My goal is to make cleanroom space more accessible. Cleanroom space is required for most micro- and nanofabrication used in the semiconductor industry (e.g. solar cells, LEDs, computer chips) and any sort of microscale patterning (e.g. metasurfaces, flexible electronics, wearable sensors, etc). While cleanroom space is such a key requirement in developing new electronics, it is not readily available to most makers and inventors in the world due to the immense cost of constructing, operating, or even using external cleanroom space. This will change with the introduction of Fabubox, a portable and modular clean box system that allows integration of basic microfabrication processes such as sample cleaning and resist development, spin coating, mask aligner, and etching in a small enclosed clean environment without the necessity to maintain an entire cleanroom facility.

2. Laminar flow box technology background

3. Fabubox Components

3.1 Box Components

3.2 Required materials

4. Electronics

5. Mechanical Parts and Assembly

Overview of Current Clean Space Solutions

MIT.nano building: Cost of construction about 400 million USD. 12,000 sqft Class 100 cleanroom, 9,000 sqft Class 1000 cleanroom and underground vibration-free facilities for high-sensitivity imaging. Reference here.

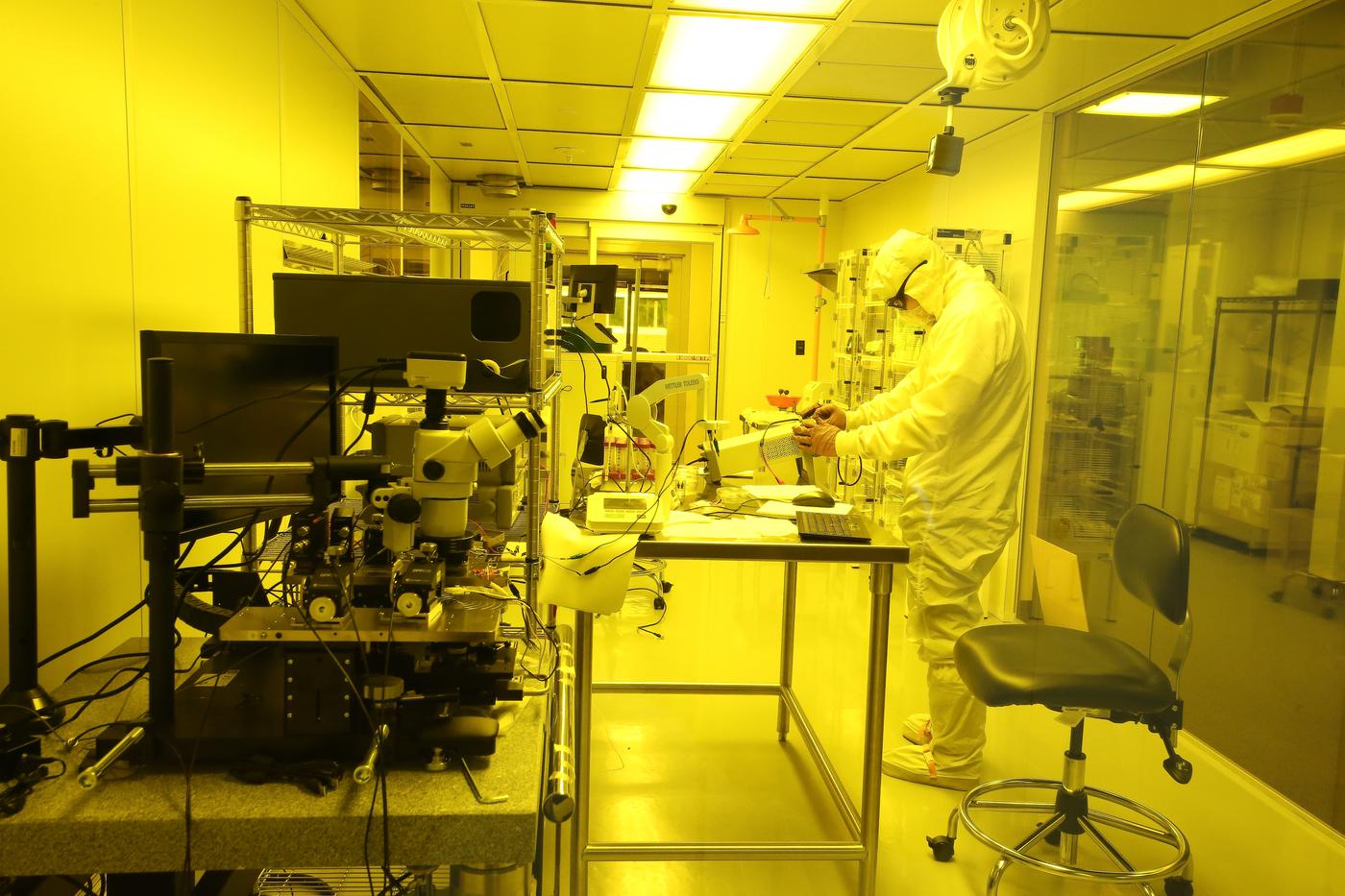

MIT Media Lab Yellowbox owned Canan Dagdeviren's Conformable Decoders Group. Cost of construction: 5 million USD plus (facility excluding equipment). Images from here.

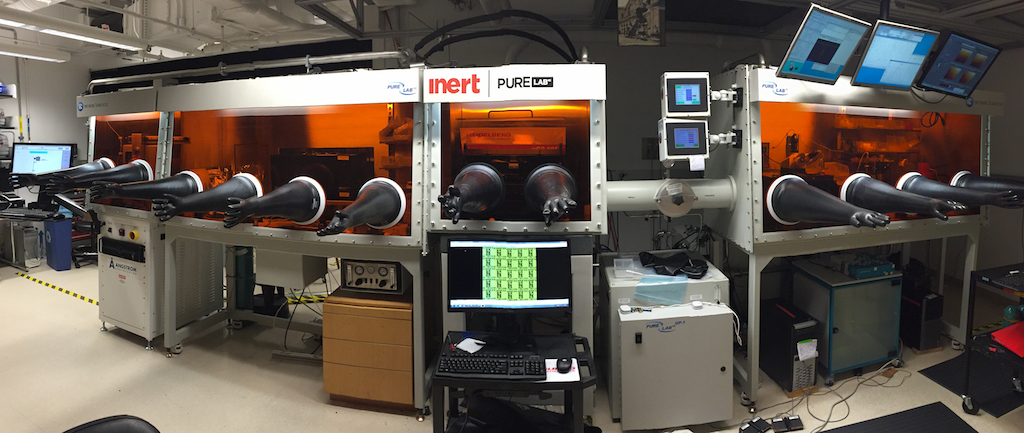

Dedicated photolithography cleanroom-in-a-glovebox system at Boston College. Estimated cost of glovebox setup >100,000 USD

Laminar flow box technology background

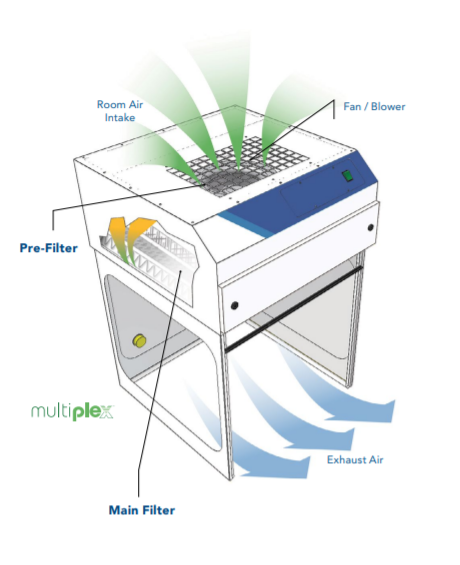

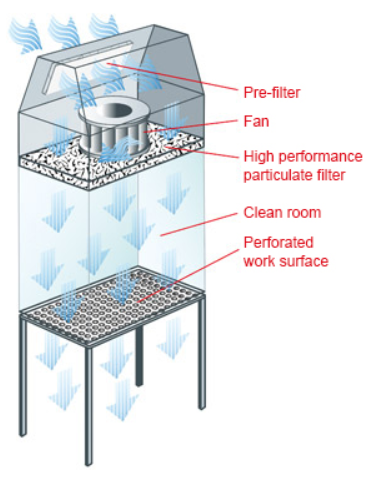

Typical components of a laminar flowbox:

- Pre-filter to take load from HEPA-filter system

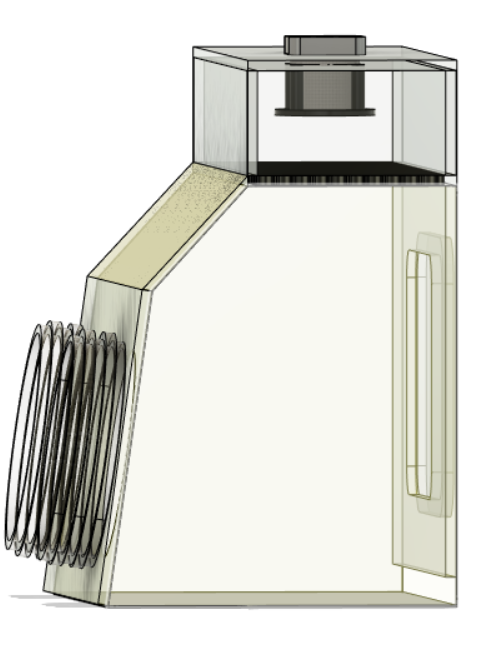

- Top compartment for air filtering separated from main box and comprising:

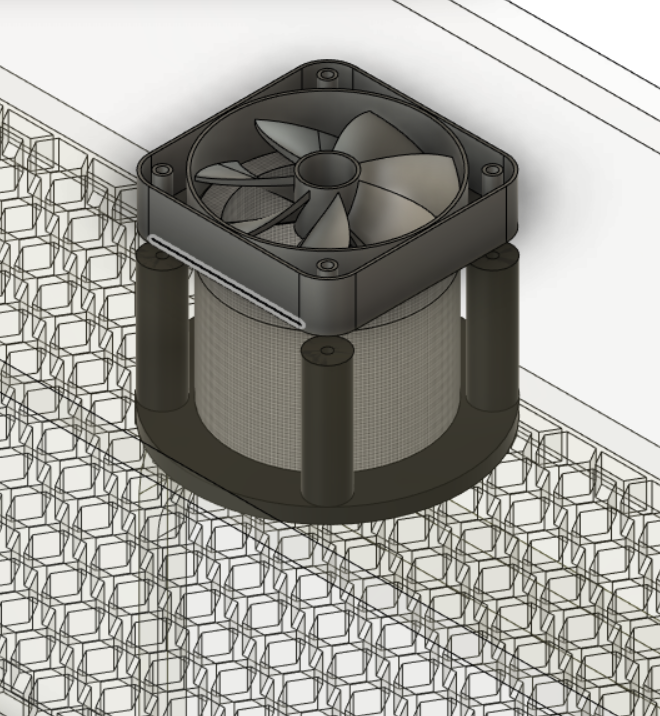

- Impeller/fan system sucking in air from environment and distributing it in filter compartment

- High-performance particulate filter layer (typically HEPA) separating main box compartment and top compartment

- Flow-rectification layer combined with particulate filter layer

- Main box compartment with laminar downwards flow of filtered air

- Air exit depending on box either open front/back sections or perforated bottom with box fully enclosed

Flow rectification is typically achieved with a honeycomb structure converting turbulent flow into laminar flow.

Fabubox Components

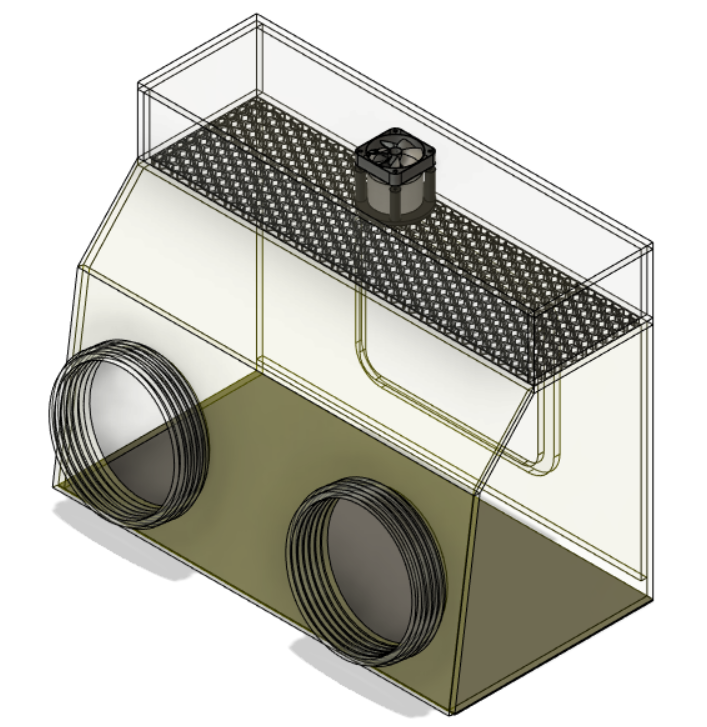

Overview of Box Components

Box overview

Separation of air filtering and flow-rectification.

Required Materials

- 1/4 inch Transparent acrylic sheets for box enclosure

- Back wall and front wall: 2 sheets of 1000mm x 700mm

- Side walls: 2 sheets of 700mm x 600mm

- Back door: 500mm x 400mm

- Filter enclosure back and front: 2 sheets of 1000mm x 150mm

- Filter enclosure top: 2 sheets of 1000mm x 600mm

- Filter enclosure side walls: 2 sheets of 600mm x 150mm

- Glove retention structure: 10 rings of 350mm dia

- 1/16 inch stainless steel sheets for bottom plate and spinner bowl

- Box bottom plate: 1 sheet of 1000mm x 600mm

- Bowl wall: 1 sheet of 800mm x 150mm

- Bowl bottom plate: 1 sheet of 300mm x 300mm

- 1 Cylindrical HEPA filter from Home Depot

- Gears for spinner

- Bearings for spinner

- Shaft for spinner

- 3D-printed parts

- Propeller for air flow into box

- Propeller holder fixture

- Spinner chuck

- Corner braces for box enclosure

- Enclosure for spinner electronics

- Enclosure for propeller electronics

- Enclosure for spinner start process button

- Motors

- Brushless DC motor for propeller

- Brushed or brushless DC motor for spinner

- Power supplies 12V for motors

- Illuminated push button for spinner, such as this or this

- Electronic components refer to box components sections for details

- Particle sensor PM2.5 from Adafruit

Electronics

PCBs

Mechanical Components and Assembly

Spinner and Flow Holder Assembly