Requirements:

To wrap up the course, we were tasked with making something that covers the range of lessons and digital abrication techniques we learned on a weekly basis.

We had to showcase a mastery of :

Incorporation of 2D and 3D design

Additive and subtractive fabrication processes

Electronics design and production

Embedded microcontroller design, interfacing, and programming

System integration and packaging

Moreover, we had to explain the following about what we made:

What does it do?

Who's done what beforehand?

What did you design?

What materials and components were used?

Where did they come from?

How much did they cost?

What parts and systems were made?

What processes were used?

What questions were answered?

What worked? What didn't?

How was it evaluated?

What are the implications?

I've been working on assignments for months, ready to answer all of the above, so let's get to it!

What does it do?

My final project, PlantFender, is a digital scarecrow. It senses the motion of birds or rodents via a passive infrared sensor and scares them away from the area it is in via a buzzer that emits a high pitched noise that bothers birds but does not harm them permanently.

Who's done what beforehand?

This is a problem as old as farming itself. How does the farmer do the work of planting, maintaining, cluitvating, and harvesting their land and crops while protecting it against pests and disease at all times during the growing cycle? The goal of PlantFender is to protect my blueberry crop, modest at four bushes, beyond what we do now, which is to put netting over the crops.The issue with the current method is that the netting is difficult to get off of a sticky shrub when you want to pick the berries. Often, my young son, wants to pick the berries before school. Taking off the netting each day takes a few minutes, as does putting it back on - tough timing for parents at the begninning or end of the day. Leaving the netting off makes the berries easy to pick for my son, but even easier for bugs, rodents, and most pesky of all, birds. This project looks to strike a balance between access to crops for a young family and protection of the crops themeselves.What did you design?

I used 2D tools to design and mill a PCB using subtractive fabrication processes to house an embedded microcontroller, which has been programmed to detect motion using a passive infrared sensor, and sound an ultrasonic buzzer in the presence of that motion. All of these functions have been integrated onto one PCB, with room to expand functionality for one addtional device to be powered by 3V or 5V, and along with a data pin.What materials and components were used?

All of the materials and components for this project were sourced from the inventory at the Harvard REEF, MIT EECS, and the Harvard EE e-waste bin. No new materials were purchased for the completion of this assignment. The material and component list is as follows:

- One Xiao ESP32S3 development board: https://www.seeedstudio.com/XIAO-ESP32S3-p-5627.html

- Flux and solder

- 12 headers for pin connections for components: https://www.digikey.com/en/products/detail/te-connectivity-amp-connectors/5-146280-2/2275896

- Jumper wire to connect components to pins on the board: https://www.digikey.com/en/products/filter/jumper-wire/640

- HC-SR501 PIR: https://www.digikey.com/en/products/detail/seeed-technology-co.,-ltd/101020060/5487425

- HW508 buzzer: https://www.elecbee.com/en-29193-10Pcs-3-5-5-5V-Standard-Passive-Buzzer-Module

- Auray monopod: https://www.bhphotovideo.com/c/product/1770083-REG/auray_mss_tbh1_telescoping_mic_stand_shaft_ball.html

- One one-sided copper PCB board for milling and tracing: https://www.digikey.com/en/products/detail/mg-chemicals/506/559720

One Jackery Bolt power supply:

https://www.amazon.com/Portable-Charger-Jackery-Bolt-6000/dp/B01A6L85CCWhere did they come from?

All of the components were in inventory or trash, but before then, all were available from DigiKey, Amazon and B+H Photo as vendors, and China as country of origin / manufacture.How much did they cost?

It depends on the costing model: free in some sense, that they were all available in inventory / trash. In more absolute terms, about $40 USD based on prices available in the links above as of June 2024.What questions were answered?

Can I design, manufacture, and test a "if this then that" system? Yes. This was my personal learning goal for this course.What worked? What didn't?

The PIR and buzzer combo worked as designed and made sense in the end. The canopy was a moonshot of sorts, in that I thought it would be nice to automate somethign that was cumbersome, but the reality was that I ran out of time to design a canopy and 3D print ribs, and, I would stll run into the same snagging problem that I have today with manually pulling off the netting.How was it evaluated?

Side by side with netted plants / crops. which have yet to mature to pickable fruit as of June of 2024.What are the implications?

This is not a cheap problem to solve and scale at this time. I thought that this could be done at a low cost, but there is still work to be done to make the power for this design more affordable and data that remains to be collected as to the efficacy of the solution.PlantFender - Assembly and Use:

Here is the current state of the state as of June 2024:

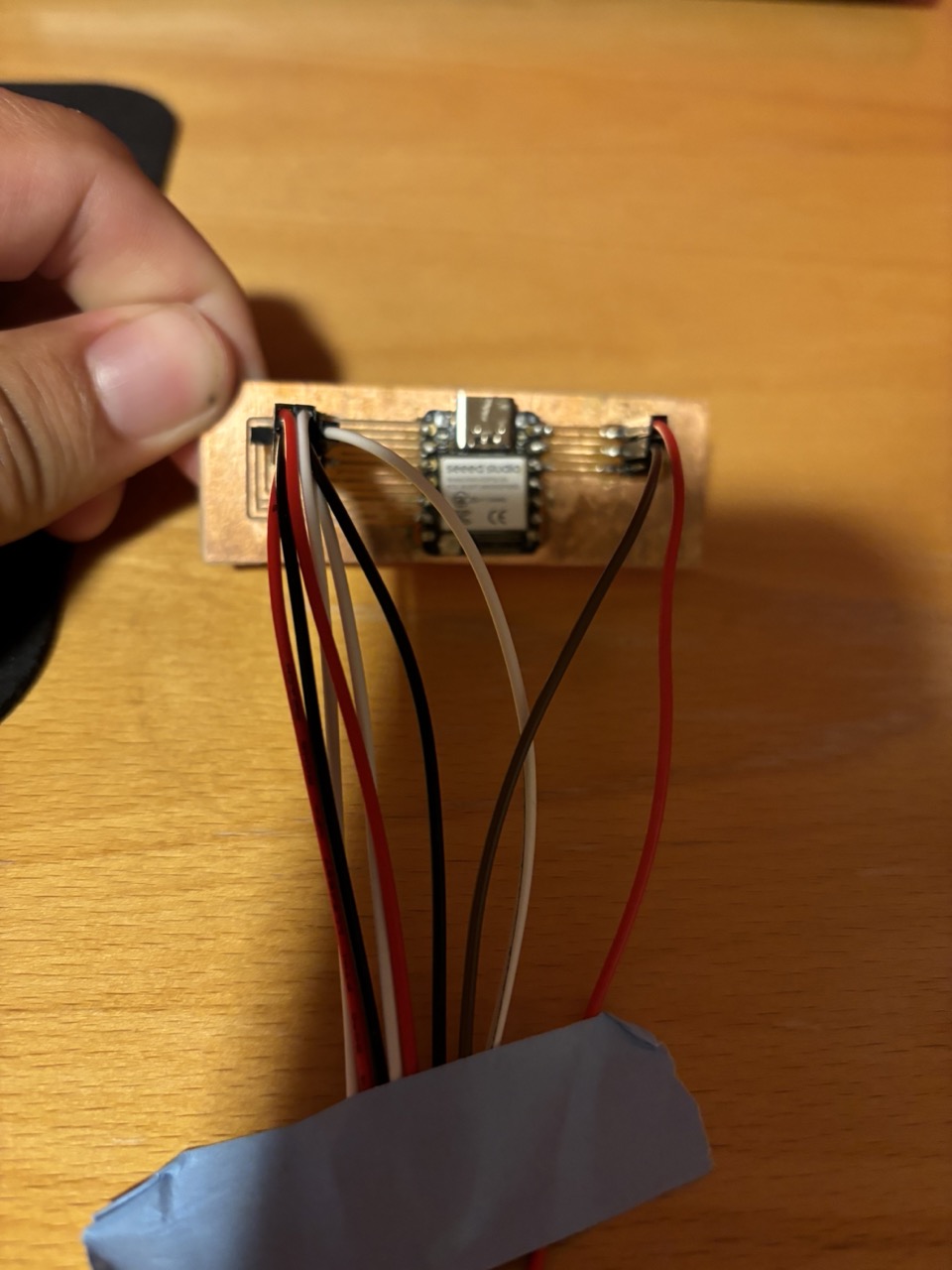

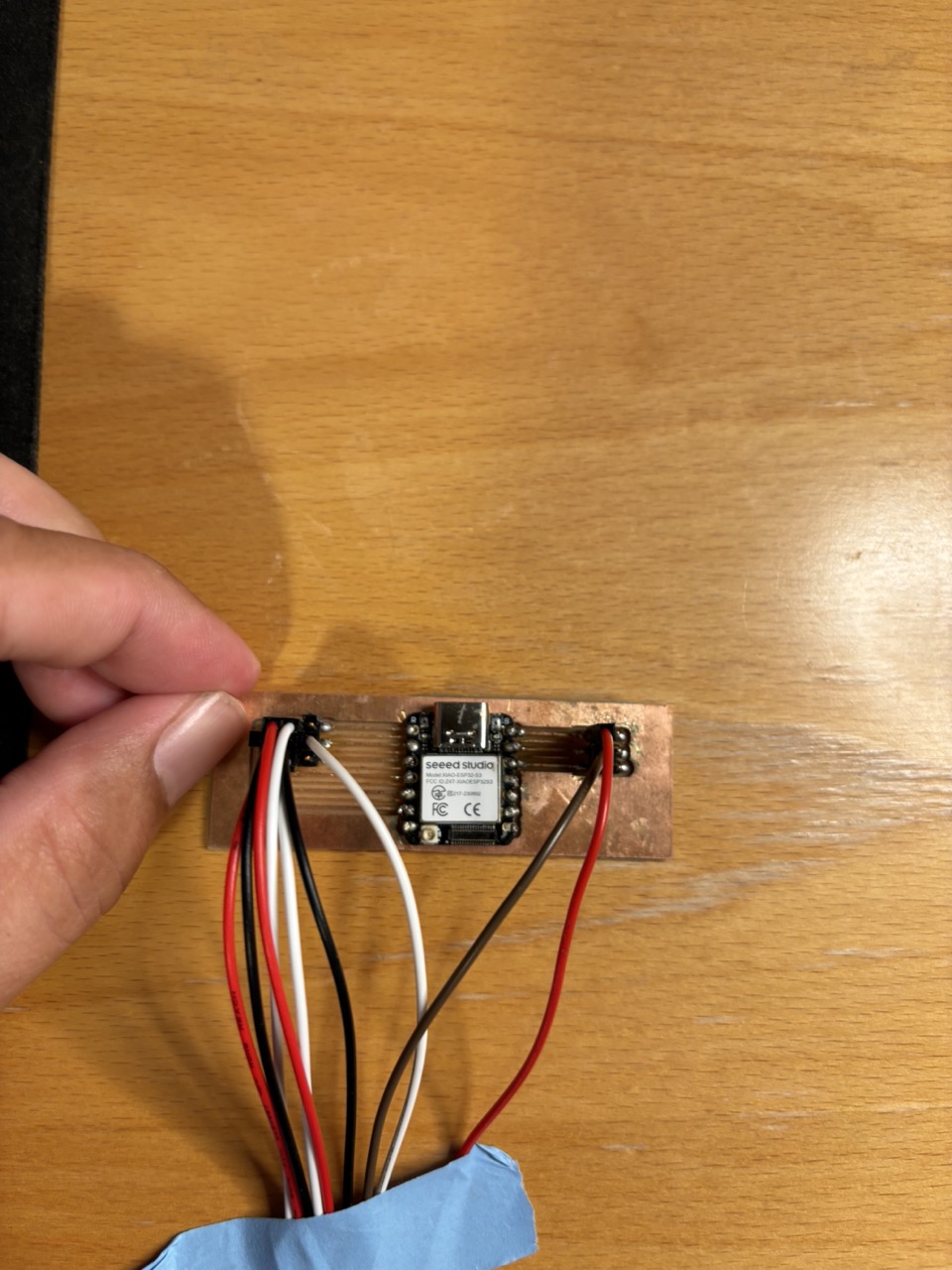

Assembly of the final project begins with connecting the data pins to the PIR and buzzer, along with power and ground:

Assembly of the final project begins with connecting the data pins to the PIR and buzzer, along with power and ground:

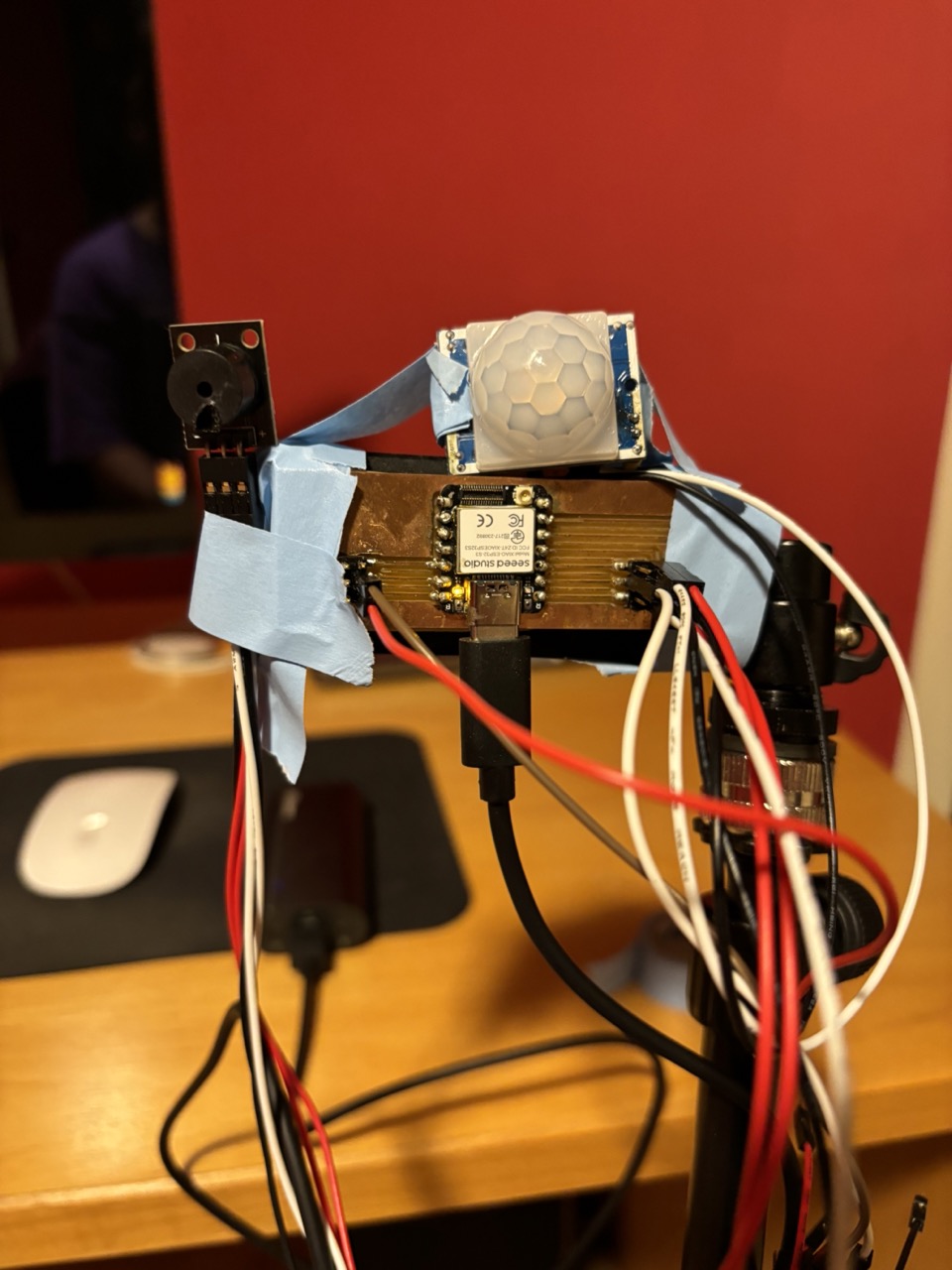

Then, to the power source:

Then, to the power source:

... and final taping:

... and final taping:

Ready to defend!

Ready to defend!

PlantFender - Watch the 1 miniute trailer:

I acknowledge the help and support of The MIT EECS staff, particularly Anthony Pennes, in thinking through the steps required to do this assignment simply, and ChatGPT 3.5, which helped me take text and images from the native OS X text editor I used to quickly document on my Mac into simple HTML for my git repo.

Updated June 9, 2024