Rebecca Kleinberger MAS865.15 Project

Objectives

potential applications:

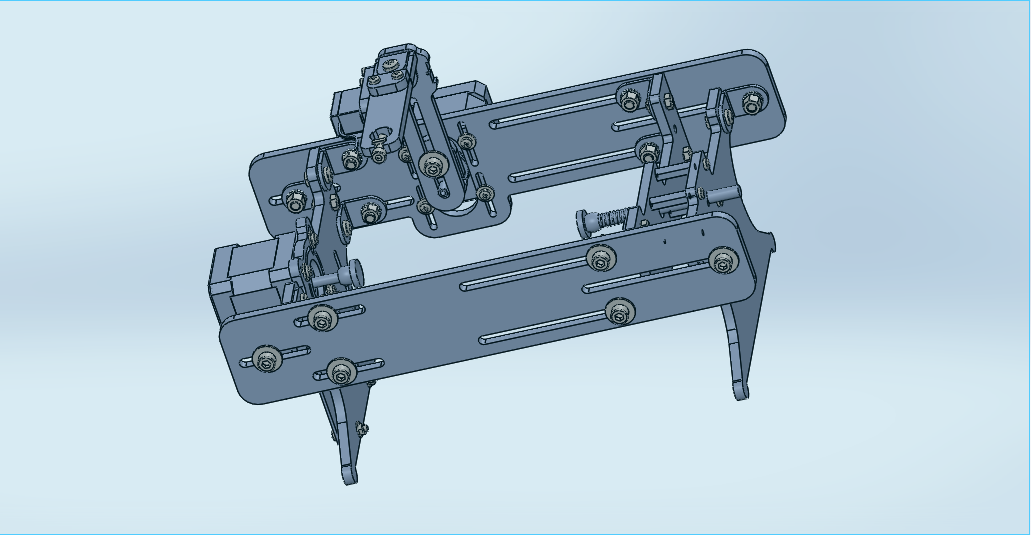

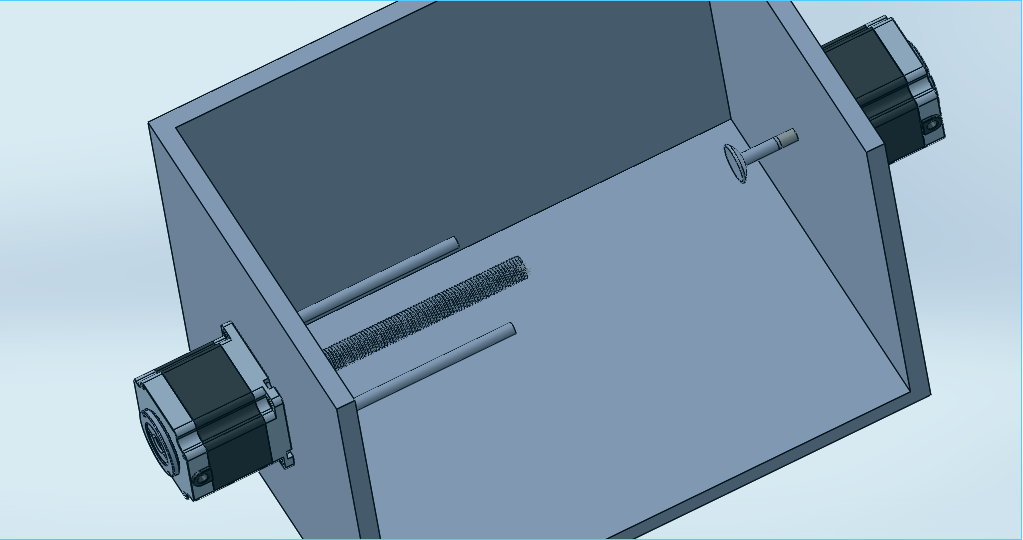

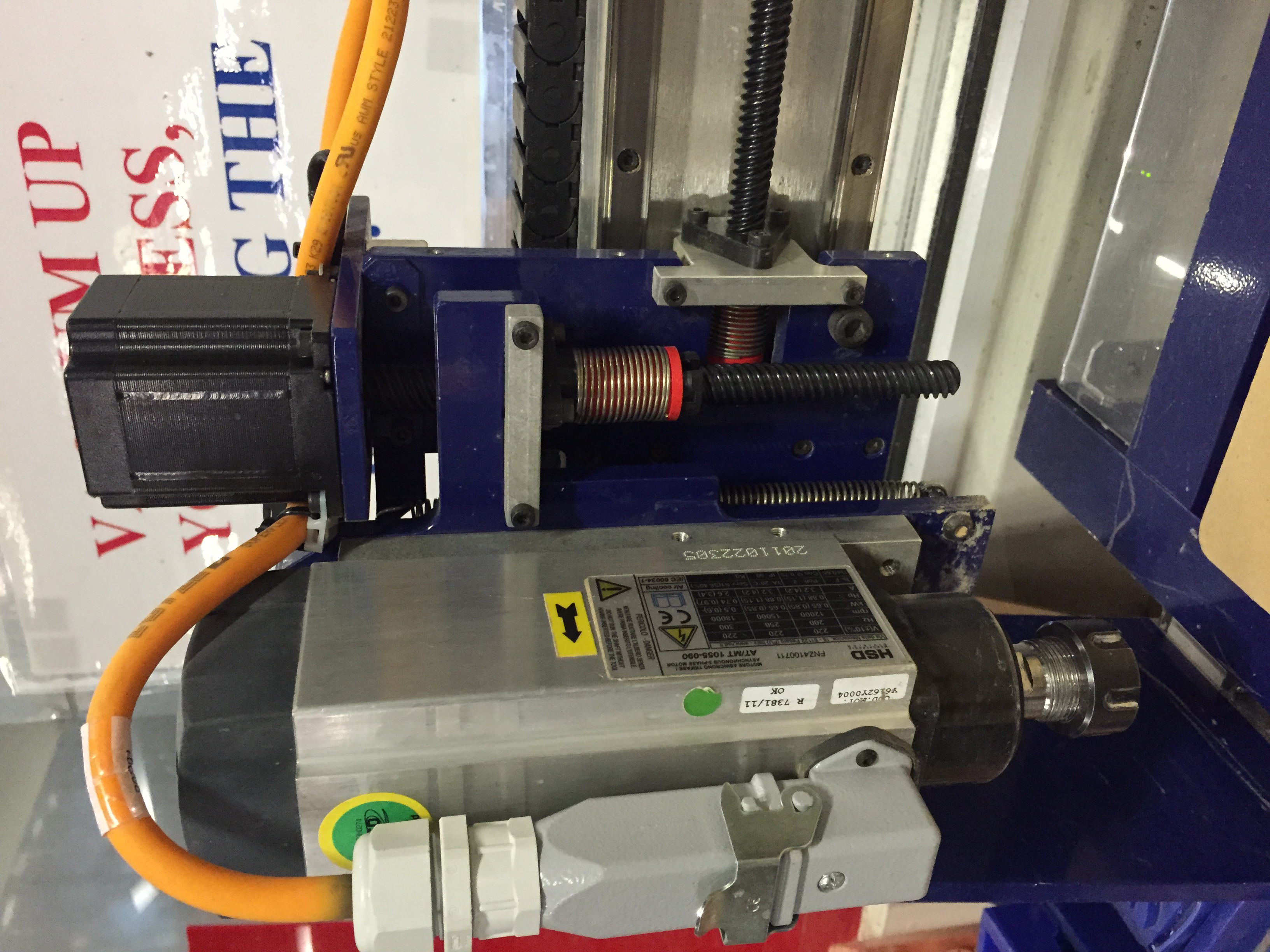

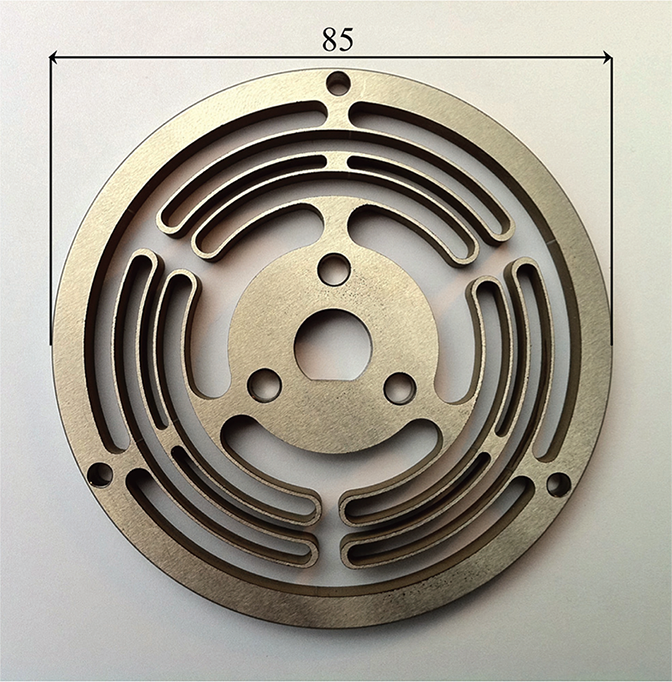

Last september I started eggshells carving. It is a very precise manual task. I would like to work on building a programmable egg carving machine.

potential capabilities:

awareness of the object to carve and the mechanical structure of an egg (such as a mechanism to scan the piece at the beginning because the size and shape of eggs can carry from one to an other)

holding mechanism that varies its strength according to the elasticity/ resistance of the egg to carve.

Assignment 2: Self-Reproducing machine

Molding Casting

By definition, this fabrication technique is based on self-reproduction. One (often) needs an initial piece to create a mold, sometimes you even need an initial alpha mold to create the piece that will serve to create the industrial mold...

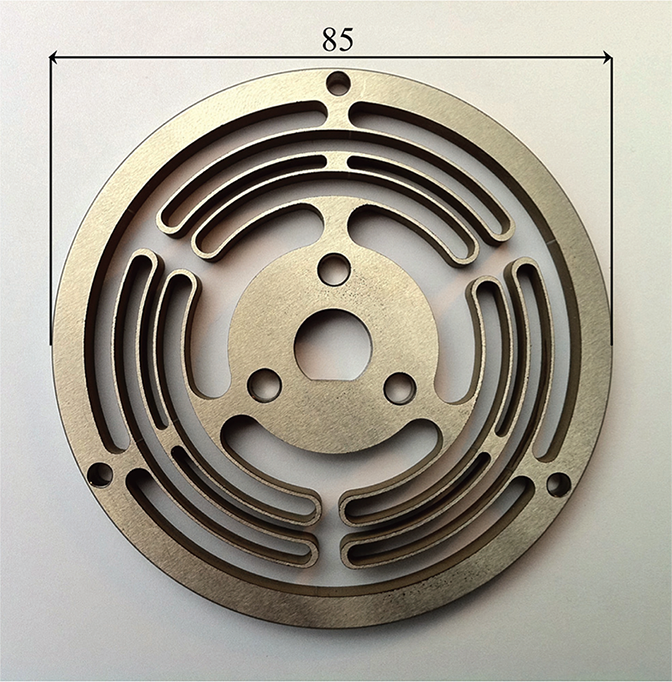

Fitting a mold in a mold?

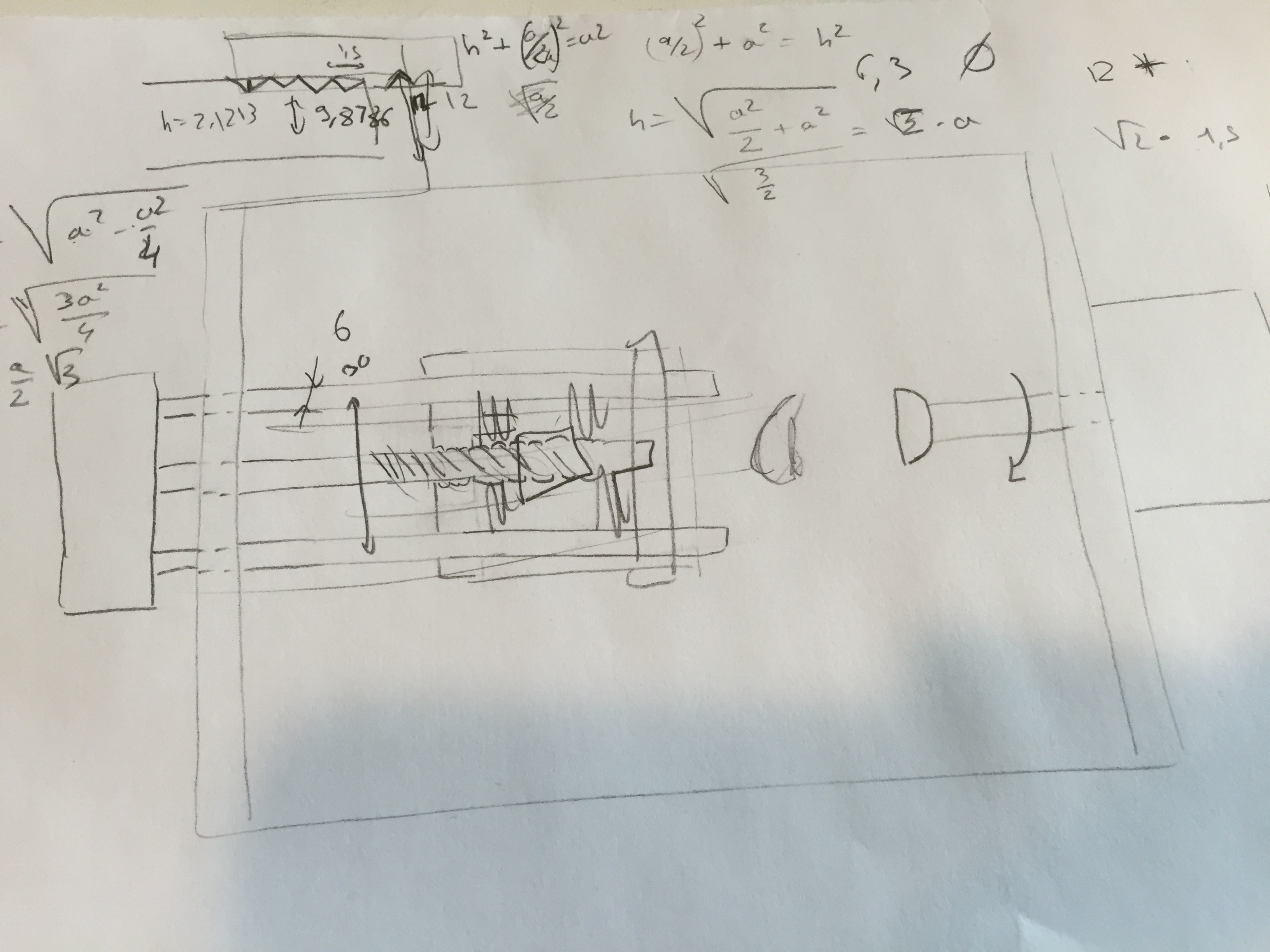

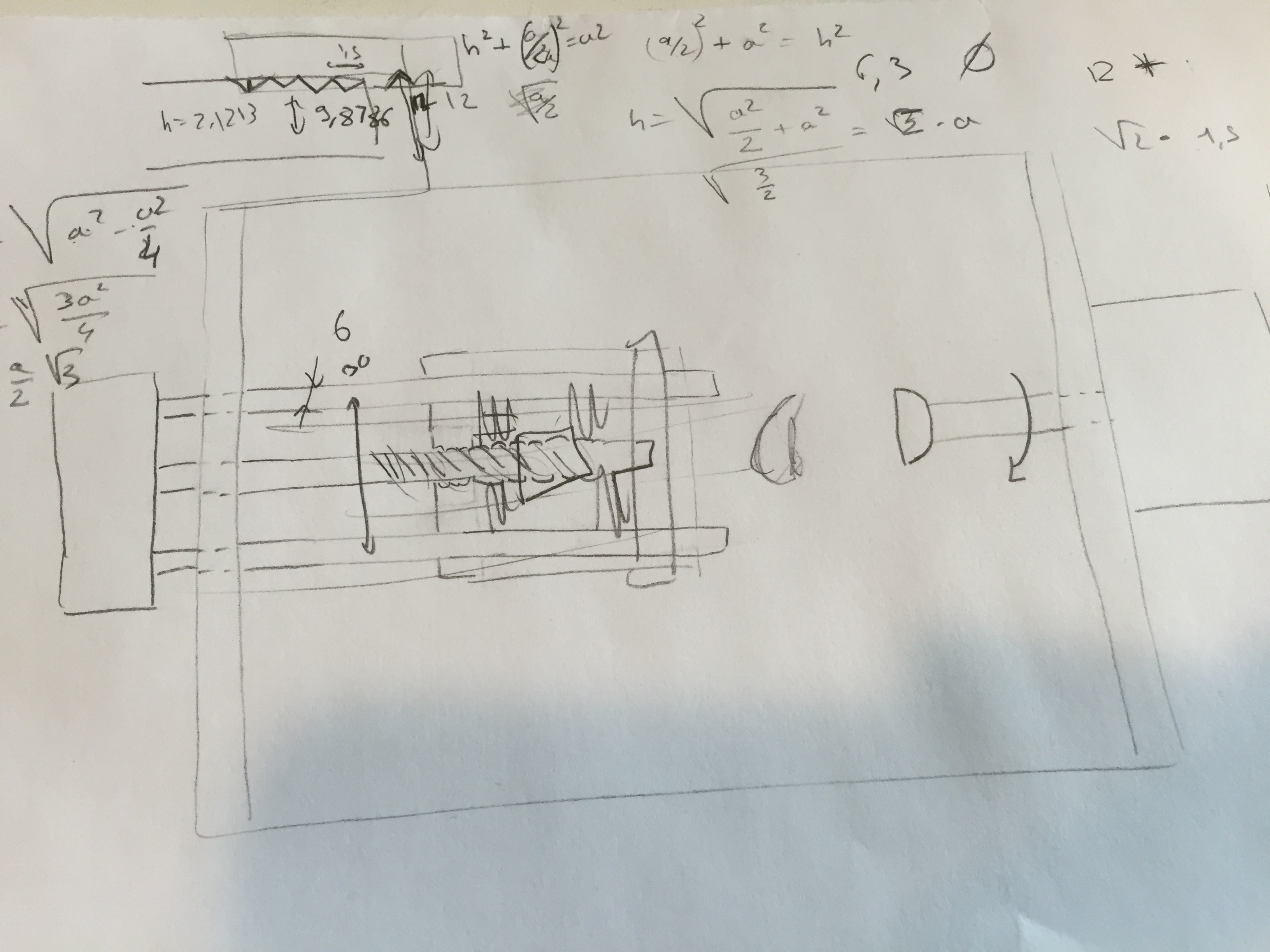

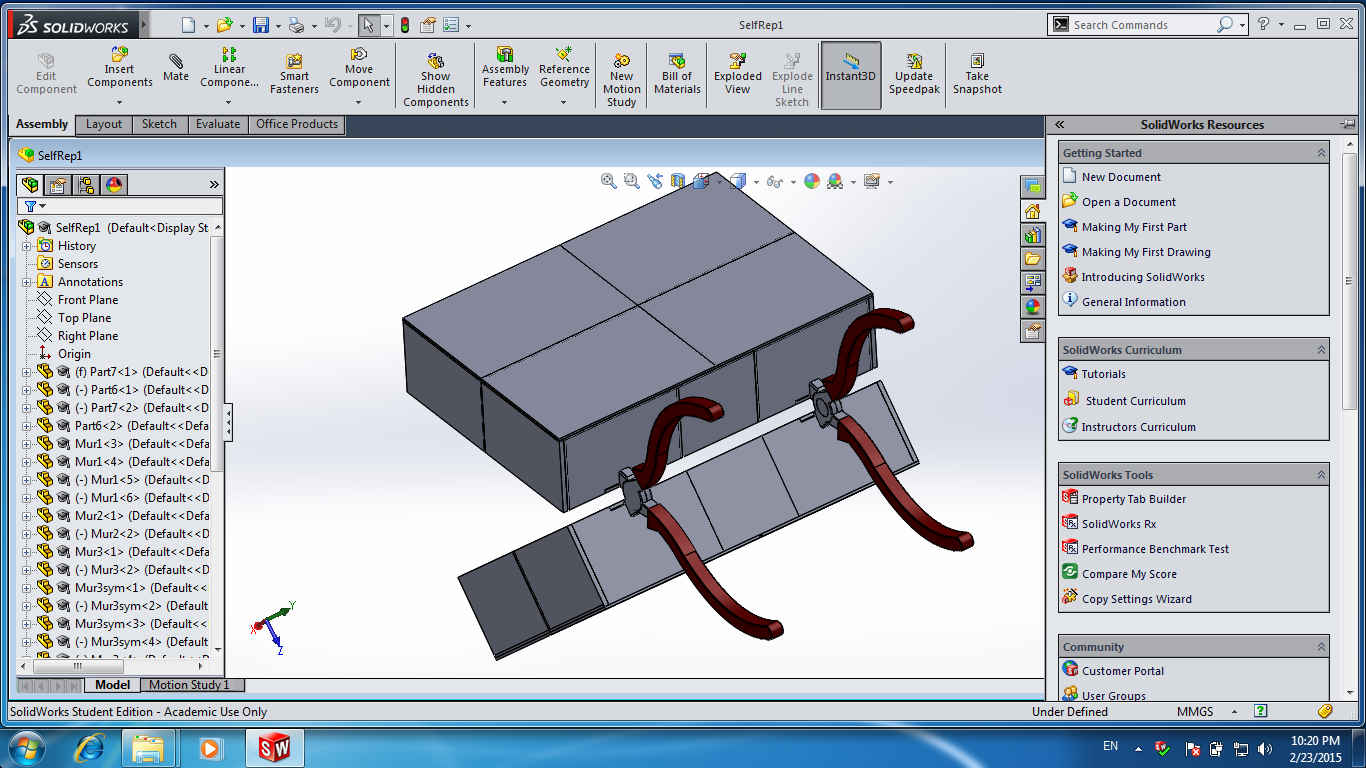

Paradox: How to fit a mold into itself? Building the system out of modulable interlocking puzzle-like pieces.

Puzzle modulable mold

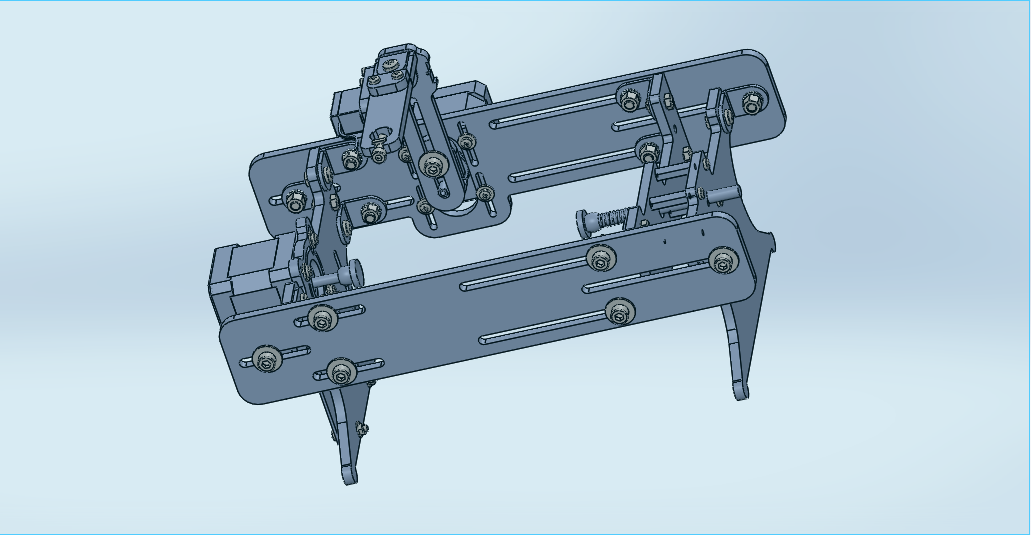

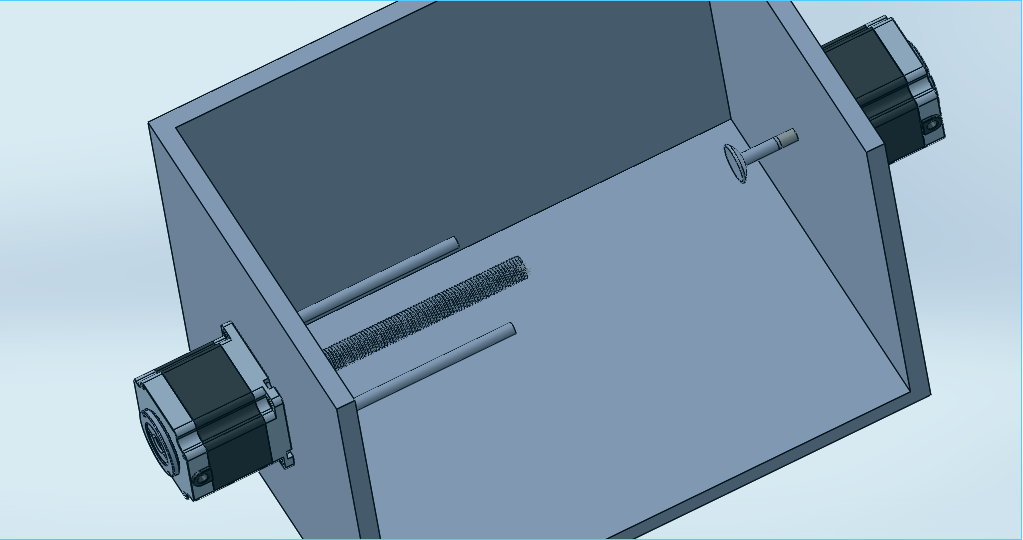

For this system, you need two initial machines to create a third one. One machine assembled that serves as the "machine", the other one is disassembled and serve to create the alpha version of the molding pieces For the current version, the pieces come as twins, so to build one machine, the system has to run twice.

Demo of the model in class

Assignment 3: Materials

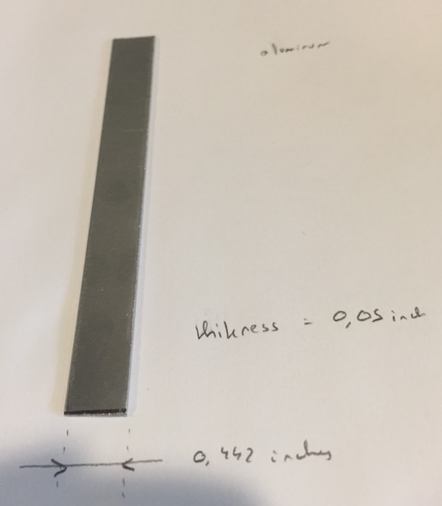

Aluminum tension test

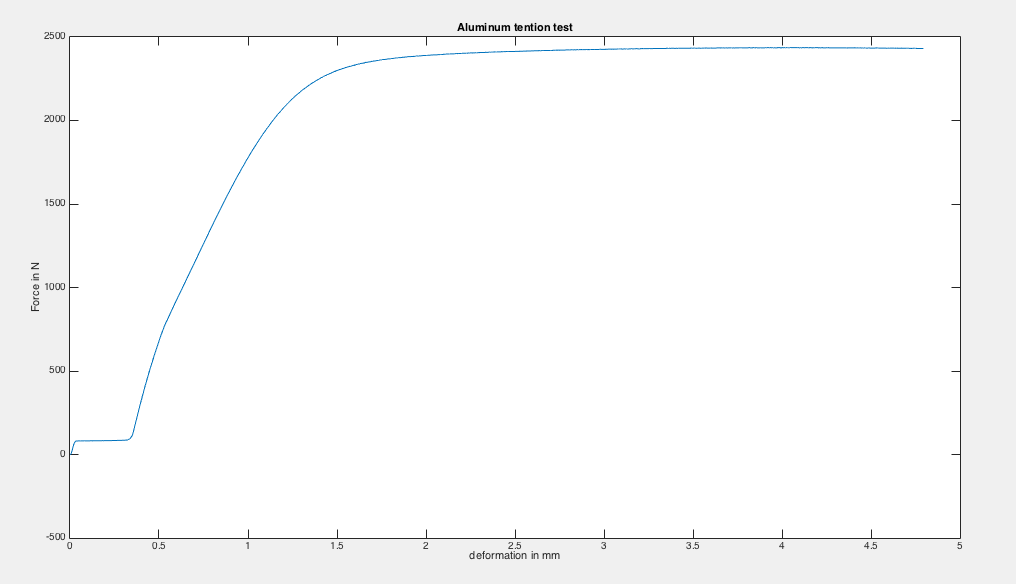

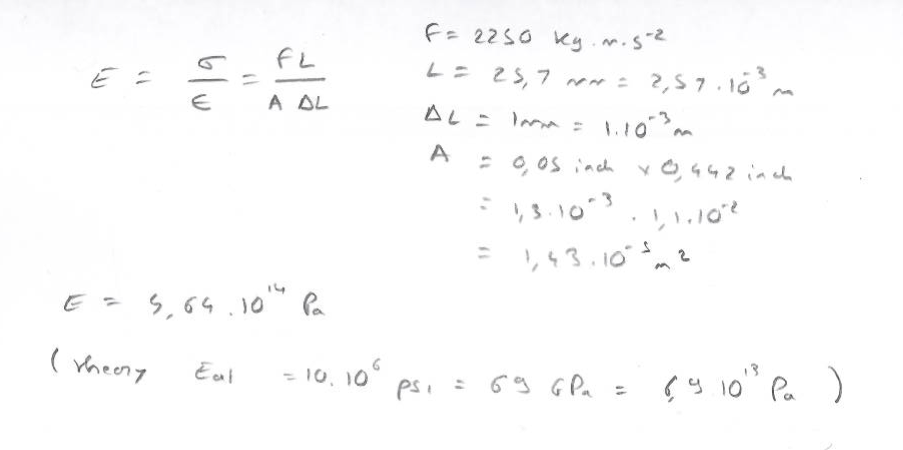

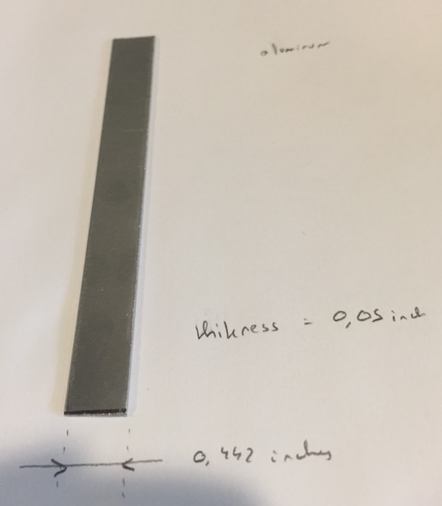

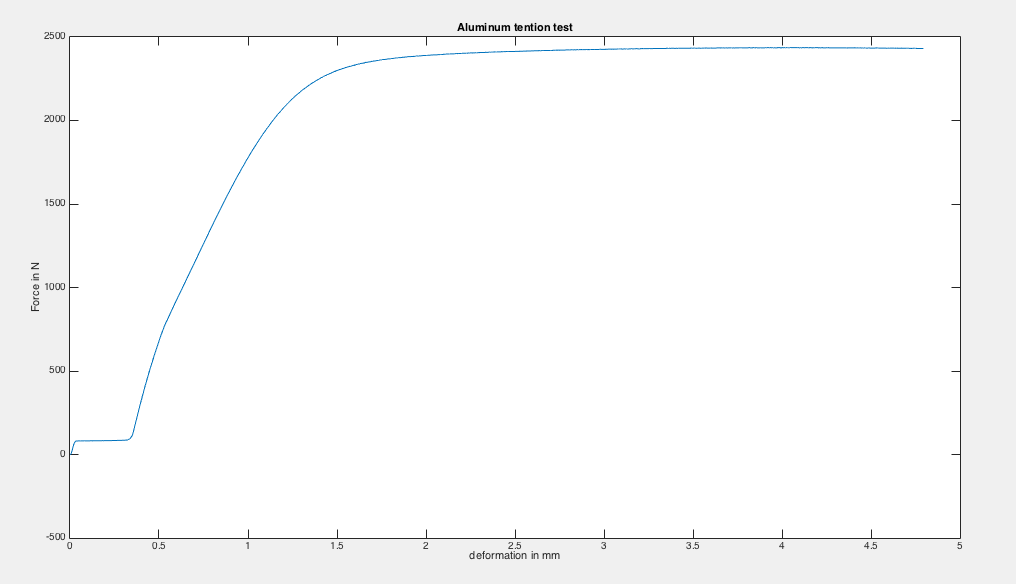

We tested the sample in tension and obtained the following curve:

We suspect that the semple has been speeping between the fixation jaws because of the flat plateau of the curve after the elasticity zone and also because the sample did not break.

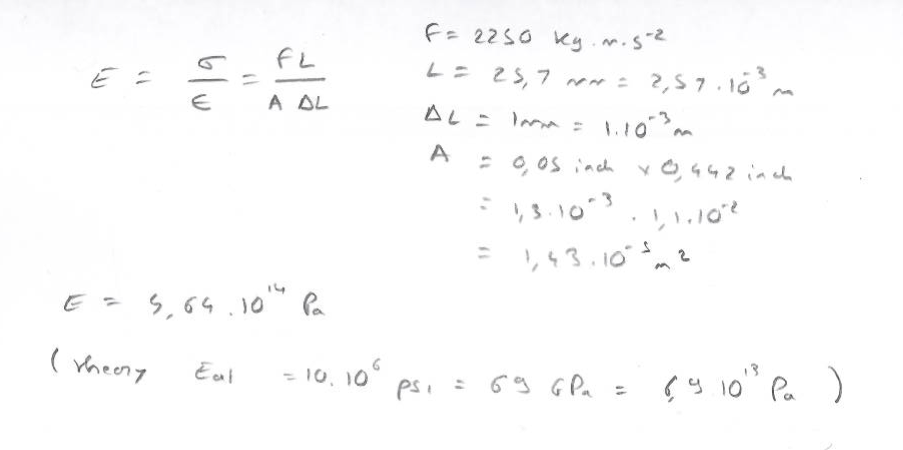

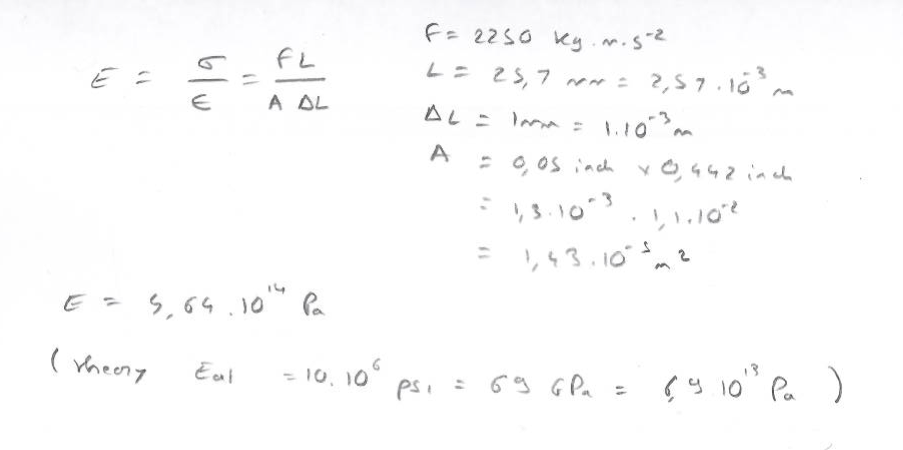

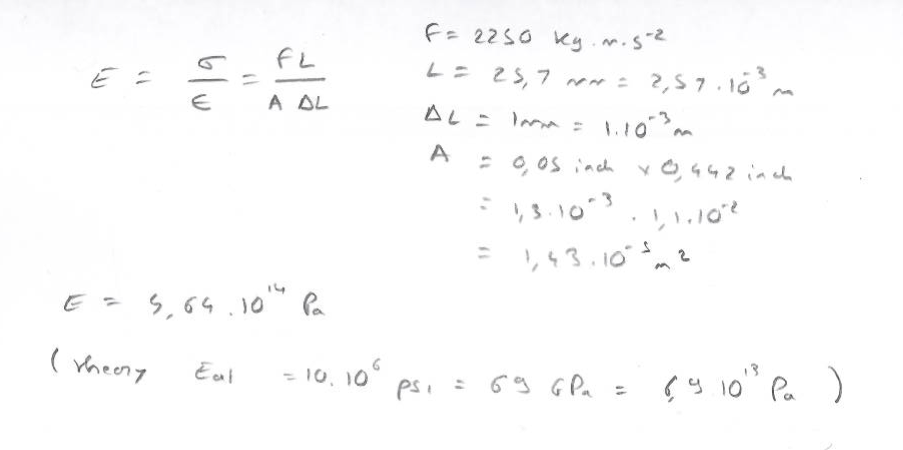

We compute the E experimental and compare it with E (al) theoretical

We tested the sample in tension and obtained the following curve:

We suspect that the semple has been speeping between the fixation jaws because of the flat plateau of the curve after the elasticity zone and also because the sample did not break.

We compute the E experimental and compare it with E (al) theoretical

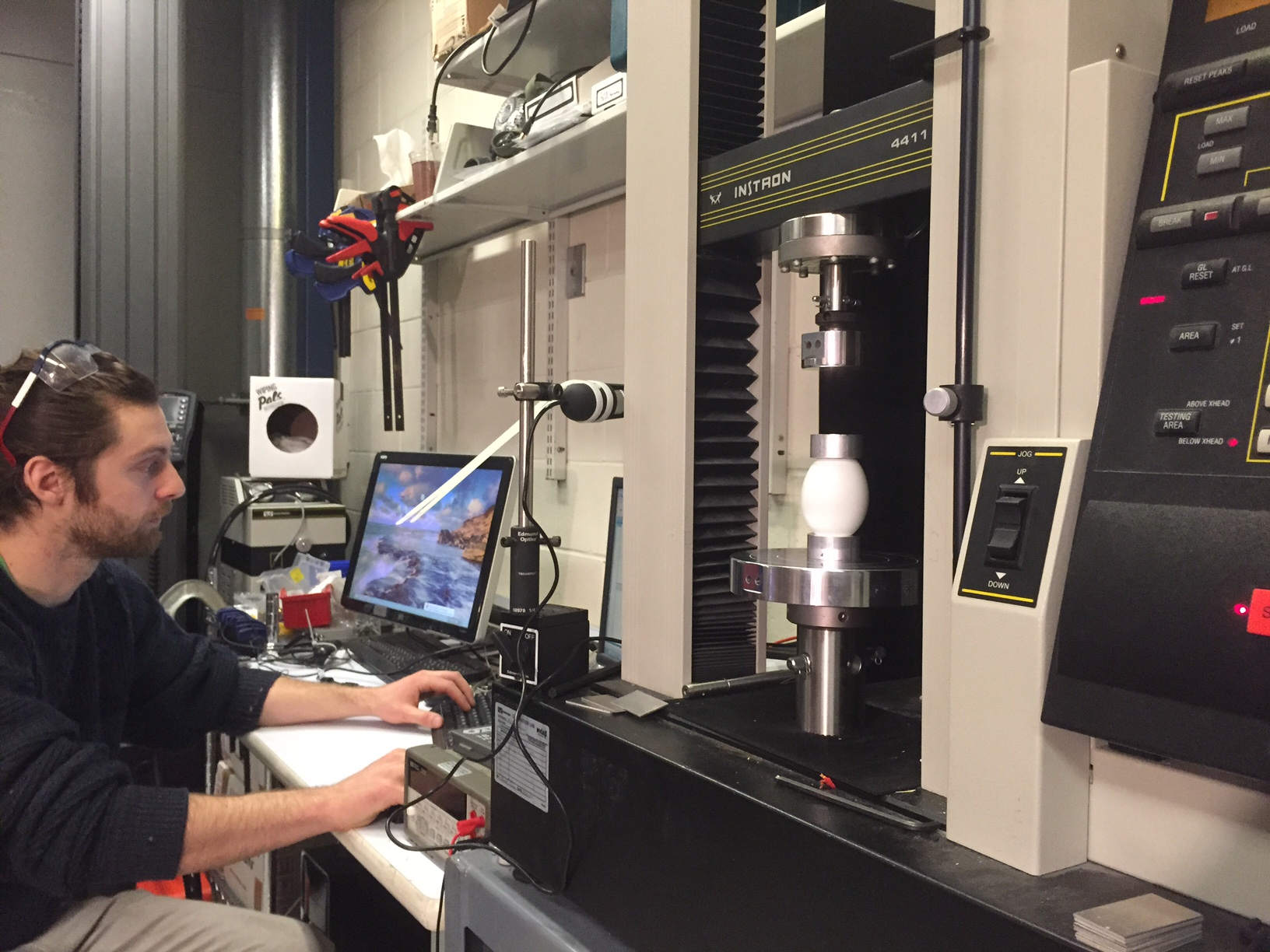

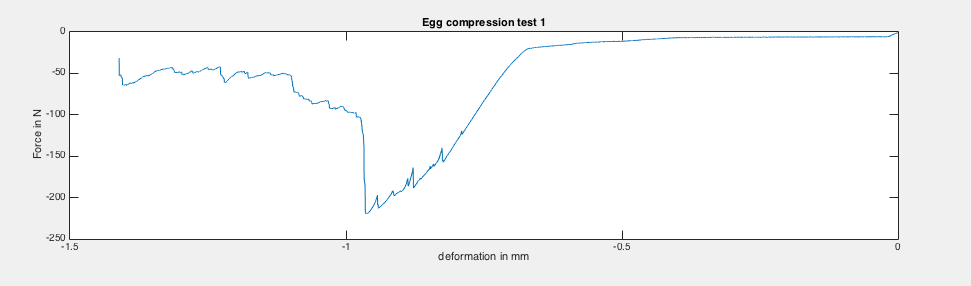

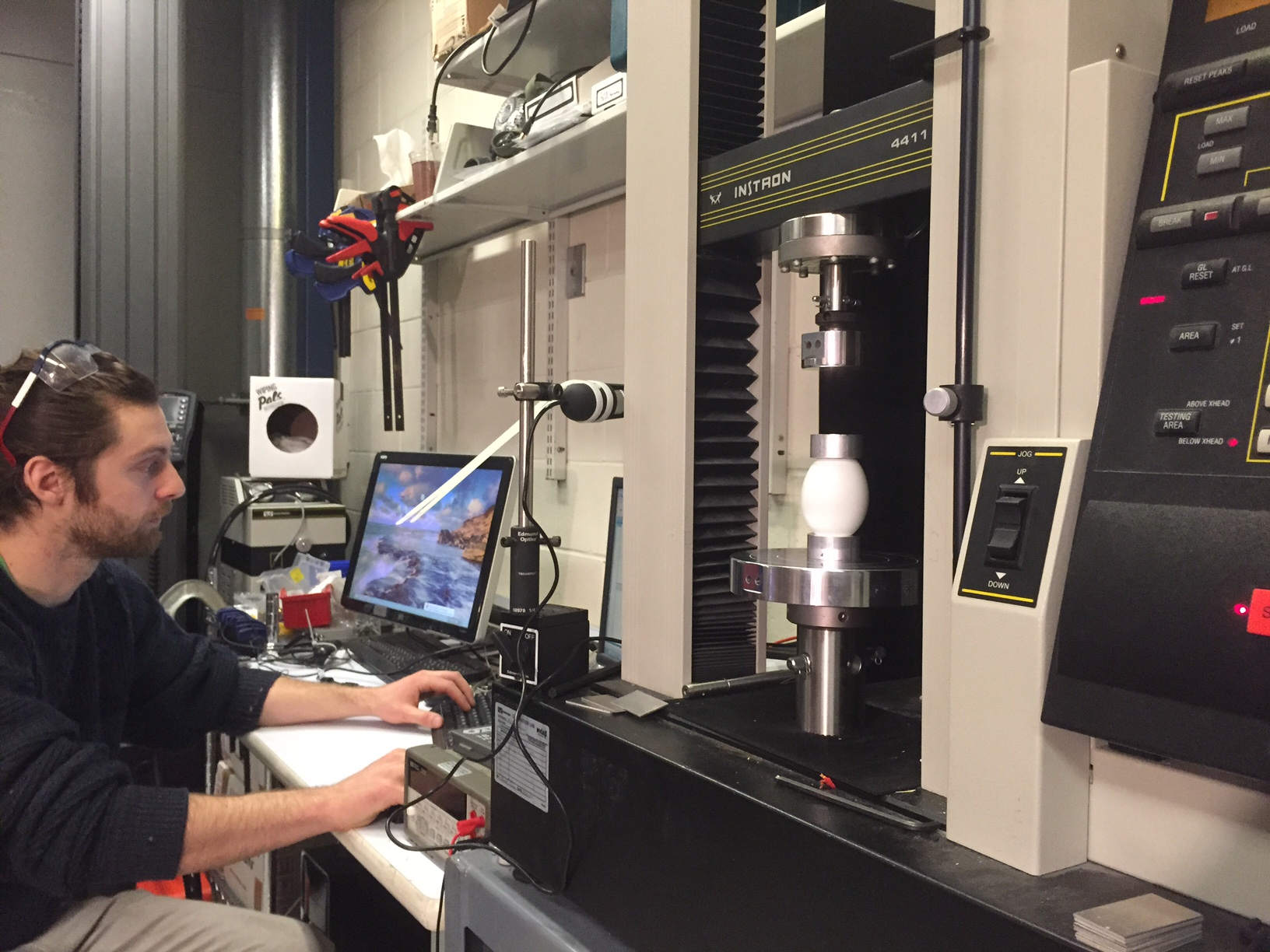

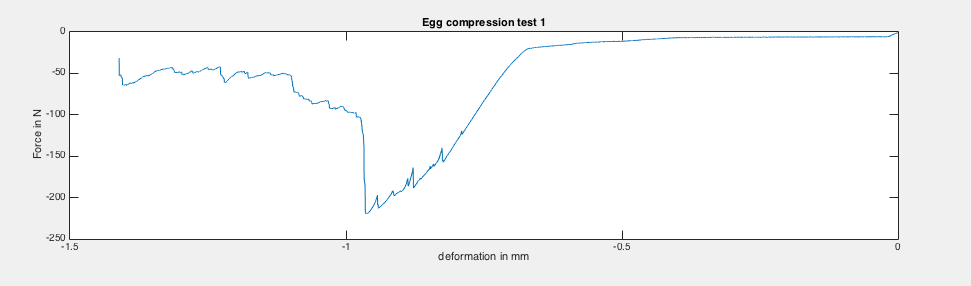

Egg compression test

We use duck, acid washed eggs (empty with no cuticles).

We built cylindrical supports to keep the egg vertical. The contact line between the egg and the support is bevelled.

The settings of the Instrom are

- load cell of 500N

- compression of 2 mm/min

- stop at 40 % on the curve

In the fist trial, the egg resisted to a load of 200 N

The egg broke in reveral microfractures all localised on the contact ring with the support

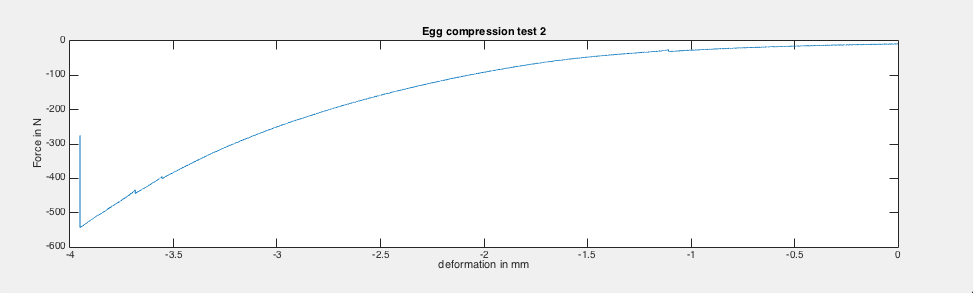

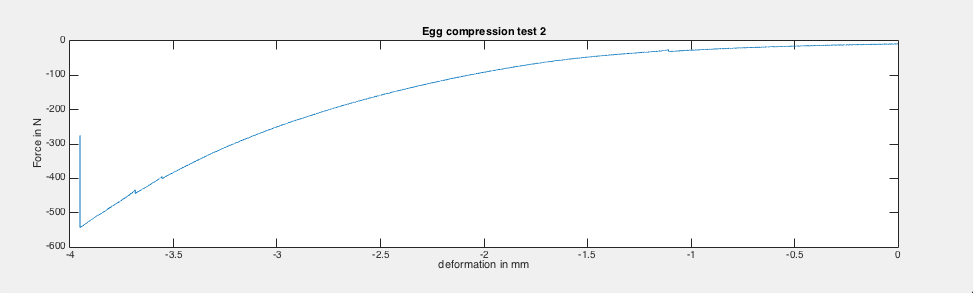

In the second trial, we protected the contact area with rubber rings

This time the egg rististed to a load of 550 N

We compute the E experimental and compare it with E(chicken) computed in work by M.A. Tung and al.

Assignment 4: Mechanisms

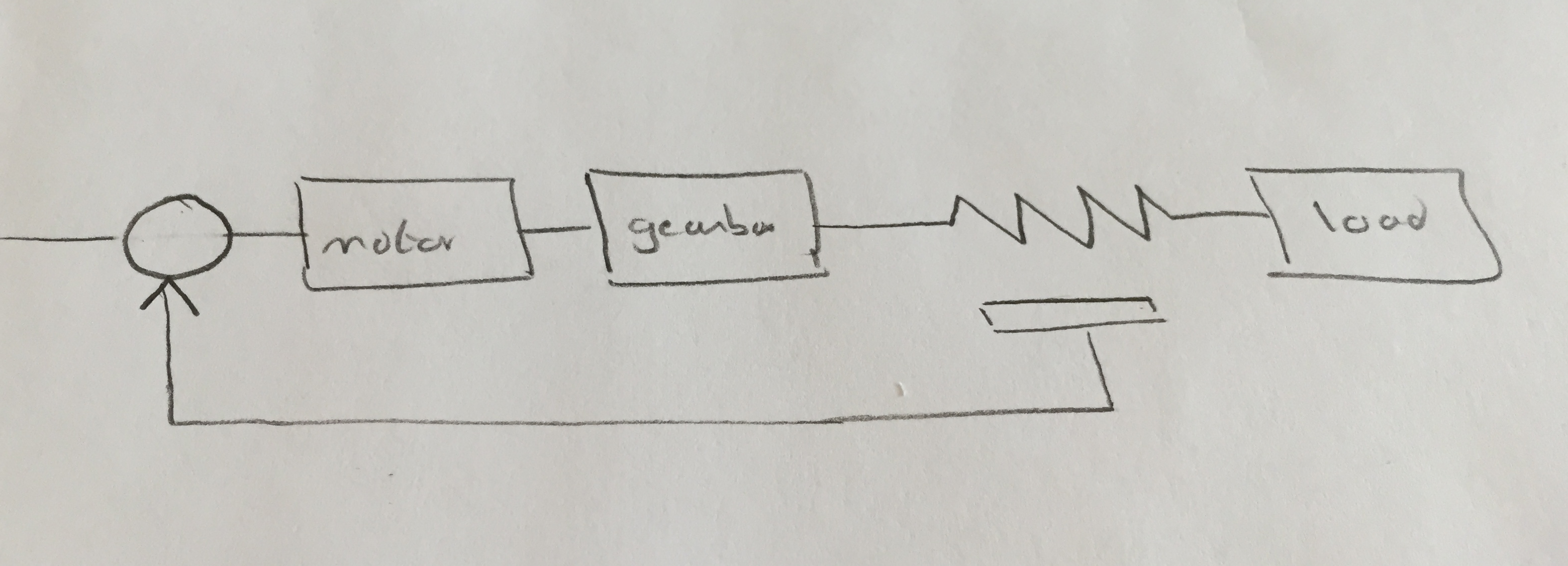

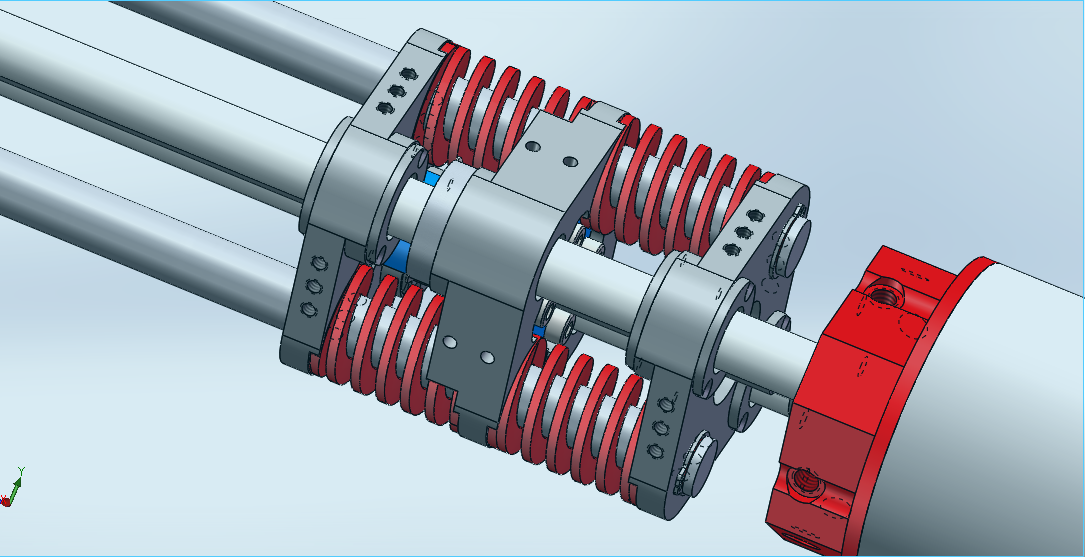

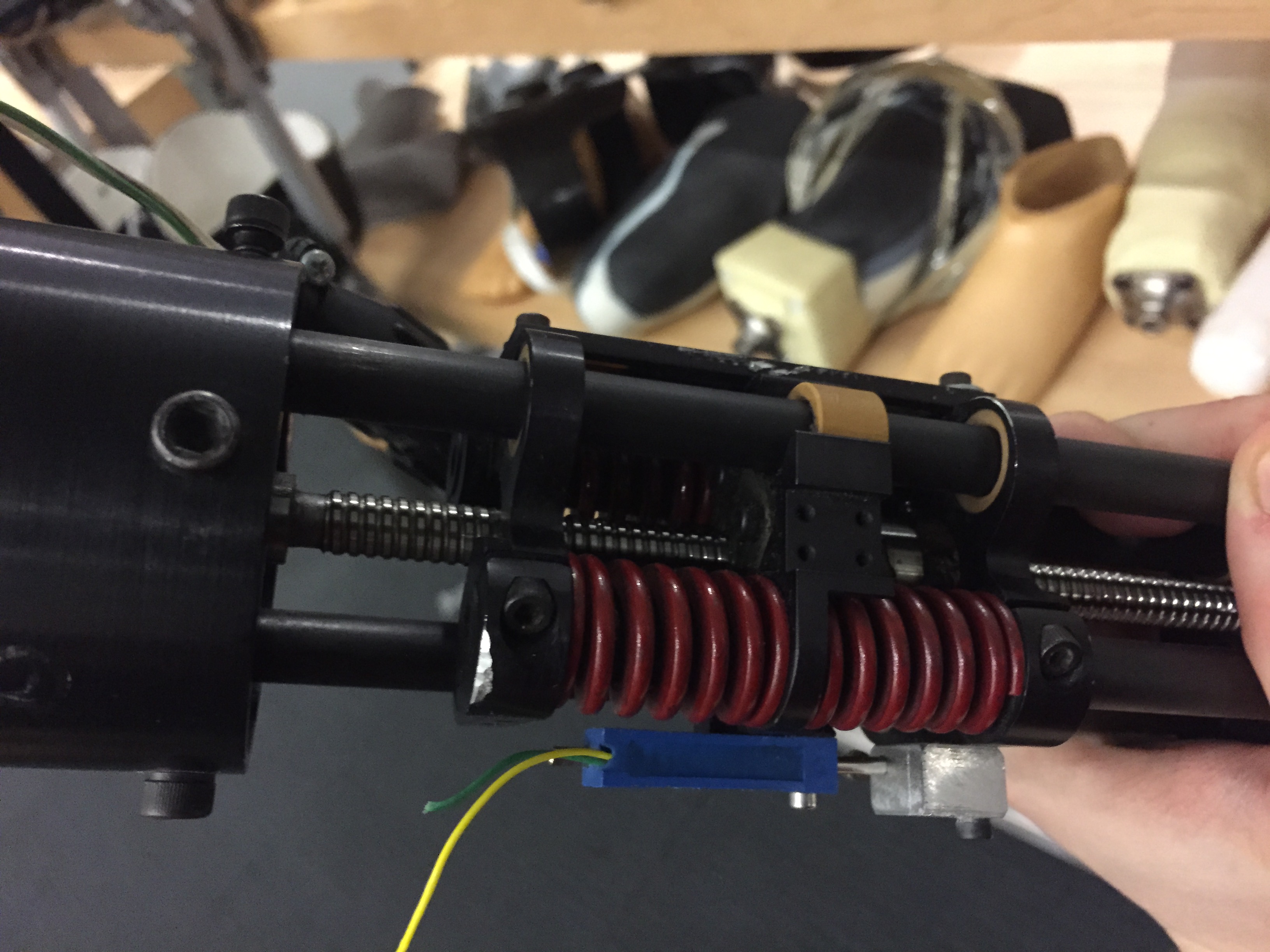

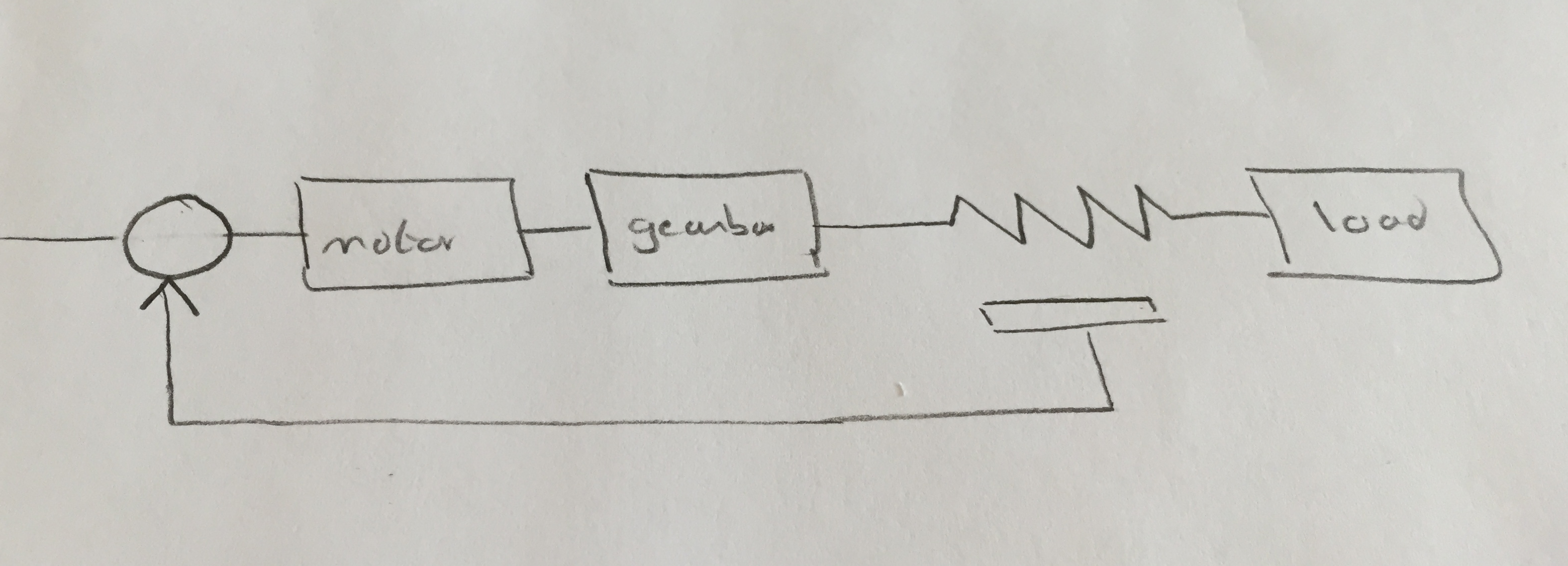

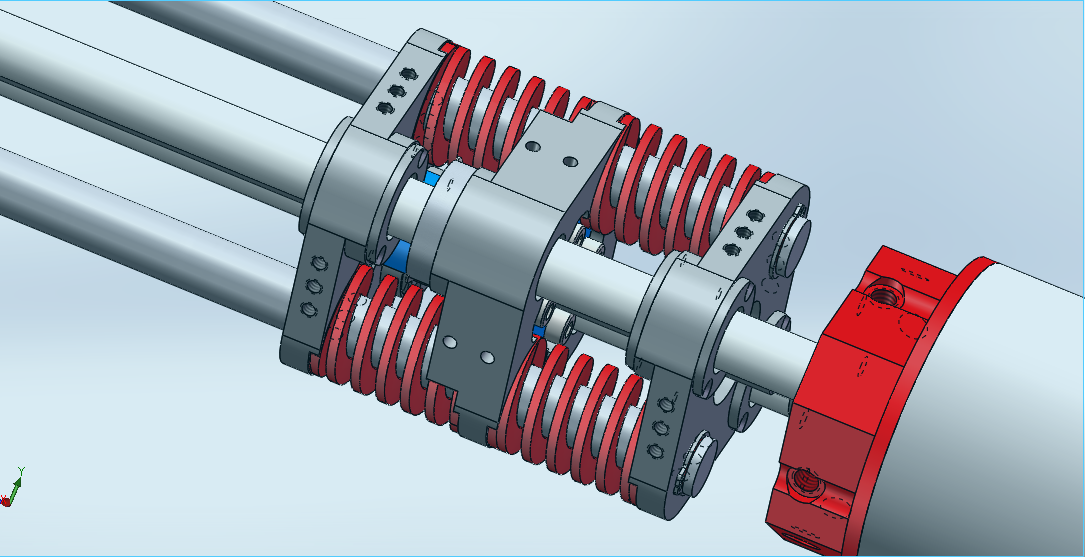

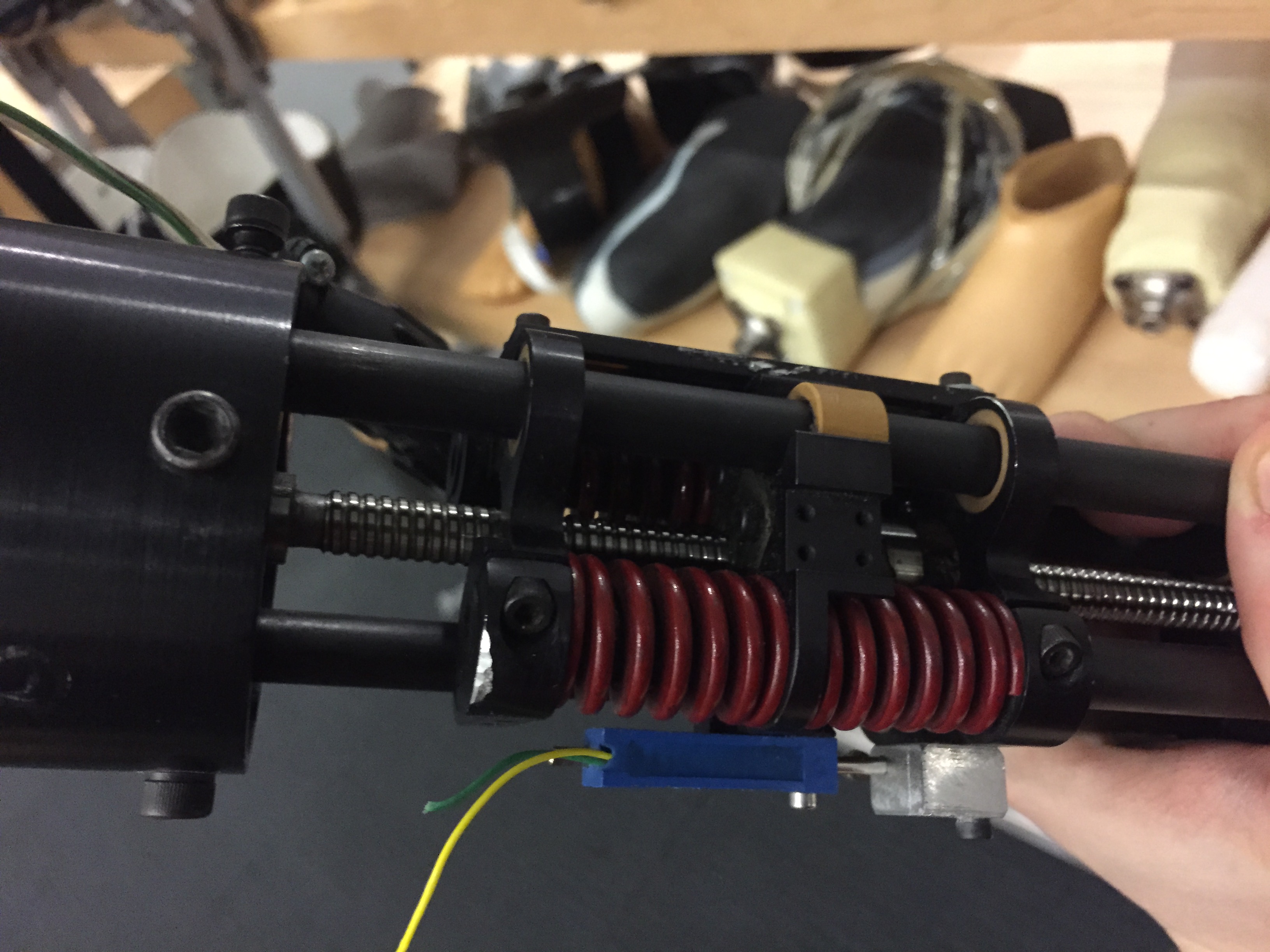

Series Elastic Actuators

Matthew M. Williamson and Gill A. Pratt

MIT MS Thesis

Report on SEA

Applications

- to store energy in the spring

- to protect the driving engine

- as an embedded force control device

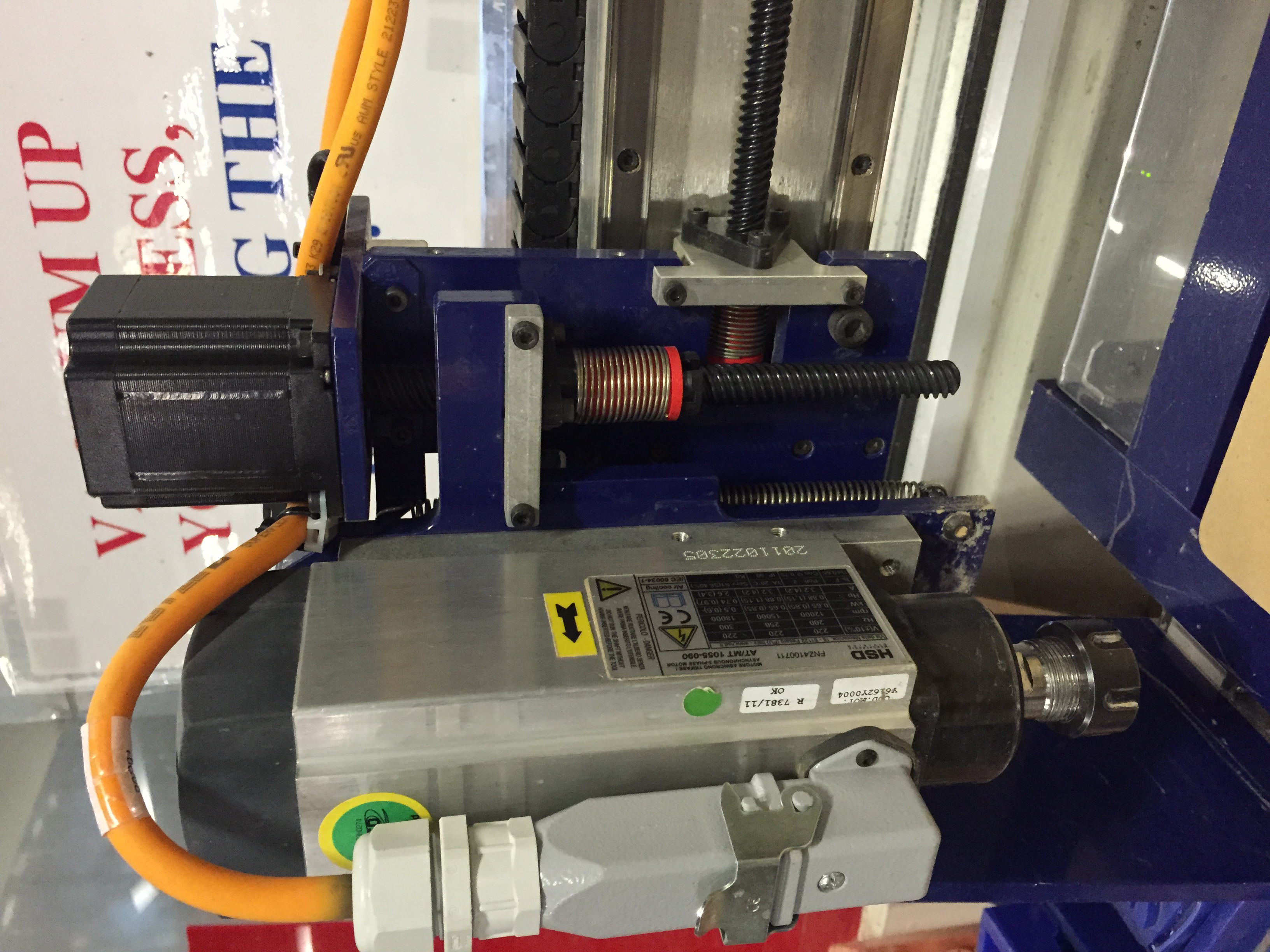

Application for the Egg carving machine

When it comes to the drilling part, it seems to me that we want the machine to be as stiff as possible and turning fast enough to not generate any non-desired force on the shell

SEA could be useful for the egg-holding part of the machine, to always control the force with which to touch/hold the egg.. That the egg could be positioned securately while being aware of the reaction force that will vary accrording to how much of the egg has been carved already… The shell will be made more and more fragile in the process.