This week, we were to brainstorm about potential capabilities and applications we would like to be responsible for in the class. Due to blizzard, I didn't complete my list.

Capability: Optical mouse++ position sensor

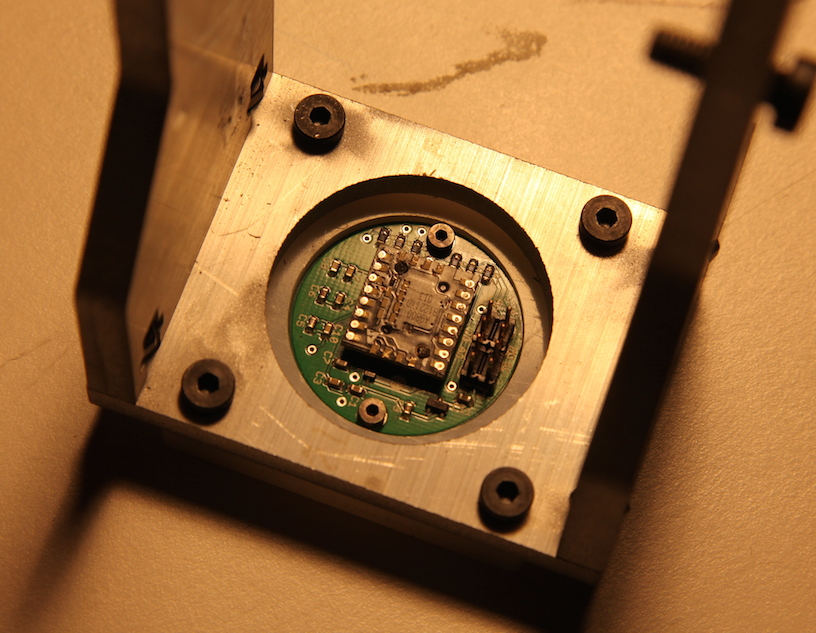

ADNS-9800 with a diy breakout board. High resolution device for measuring velocity. 10^4 counts per inch. Integration causes drift, like an accelerometer.

The ADNS can send the 30x30 pixel values over SPI. Below is an animated GIF where each frame is a movement of .001 inches.

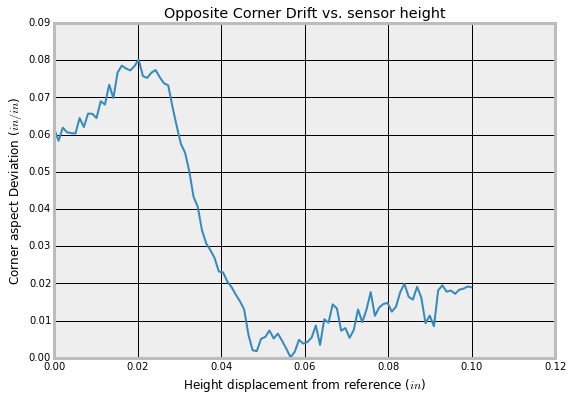

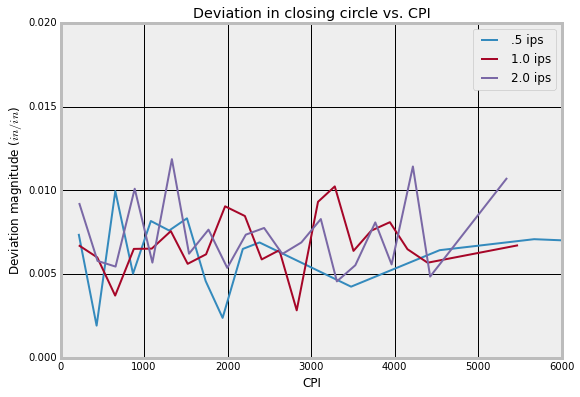

Accuracy depends on height. Precision doesn't depend on speed or the resolution setting.

I just added two millimeter-resolution ultrasonic sensors to this project, so next step will be using a Kalman filter to combine these complementary measurements.

Application: Precision cutting of composite tube and rod.

Composite tube cutting jig with distance measurement. This is fussy business. My machine would use a dremel abrasive wheel to cut, while automatically rotating the tube. A water drip would prevent the hazardous dust from getting in the air. A hard stop would hold the tube at a specific length, which would be measured with a combination of the optical mouse sensor for fine measurement with an optical encoder for coarse grain correction.

Application: Laser mouse cutter.

Maybe a bad idea...

Capability: Optical micrometer

Measure a dimension based on webcam. Used for getting consistency in extrusion.

Capability: 5 axis machining

Start with Handibot for rapid iteration.

Applications: ...

Applications: Knot tying machines