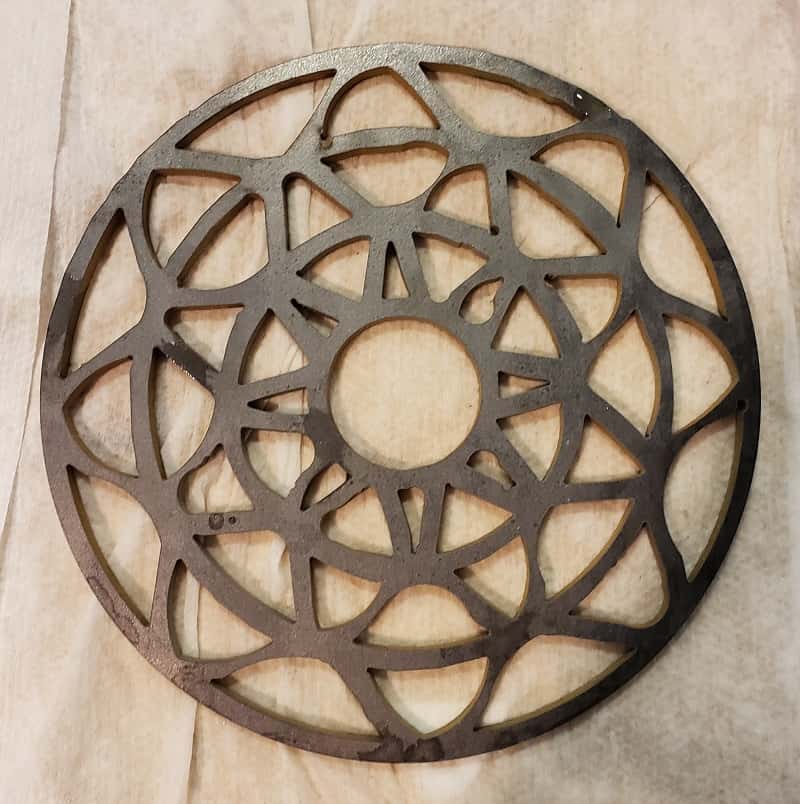

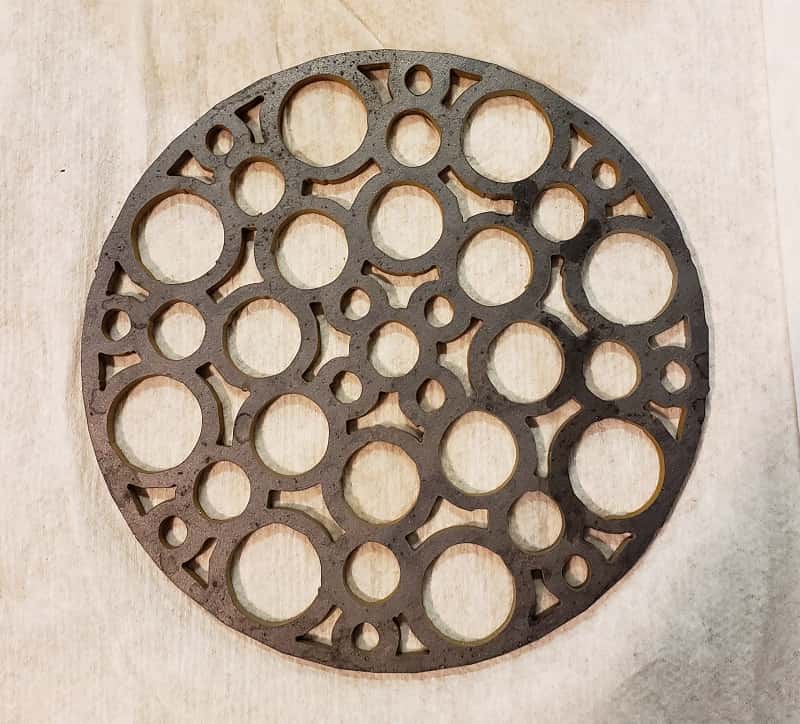

This week I took a break from working on my pinball machine for wildcard week. This week I worked within the

waterjet group to create some steel coasters. The waterjet machine is an OMAX abrasive machine. This machine

uses a fine grain -- similar to sand -- along with water pressurized up to 60,000 psi to cut materials. As such,

I worked to create coasters because I thought they looked cool and I will need them one day.

Files:

Coaster 1 Layout File

Coaster 1 Make File

Coaster 2 Layout File

Coaster 2 Make File

Coaster 3 Layout File

Coaster 3 Make File

Coaster 5 Layout File

Coaster 5 Make File

Coaster 7 Layout File

Coaster 7 Make File

This process worked similar to that of the Shopbot. I imported in the images of my design, used the OMAX Layout software

to define the lines of the sketch, created the toolpath and saved the document as an ORD file. From there, I opened the file

in the OMAX maker program, set the thickness of the material and ran the process. For the more intense, geometric shapes

it took about 15 minutes to complete. I didn't run into many difficulties this week to report. My biggest difficulty was learning

that there is a minimum size hole you can create with the machine. I lost some detailing on my geometric images as the holes got smaller

but it wasn't a large deal.