Assignment 3

3D Scanning & Printing

This week, the assignment is to 3D print something that cannot be made from subractive manufacturing techniques and to 3D scan an object.

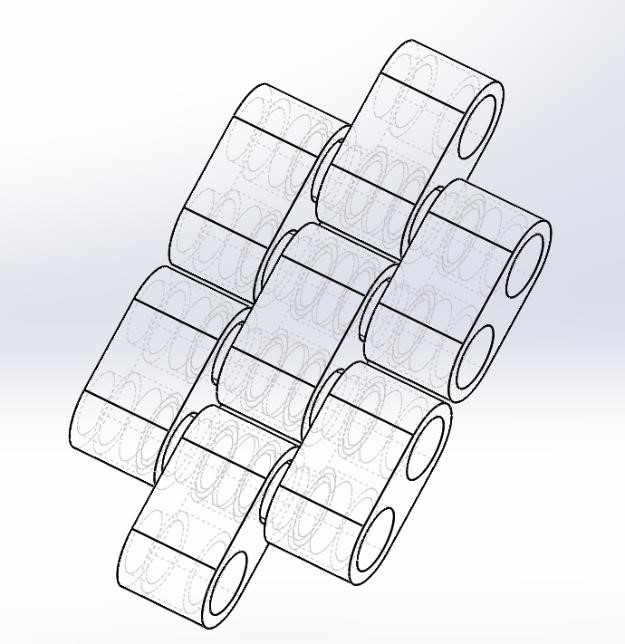

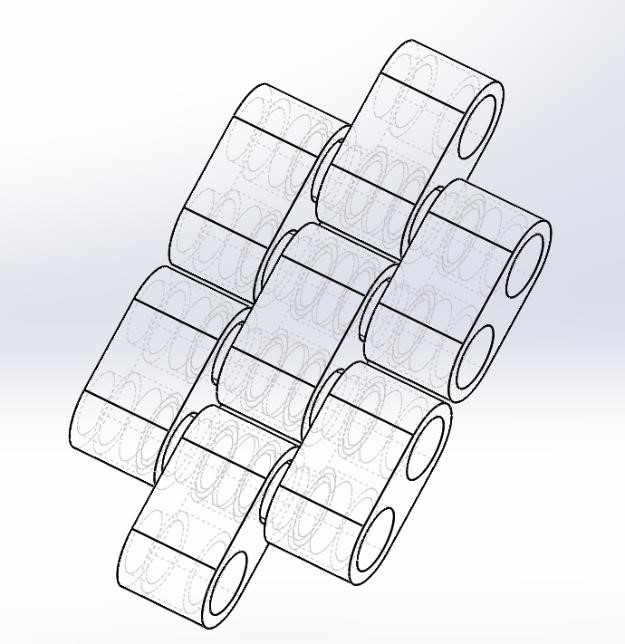

For a challenge, I decided to try to make a uni-directional 3D printed mesh. I made small pegs and block that interlinked with each other in Solidworks, with careful attention to dimensions.

I chose to print this on a Stratysis machine with support material to remove any potential margins of error in printing. I later tried this out on an Ultimaker machine without support, but I stopped it--immediately it seemed that it would fail.

After printing, I moved it to a basic solution to remove the support material. Unfortunately I forgot to turn on the bath to accelerate the dissolving of the material, so I had to take it out before fully dissolving to bring it to class, leaving little pieces of white support material stuck to the piece. But eventually I put it back in the bath to finish dissolving, and it turned out well.

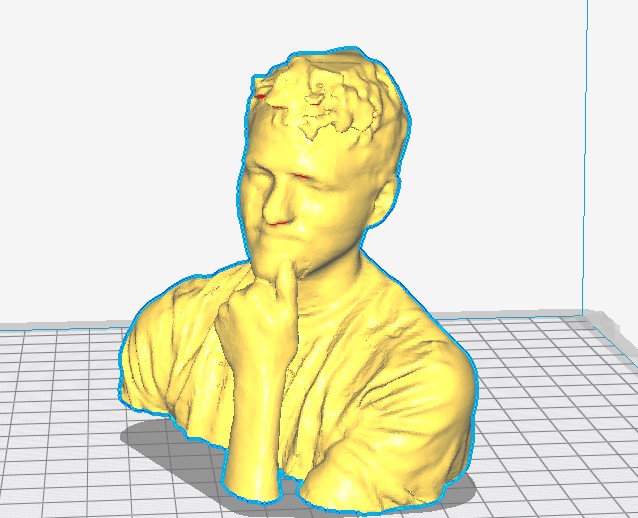

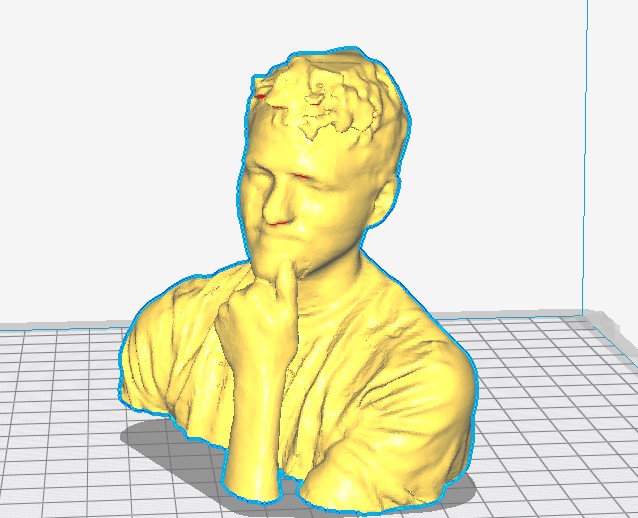

For the second part of this week's assignment, I chose to 3D scan myself. Easier said than done, I spent a few hours perfecting the art, and eventually came up with a good scan:

From my prior knowldege of 3D printing, I knew the scan would be difficult to print in the chin area, so I scanned myself with my hand on my chin to utlize a create form of support material. And since I made the scan printable, I decided to go ahead and print it: