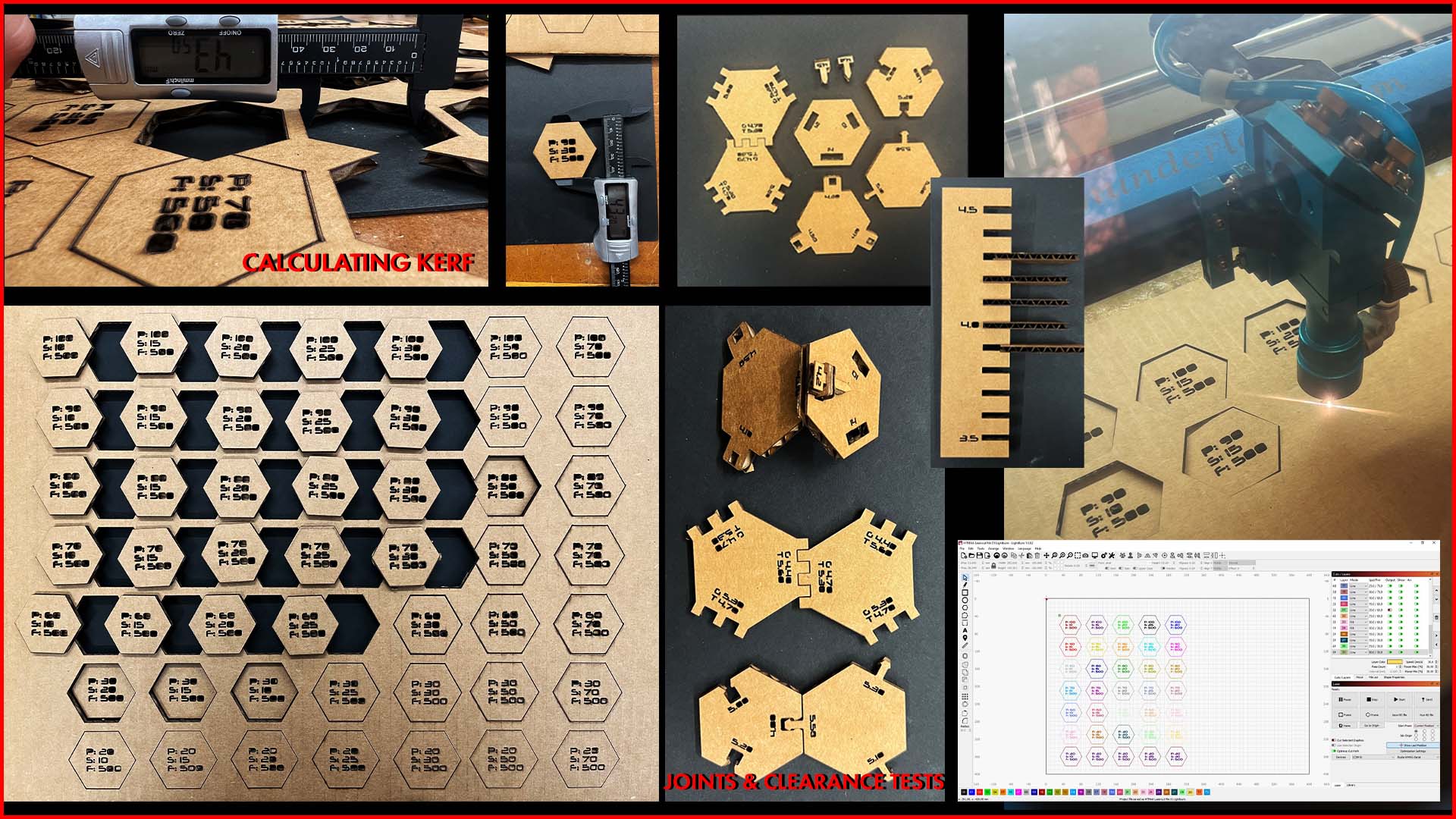

This week’s GROUP assignment was to characterize our lasercutter's focus, power, speed, rate, kerf, joint clearance and joint types. This was necessary in order to calculate the Kerf and proper dimentions for the joints were assigent to create for the individual projects.

Working with Alexia Asgari and Selin Dursun, we started by printing hexagons with the Thunder laser cutter, incrementing the percentage of power and speed. Our goal was to determine the optimal setting for cutting and rasterizing our cardboard which we measured to be 4.5 mm thick. Through our 49 different variations or setting, we determined the most effective setting for cutting were 90% power, 20 mm/s speed, and 20% power and 30mm/s speed for rasterizing.

Measuring the size of the outer and inner dimensions of our hexagons and comparing these outputs to the intended CAD dimensions, we calculated our machine’s Kerf to be .3 mm (rounded).

Next, we cut out a comb with incrementing gap sizes from 4.5 mm to 3.5 mm thick. From this trial, we determined that a finger joint of 4.0 mm was a sturdy fit vs. a 4.1 mm joint was a functional size for disassembly. Lastly, we used this data to experiment with different joint types -- finger, snap, and wedge. Based on the strength of the material, the finger joints seemed to be the most functional.

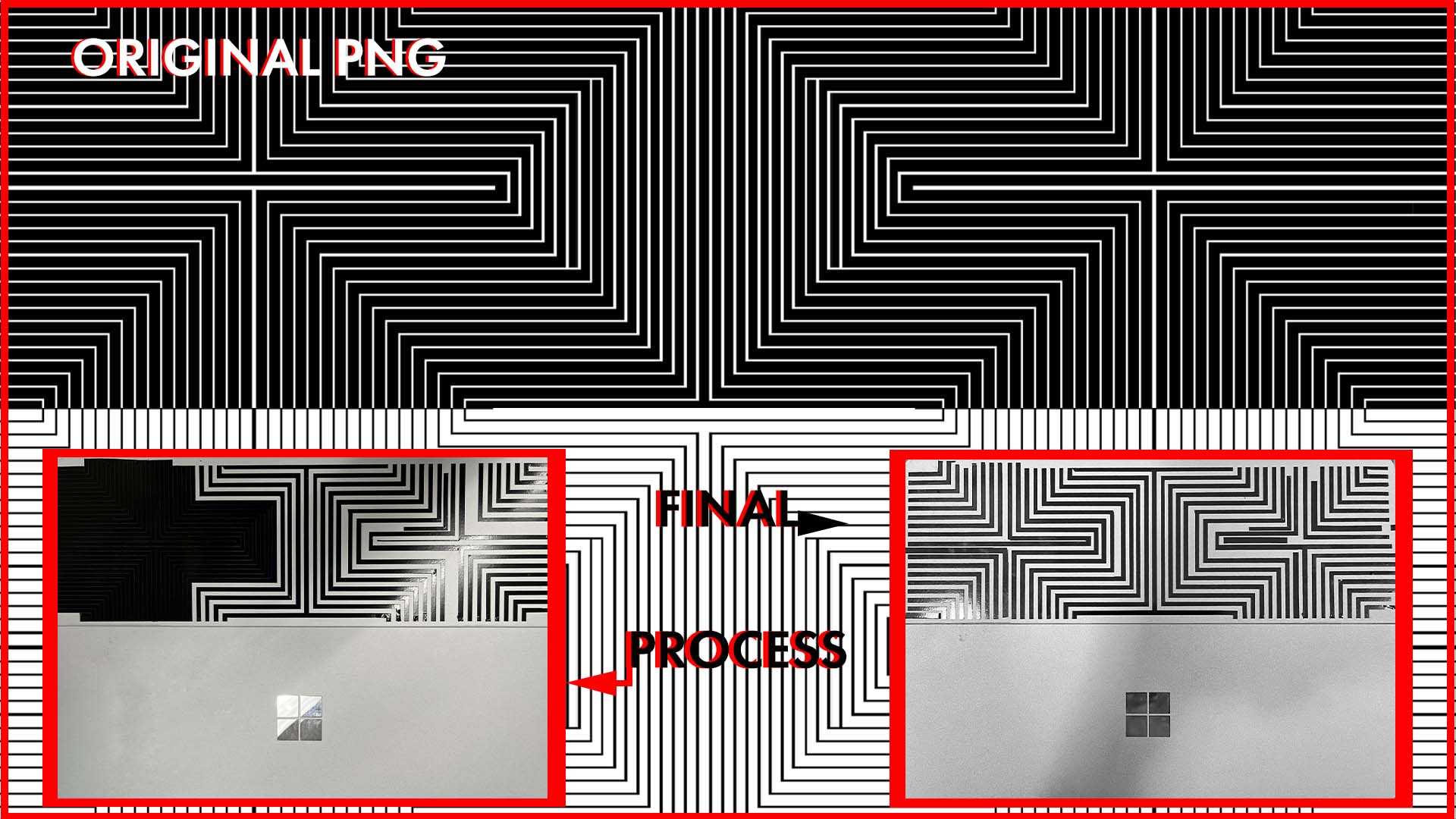

Individually, we were assigned to cut out a vector design using the vinyl cutter and design a parametric construction kit using cardboard.

I took inspiration from a geometric Frank Stella painting for my vinyl sticker. Using photoshop, I created a png file tracing one of Stella’s paintings, defining a clear distinction between the white and black boundaries. Importing my png file to Mods, I then converted the file into vectors and sent it to the printer. Once printed, I applied the sticker to the back of my laptop and used tweezers to peel off the excess vinyl. My design was intricate and the aluminum of my computer wasn’t an optimal adhesive substrate. Therefore, a few pieces ended up being lost in the application process. Although the final product wasn’t a perfect representation of the original, I believe it has an analog glitch-like charm.

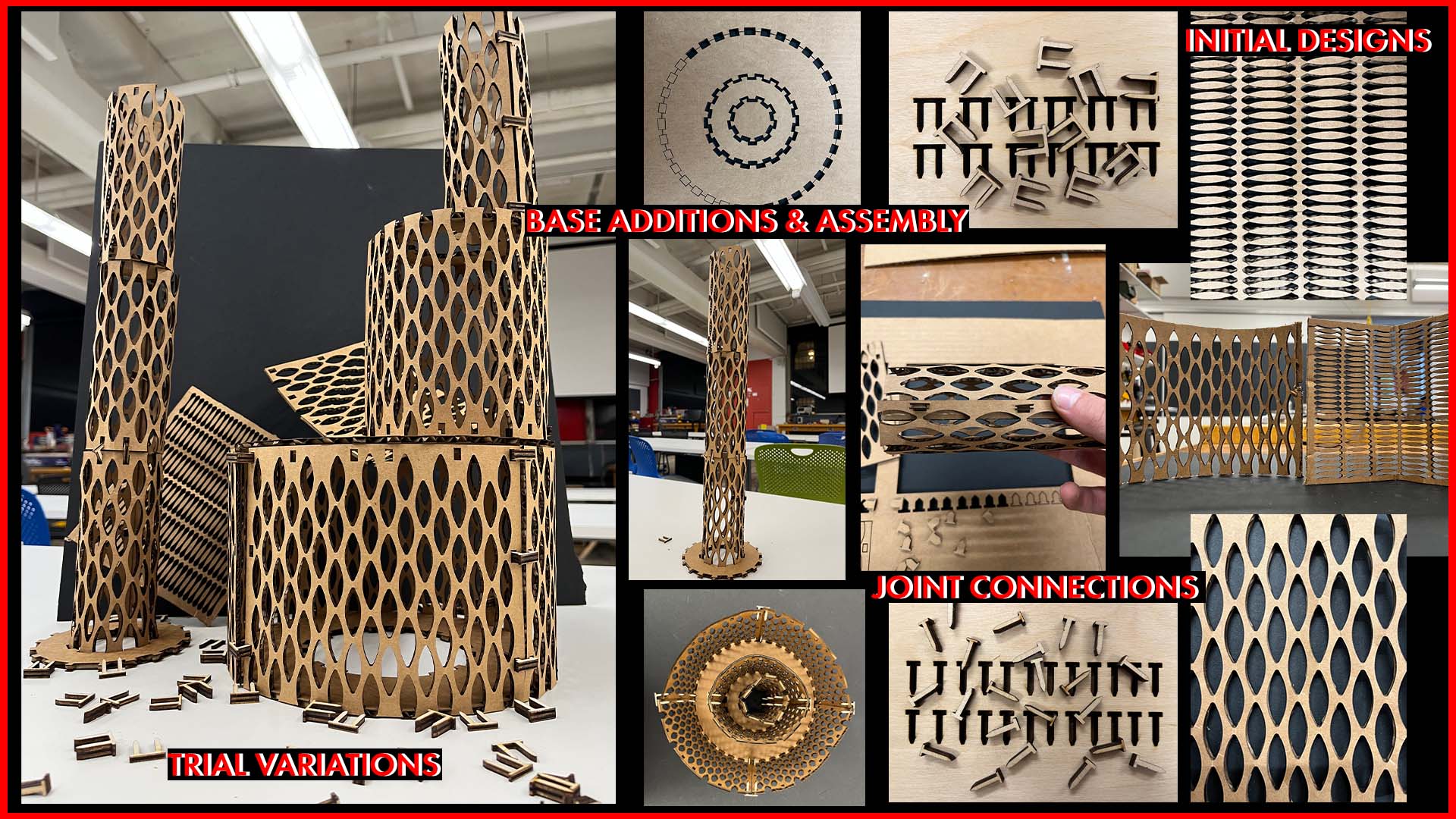

My goal was to create a flexible modular structure kit with minimal parts that used the least amount of cardboard and could be parametrically scaled for the user’s needs. I began by experimenting with two flexible exterior walls I created in Rhino. Next, I iterated on the more flexible design, which used a repeated oval-like shape. Nails and staples were created to link the pieces through a wedge-type joint. I used wood for these nails and staples to keep the walls flexible because the walls required a joint connection too thin to be built out of cardboard. Sockets were then added to the wall design so that multiple pieces could be strung together vertically or horizontally using the staple and nail joints. Next, I developed three base platforms that increased in scale and could be printed inside of each other to limit cardboard waste. A finger joint was used to attach the walls to all base variations.

If I were to continue iterating on the kit, I would like to add the possibility of attaching multiple platforms though out the vertical and horizontal structure.

After finishing this project, I feel confident working with the laser and vinyl cutter. I want to develop this design further with materials other than cardboard. The potential use cases vary drastically depending on the materials used for the individual pieces. I typically think in a site-specific creation framework, but this assignment expanded my awareness of material-specific design and the dedication required to analyze the advantages and disadvantages of your material of choice.

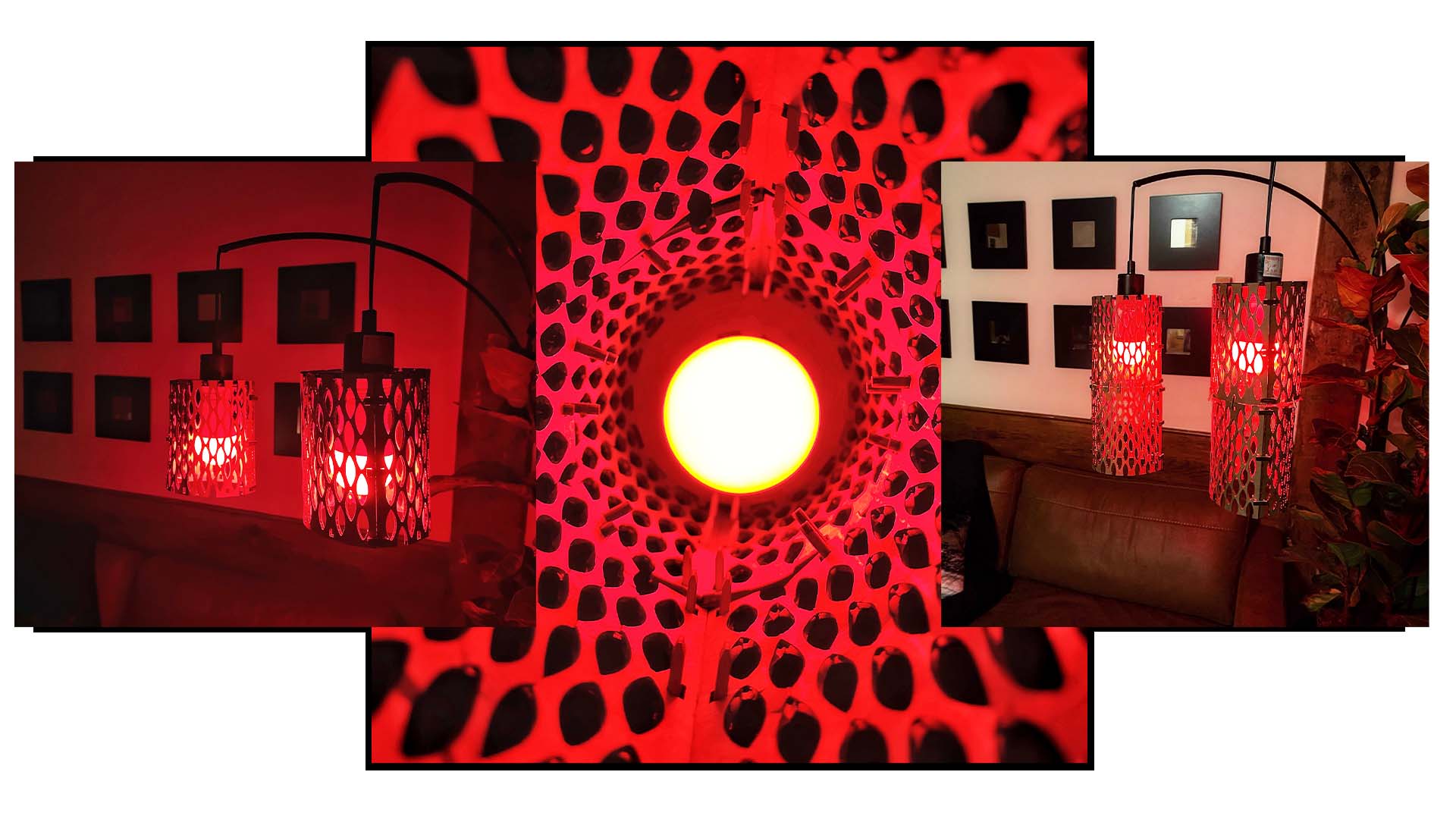

Ideally, I would like to scale this structure to create beautiful lampshades, facades over glass flower vases, trash cans, or an umbrella stand for my apartment.