This week was devoted to project development, and continued documentation of work from the semester.

Lost foam casting

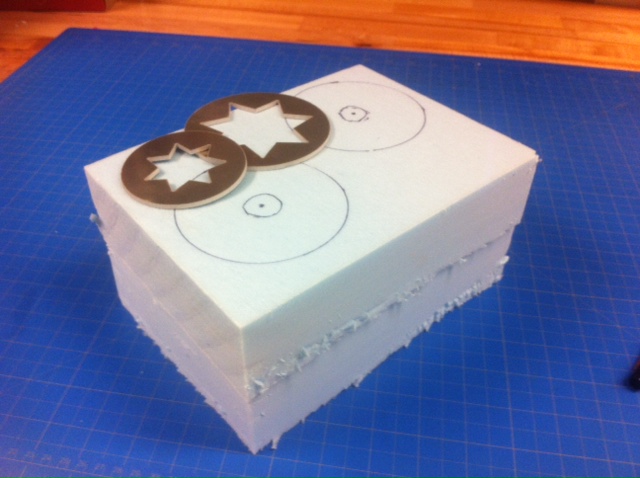

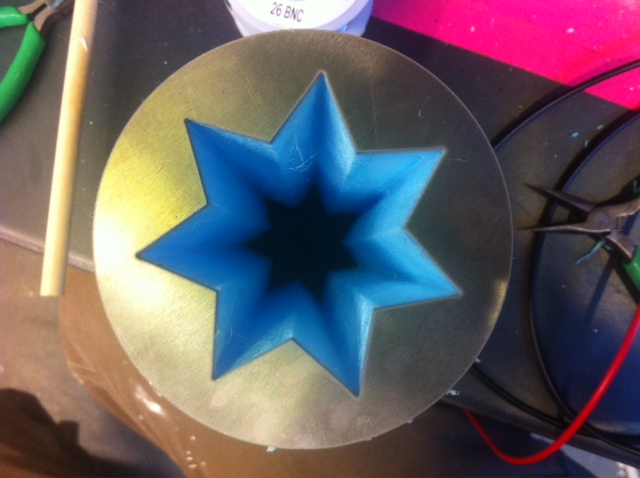

A couple weeks back I played with lost foam casting Aluminum for recycling off cuts from the waterjet. I decided to take as a test object an optic mold, a tool used in the glass shop, where I've been spending a lot of time this semester. To shape the foam, I used a piece of nichrome wire and a bench-top power supply to make a simple hot wire cutter. To guide the form, I just cut a pattern for the top and bottom faces and carefully traced between them with the wire.

Per advice from internet forums, I covered the foam with drywall mud (diluted with some water) and let it set overnight. In retrospect I should have given it more time to dry, but I was in a hurry.

The video below shows a test pour of molten aluminum into this mold. Note: this was done immediately below an exhaust snorkel to carry away the smoke.

The results of this first test weren't that great. First, I didn't get enough head pressure to push into all the corners of the mold. Second, I applied the drywall mud mixture too thick and it didn't capture all the internal features of the mold. Third, I should have removed/dissolved some of the foam first to avoid a lot of the flame and smoke. Some people use acetone to do this, but this can leave a thick residue that must be removed. I think I might next try a mold material I could melt out, like wax, instead of the foam.

Tube Cutter

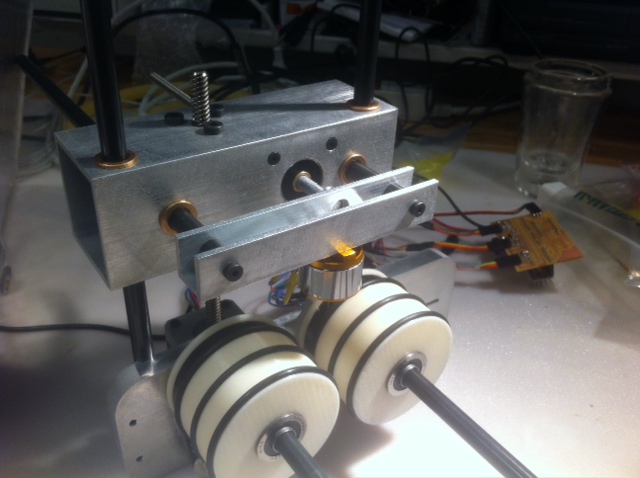

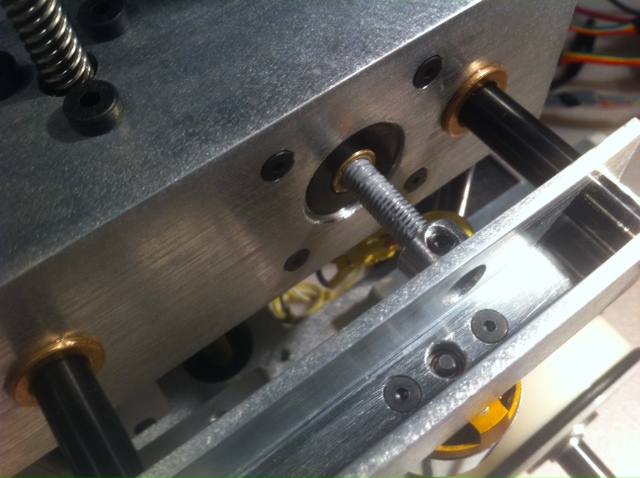

This week I continued work on my tube cutting workflows. I finished the y carriage and BLDC motor mount. I moved away from an explicit kinematic coupling, and opted instead for flat head screws, the conical surfaces of which locate the spindle in a simpler, but less repeatable way. I think for my purposes, this will be just fine.

I chose a non-captive lead screw NEMA 17 stepper motor to drive the y axis. Because the lead screw feeds through the Z stage, a lot of potential collisions in the work area area avoided.

Tube cutter web tool

I continued work on the javascript app that allows a user to design tubes to cut. I moved work from last week into a "specify" mode, and added functionality for a "fab" mode that talks directly to the machine. Communication is bidirectional right now, Right now I just have jogging the axes working, but next I'll add some simple homing routines, path planning (line drawing), and buffering.