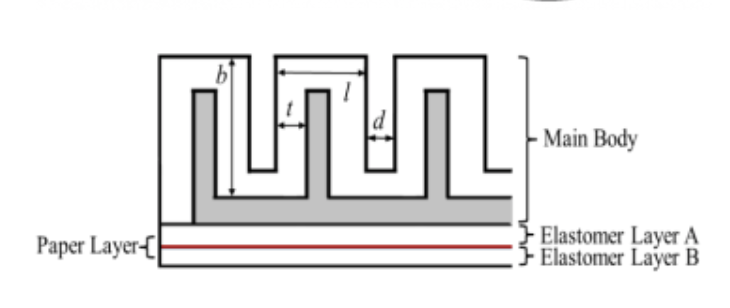

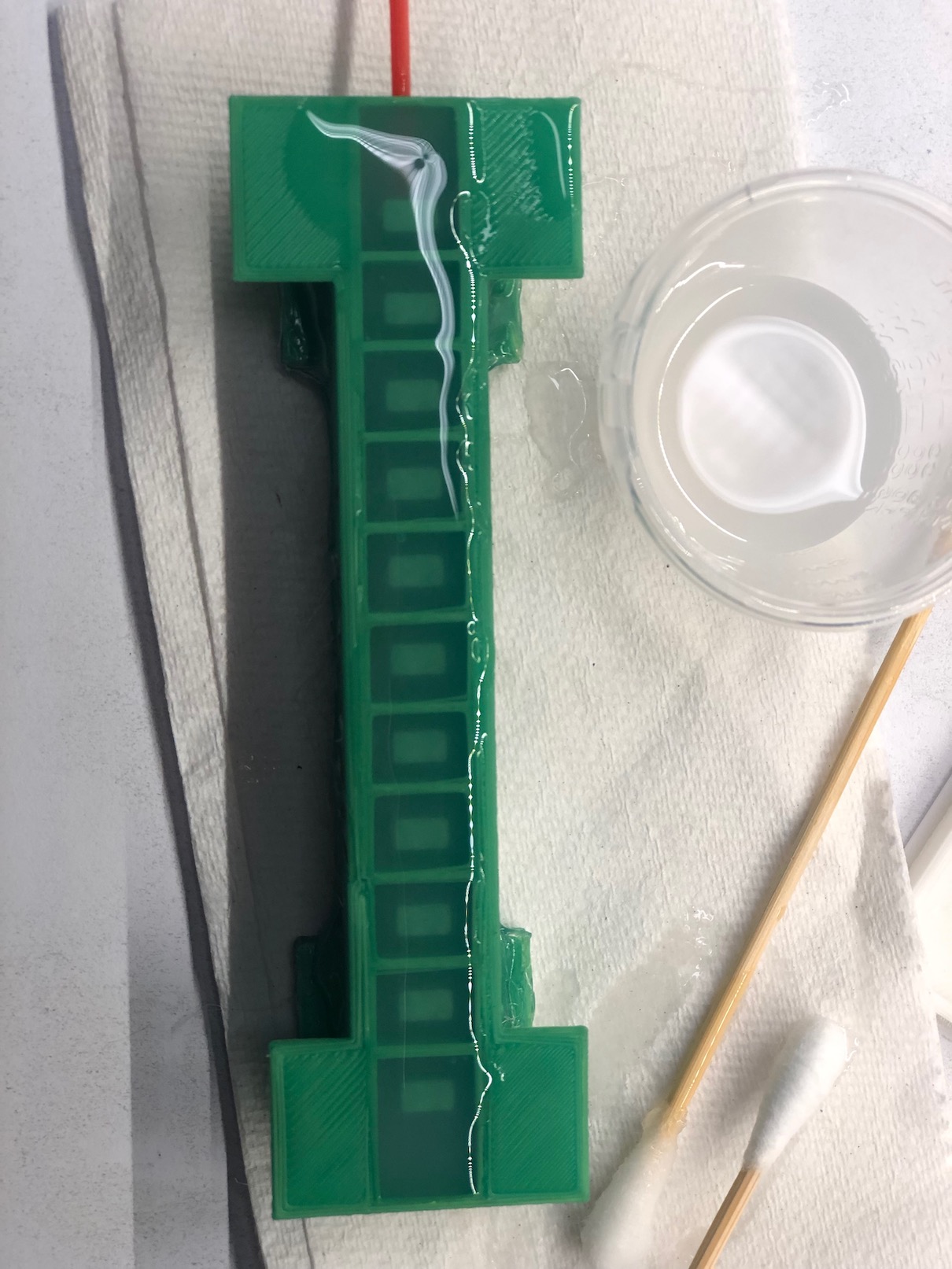

This week was our Wildcard week. I ended up being really interested in this topic that I decided I wanted to further elaborate this week into my final project. PneuNets (pneumatic networks) are a class of soft actuator originally developed by the Whitesides Research Group at Harvard. They are made up of a series of channels and chambers inside an elastomer. These channels inflate when pressurized, creating motion. The nature of this motion is controlled by modifying the geometry of the embedded chambers and the material properties of their walls. When a PneuNets actuator is pressurized, expansion occurs in the most compliant (least stiff) regions.

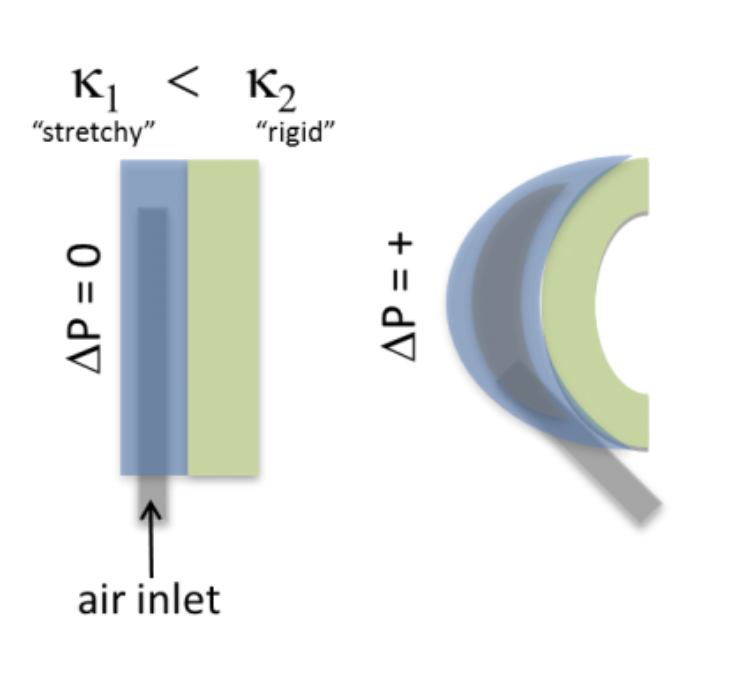

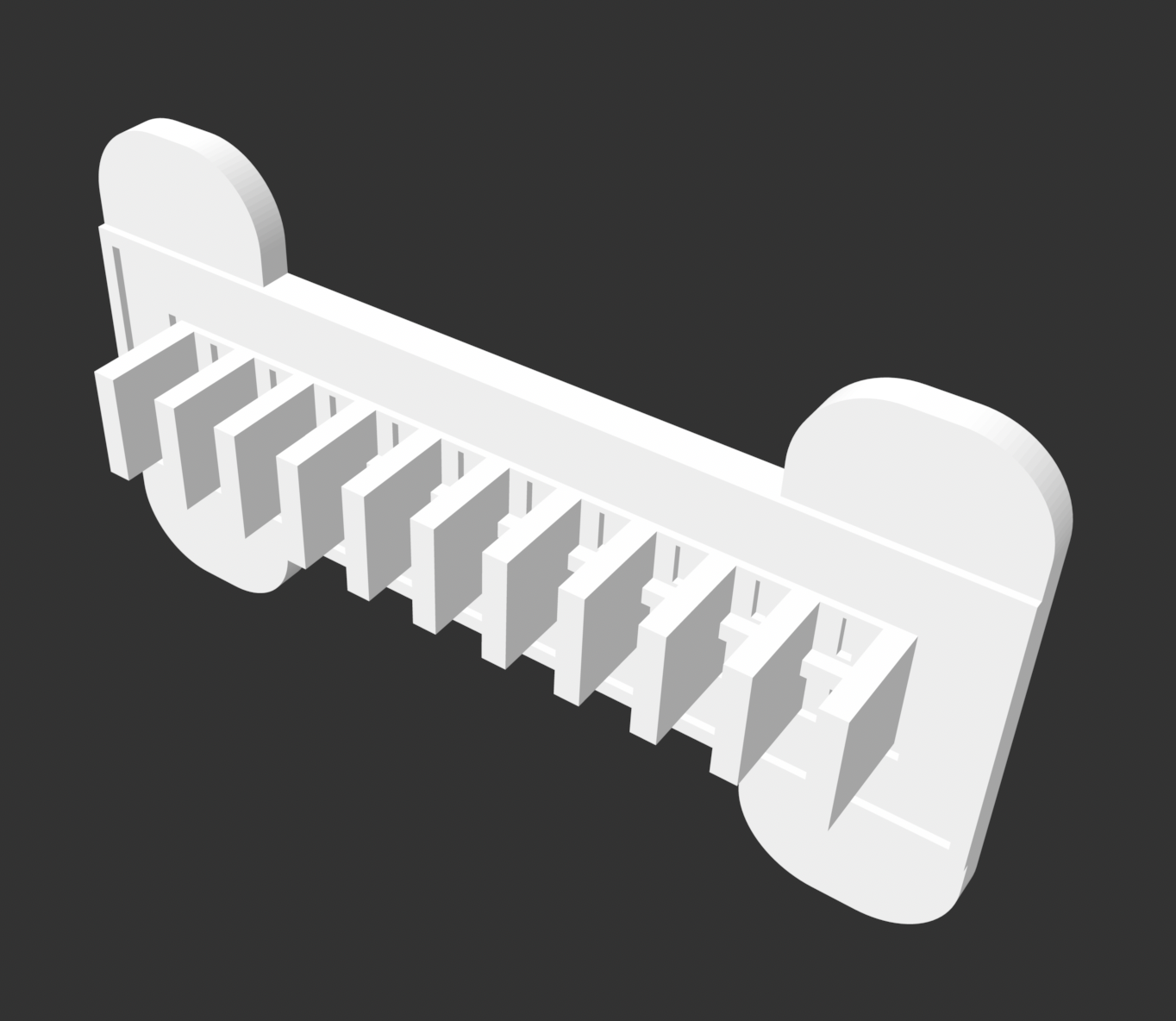

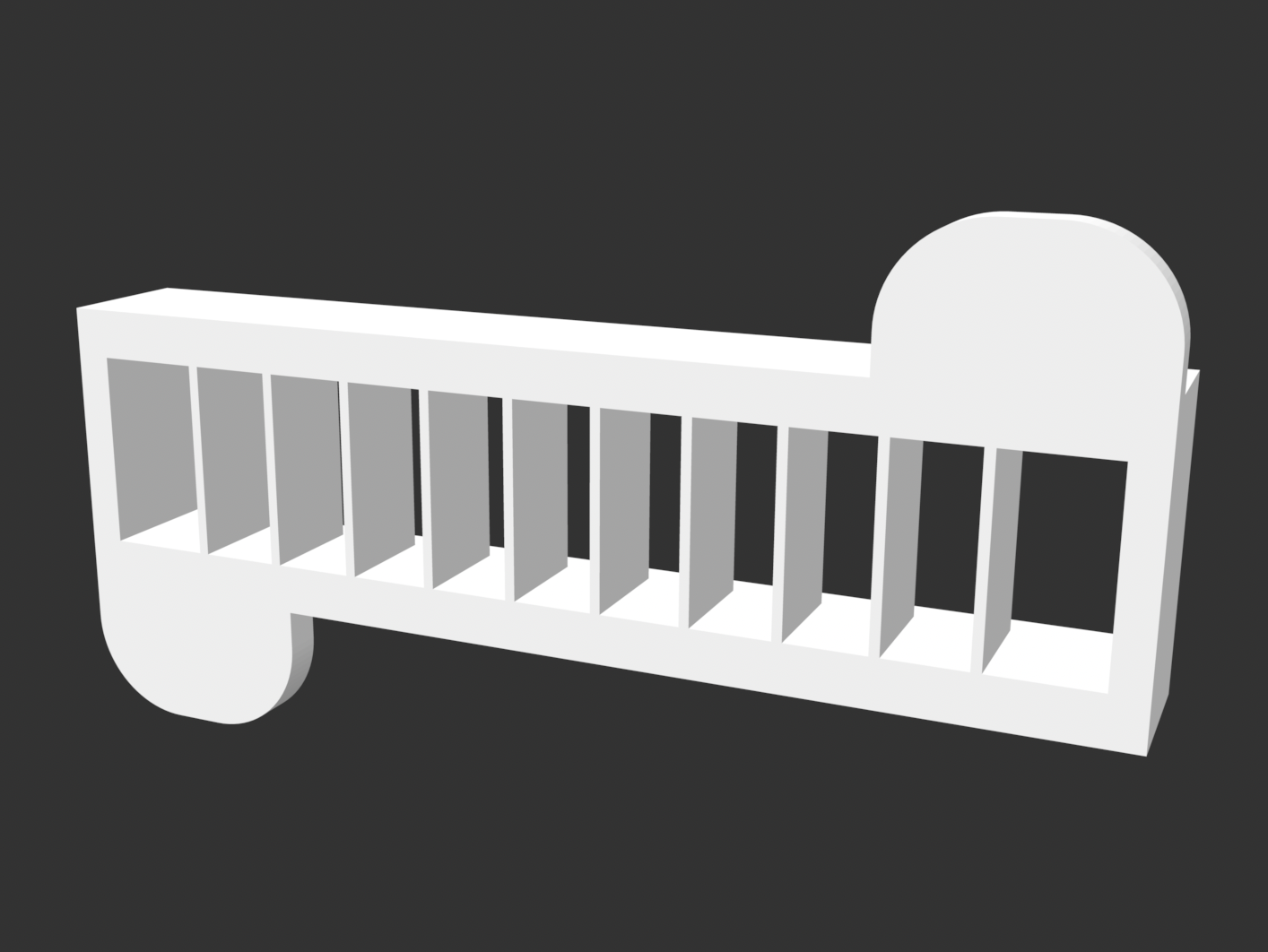

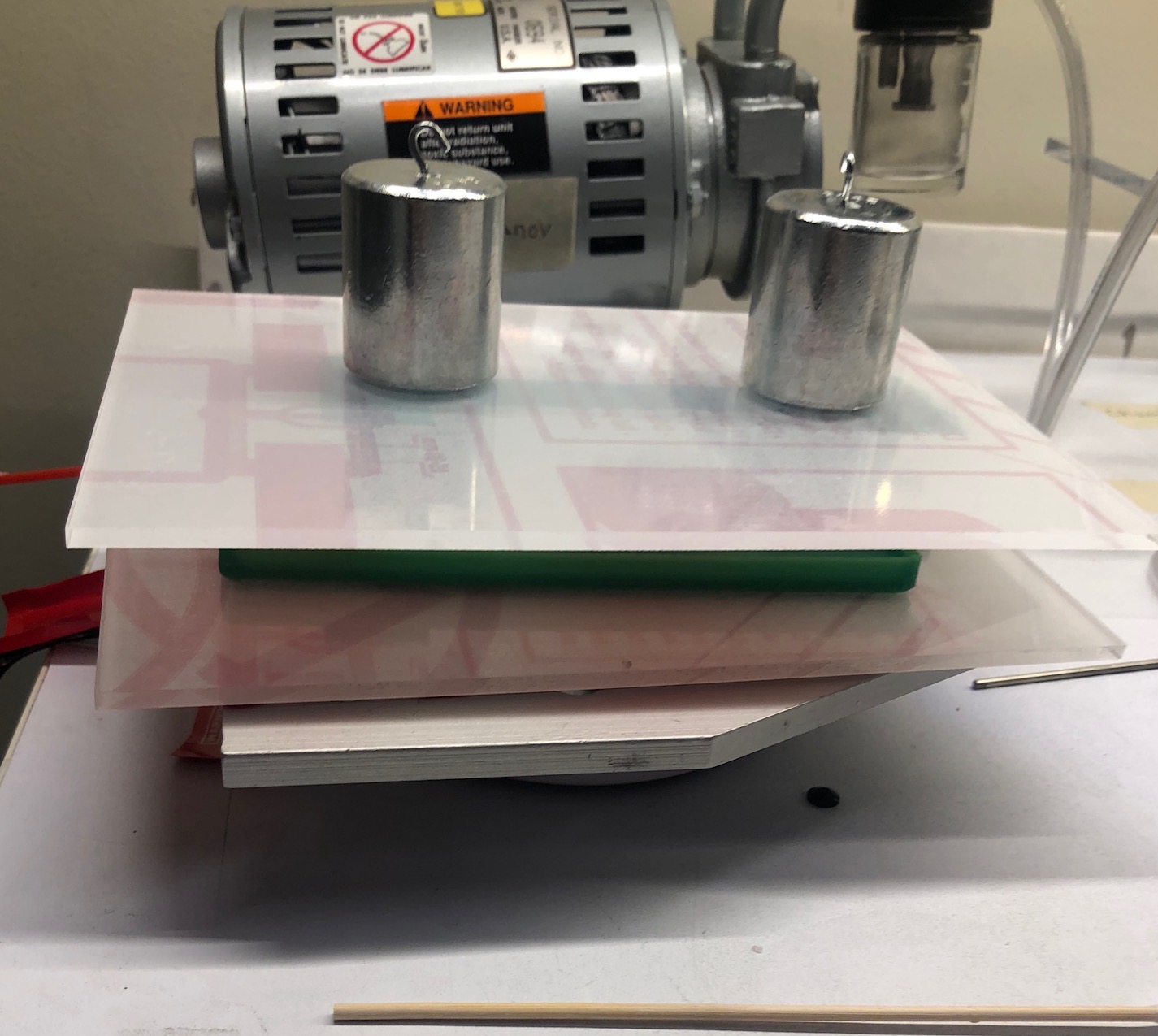

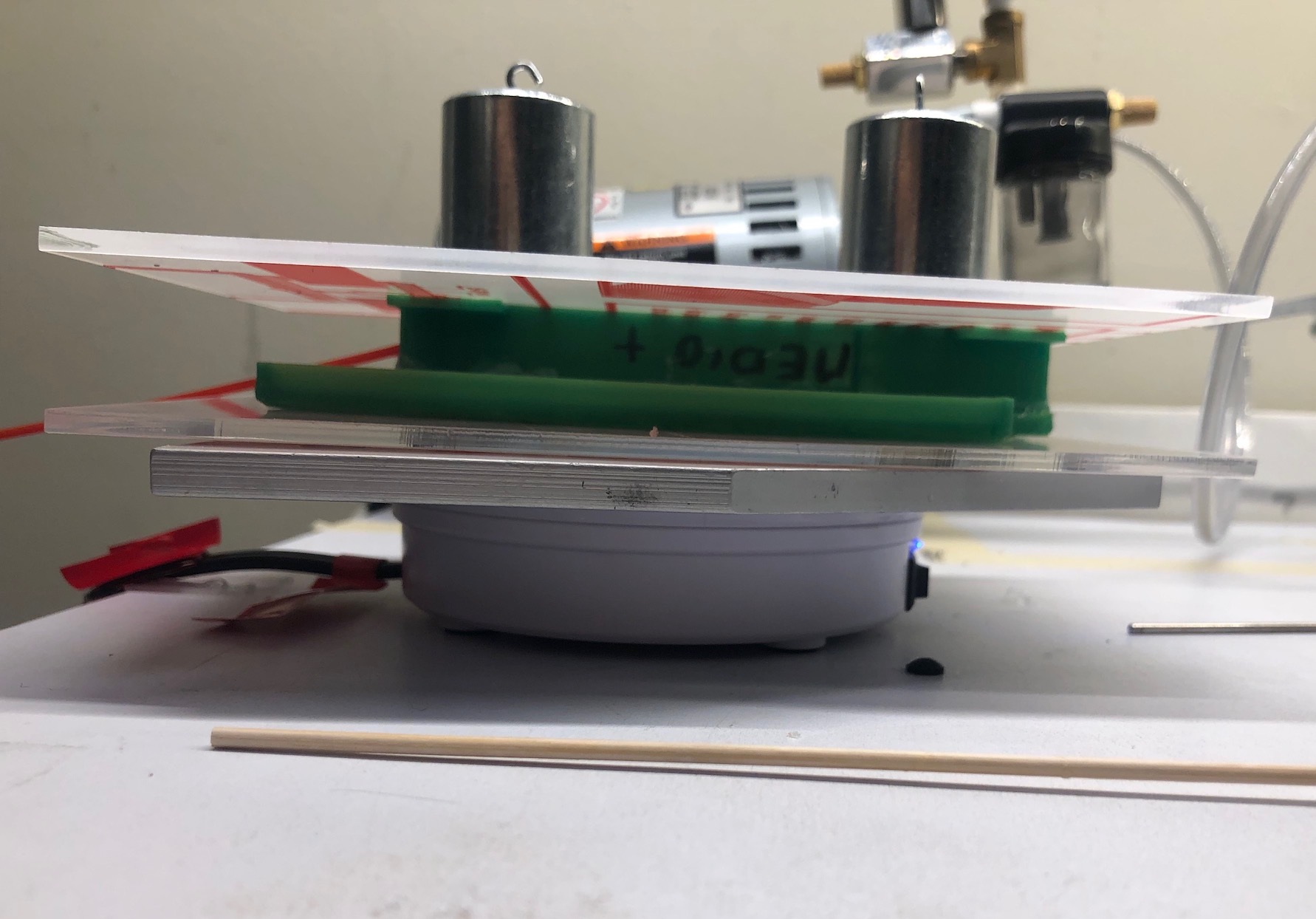

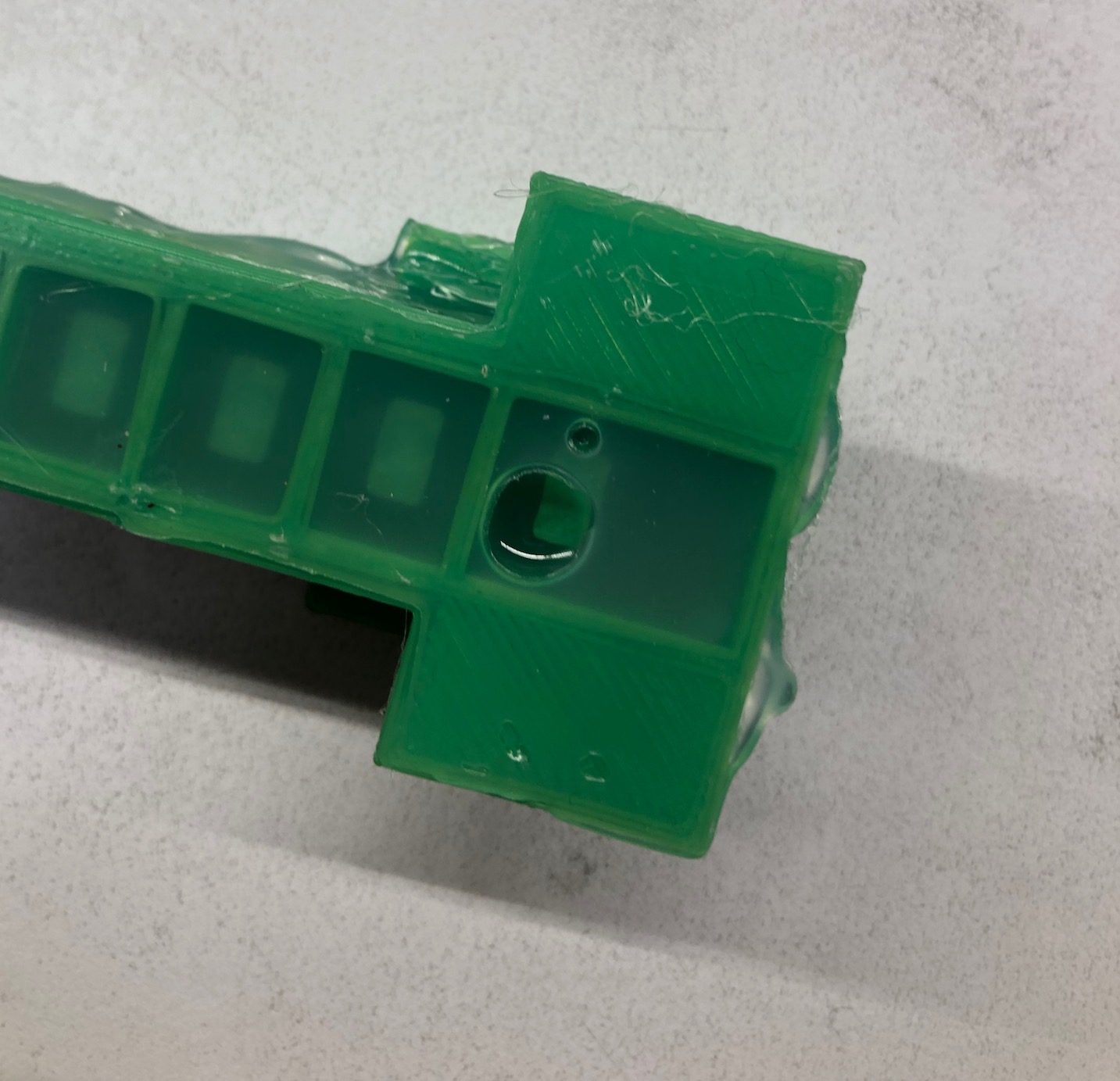

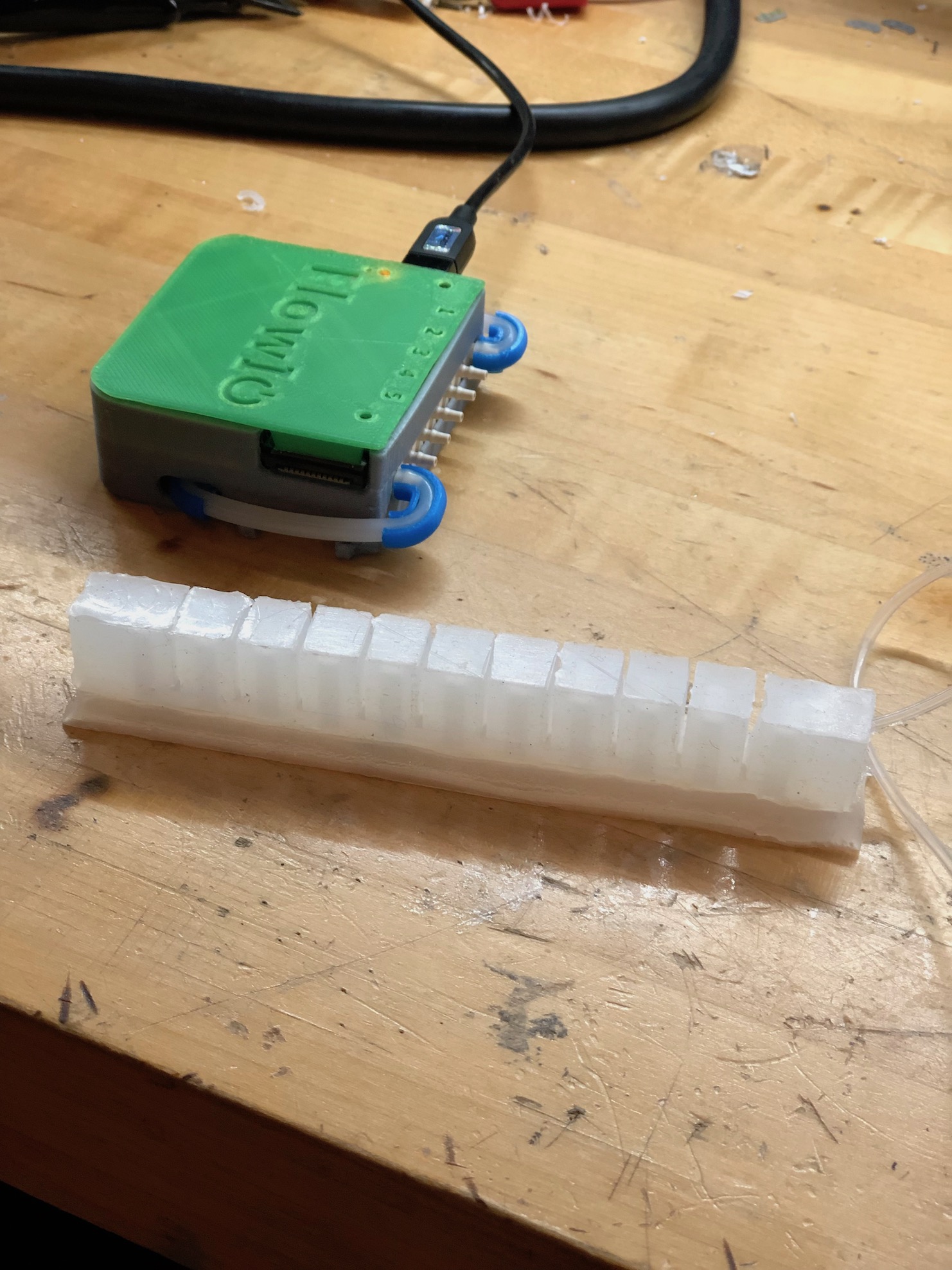

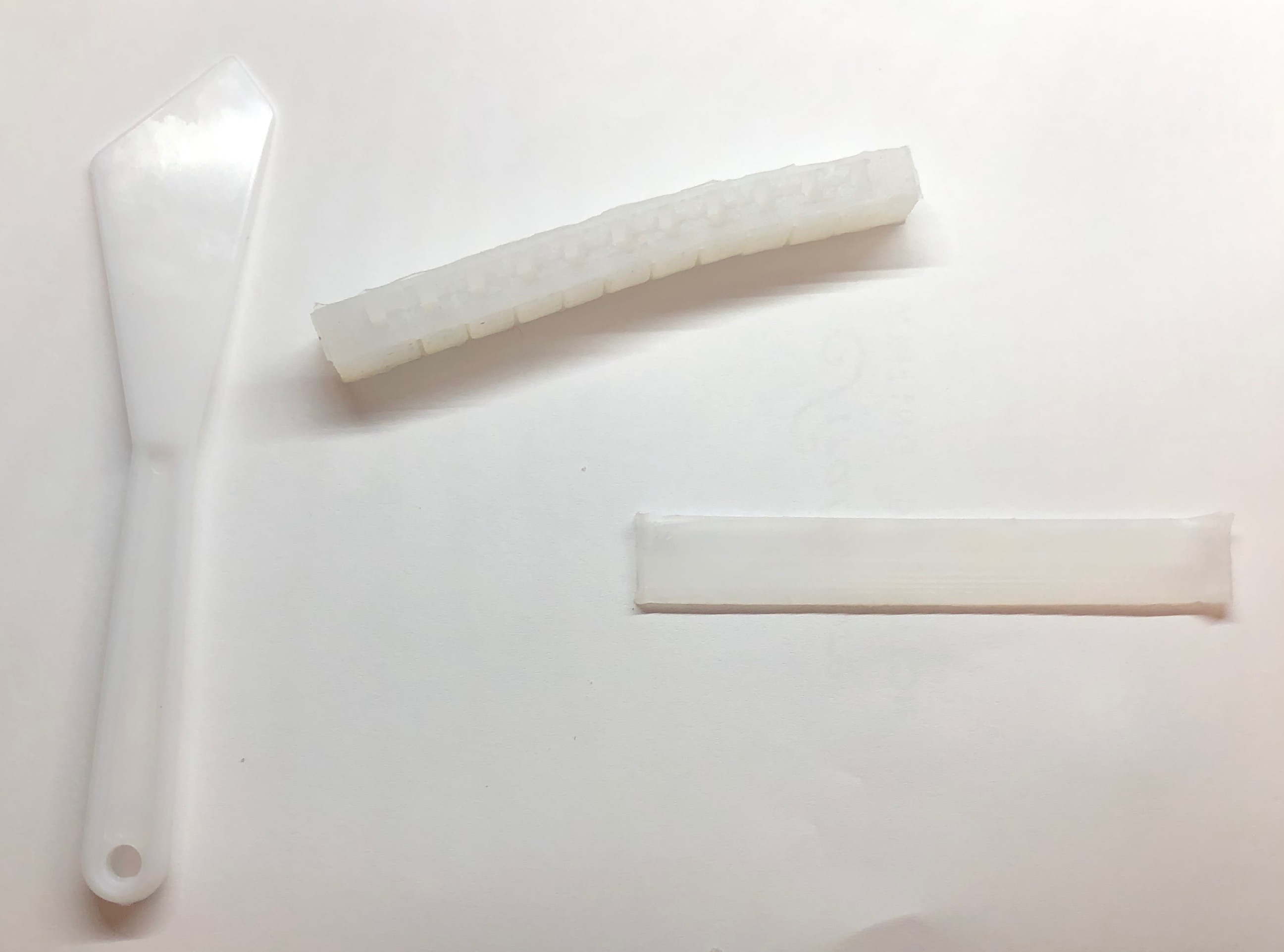

In order to make the bending motion instead of having the silicone just expand, the PneuNets actuator contains layers of materials with different elastic behavior (as shown in the image to the right), the "stretchy" material will expand more than the "rigid" material when the actuator is pressurized. In this type of configuration, we call the more rigid material the "strain limiting layer", as it restricts the amount of strain that can occur. The "differential strain" effect can be used to achieve useful motions such as bending and twisting.

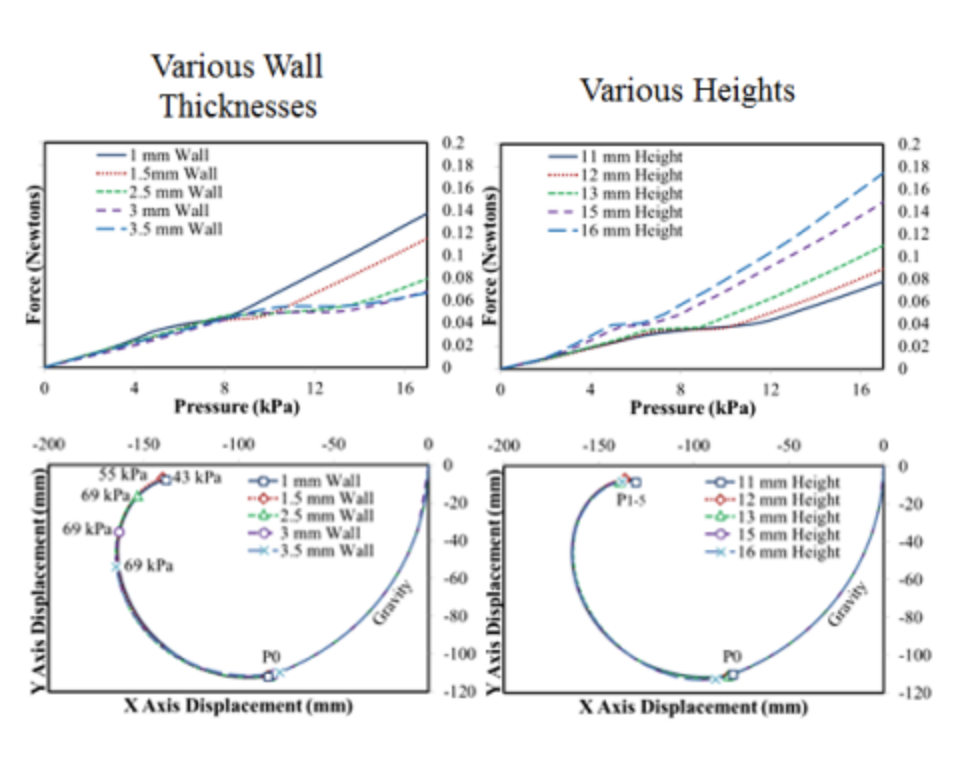

Even without changing the material, the actuator's behavior can be modified by adjusting its shape (morphology). For example, simply making a wall thicker will make it stiffer than a thin wall of the same material. Thinner walls lead to an increased force output, and require less pressure for the actuator to reach maximum bending. Increased chamber height increases force output, but doesn’t seem to affect the trajectory of the actuator tip.

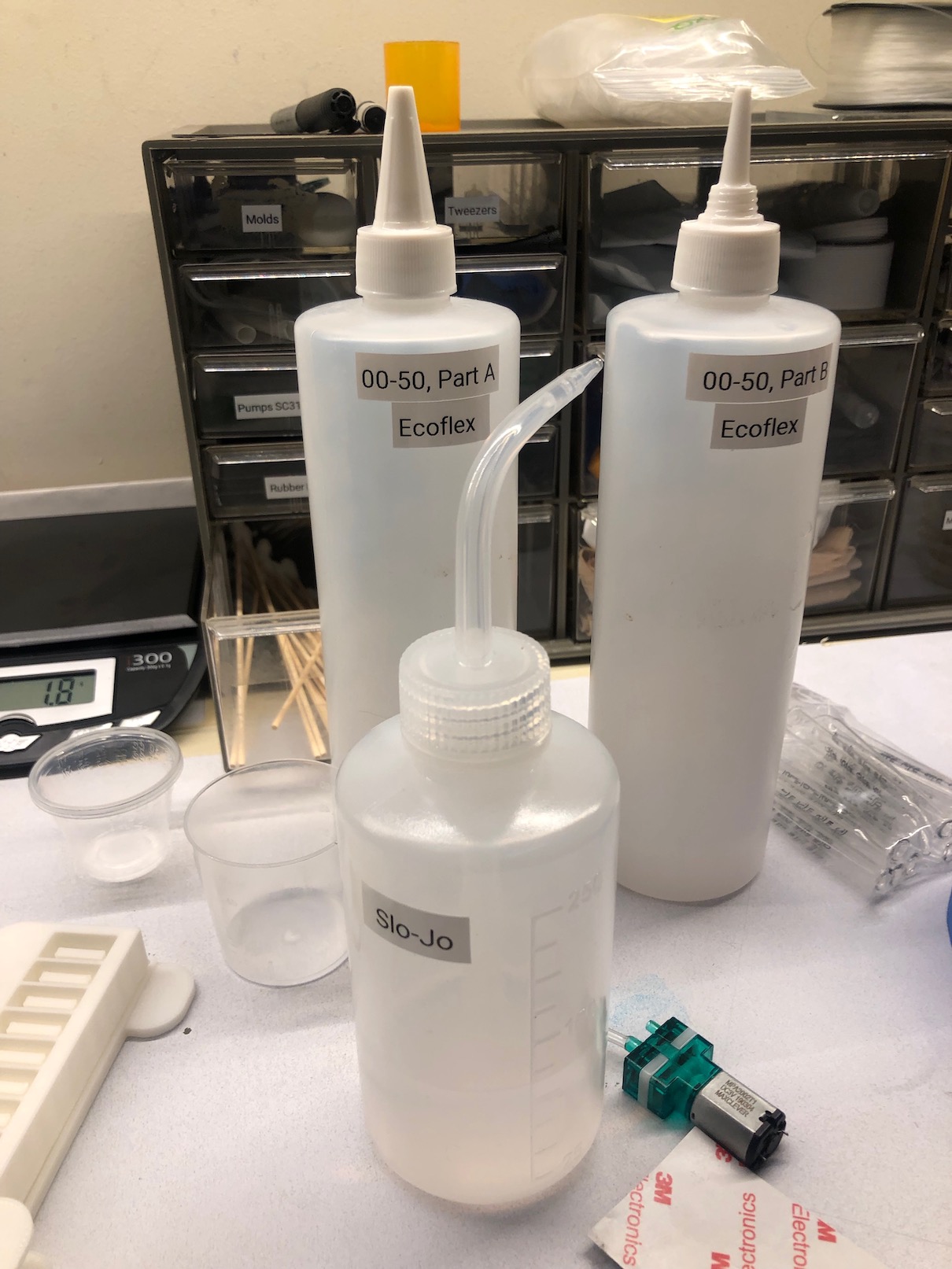

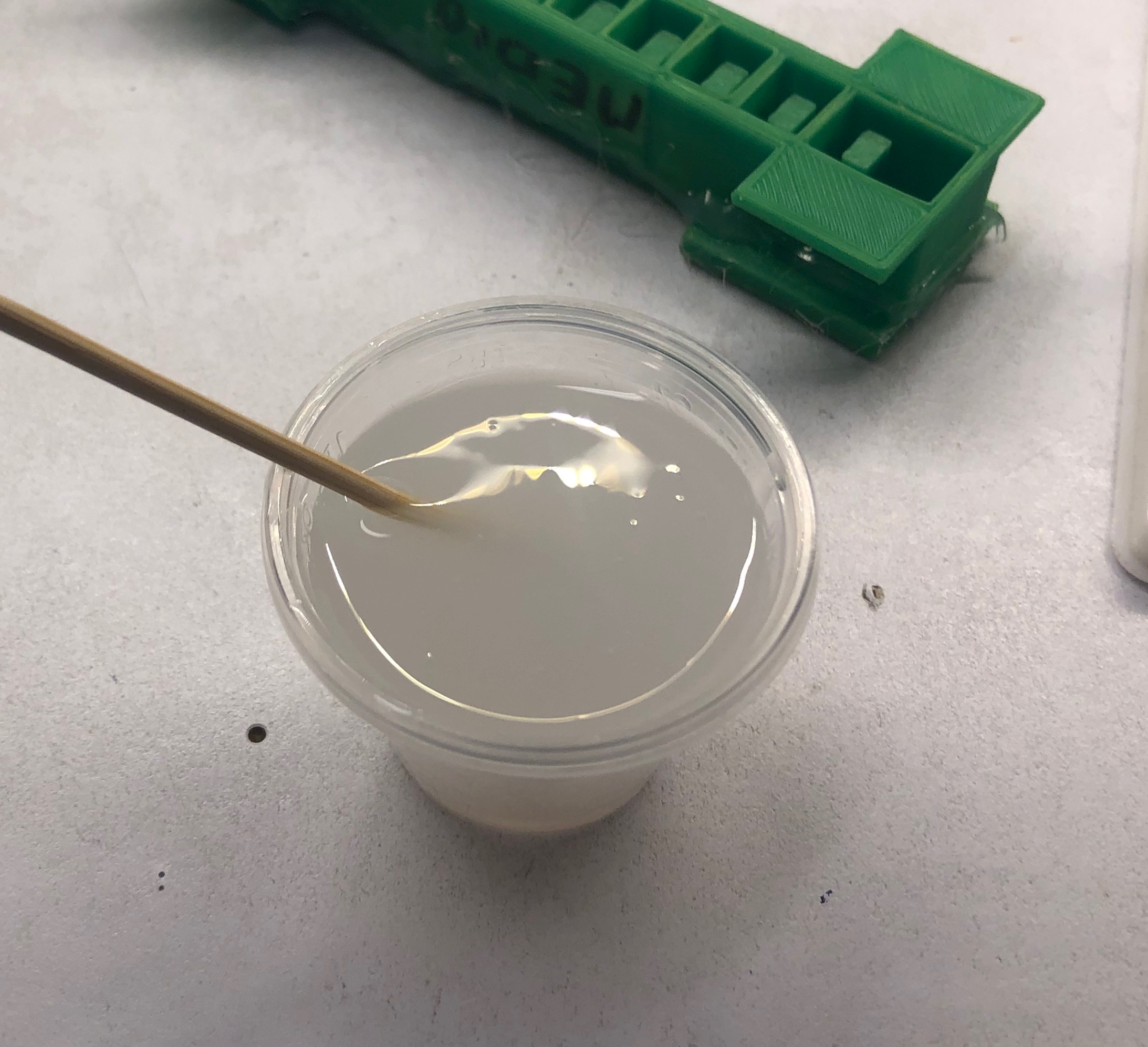

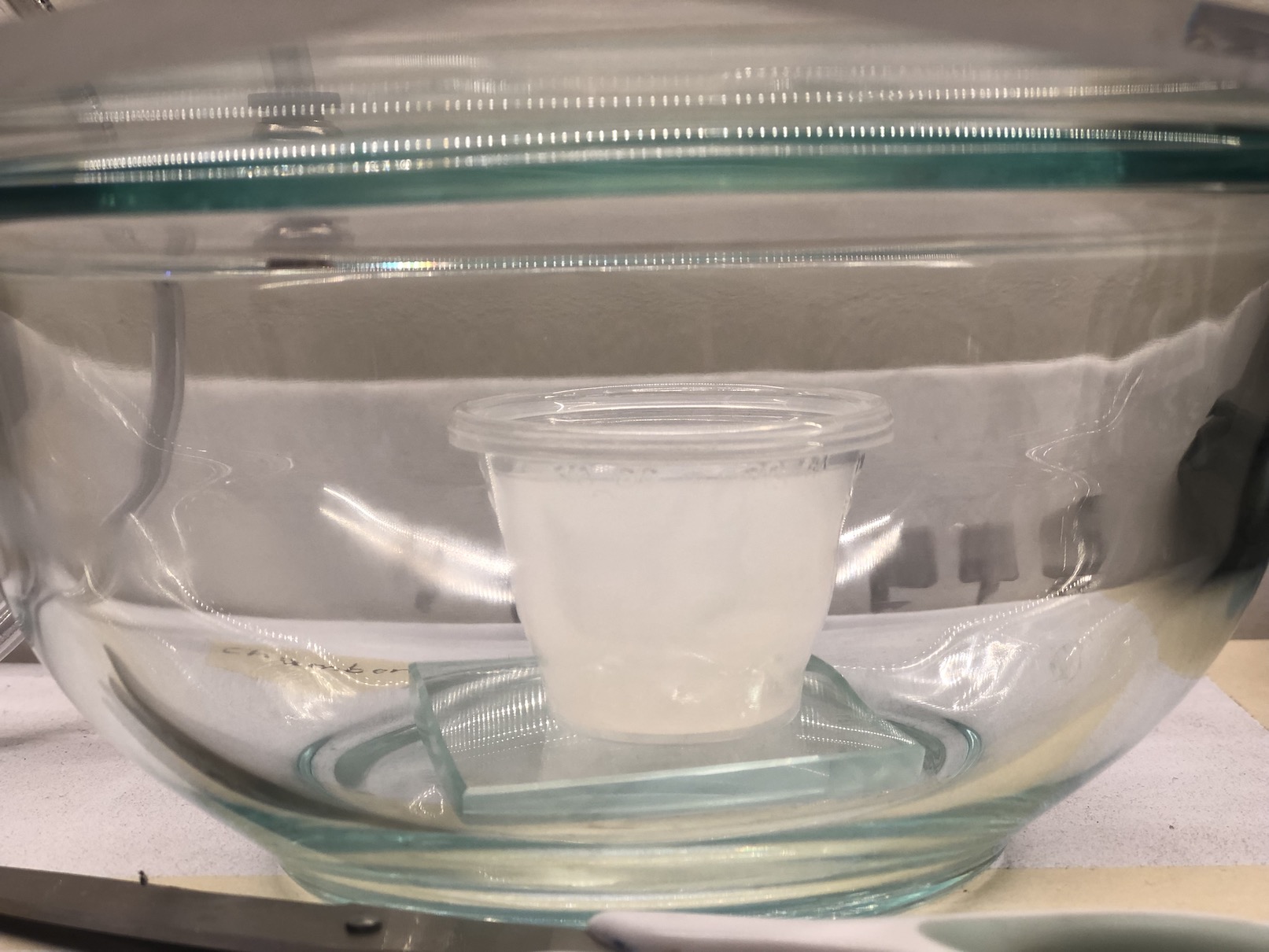

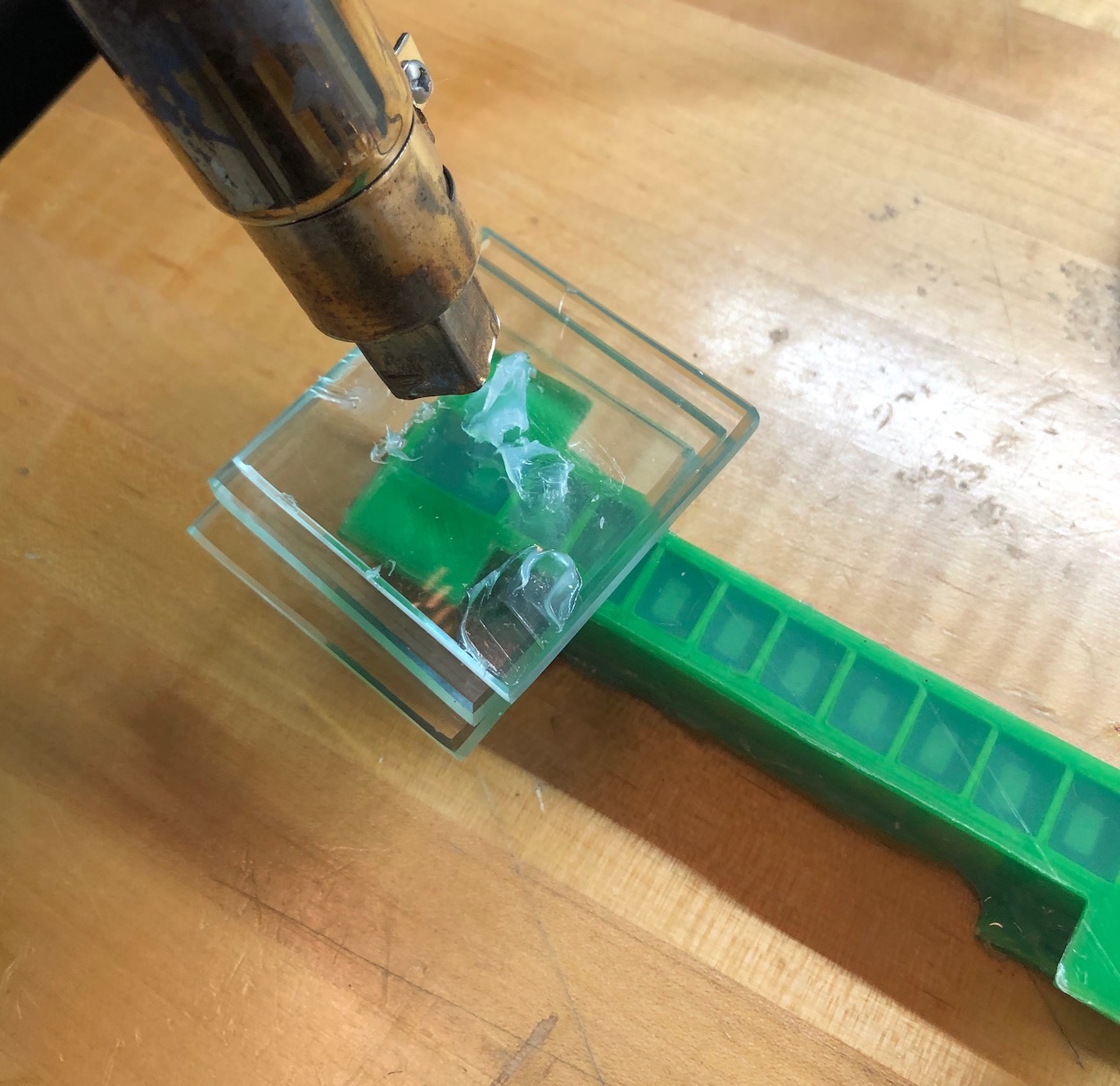

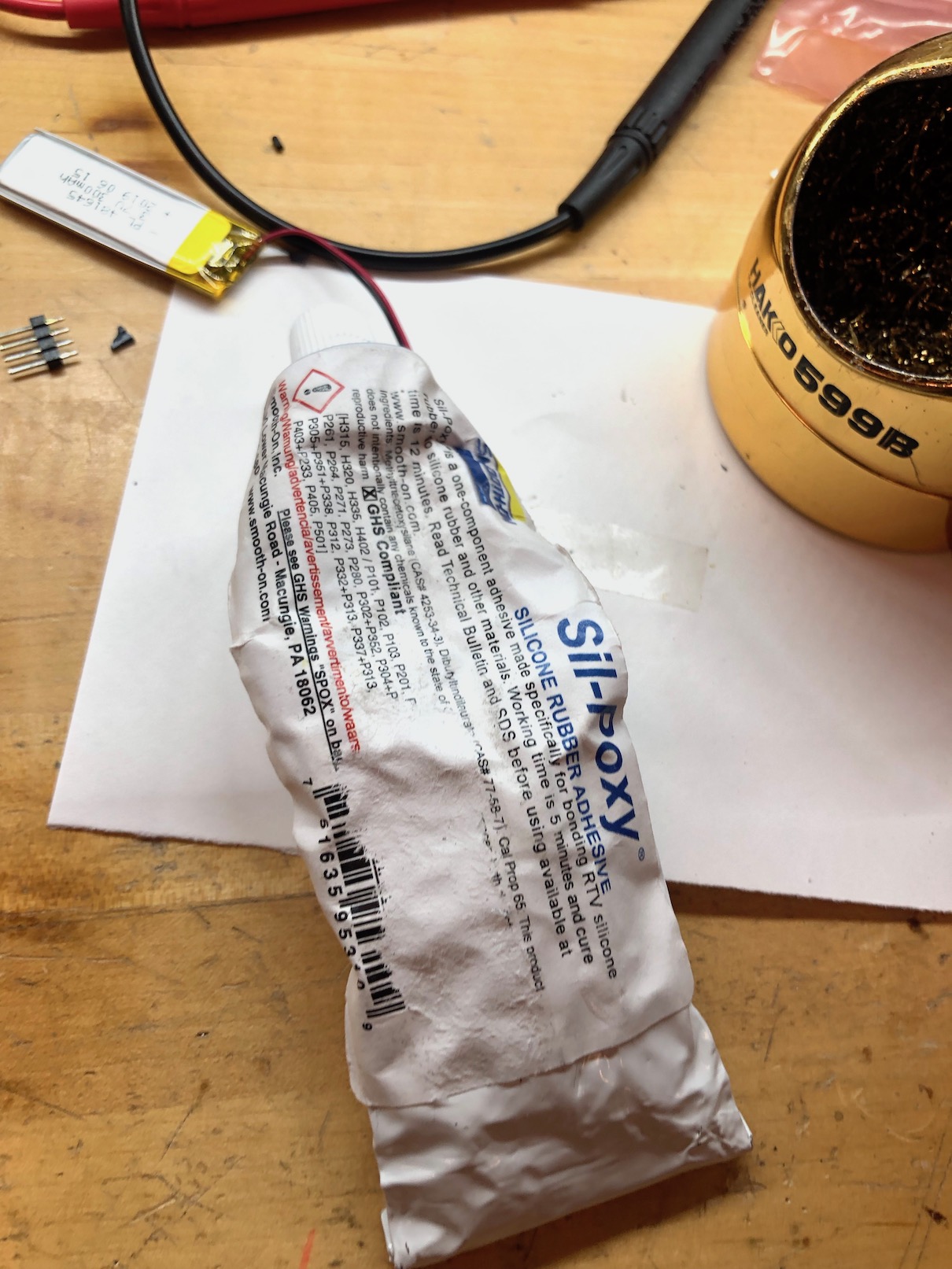

Used Sil-Poxy