"We shall never experience our relationship to the essence of technology so long as we merely conceive and push forward the technological, put up with it, or evade it. Everywhere we remain unfree and chained to technology, whether we passionately affirm or deny it. But we are delivered over to it in the worst possible way when we regard it as something neutral; for this conception of it, to which today we particularly like to do homage, makes us utterly blind to the essence of technology"

– Martin Heidegger, The Question Concerning Technology

Final Project

semi-automatic tablet loom / winding machine

Tablet weaving originated in ancient Egypt. The premise of this method is simple - a series of tablets (typically flat squares with 4 holes) are strung and arranged in a particular way to achieve certain structural and aesthetic goals. The inherent simplicity of the process allows for a great range of creative freedom. Within the context of a mechanism this freedom includes the shape of tablets, the number of holes (also determines number of colors in a particular column of a weave), warping strategies, the frequency and sequence of tablet roatation.

First steps

The most basic tablet weaving scheme.

Initial "design"

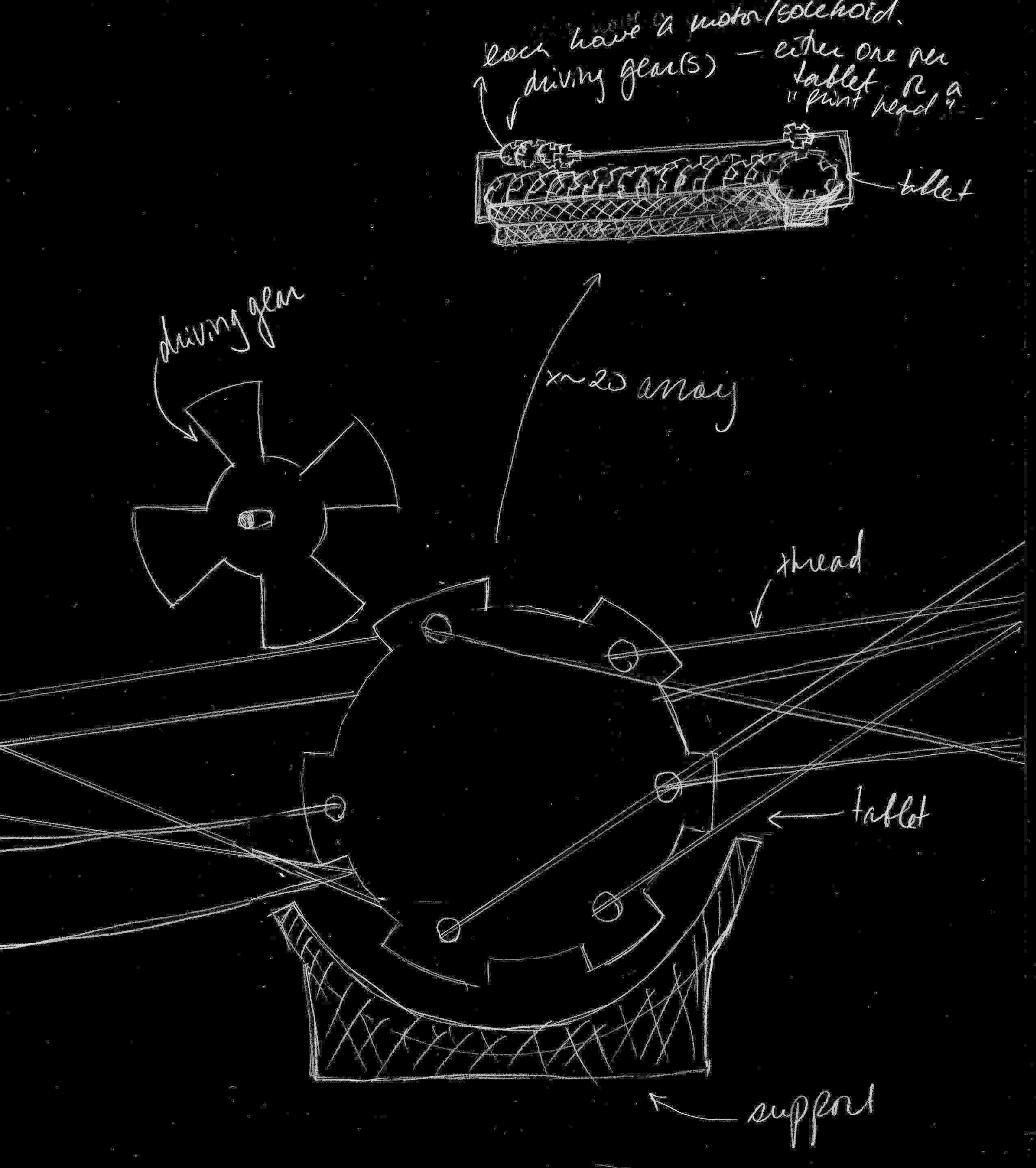

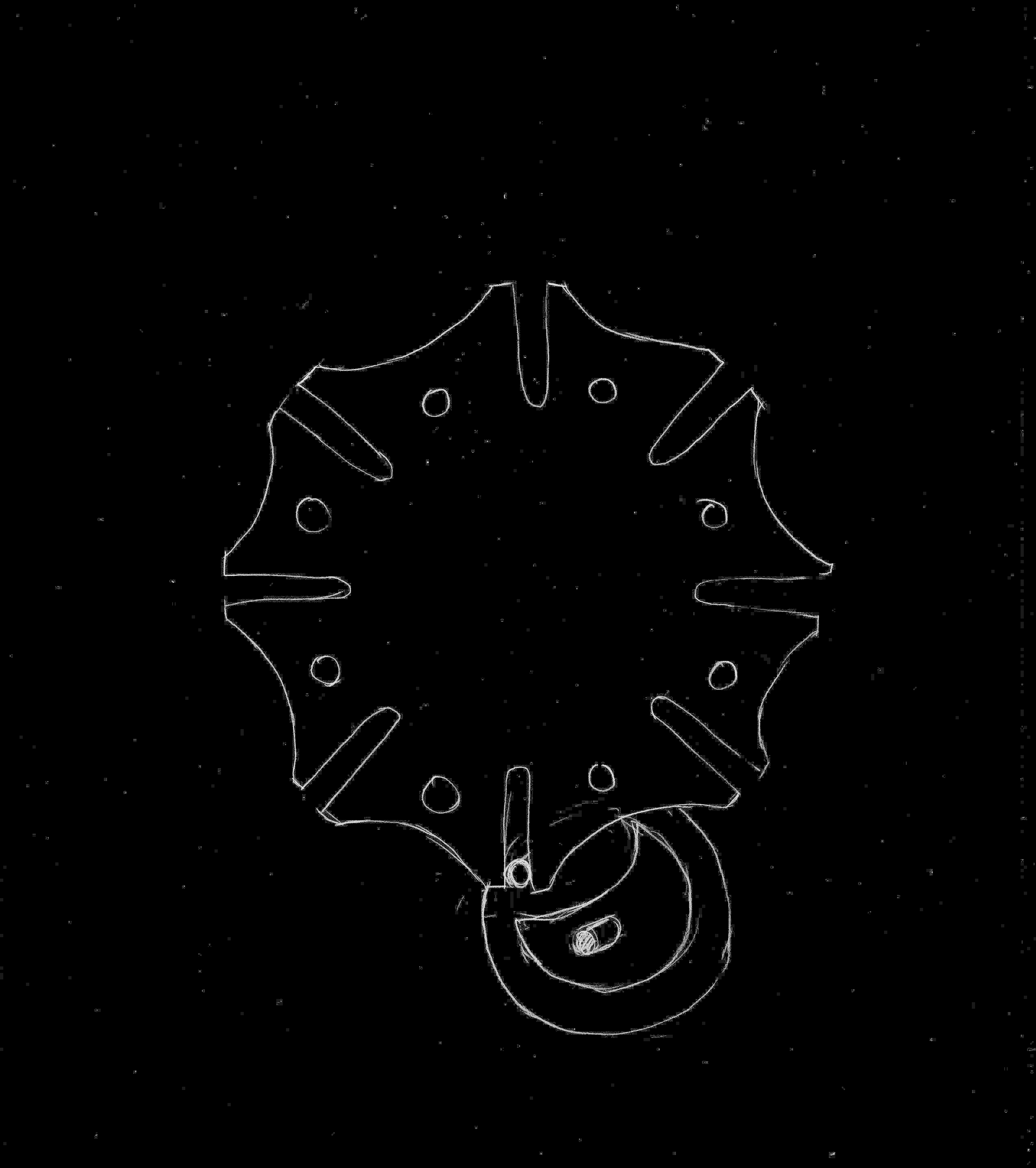

Rob made a great suggestion on considering the tablets as gears. I thought this would accomodate a lot of use cases and free the craft enthusiast from having to make separate tablets everytime. There was one caveat however, the "tablet" gear could not have a central axis of support due to the thread motions.

-

"Gears"

-

By Eyrian - Own work, CC BY-SA 3.0

-

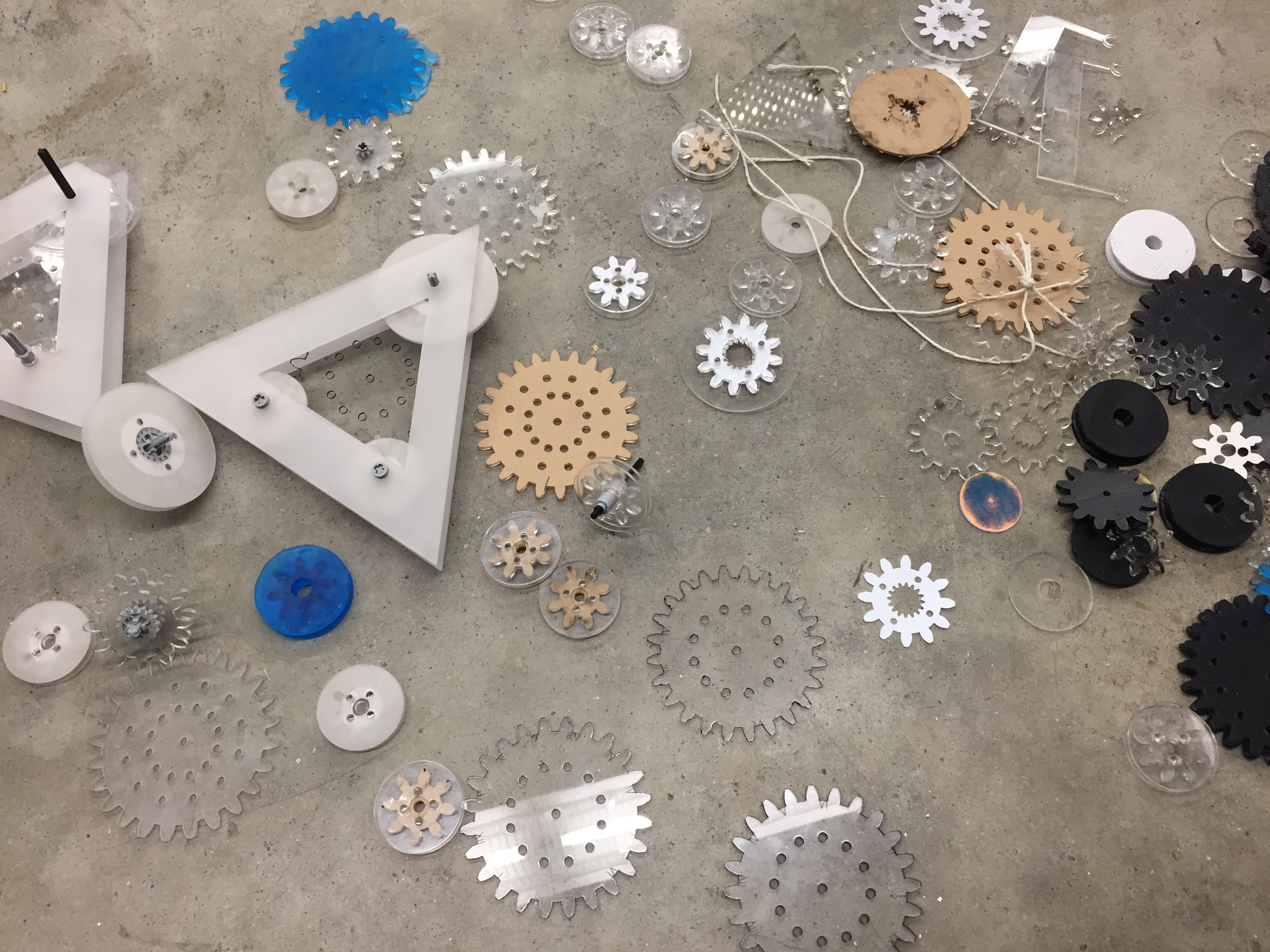

More "gears"!

Lots of gears

What followed was a lot of gears – helical and the straightforward kind in ABS, PLA, plexiglass, and the formlabs "tough resin" varieties. I settled on configuration that involved 1 driver gear, 1 tablet gear, and 2 supporting idler gears. The driver and the support gears are a cross between a gear and a spool – with walls on either side of the gear to keep the configuration in place. The driver gear is to be mounted onto a spline shaft while the idlers can be accommodated by a round rod. In the interim, I am using LEGO technic pieces to bind the structures.

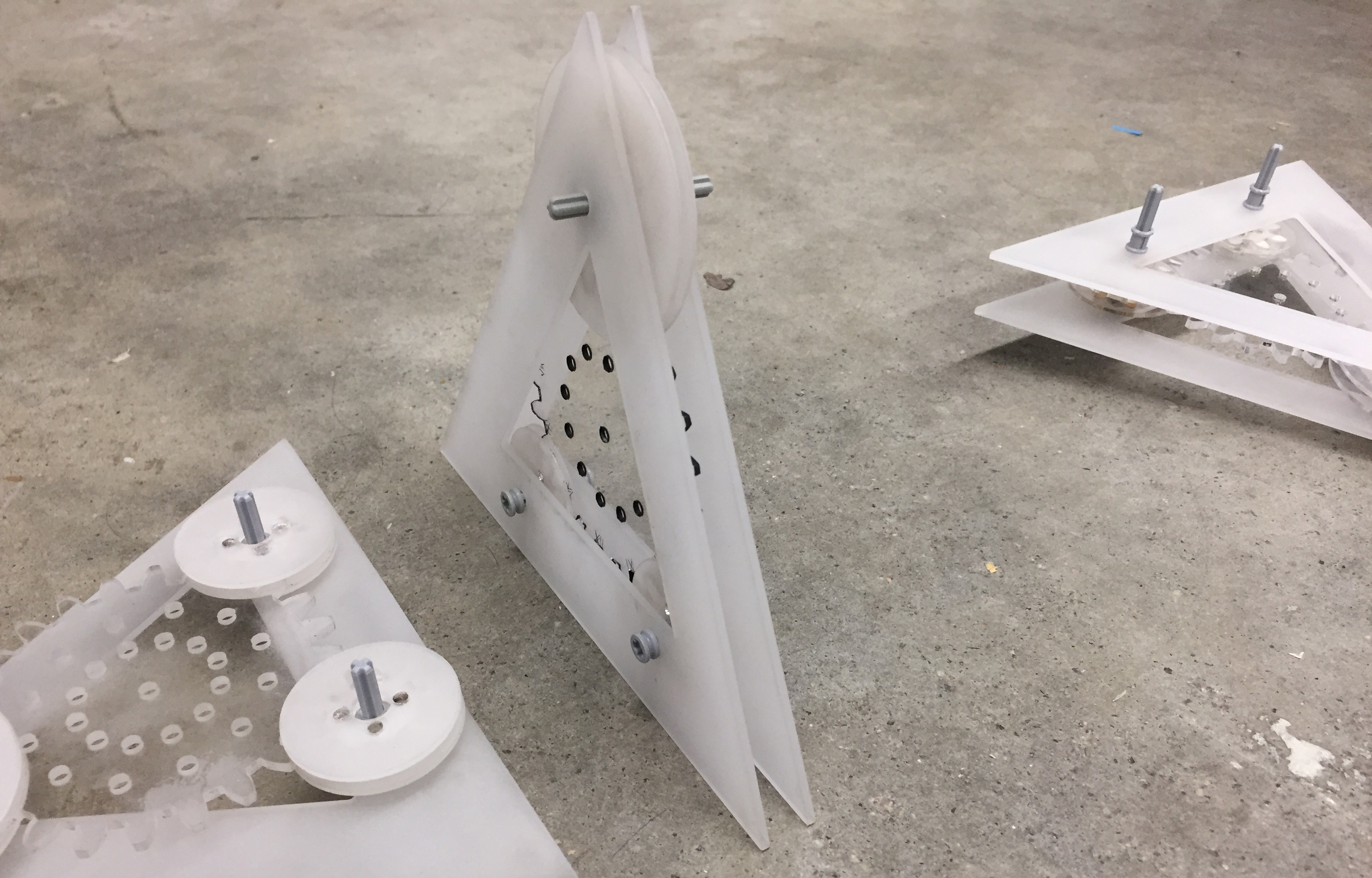

...And triangles

Here are a few examples of a single piece.

Goals?

It would be great to have the designs be modular and snap in place. However my first couple of attempts were silly. Some inspiration includes: gear train patent and Stig Anton Nielsen's braiding machine.

-

Handle-like bar binding to idlers and lego clasp

-

A combination of triangle and handle

-

Single structure binding together idlers and driver gears