How To Make Almost Anything Neil Gershenfeld

MIT Center For Bits And Atoms

Fab labs share an evolving inventory of core capabilities to make (almost) anything, allowing people and projects to be shared. These are my projects.

Molding Casting-

10.27.21

assignment

group assignment: review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

individual assignment: design a mold around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts

[1] During Molding and Casting week I wanted to cast my very own Cerros Orientales. This mountain range is what I miss most from Colombia, so I wanted to create a way have them in Cambridge. I began by extracting the shape of the mountain range using this website. It allows you to extract the shape of any geography. It was difficult determining the length of the mountain range to extract. To do this, I looked at the size of the wax we would be milling and using those proportions I scaled them to determine the size of the Cerros I would be able to cast. Molding and casting consist essentially in learning how to substantively create a mold and then using different types of substances to cast a model. As different substances have different properties and casting times, as a group we reviewed the safety data sheet for each of our casting materials and made test casts with each of them. This can be observed here. This allowed me to select the appropriate material to cast the mold first, and then to cast the final model from the mold I had previously cast.

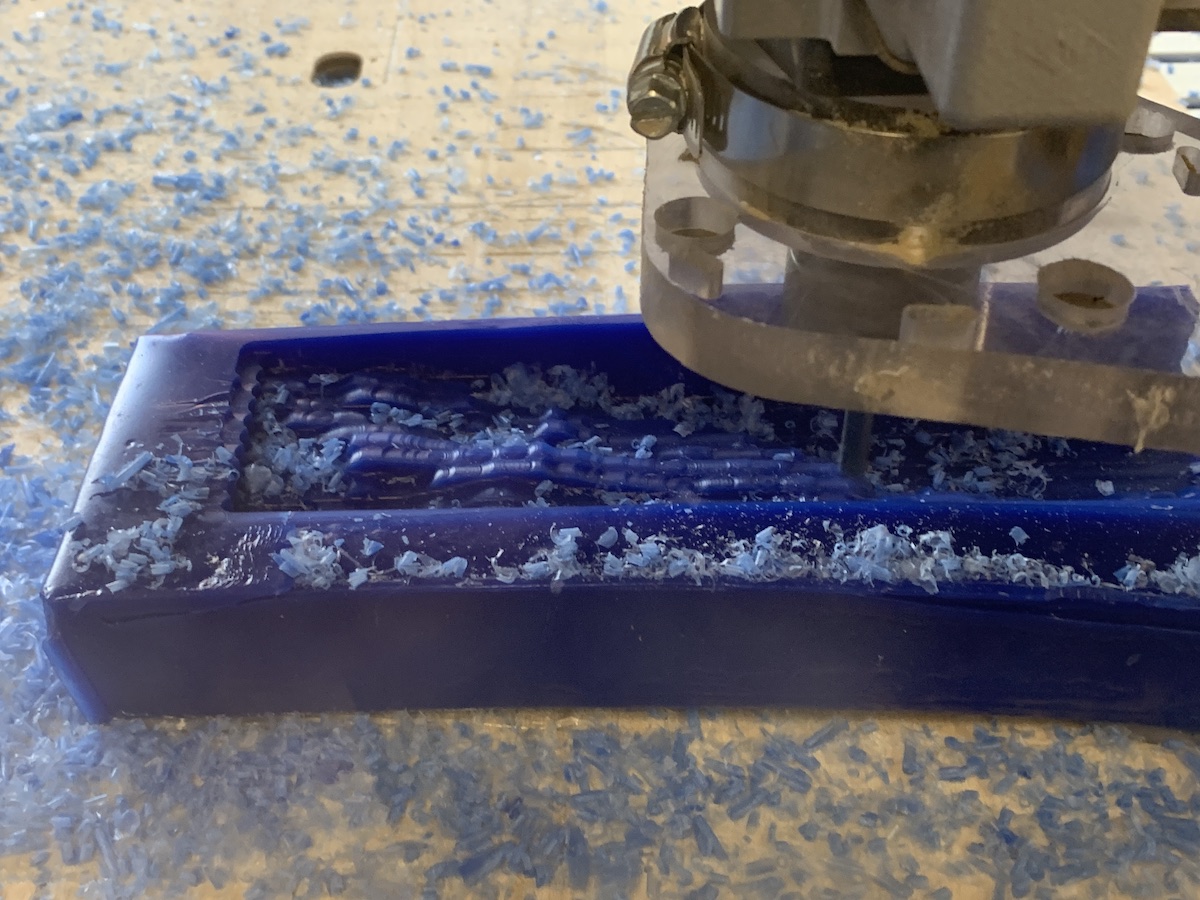

This week we used a smaller version of the milling machine we used in the Make Something Big week. To begin, we used wax which we attached to the milling bed using hot glue. Milling the Cerros Orientales took a lot longer than expected. I created a rough cut first, and then a fine cut file, yet it still took more than 2 hours to mill. This was unexpected, as I thought wax could be easily milled by the ShopBot machine. A question that was left lingering, was how the ShopBot “knows” I already milled a rough cut before sending in my fine cut. Initially I thought by doing a rough cut first, the fine cut would be faster.

After having the mold to be cast, I used Ecoflex 50 to create the mold of the Cerros Orientales. Using equal parts of each of the two substances to create the Ecoflex 50 and stirring all the bubbles I could before pouring, I managed to create a mold of the Cerros Orientales. Using this mold, I then created a cast of the Cerros Orientales I wanted. Now, it is just a matter of waiting for it to finish drying.

Considerations:

-Create a rough cut and then a fine cut using Aspire, so that the milling machine can be run at a faster speed.

-Use a caliper to measure the exact depth, width and length of the Wax or material you will be milling to create your mold.

-Use more hot glue than you think will be necessary to attach the Wax to the milling bed. The vibration of a long mill will eventually loosen up the material and ruin your mill.

-Try to shake and vibrate the substance you will use to make the mold and cast to remove as many bubbles as possible. This will guarantee a good quality cast.