I think it was a very gruelling experience.

The step after this was to flatten the bed so that I can start to mill a board just to get comfortable with milling boards. To do this, there’s a bunch of steps to take:

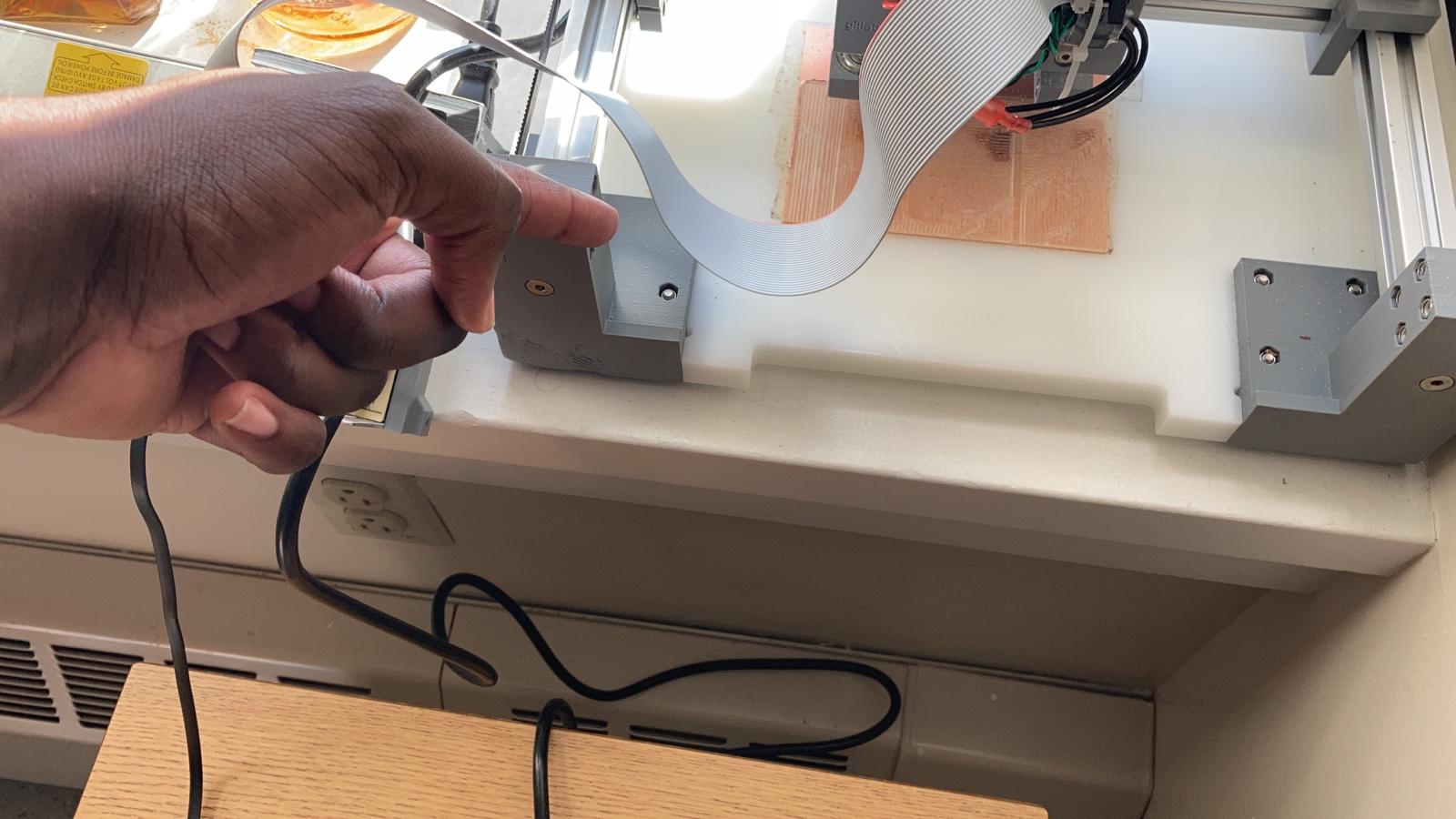

Going on to the Fab academy website and playing around with the keys and functions showed me that there’s zeroing of the mill. The x, y, z keys help to position the end mill. When i was trying to do this, to position and start milling to flatten the bed, i realized my z keys - up and down were not working.

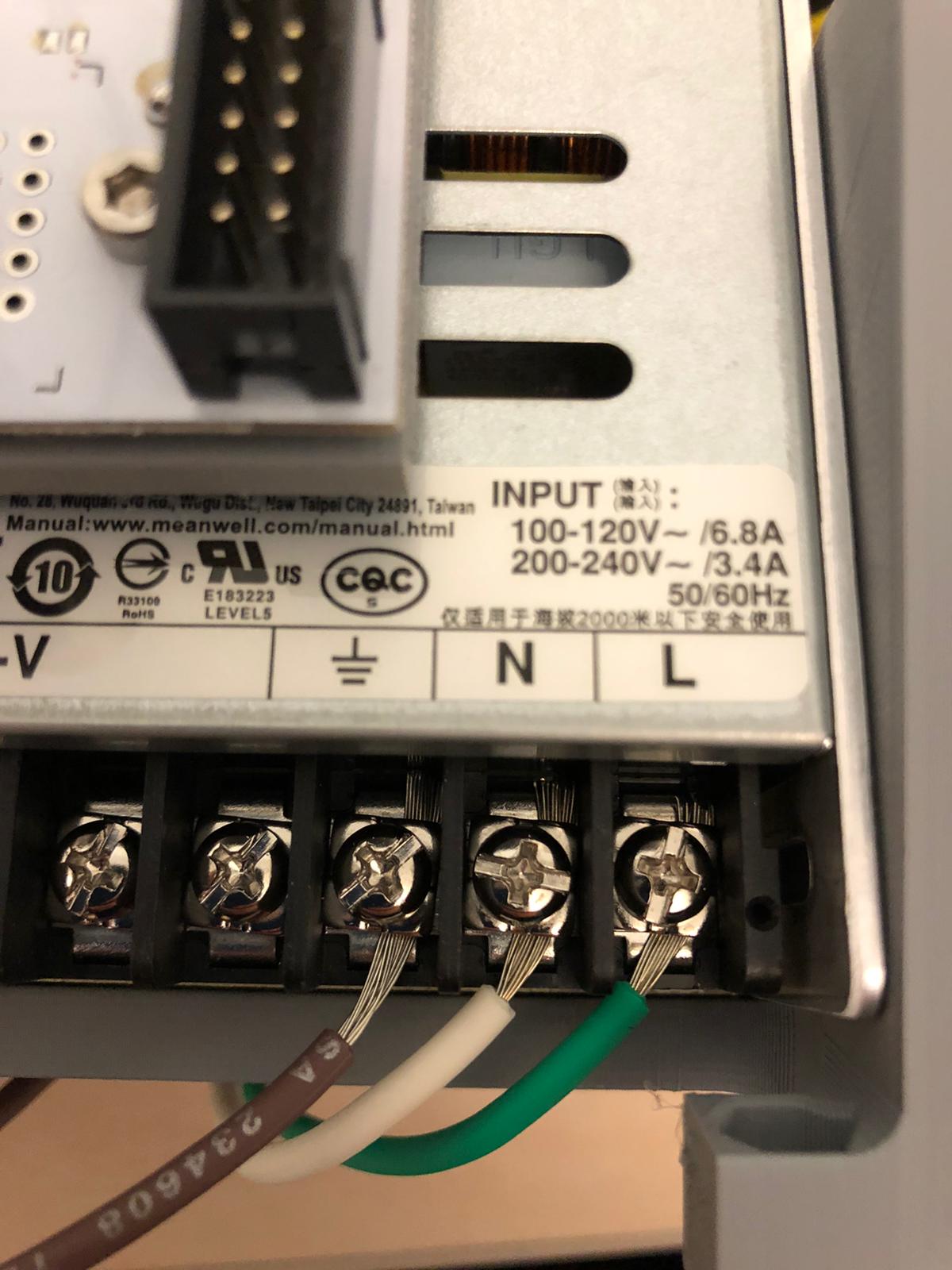

I tried a bunch of times to figure this out by myself but unfortunately, i no longer could see the leds on the power supply board lighting up. I knew then that the code is not talking to the board and that this means the machine is no longer going to work and run.

Trying to troubleshoot with premila over zoom at home, only made me more acutely aware that the machine is off. I brought the machine into the Lab where Premila and I spent hours trying to figure out what might be the issue. A week after, I tried to run the clank again. The first thing I did was flatten the bed.

This came with its own sets of learnings for me.

I let the laptop go to sleep and because of that, the bed flattening stopped midway and I had to dig slightly deeper - 1.5 mm and reflatten.