Paper Folding Machine

Introduction

What if there is a machine that automatically folds paper on my behalf?

I like to fold paper to make things. Paper itself is one of the most accessible, and relatively cheap to play with. Moreover, it can be formed into both a rigid structure and flexible buffer depending on how we fold it.

Even though folding paper is a fascinating method for making design objects, it is painful to do it all by hand. As the paper gets thicker and as the number of creases increase, folding takes a considerable amount of time and effort to create the initially intended shape.

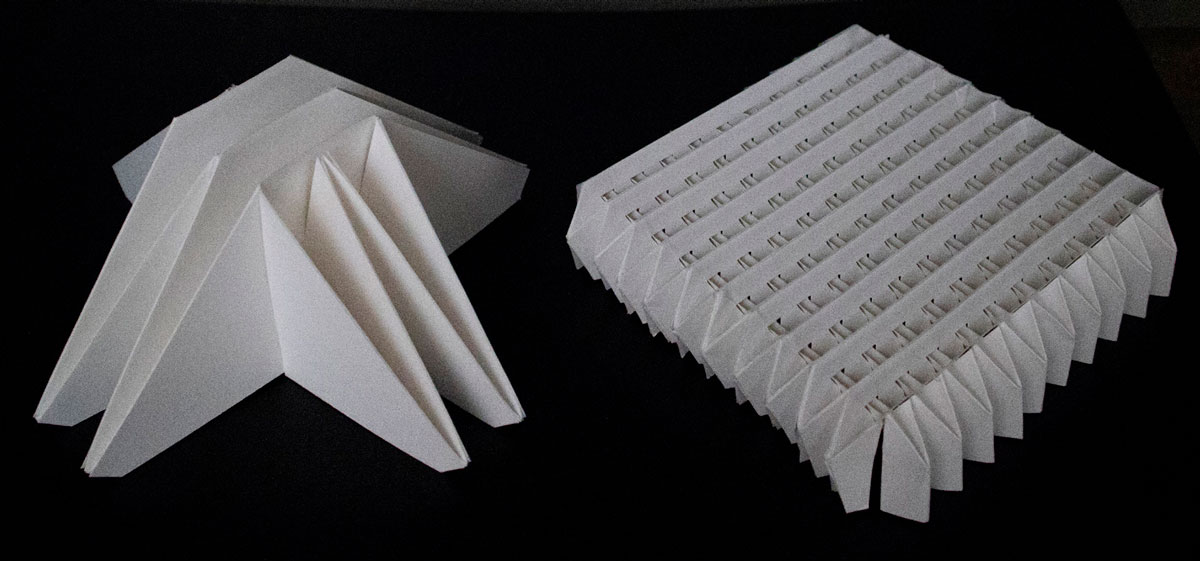

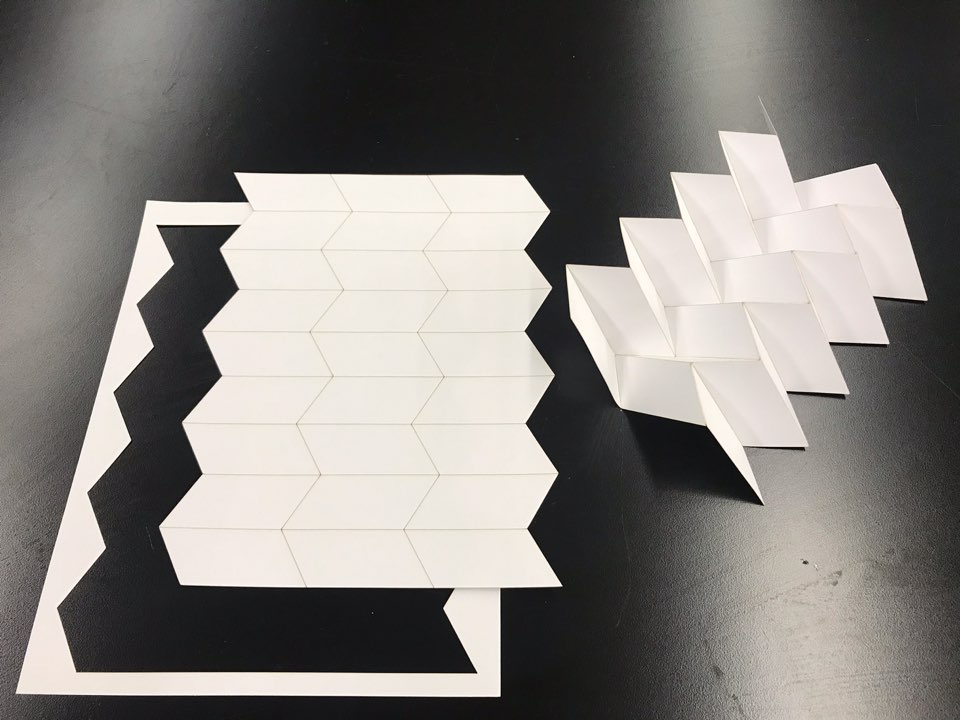

1: Folding chair design - Joonhaeng Lee + Sohyun Chin

2: Diversity of folded paper, typical A4 size office paper used

Objectives

For my final project, I would like to build the whole process of design, fabrication, and assembly. Here are the detailed processes I wanted to make.

- Parametric paper folding webpage

- Folding Machine with Pins

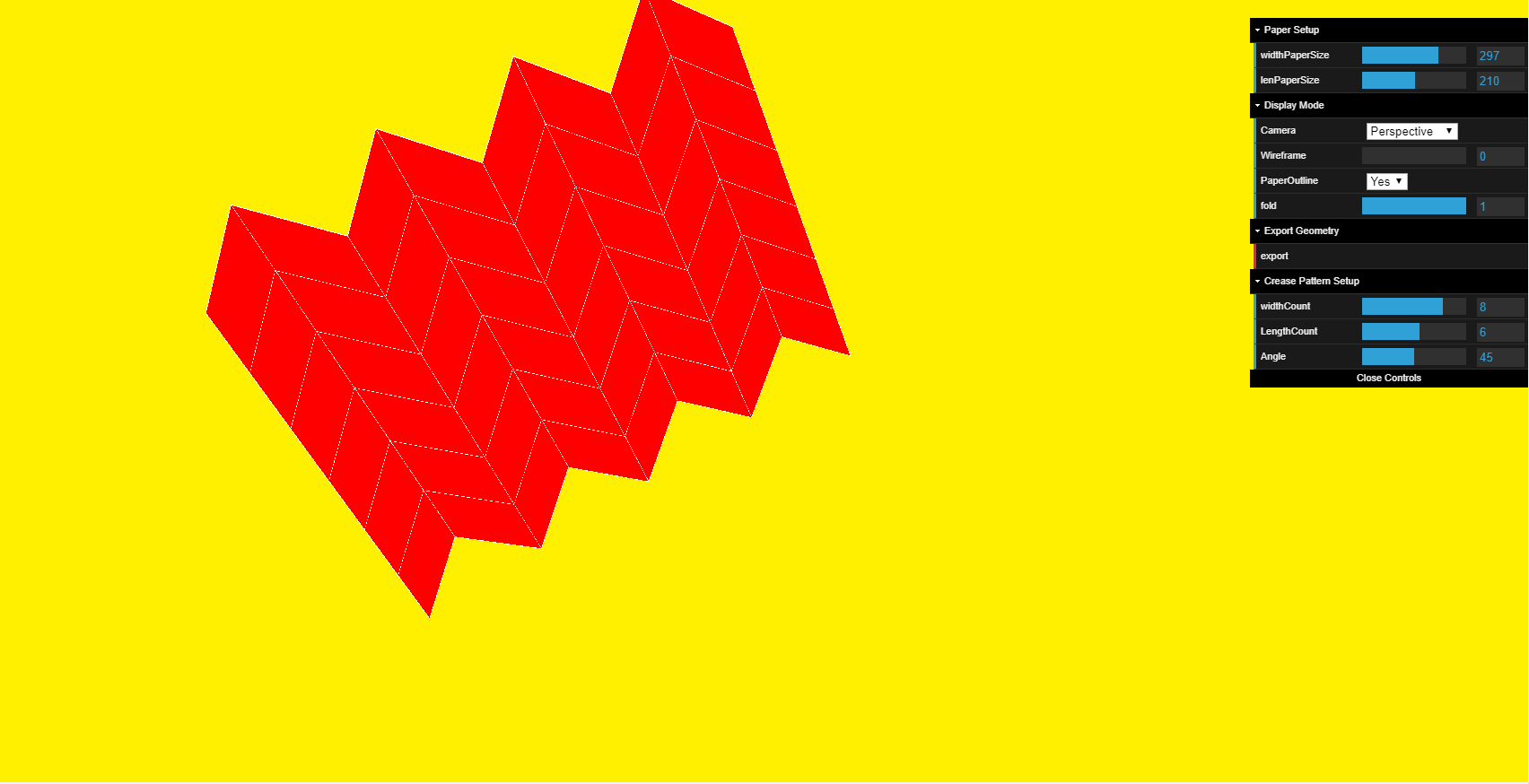

Generating paper crease pattern and simulating fold shapes based on user input value on my design formula. For this project, only focus on creating Herringbone pattern fold.

Input: user selected values

Output: paper crease patterns and laser cut-able drawing, assembly drawings.

Machine that can fold Letter size paper.

Fold paper based on data created from paper folding webpage.

Folding is a process that converts the volume of geometry. During the procedure, paper increases boundary volume by increasing height. As Width and length of paper gradually shrink as height rise. Thus, if the folding machine pushes the outer boundary in precalculated speeds, it can fold the paper. Meanwhile, depending on its crease pattern, some areas will sink down become valleys and other areas will rise to be mountains. In order to do that, we need a finger-like part, or pin, to guide the folding.

Project Development

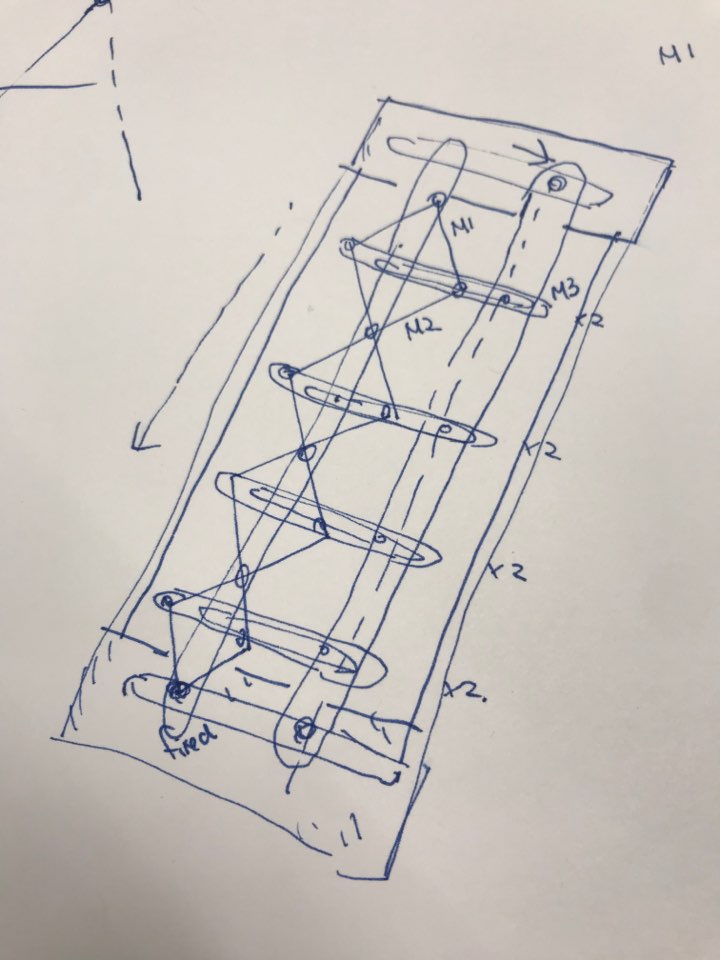

Idea Sketchs

Sketch1: Folding using pins

Sketch2: Machine that fold curved geometry

Machine Study Model - CNC Milling Week

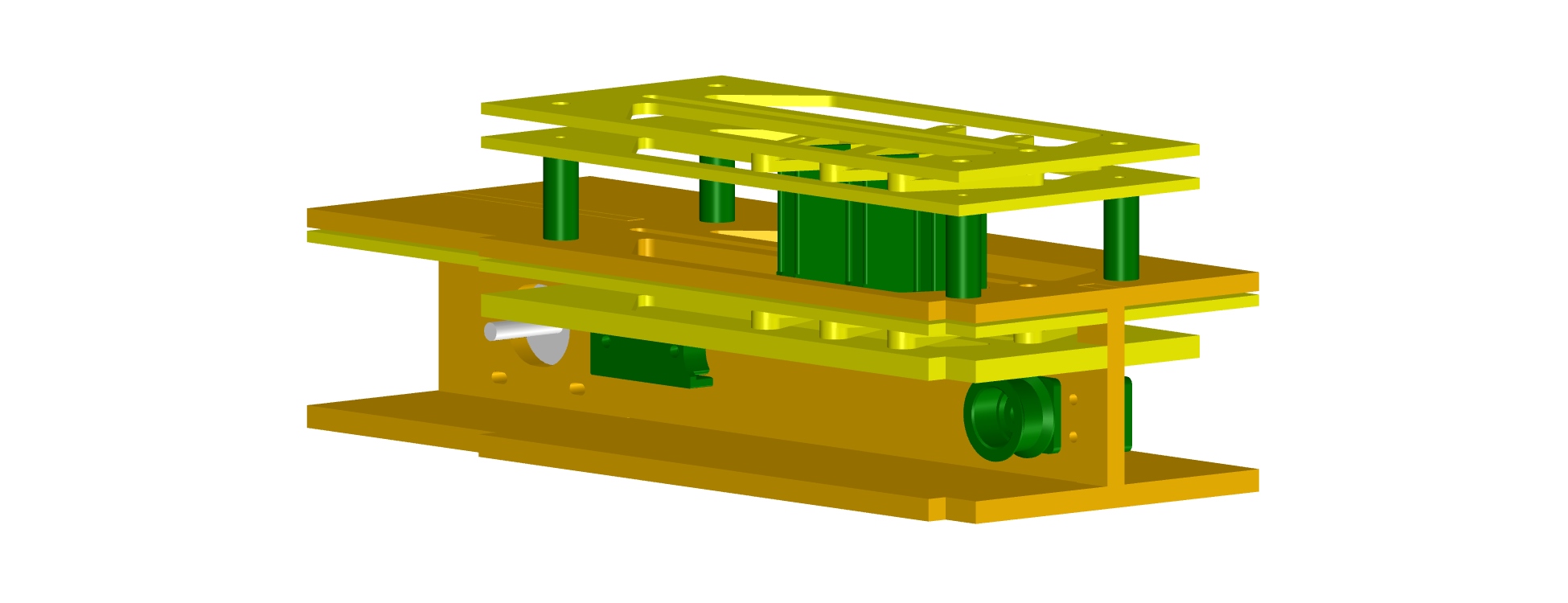

During the computer-controlled machining week, I made a study model for my folding machine. Mechanism of the folding machine is pressing paper gently into one side while guiding objects (pins) are leading paper to proper folding directions. Thus, as seen in the video, the device has three moving parts to fold a letter size paper; bottom pins top pins and compressing wall. Top and bottom pins are controlled by moving rails, and small rectangular nodes roughly indicate those pins in this model.

Press Pin Location Calculation - Input Device Week

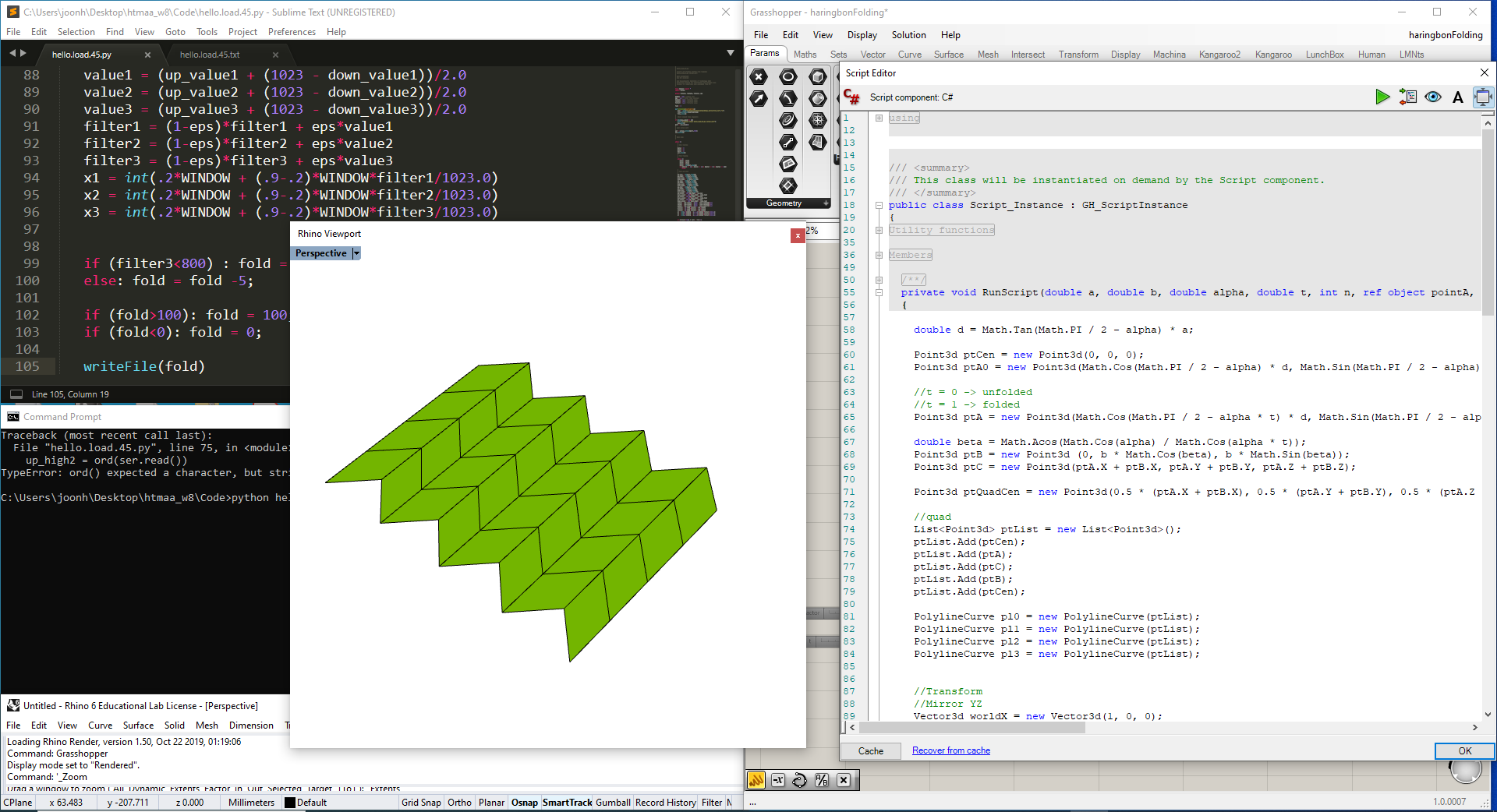

It is necessary to simulate folding and compute the XYZ coordinate of creases of paper to control the location of the guide pins. Using the trigonometric method, I calculated geometrical folding simulation of herringbone pattern folding. The code used for making this simulation will soon be implemented on a webpage.

Haringbon Pattern/ Top and bottom move XY direction/ Paper and Pins

Final Project Review from Rob - 11/1/2019

- Linkages

- Use existing machine machenism

- Make something small first

If linear pins' location deviation fixed, try to use linkages.

How it really moves? how many step moters or other device I should use? Try to adopt existing machines such as 3D printer's machenism.

Control one row before making multiple rows.

Linkage Studies and Folding

After Rob's review I started to study and develop linkage idea to fold a papaer. Interestingly, I found that it was possible to trace paper foling movment using scissor linkages. Initially I start with single layer of scissor linkage and devloped into dobule layer linkages. Also I made parametric design script of linkages and paper using Grasshopper.

Folding Pattern Generator - Interface Design Week

I already made a scirpt that folds a paper in Grasshopper, but, it is not easily accessable to general users, since it is built in Grasshopper. During the interface design week, I translate my code into webpage using Three.js. Amira help me out a lot to trobuleshout the coding problem. The script allow users to export stp file export. I will develop this code further to make svg export function. using the geometry, it is possible to extract boundary lines in other softwares such as Autocad and Rhino.

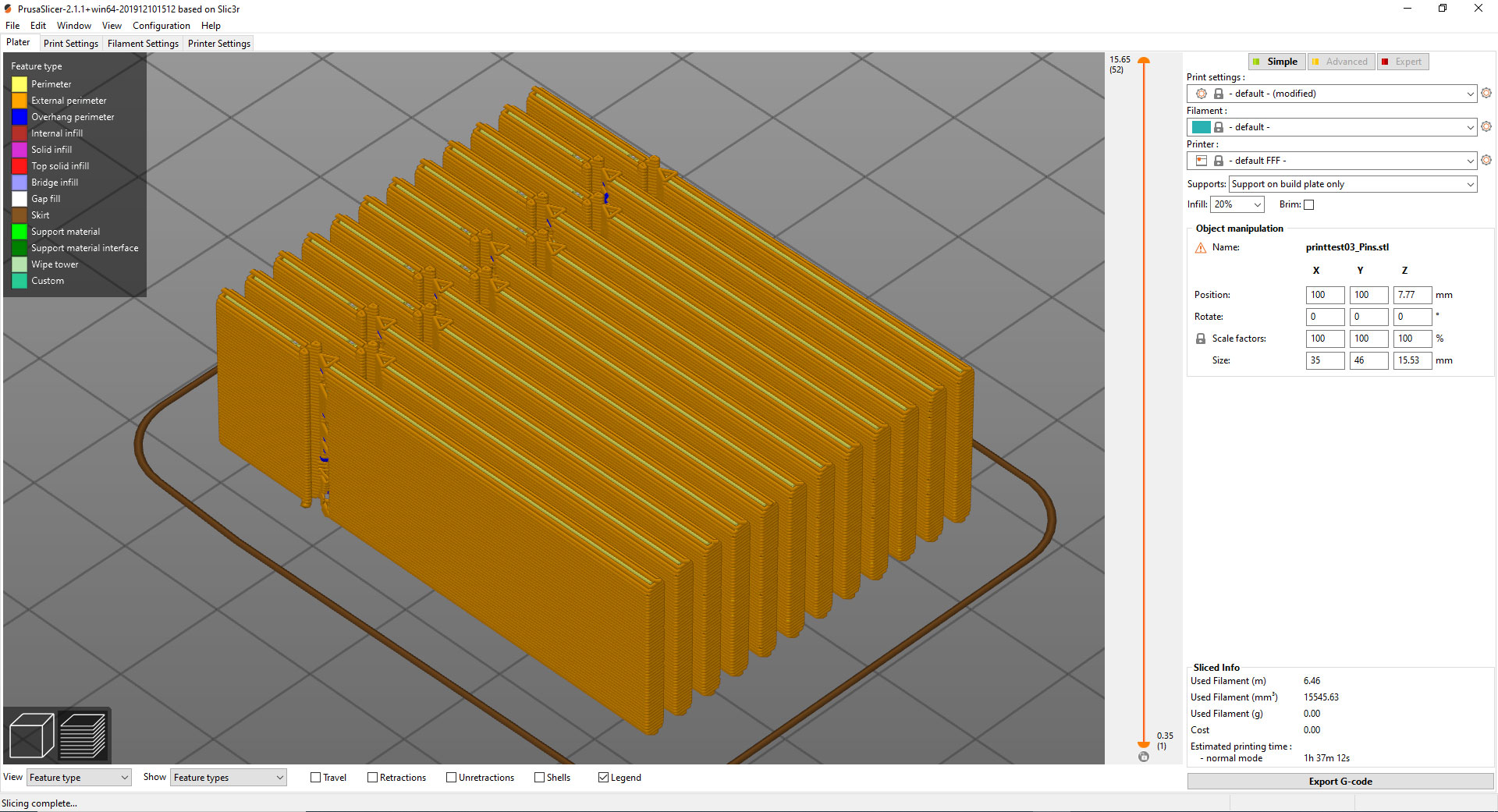

3D Modeling

Using parametric design method in Grasshopper, I create linkages and machien frame 3D model for fabrication. For main moter axis, I used the Jake's Axis model as a reference. Yellow indicates 3mm laser-cut acrylic, gold for 6mm acrylic, and green for 3D print pieces.

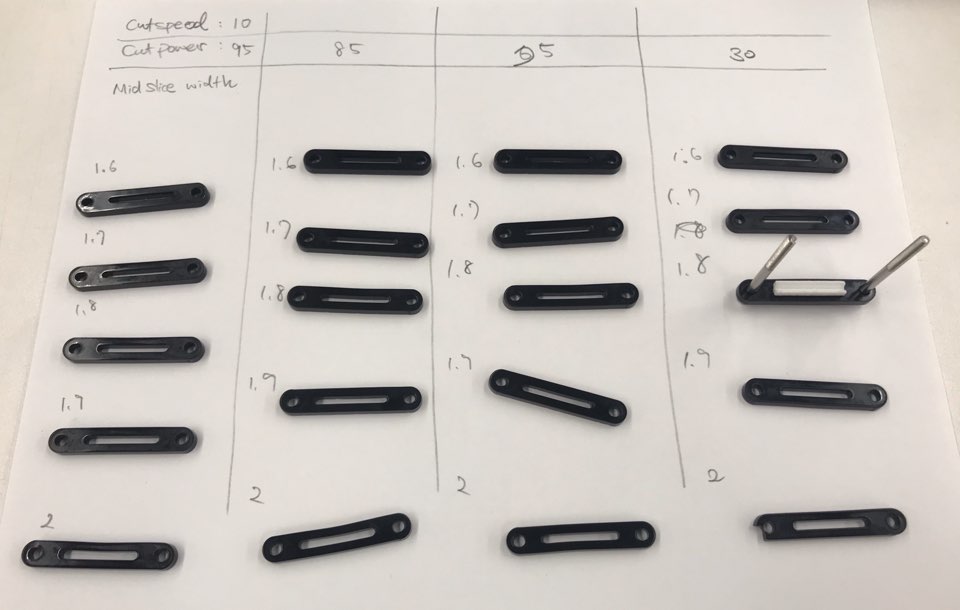

Laser cut linkage and 3D printed pins size charactorizing

The linkages that I designed have slots which are fit with 3D printed pieces. Since both laser-cut and 3D print have discrepancies in size, first I varied size of slots in linkages. I varied speed/power of laser cutter and the slot size by 0.1mm to find a sweet spot.

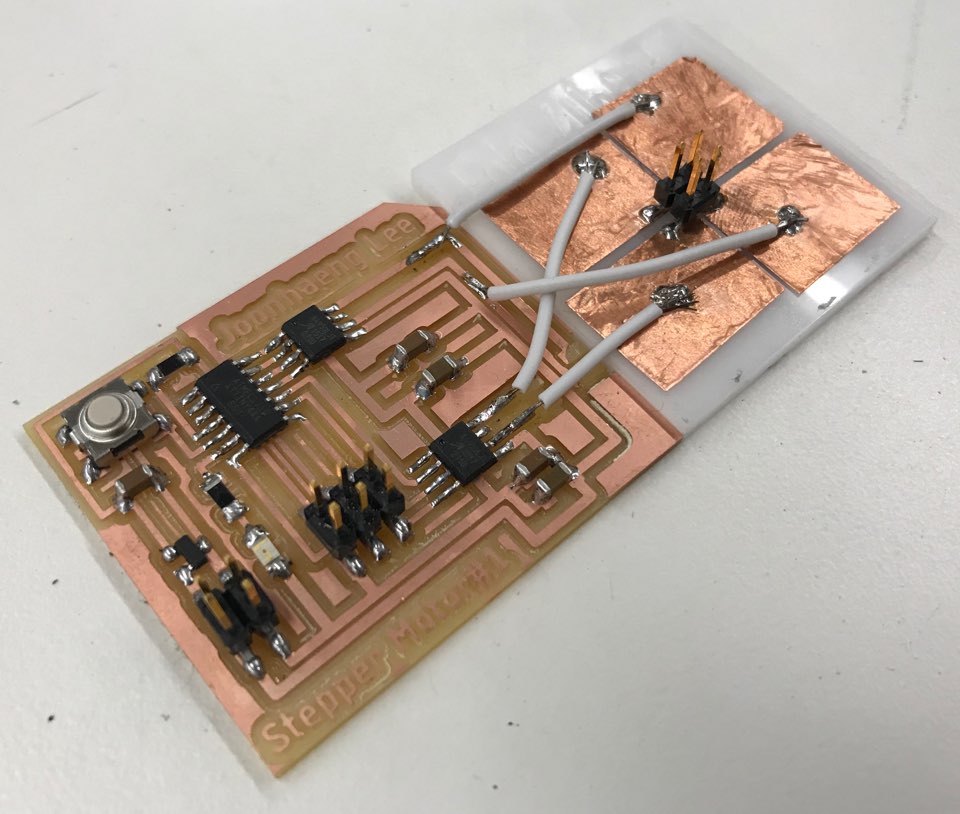

Electronics

A day before the final, I accidently broke my stepper moter board that I made in output week. I did first aid of the board and found that It was working. However, I would like to do better packaging all the stuff in may machine, I make a same board again.

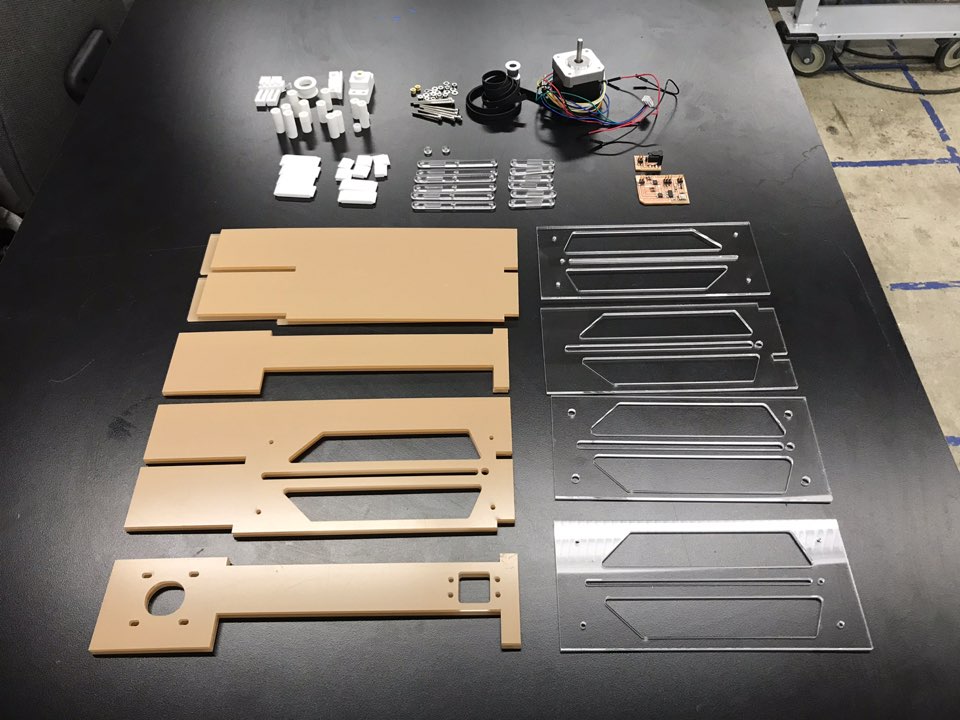

Assembly

All pieces are ready to be assembled together.

This was my How to Make (Almost) Anything

I will keep continue to develop Paper Folding Machine. Thanks!