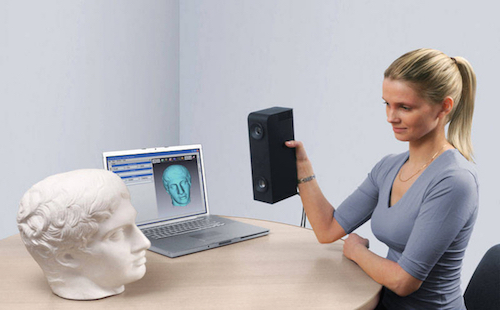

My potential application proposal for the class is to make an affordable 3D scanner that can be used in every single household. The current market price for 3D scanners range from $499 to $10,000, and is prohibitively expensive, and out of reach of the average consumer. I hope to come up with an affordable 3D scanner that consumers can use in the comfort of their houses.

I hope for the 3D scanner to be used for two main functions (1) To help people measure their exercise and gym improvements or even just watching their waistline or body shape (2) To help consumers who want to tailor make clothes to readily deliver their measurements to the tailors, instead of having to make the trip down to the tailor's to have their measurements made. In the picture, you will a guy trying to bench-press, and what he will do is he will go to the mirror and try to flex his muscles to see whether they have grew, but a 3D scanner can do a far better job at that!