The origami chair I designed and build was based on an example I found online (see picture on the right). I liked the shape of the seat and the way it folds and unfolds. However, I didn't like the fixed base, which I feel negatively affects the whole concept of a foldable origami chair. In addition, it looks a bit uncomfortable with the bare wood and piano hinges. So I set out to use this design as a basis but improve the origami, foldable concept.

To make the chair more comfortable (or at least appear more comfortable) I decided to use fabric. And to have the fabric serve multiple purposes I wanted it to function as hinges too. To ensure that the hinges would be strong enough, I did a few tests with wood, different fabric types (burlap and very thin fabric), an optional increase in adhesion or strength with different tapes (duct tape and drywall adhesion tape), and woodglue.

To test which hinge performed the best (in other words: which hinge delaminated the least) I attached to same amount of weight to all of them. This first test already showed that the burlap without any tape performed the worst. Then I also roughed them up a bit myself. The hinge with the duct tape performed the best, and I was pleasantly surprised of the adhesion strength. Even with this small sample, I expected the performance to be sufficient for a larger, heavier piece.

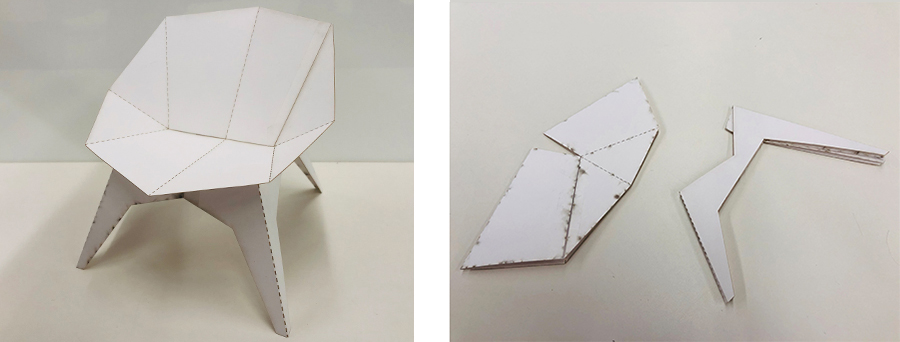

Before cutting the wood I made a test model by lasercutting Bristol paper, to make sure the pieces align and fold as I intended. I slightly changed the model of the base a bit afterwards, to give the seating more support.

With the shopbot I cut the pieces and used a scoring to outline the locations to attach smaller pieces of wood that would eventually serve the stability of the chair.

I taped the pieces together with the duct tape and glued the pieces of fabric on the wood with wood glue. Unlike my earlier hinge tests, the tape did not adhere properly. Most likely because the OSB consists of a rough surface with pieces and fibres that easily come off. So I decided to use small nails along hinges, and let the fabric act as a hinge. In the end, this actually suits my concept much more.

To give it a nice finish, I would have liked to stitch the seams, but that would have been too time consuming. So instead, I folded the extra fabric inward, ironed the fold flat, and glued it to the wood.