PROCESS

This week we started by doing soem characterizations as a group. The results are shown beoiw. Overall the supplied plywood is not that great, but I knew I would be buying my own wood later one.

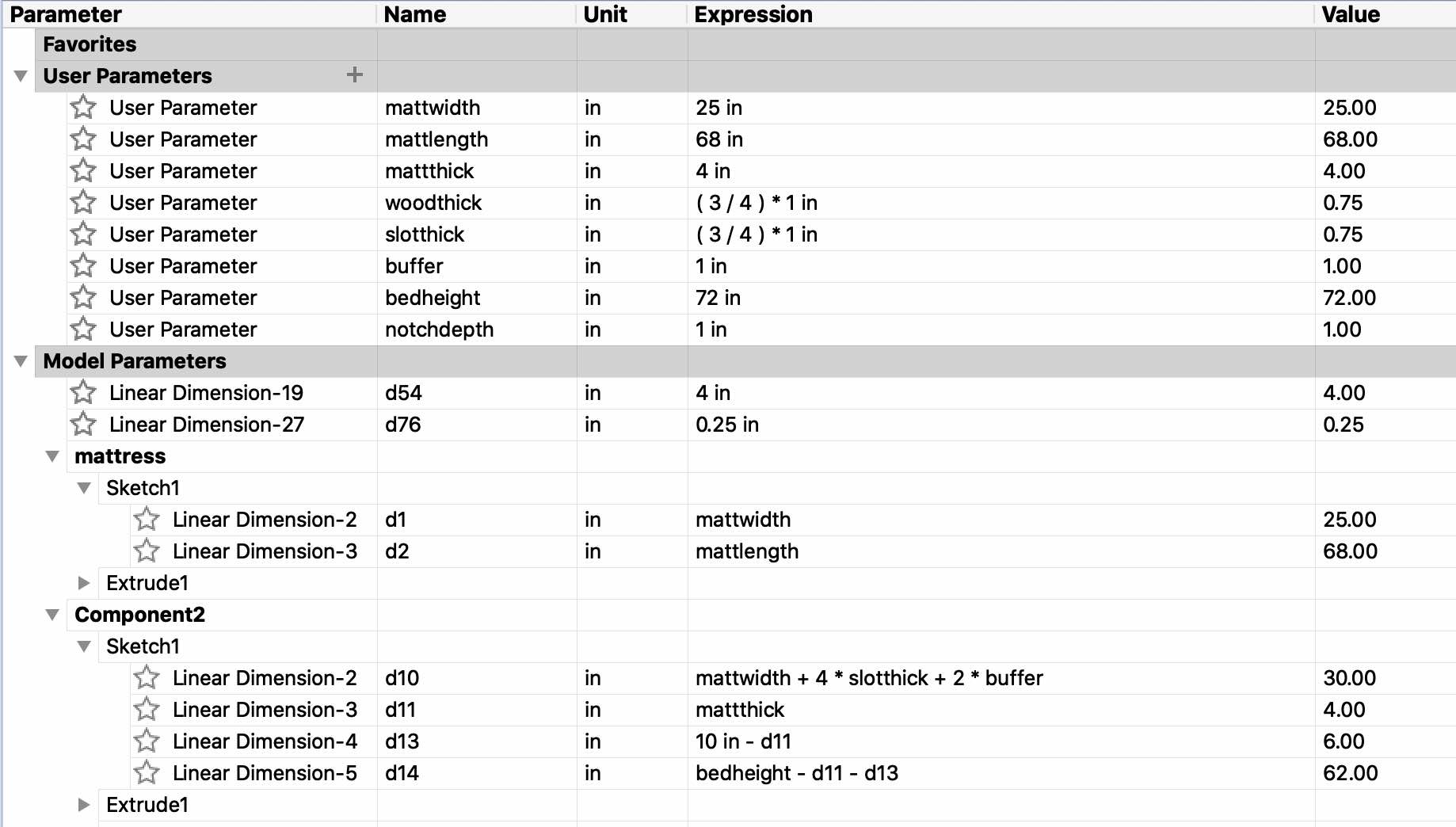

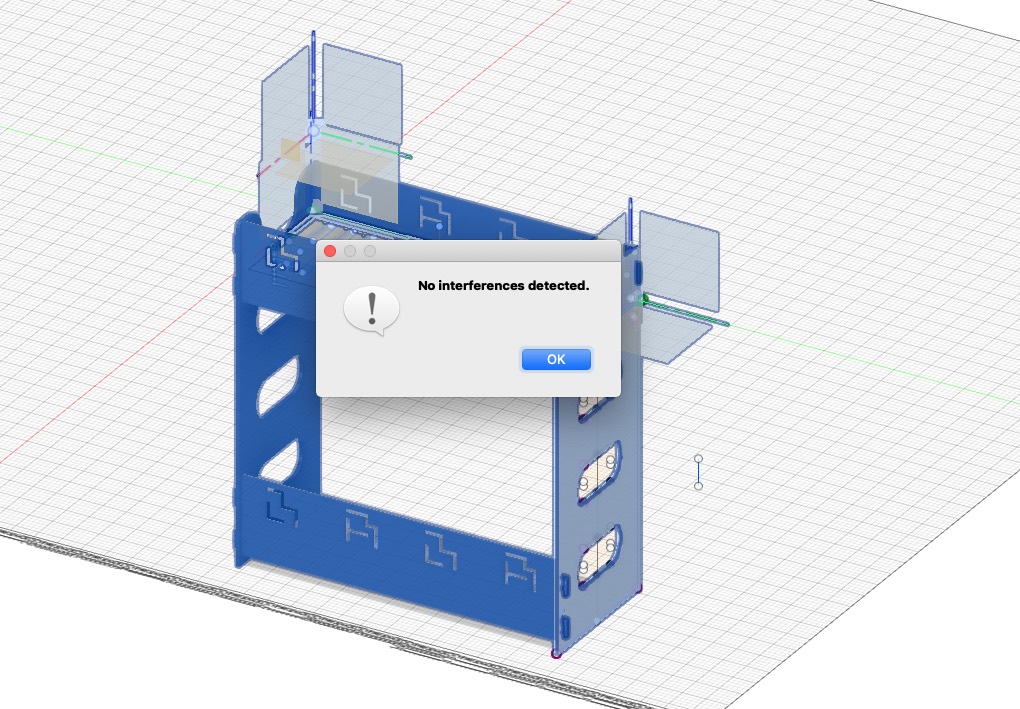

Now that we have characterized stuff, let’s model the bed! I used freebunkbed.org as a design reference, although I cad’d everything from scratch and in no time I had a model. I did everything paramterically, and was so happy to finally get to a point where I had no interferences (took a tremendous amount of time).

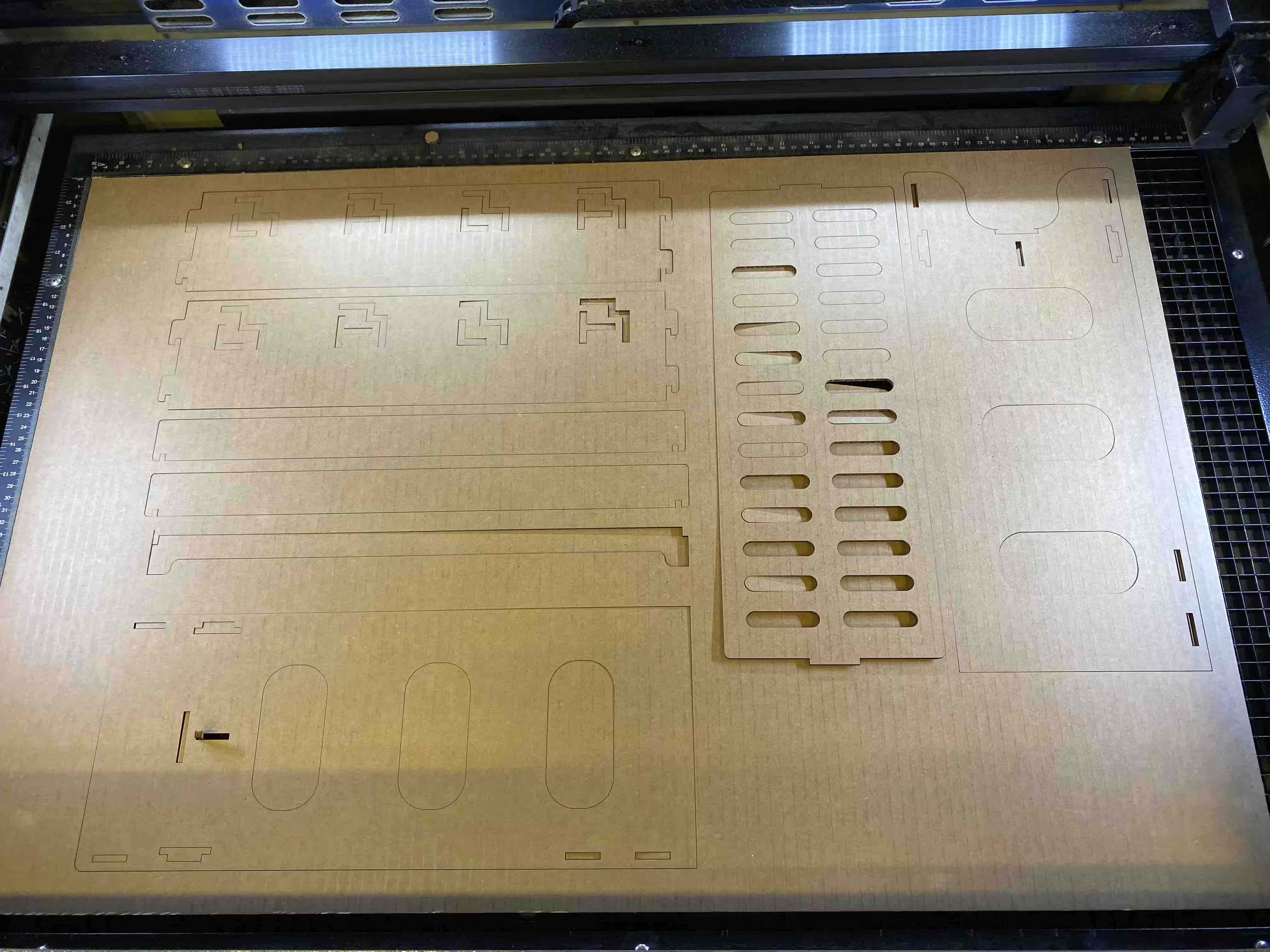

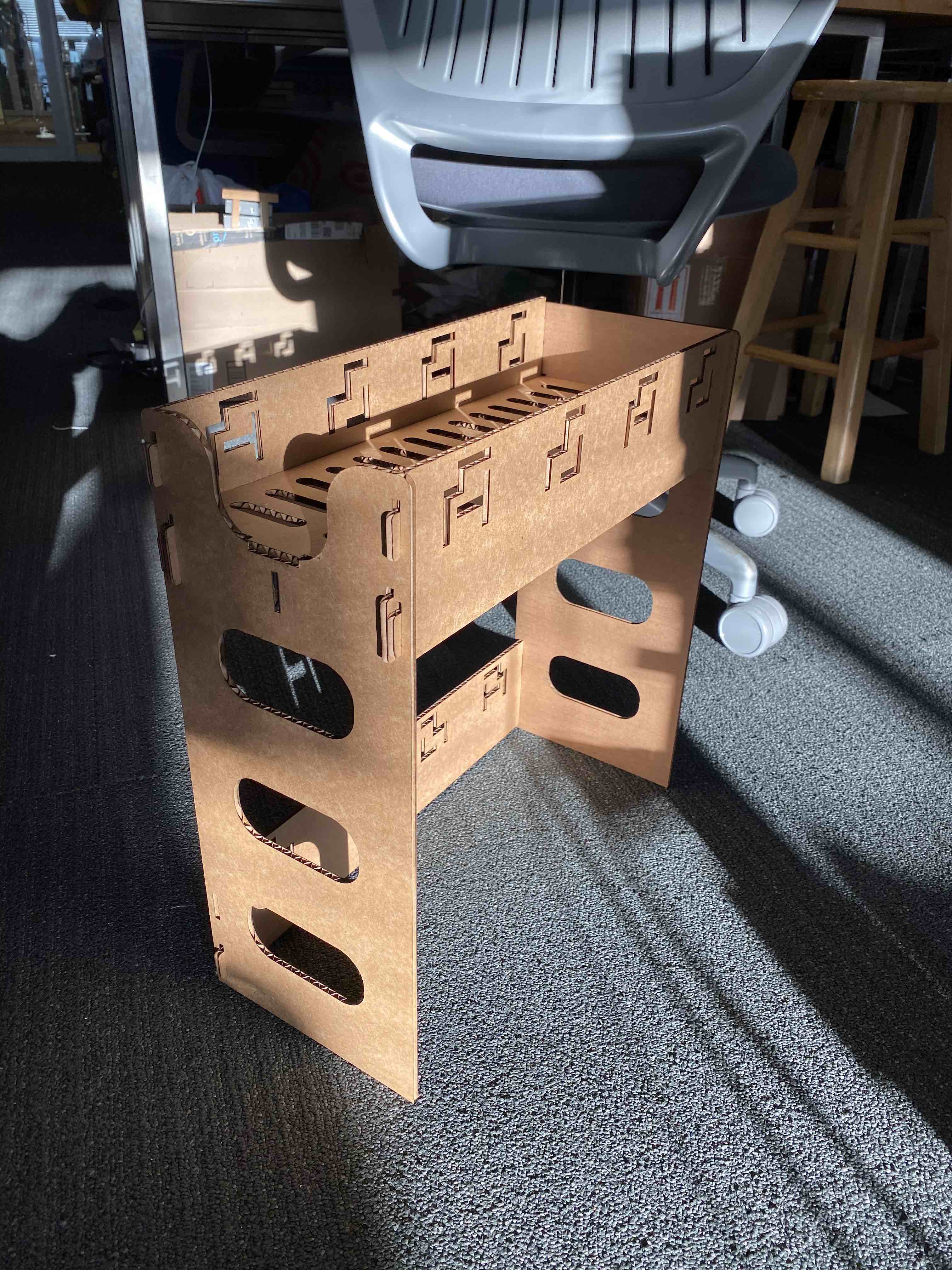

I then laser cut a miniature out of cardboard, which was a great idea since I had some joinery issues that needed quick fixing.

Once everything was ready, I headed to home depot with Cynthia and Daniel. I had my eye on some sande plywood, which was expensive but really the only type I could visually bear.

Once I got my wood I began CNC’ing. There were some major delays but eventually I got time on the shop bot.

After many cuts I ended up with a stack of puzzle pieces, with my fingers crossed they would all fit together.

And they did! Although as you can see in this video it is very wobbly.

Oh well, it’s late, let’ do some glamor shots.

Fit perfectly in our office. Ken approved!