This is a video of growing flowers!

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel (e.g. an eccentric wheel) or shaft (e.g. a cylinder with an irregular shape) that strikes a lever at one or more points on its circular path. I got interested in this because I was speaking to Rob Hart, and wanted to model something that will create motion, and can perhaps directly work as a machine for sewing or making a scarf in the future. My current final project plan is to improve the 3D scanner, and hence the mechanism for that are a bit difficult to model, and hence I decided to focus on the cam, which turned out to be very interesting!

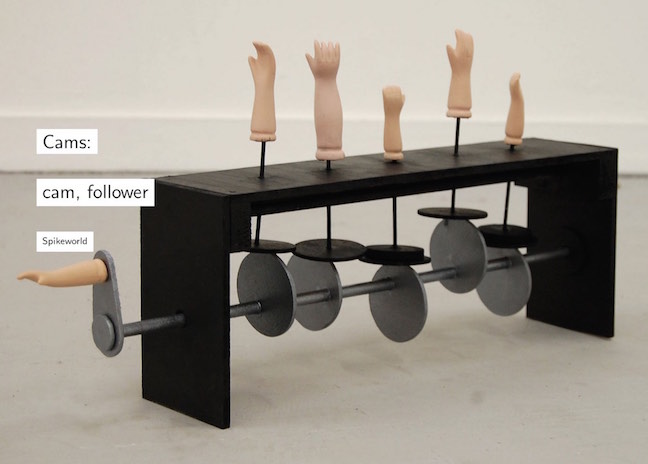

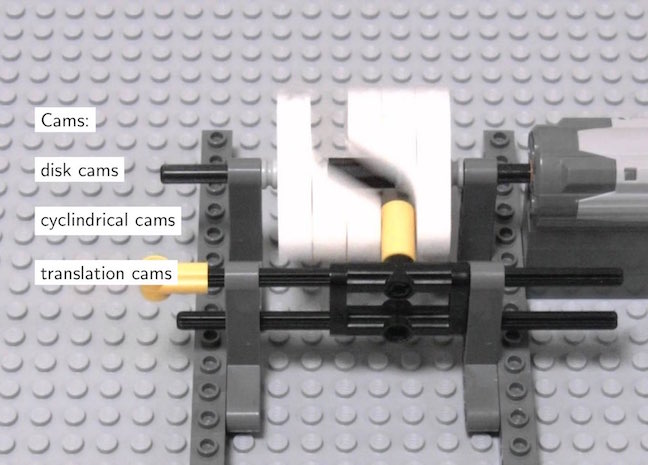

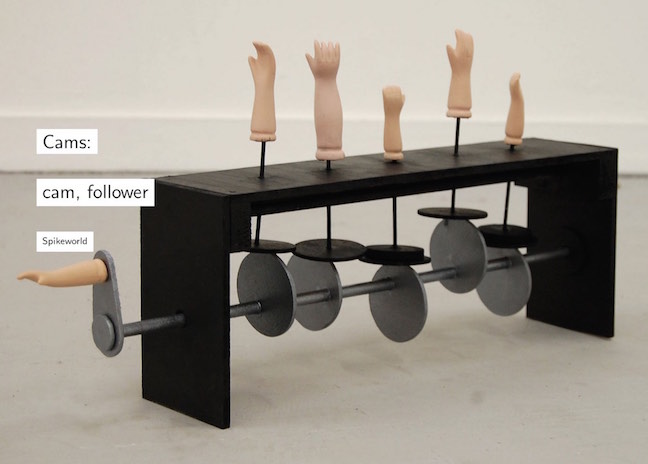

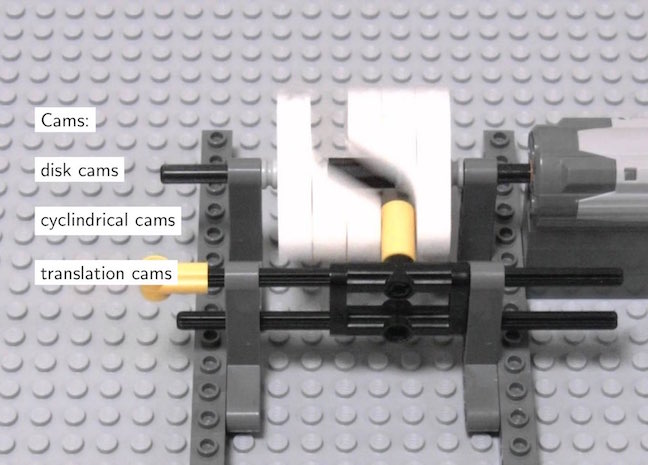

There are different types of cams, including plate cams, cylindrical cams, face cams, linear cams, among others. I decided to focus on making a plate cam as I felt it was an interesting concept to work on and is the most commonly used type of cam.

My first step was to create the stand for the plate cam. I first designed the model on Rhino, and was going to cut it out on the laser cutter. But the laser cutter as Harvard was down these few days. Without a laser cutter, I decided to use foam board and use a saw/blade to slice the parts and use glue to hack everything together.

Next step, I went on to create the plate cam. Here, the follower moves in a plane perpendicular to the axis of rotation of the camshaft. Therefore, I needed to do the relevant measurements to ensure that the right axis and holes were made so that they will all be on the same plate.

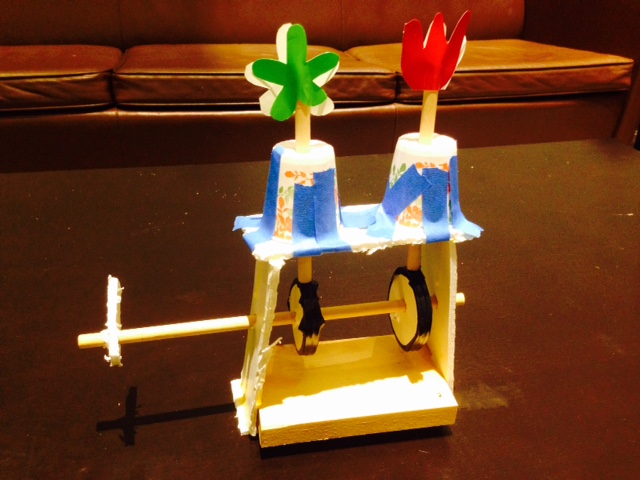

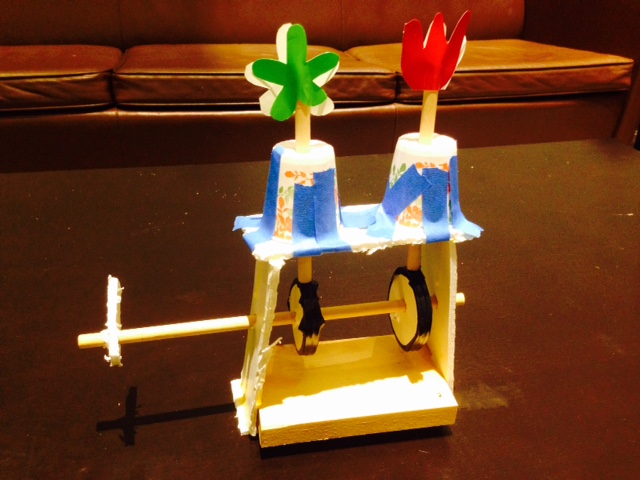

This is the completed cam. As you can see, when I rotate the cam, the flowers will start "growing" up and down. I think the key tricks to making the cam work was a few (1) The plate cam needs to be wide enough (I used two foam board to make it wide enough) (2) The structure must be strong and sturdy enough (I used couple of wood planks to secure and steady it (3) The follower must be wide enough and sturdy enough, and needs to be stabilized by at least 2 to 3 layers of board (I used the two cups to steady the wooden stick and it worked!)

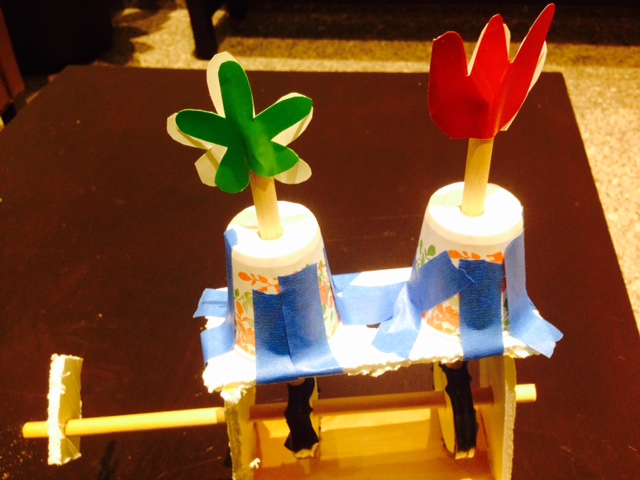

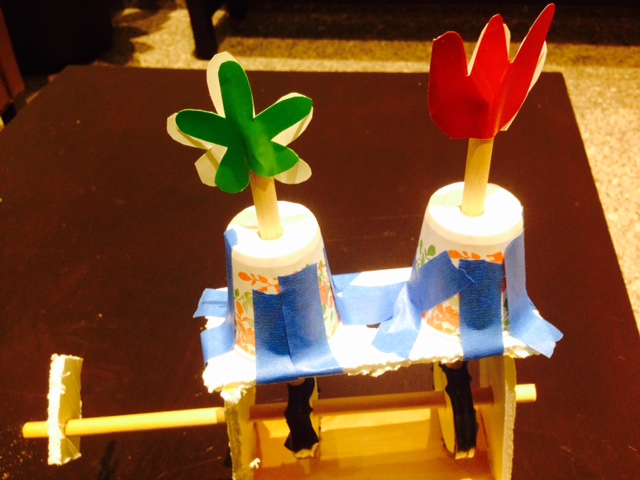

Another better picture of the completed cam!

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel (e.g. an eccentric wheel) or shaft (e.g. a cylinder with an irregular shape) that strikes a lever at one or more points on its circular path. I got interested in this because I was speaking to Rob Hart, and wanted to model something that will create motion, and can perhaps directly work as a machine for sewing or making a scarf in the future. My current final project plan is to improve the 3D scanner, and hence the mechanism for that are a bit difficult to model, and hence I decided to focus on the cam, which turned out to be very interesting!

There are different types of cams, including plate cams, cylindrical cams, face cams, linear cams, among others. I decided to focus on making a plate cam as I felt it was an interesting concept to work on and is the most commonly used type of cam.

My first step was to create the stand for the plate cam. I first designed the model on Rhino, and was going to cut it out on the laser cutter. But the laser cutter as Harvard was down these few days. Without a laser cutter, I decided to use foam board and use a saw/blade to slice the parts and use glue to hack everything together.

Next step, I went on to create the plate cam. Here, the follower moves in a plane perpendicular to the axis of rotation of the camshaft. Therefore, I needed to do the relevant measurements to ensure that the right axis and holes were made so that they will all be on the same plate.

This is the completed cam. As you can see, when I rotate the cam, the flowers will start "growing" up and down. I think the key tricks to making the cam work was a few (1) The plate cam needs to be wide enough (I used two foam board to make it wide enough) (2) The structure must be strong and sturdy enough (I used couple of wood planks to secure and steady it (3) The follower must be wide enough and sturdy enough, and needs to be stabilized by at least 2 to 3 layers of board (I used the two cups to steady the wooden stick and it worked!)