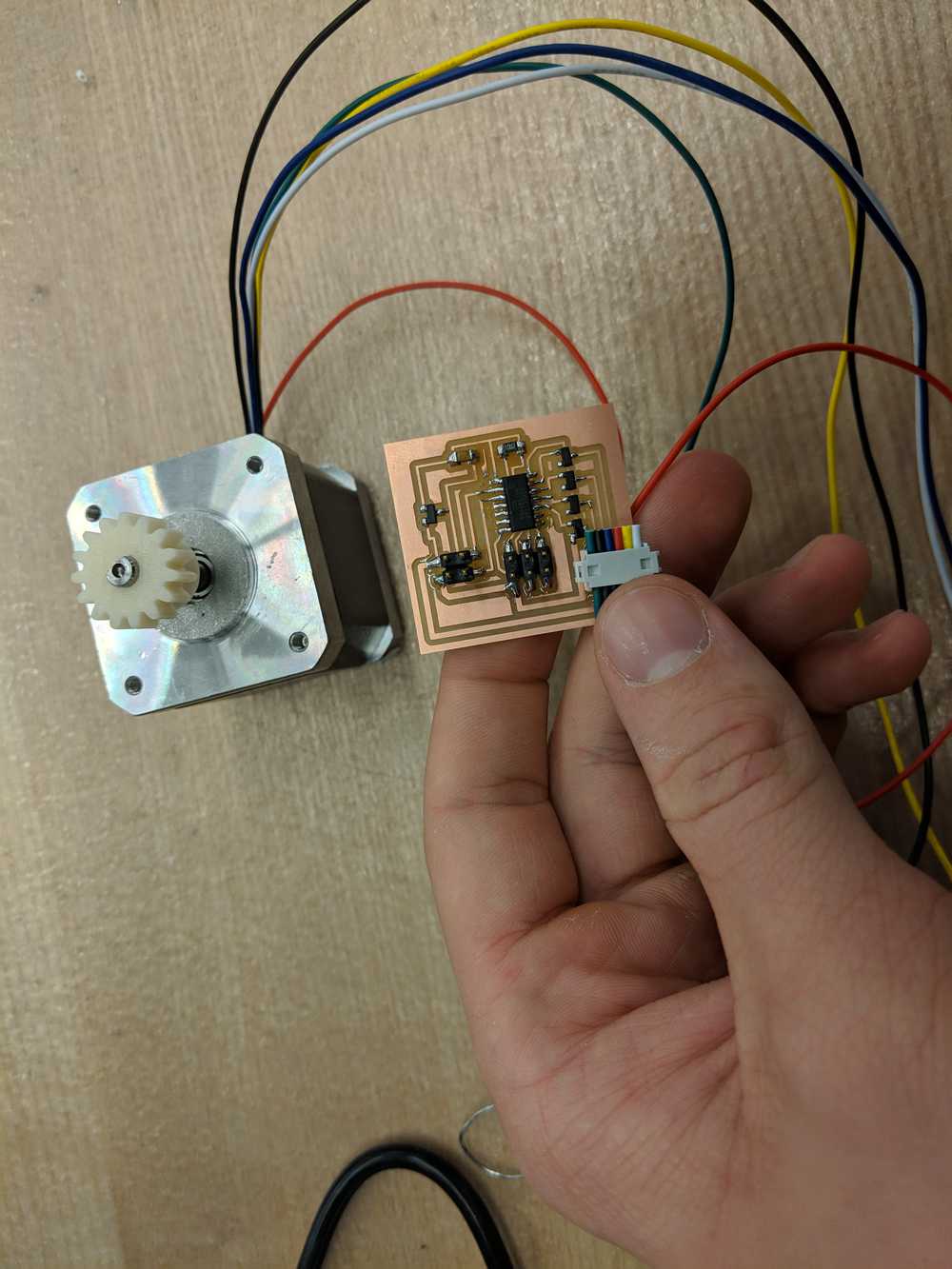

I powered the board and motor using a 9V battery (stepped down to 5V to power the ATtiny). Connecting the stepper motor to the board is important because you need to know how to set up the H-bridge properly. Below is an image of the 9V battery connection and the correct wiring for the stepper motor. Consult your wiring diagram to get the right ordering. Here is the data sheet for the stepper motor I used (Jameco 238538).

Programming

I ran a very basic program just to see if everything was hooked up correctly. All I did was to take one step, wait a very short amount of time, and then step again. The resulted in a pretty smooth motion. However, the motor vibrates a lot. I'm not sure if this is just the nature of stepper or if it's something I have done wrong. I'll do some further investigation to figure out this issues. But, for the time being, here is the motor working!