This week, the assignment was to make an input device. Here I decided to try to make an experimental sensor for my final project. The idea is that this sensor will ultimately be able to produce a reliable interger that will eventually be implemented to be wirelessly sent to another circuit board.

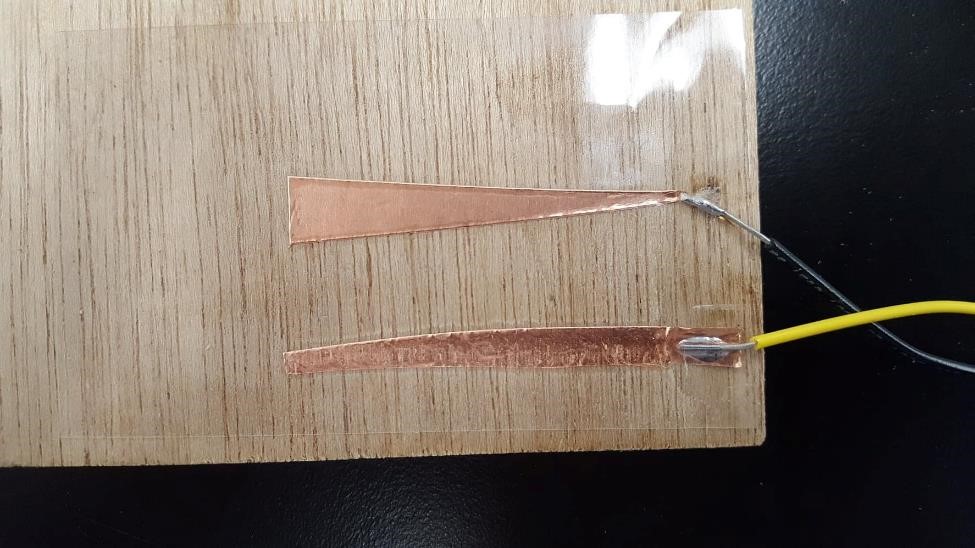

Out of curiousity, I tried to make a transmit-recieve capcitive step sensor that acted as a safety trigger and a throttle. As a basis, I initially tried out the typical layout for a variable capacitive touch sensor with two small sheets of copper. In my case, instead of varying the distance of your hand to the sensor, the effective surface area would change. I cut out some small peices for proof of concept on a straight-edge paper slicer, then applied them to a board and covered them with a thin layer of tape.

This design (in theory) utilized one small sheet as a safety trigger, always touching the hand, while the other would vary in effective surface area as the thumb moved up and down on the sensor.

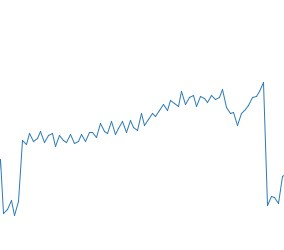

Because I was focusing on building the sensor this week and building a board for it would be very straighforward, I decided to test it with an Arduino board to save time. I used a relatively simple step response code for getting some serial data in the serial plotter.

While the concept worked, the signal was noisy and only provided a very small sensing range relative to this noise. However, I assumed it could later be easily amplified if need be, so I moved on with this concept.

To build the physical handle for this sensor, I got some clay, squished it, and traced it onto wood so that I could cut it out on a scroll saw

I then adhered the copper strips to the sides of the wood, and then applied epoxy over the whole thing to act as an insulating layer for the sensor. However, the weak adhesive did not like this and started to un-stick from the board with the gooey epoxy all over it. I had to use some creative clamping and a pin to hold everything in place.

After everything dried, it looked nice, and I sanded down the sides to make it look even better.

Unfortunatly, all the data that came from this finished sensor was illegable gibberish. I think it was because the epoxy dried unevenly and was affecting the sensor values. If I were to try this again, I would use tape or some other creative way to cover the copper sheets.