Group Project

Configuring Laser Cutter Power and Speed

In the EDS labs, there are two laser cutters, a small one and a big one. I tuned the parameters on both to find the power and speed values of the laser cutter that would a) make a clen cut b) make a partial cut such that I could bend the cardboard on the partial cut. Luckily, I found the right parameters on the very first go. For the clean cut, a power of 100% and a speed of 13% worked. For the partial cut, laser power of 100% and speed of 50% made the right cut.

Testing

Testing

Settting Up Website

Bootstrap

I had the notion that my website needed to be perfect and that made progress very slow. There were so many way of making the website, especially the CSS. I got overwhelmed by looking at all the options. Finally, I decided, I will make a simple website to start with and then make incremental progress on the way. Therefore, I has very simple CSS. I used Bootstrap for CSS, but I did not have anything fancy.

Bootstrap

Bootstrap

Vinyl Cutting

Making Stewie's Vinyl Cut

I decided to cut Stewie (Family Guy) for my Vinyl Cutter Assignment. Anthony taught me how to operate the Vinyl Cutter and everything was pretty straightforward.

Original PNG Image

Original PNG Image

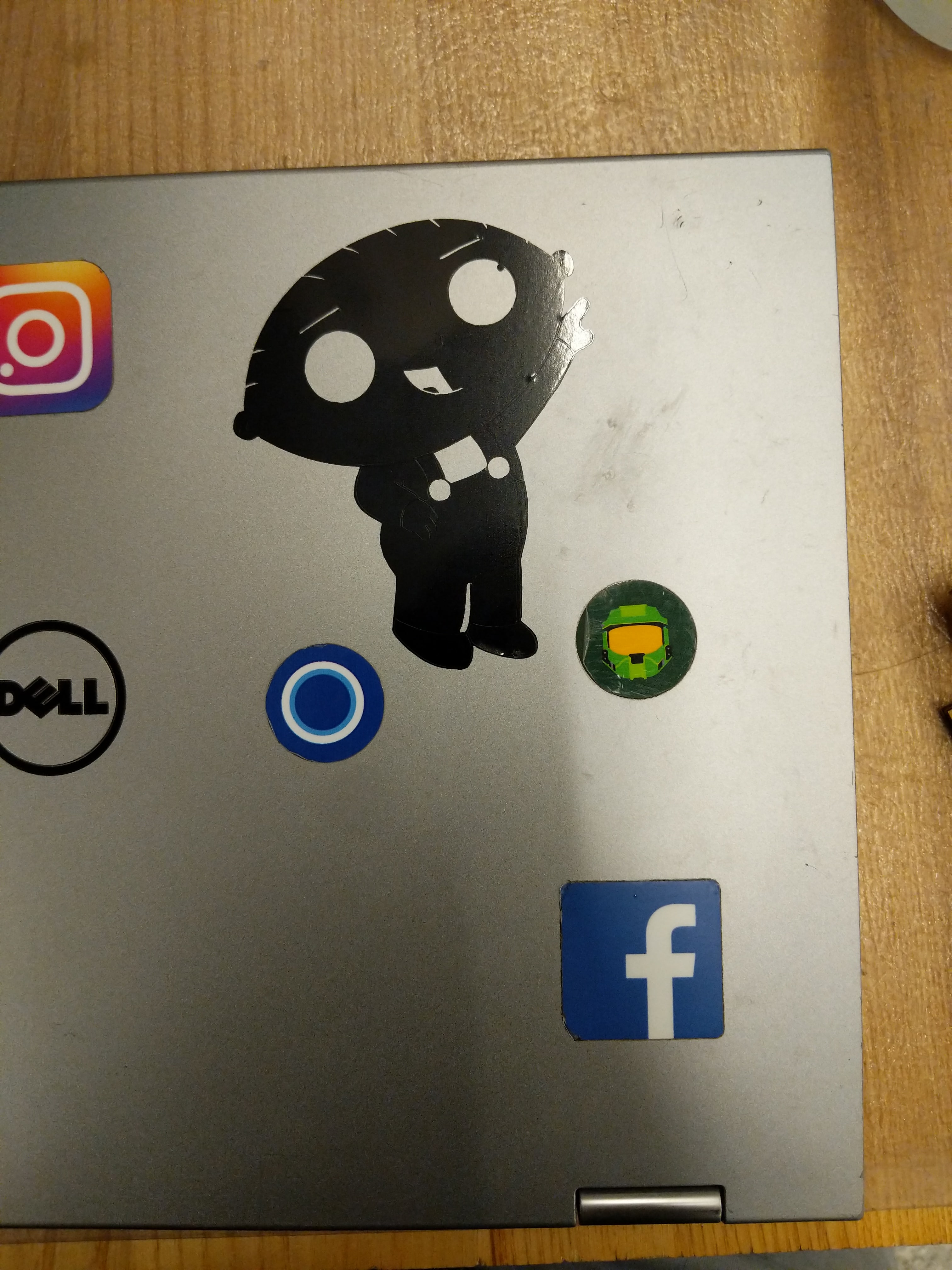

Vinyl Cut

Vinyl Cut

Laser Cutting Something

Struggling With CAD

First, I struggled to choose the right CAD software. Anthony suggested I use SolidWorks since he was most familiar with SolidWorks and could help me if I got stuck. Unfortunately, my computer did not have enough memory not the right graphics to support solidworks. I spent around 3 hours trying to make SolidWorks work on my computer. Finally, for the purposes of this project I decided to use OnShape, an online CAD software. Doing CAD felt difficult, especially since I did not have a mouse.

OnShape

OnShape

Making a Laser Cut Boat

It was difficult coming up with ideas for laser cutting. I had never done anything like this before. I searched for some ideas online too. Soon, I started thinking about paper boats. I could potentially laser cut something and make a boat. However, making a CAD for a boat felt difficult since this was my first time using a CAD software. Progress was slow and time was running out. In the end I decided to make a simple circular boat. The base would be sort of like a wheel and I could just wrap a rectangular thing to make its circular side.

Paper Boat

Paper Boat

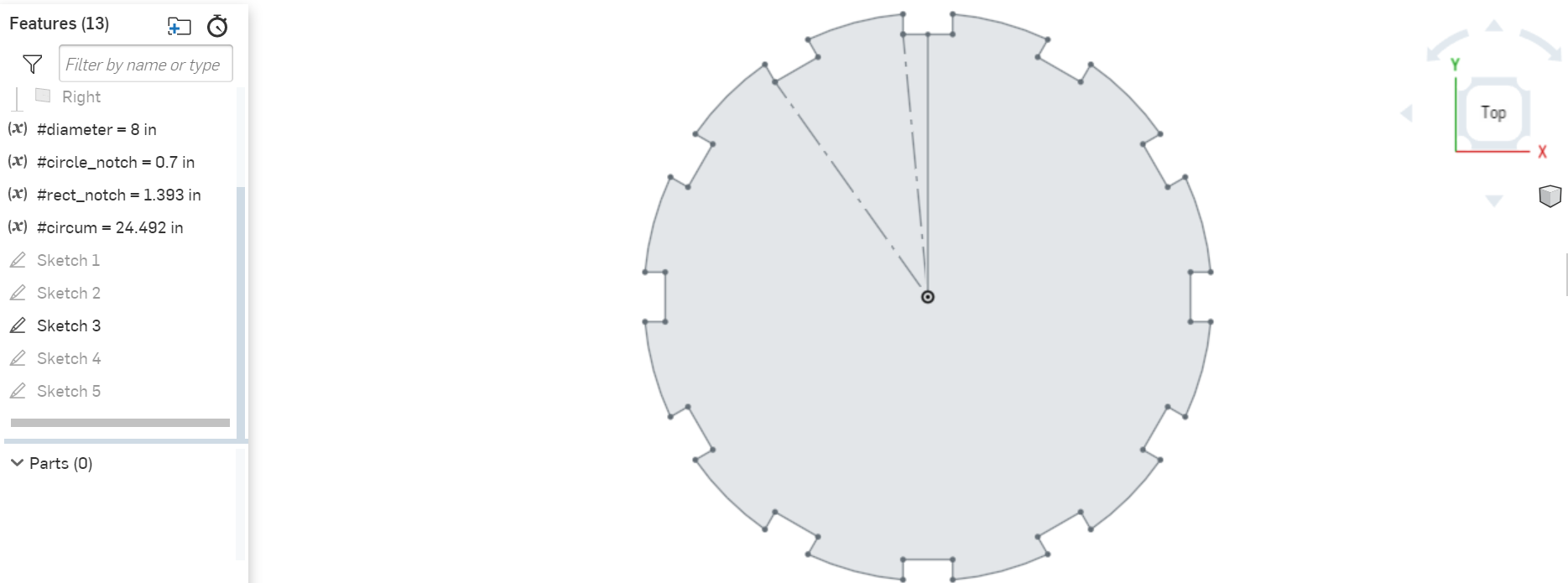

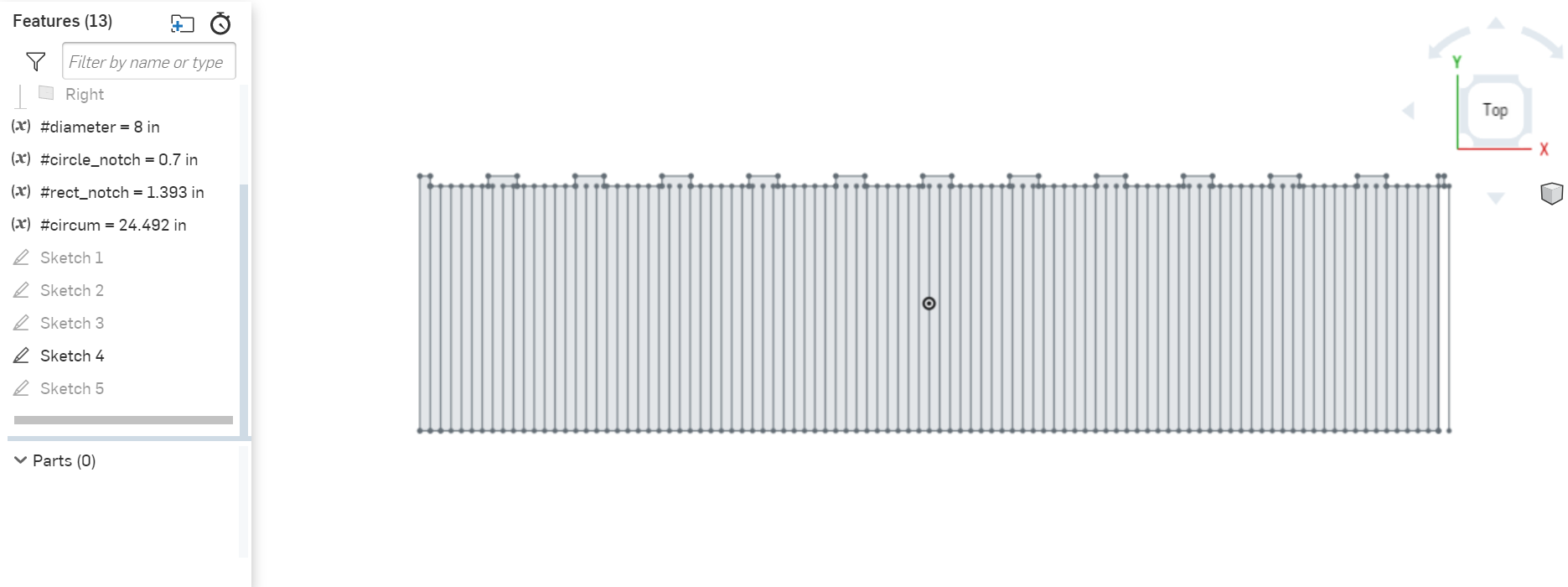

Making CAD

It took me a while to make the very simple CAD. I was happy I was learning though. Soon enough I had the CAD.

Boat Base (CAD)

Boat Base (CAD)

Boat Side (CAD)

Boat Side (CAD)

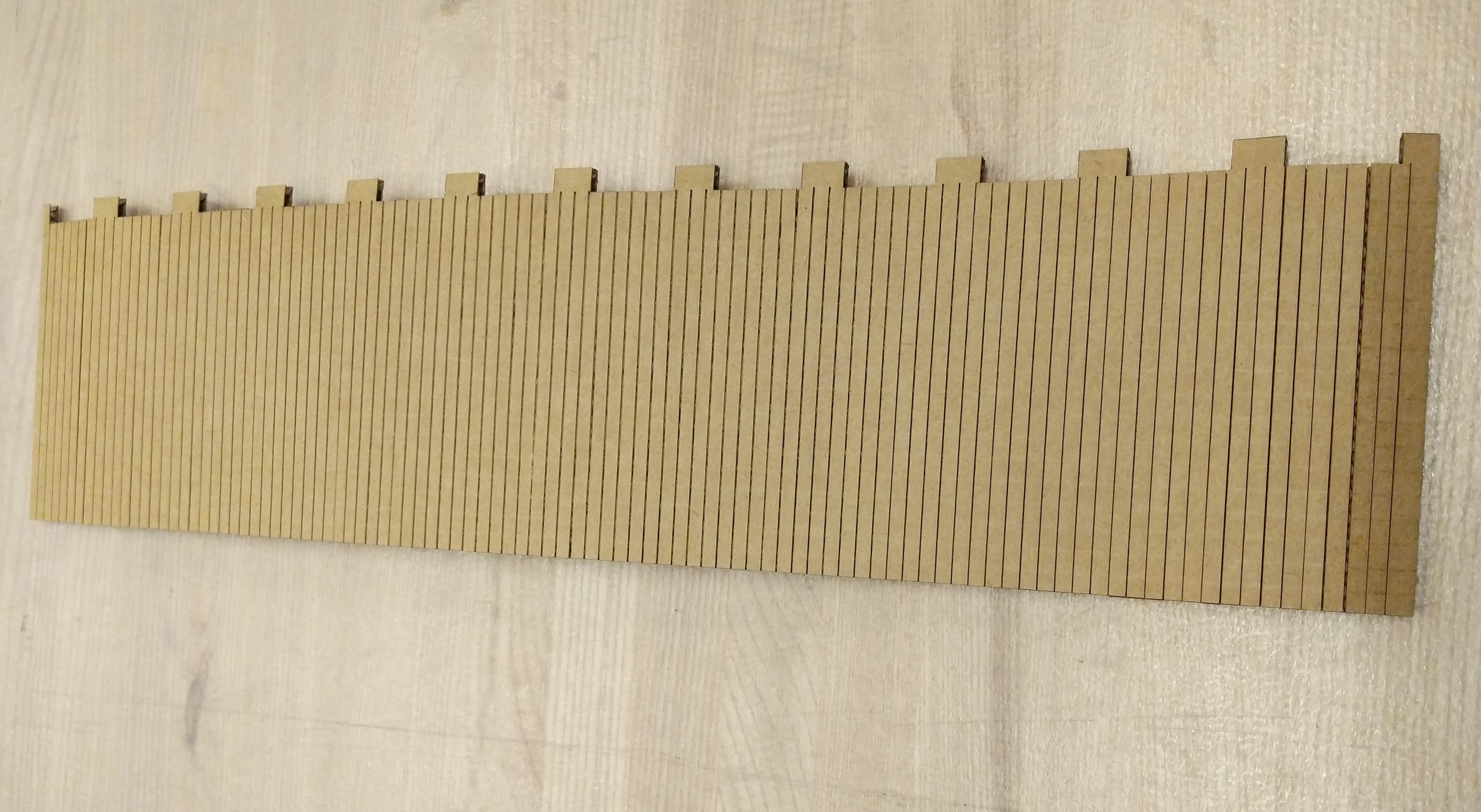

Laser Cutting Boat Pieces

Just like we had done for the group project, I went ahead and cut the boat parts from the cardboard.

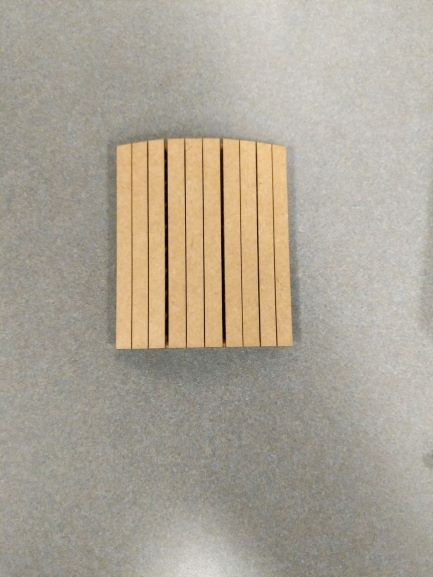

Boat Base Printed

Boat Base Printed

Boat Side Printed

Boat Side Printed

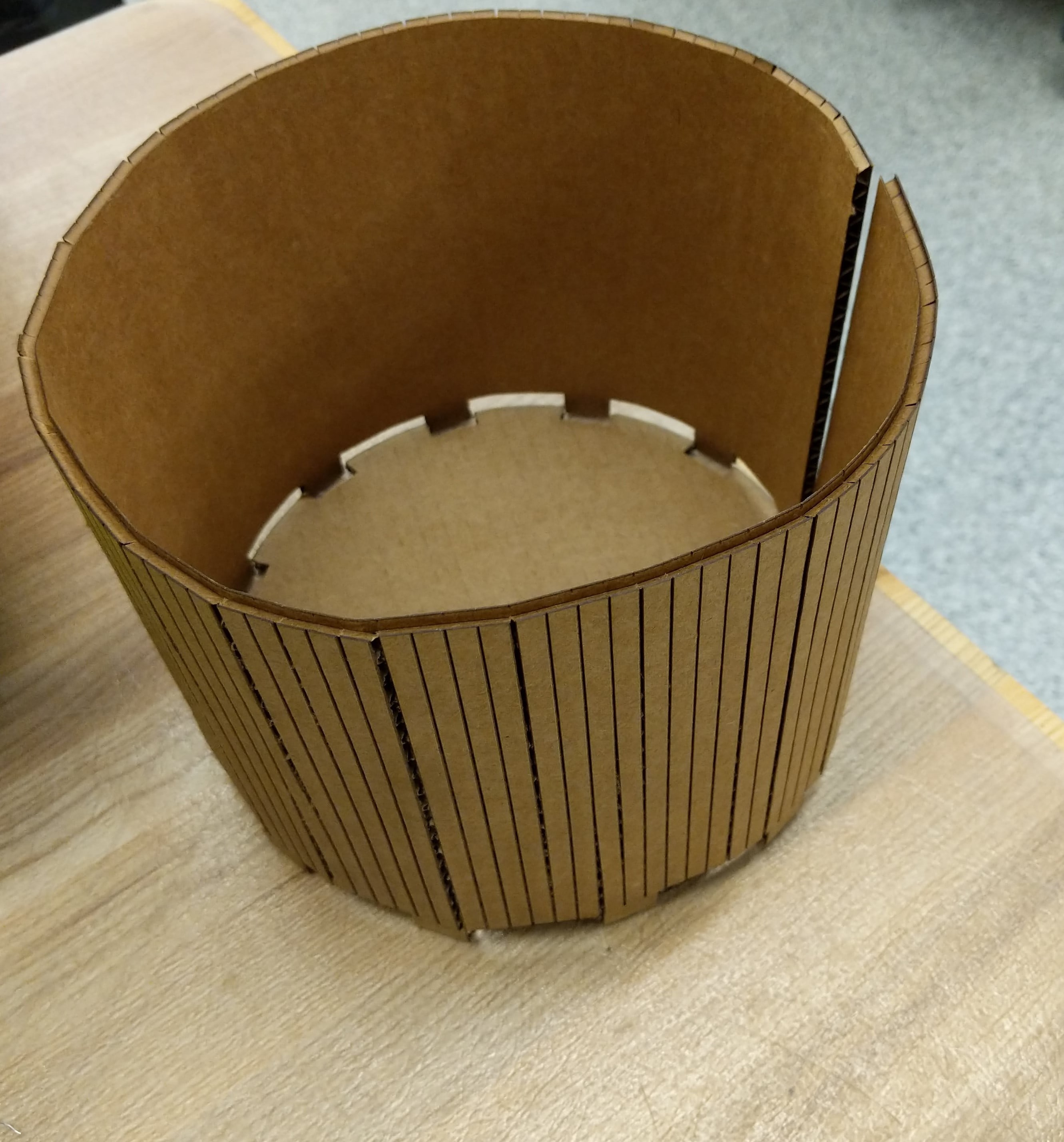

Putting it Together

Since it was a very simple design, putting it together was not difficult at all, I just had to attach the side part to the base. It was not a perfect press-fit, but it was good enough.

Boat From Top

Boat From Top

Boat From Bottom

Boat From Bottom