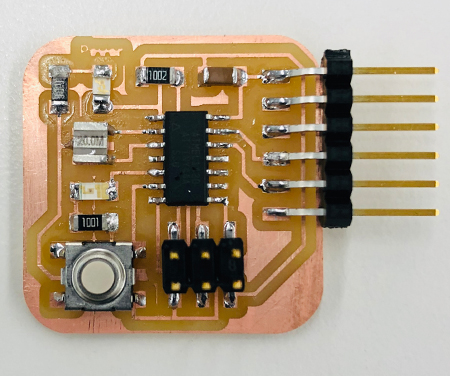

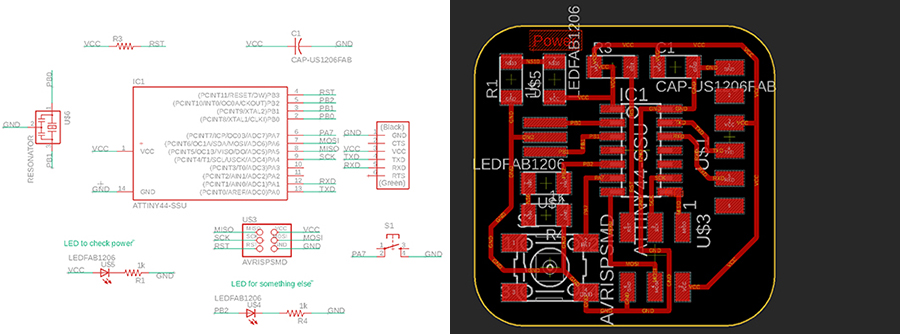

I used Eagle to design my board. In addition to the required components I added a blue LED to indicate the board is receiving power, and a green LED and a button for future programming.

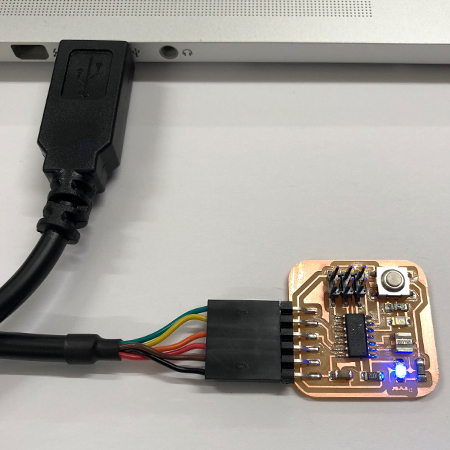

First triumph: the power button works at least...

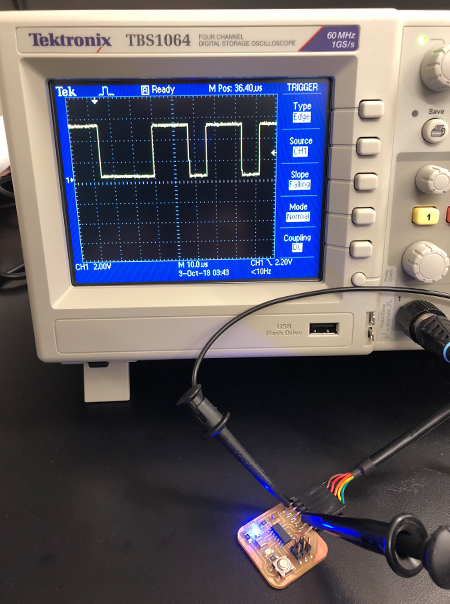

Subsequently, I programmed the board programmed successfully, and after some troubleshooting I also managed to test it. When hooked up to an oscillometer, I could measure signals send out from my laptop to the board. (l = 0110 1100)

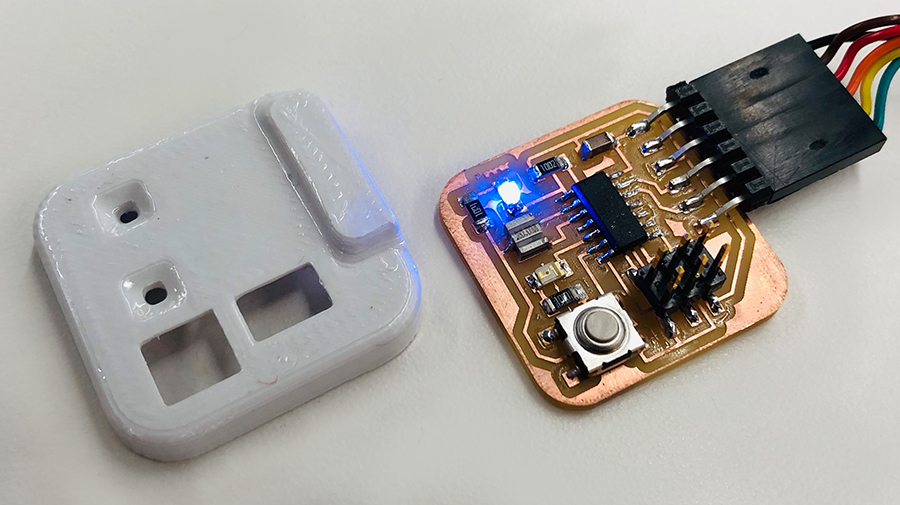

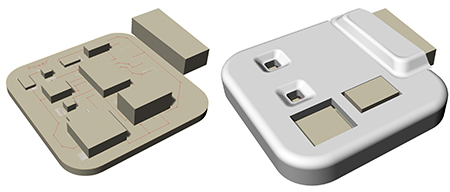

I decided to model and 3d print a case for the board. Eagle, however, is not able to export 3d file formats other than IDF, which Rhino cannot open. I tried to find Grasshopper components that would be able to open an IDF format but had no such luck. Importing an IDF in Freecad, or importing the Eagle file in KiCad were also not successful. I therefore decided to export a DXF from Eagle and use that as a baseline to build my own simplified model of the board in Rhino, and used a digital caliper to measure the size and location of the components on my board. It was a quick process.

Subsequently I modeled a case around the components, making sure to leave a bit of extra space around the components for alignment errors.

I printed the part on a Sindoh printer. (I would have preferred to use translucent PLA, to give a hint of what's inside, but was not able to.)

The print turned out a bit too small to slide onto the board effortlessly. However, that worked to my advantage, because after pushing the board in it is kept in place. Still, the case can easily be removed.