<br>

[MAS.865](../../index.html) > [Motion](../../motion) > Dielectric Actuators

## Dielectric Actuators

#### High strain, High Energy Density

---

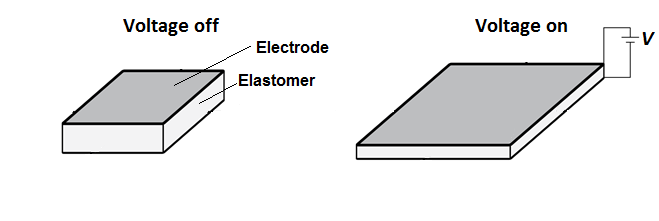

### Basic Theory of Operation

Dielectric actuators work using a similar way to piezoelectric actuators. Usually these actuators take the form of Dielectric Elastomer Actuators (or DEA's). They're also often colloquially referred to as "artificial muscles."

Just like with the piezoelectric actuators, these work by converting an electric field across their thickness into a strain. They exploit the poisson ratio of materials in order to convert a small change in thickness into a large change in area (length and width).

<iframe width="560" height="315" src="https://www.youtube.com/embed/hsd7_vQqt5w" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>

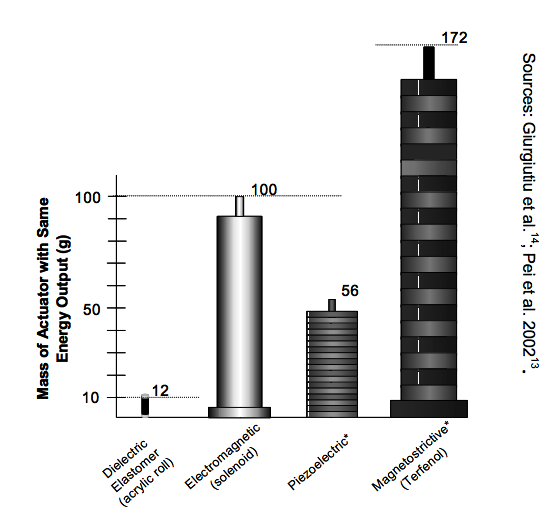

These are the subject of a lot of recent research because of their very promising energy densities and strains. One of the seminal papers that spurred the recent research was written by [Ron Pelrine et al](http://science.sciencemag.org/content/287/5454/836.full). In it, they show that by pre-straining the elastic layer, they were able to achieve strains of over 100%, meaning that it expands to more than double it's initial size.

The result of this, is that these actuators are actually quite easy to make yourself and often requires just some 3M VHB (very high bond) tape, some carbon grease or powder, and a high voltage supply. It turns out that the widely available 3M VHB tape just happens to have the right dielectric and mechanical properties. [Here is a very good tutorial for how to make these from scratch.](https://www.youtube.com/watch?v=uw8FLgiXsmk).

The one caveat to this is that these actuators do require very high voltages: usually several hundred to several thousand volts. This is of particular concern for embedding these actuators in small-scale devices (where they would be well suited) since the high-voltage drive electronics has not been able to be sufficiently miniaturized.

### Configurations

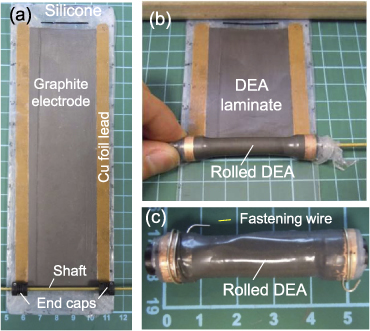

#### Rolled

These actuators can be [rolled to form dense stacks with much higher forces](http://iopscience.iop.org/article/10.1088/0964-1726/23/2/025021).

#### Spring Roll Bending Actuator

By rolling the acrylic and electrode around a central spring, they can make a very high force and large stroke actuator.

These can be made into bending actuators by patterning the electrode before rolling, this enables separate voltage regions that can be excited to bend the actuator in one way or another:

<iframe width="560" height="315" src="https://www.youtube.com/embed/eIh8L59sd30" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>

### Applications

These are being used increasingly more these days for applications ranging from [transparent loudspeakers](http://science.sciencemag.org/content/sci/341/6149/984.full.pdf?sid=5490a6f0-a4d2-40bf-8abf-807eeeb34c8b) and [haptic devices](http://iopscience.iop.org/article/10.1088/1748-3190/12/1/011003) to, of course, creepy robots:

<iframe width="560" height="315" src="https://www.youtube.com/embed/7Qxvyw5tUko" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe>

#### Other Resources

- [A good page with information about modelling, fabrication, and testing.](https://softroboticstoolkit.com/book/dielectric-elastomer-actuators)

- [A very detailed book chapter](https://www.spiedigitallibrary.org/ebooks/PM/Electroactive-Polymer-EAP-Actuators-as-Artificial-Muscles--Reality-Potential/Chapter16/Application-of-Dielectric-Elastomer-EAP-Actuators/10.1117/3.547465.ch16)