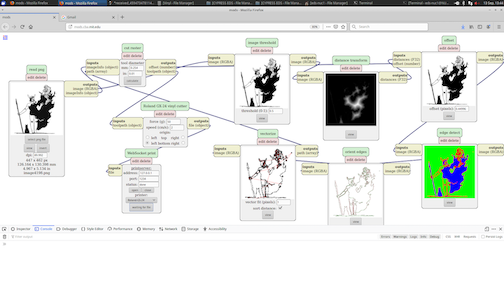

Week 2: Computer-Controlled Cutting

Vinyl Cutting

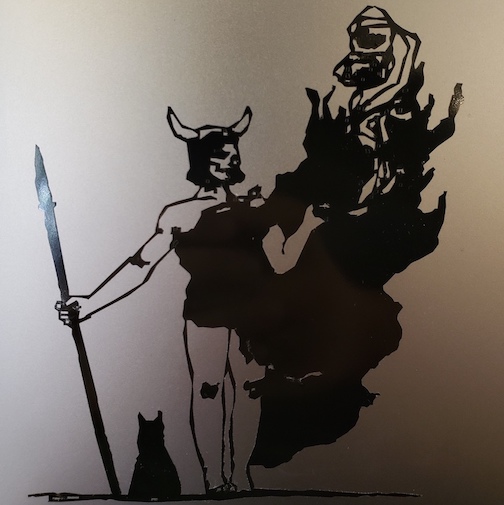

I wanted to cut a new laptop sticker. I got the design from my friend Miana

... and I used mods to process the image to send to the vinyl cutter.

To make it easier to transfer the isolated and finer parts of the vinyl (knee, face details, smoke lines), I first weeded the vinyl and then used the transfer tape to move the sticker to my laptop. The sticker looks like this:

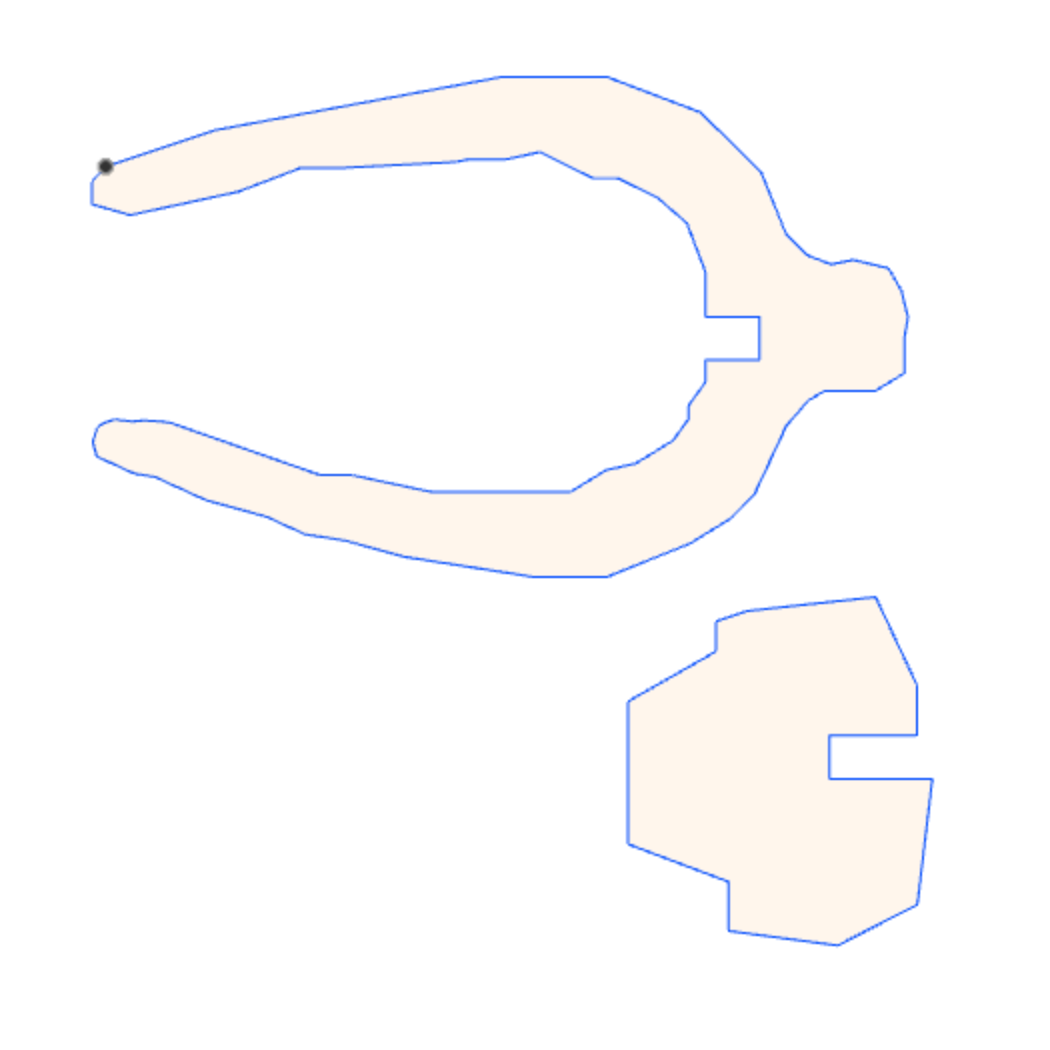

Laser Cutting

For the group project, we were asked to characterize the laser cutter's focus, speed, rate, kerf, and join clearance. We used ± 0.2004 for depth of focus, 2.0" for focal length, and found the kerf to be 0.005". We chose to use the predetermined Balsa wood settings but changed the speed from 16% to 13% to ensure that we could cut through cardboard. I was inspired by wooden T-Rex Dinosaur puzzles while designing my parametric construction kit. I used this and Fusion360 to design the bones of my dinosaur. I constrained all the joints to be equal so that I could easily modify the width of my cut-outs. This was useful because the first few pieces I cut were too loose and I needed to recut the pieces with a smaller width at the joints to ensure a better fit.

I will update when I get a chance to attach arms. Another small improvement I would like to make is to cut slits in tail so that the tail becomes bendy. A larger-scale improvement I would like to think about is the balance of the entire skeleton. It balances precariously right now so I could work on the design to spread out the balance more evenly across the front and the back.