Honghao's Rapid Prototyping Basement

Machines

1 meter (Bed size)

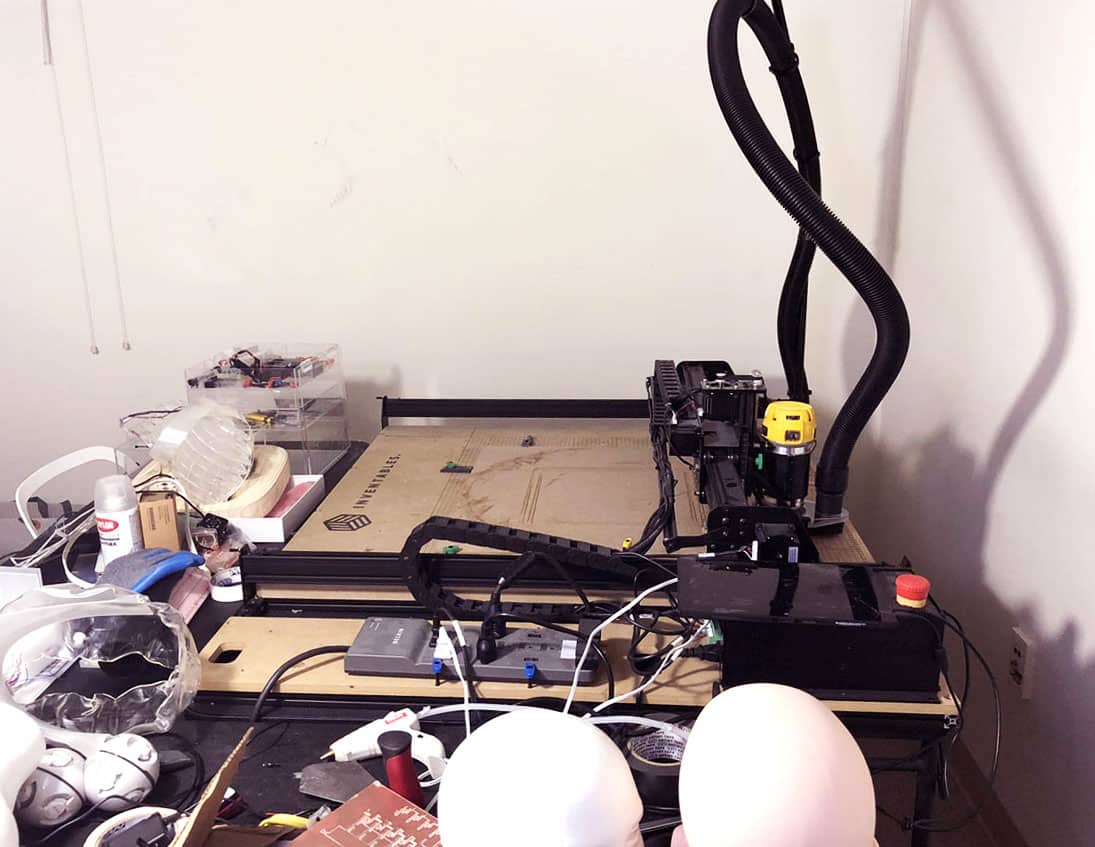

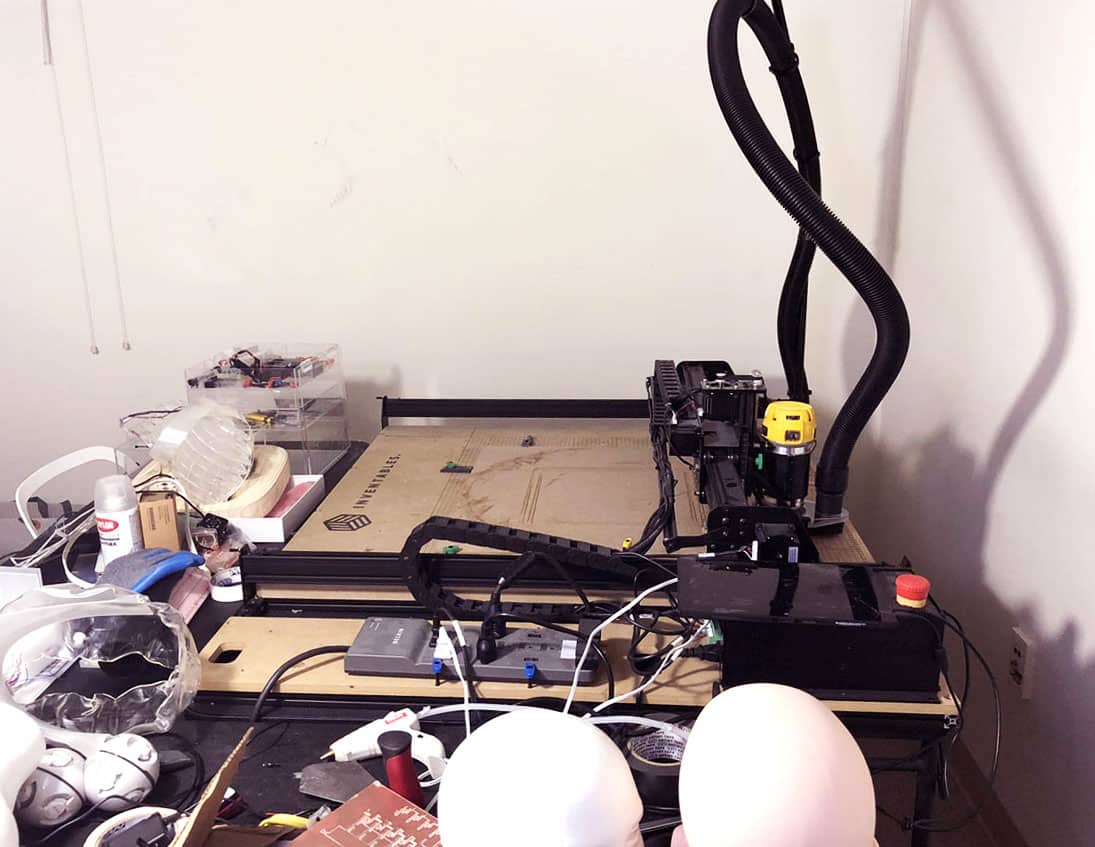

X-CARVE 1000MM

(Setup Time 15 hours)

|

|

X-carve 1000mm

|

| bed size: 800mm x 800mm x 65mm (Expandable) |

|

Software: Web-based Easel

Workflow: 3D model -> Vcarve(gcode) ->Easel

|

|

Things Could Go Wrong:

1. Shaft and screw on each axis's linear actuator will need grease from time to time

2. Belts should be tightened up, or it can secretly lose "steps"

3. Problem no.2 happen on one of the Y stepper motors that drive the X-axis gantry and X-axis end up being unparallel

(Time will slowly make the truth come to the surface. Reliable machines should eliminate slow-kill problems)

|

|

Interesting Features:

1.Expandable

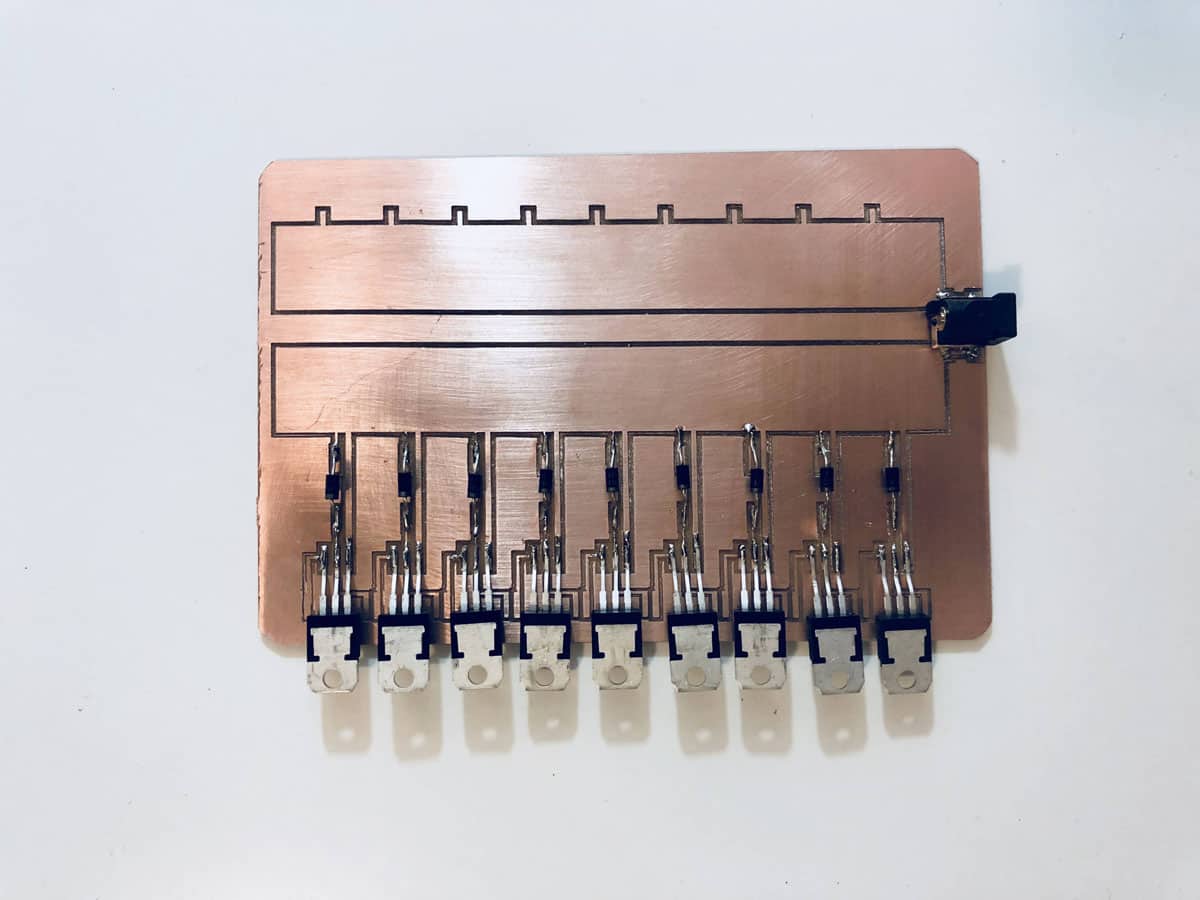

2. Can make PCB with through-hole package electric component

|

|

Interesting features:

Expandable

Make PCBs

Why can't make surface-mount package size:

1. larger bed size increase relative movements

2. larger bed size will have uneven Z-axis more easily

0.5 meter

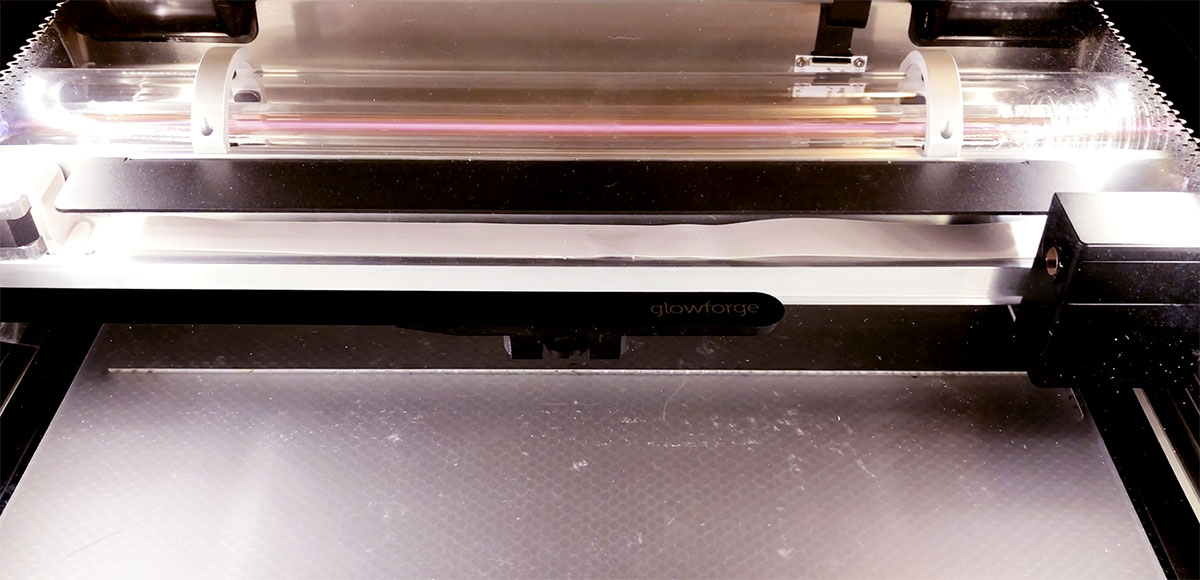

GlowForge

|

|

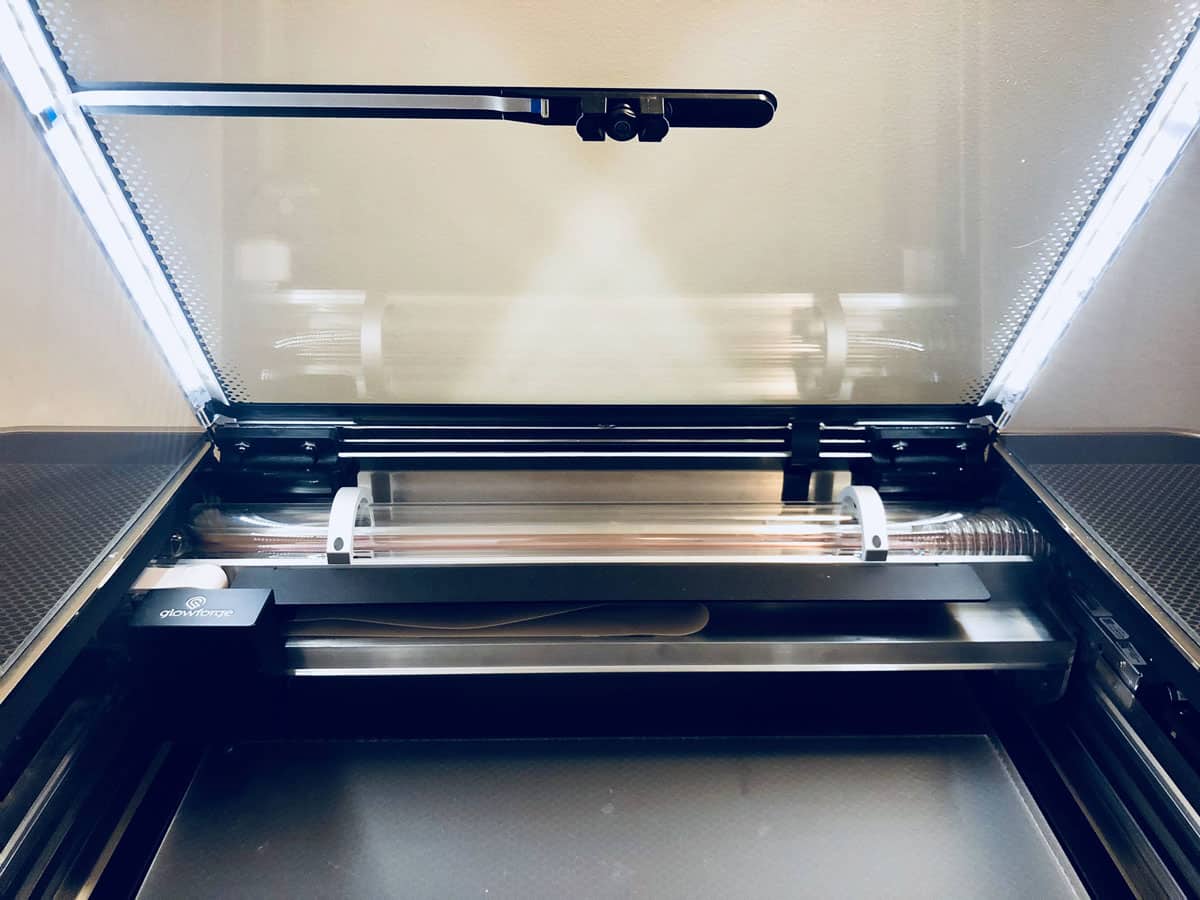

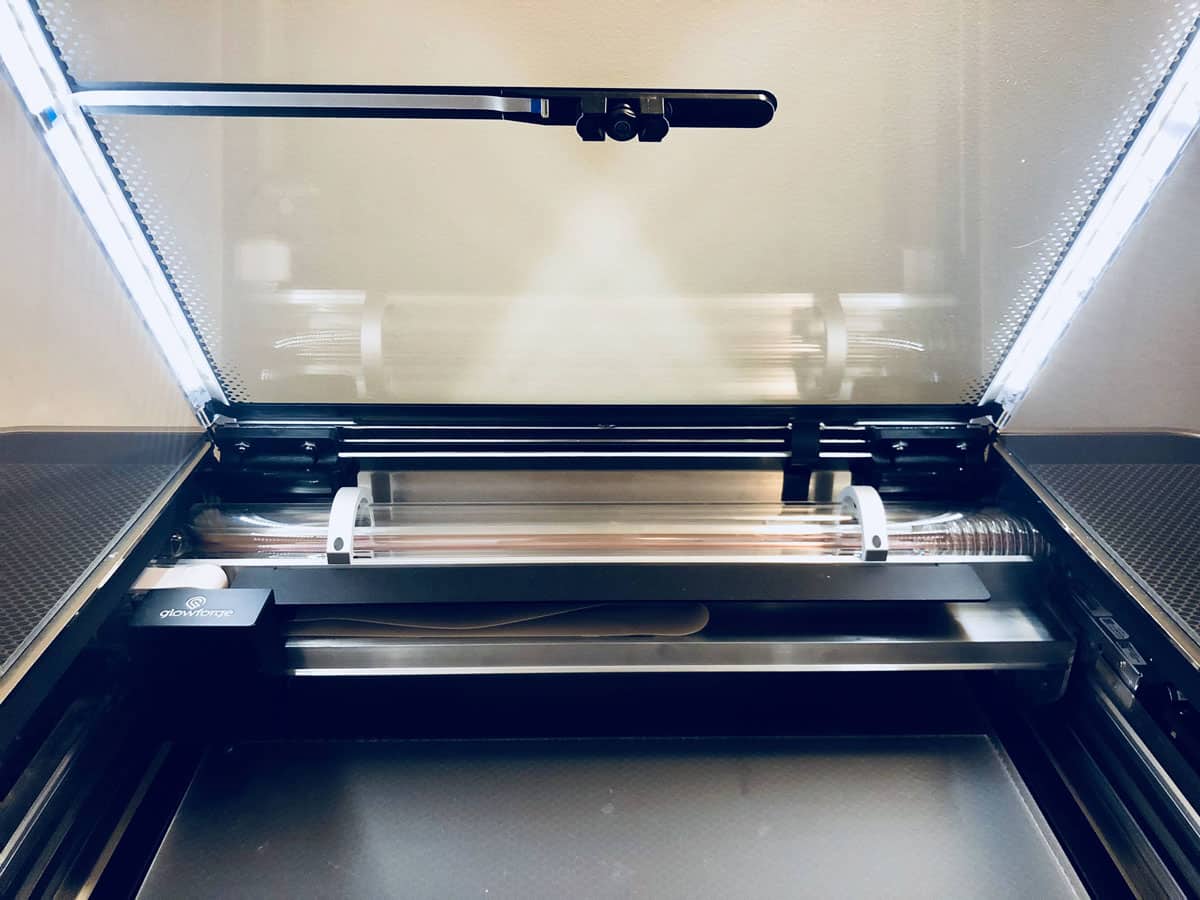

GlowForge LaserCutter (45W)

|

|

bed size: 270mm * 590mm

|

|

Software: Web-based GlowForge App

Workflow: CAD software (svg) ->GlowForge App

|

|

Things Could Go Wrong:

1. Temperature sensor sometimes too sensitive and constantly stop machine for cooling

|

|

Interesting Features:

1. Beautiful Laser Tube Design

2. Vision System:

a. Ulimited cut size on one direction (∞ * 590mm)

b. Engrave/Cut without CAD file

|

|

Interesting features:

Beautiful Design:

a. Integrated Laser tube cooling system

b. Mounted on gantry and remove a set of lens

VisionSystem

a. Ulimited cut size on one size (∞ * 590mm)

b. Use the machine as a powertool

300mm

Zortrax M300

|

|

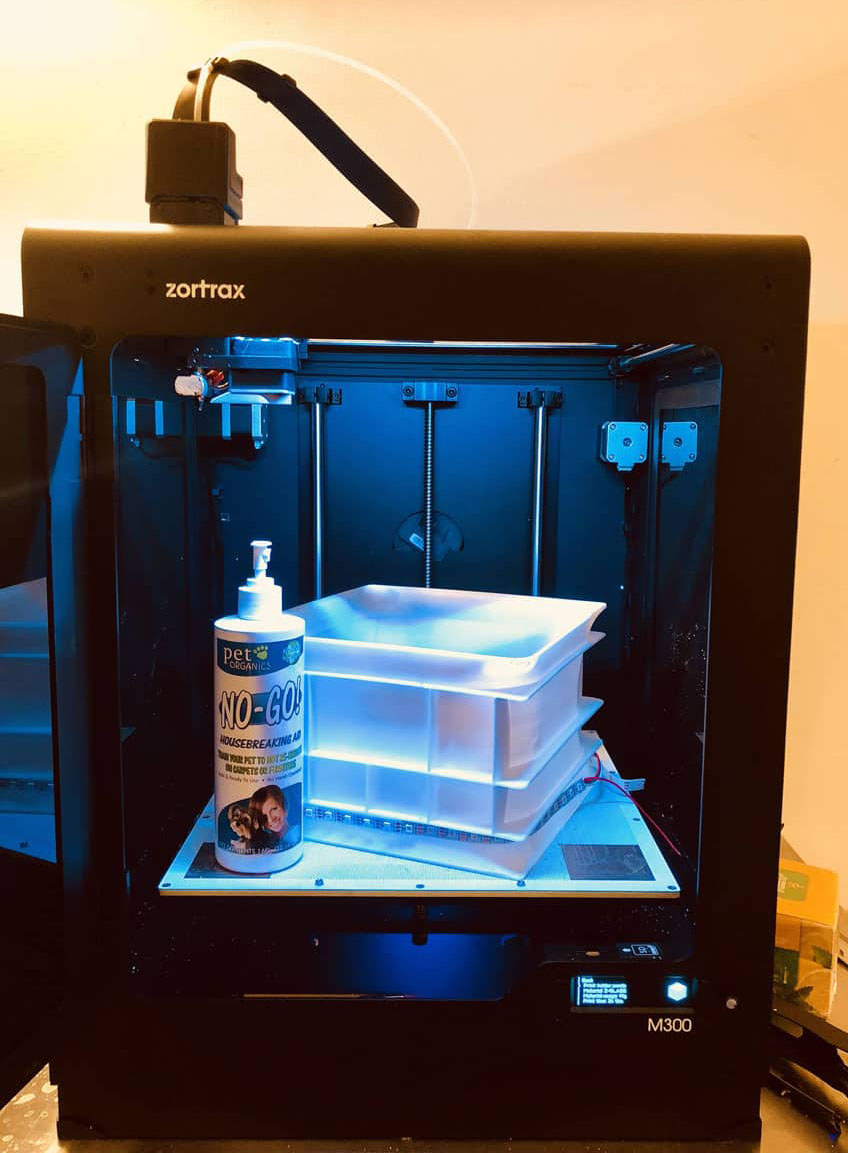

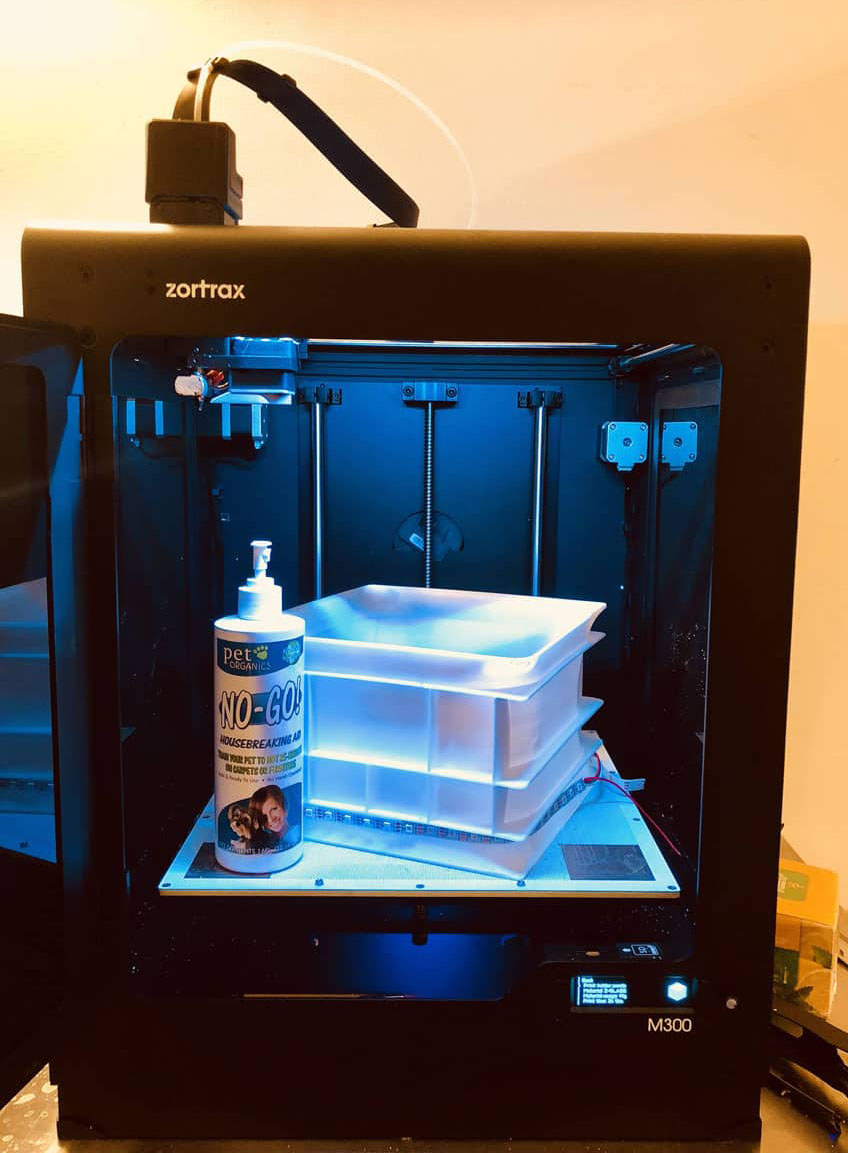

Zortrax M300

|

| bed size: 300mm * 300mm * 300mm |

|

Software: Z-Suite

Workflow: 3d model (stl) -> Z-suite (gcode)

|

|

Things Could Go Wrong:

1. Large Prints can last days, usually it's not the machine that go wrong

When Printing large, FDM's speed limitation is revealed compared to SLA & DLP

|

|

Interesting Features:

1.Built-Platform have holes to make the raft have enough grip and doesn't warp over time.

|

|

175mm

Formlabs

|

|

|

|

Form 2, Form 1+, Form 1

|

|

bed size: 145 * 145 * 175mm (form 2)

125 × 125 × 165 mm (form 1, 1+)

|

|

Software: Preform

Workflow: 3d model (stl) -> Preform

|

|

Things Could Go Wrong:

1. Mix Different version Resin

2. Didn't listen to Preform

|

| |

|

150mm

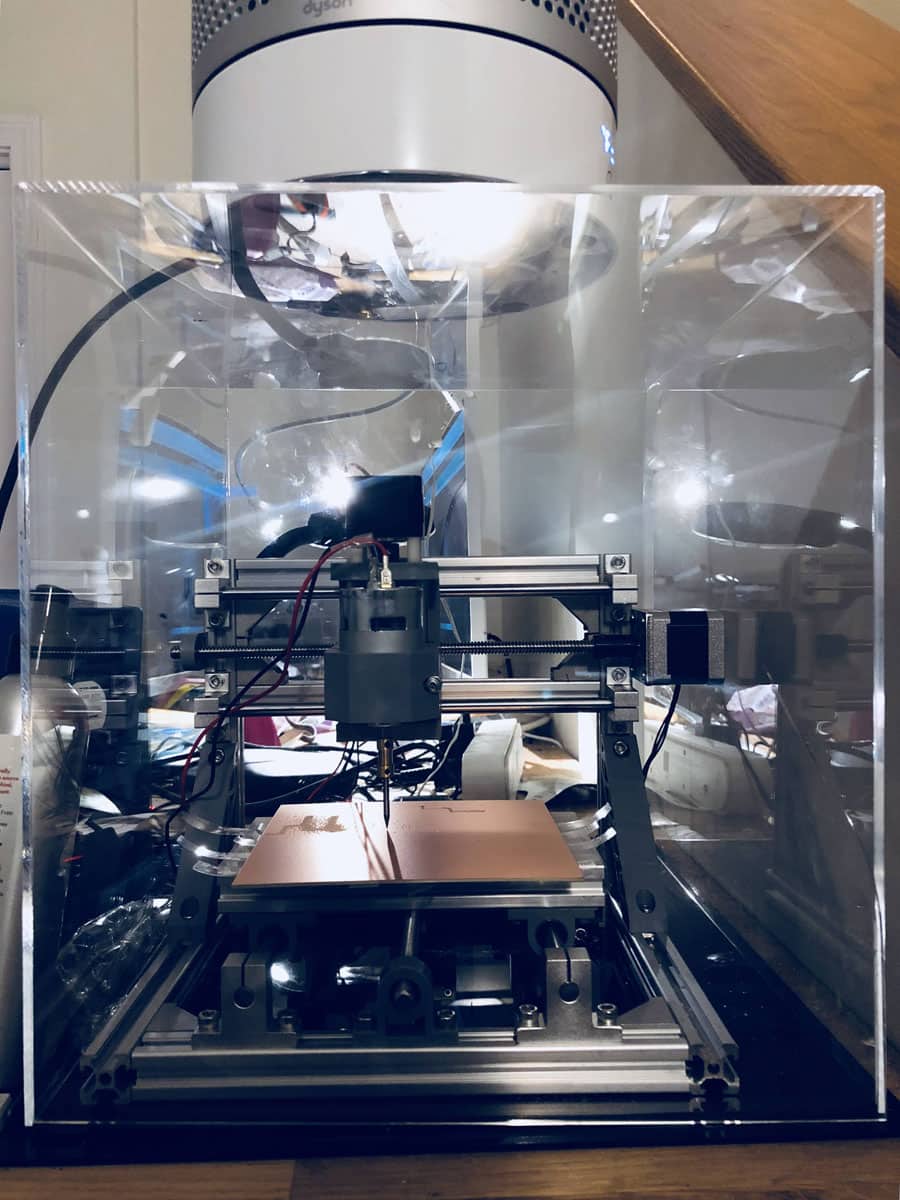

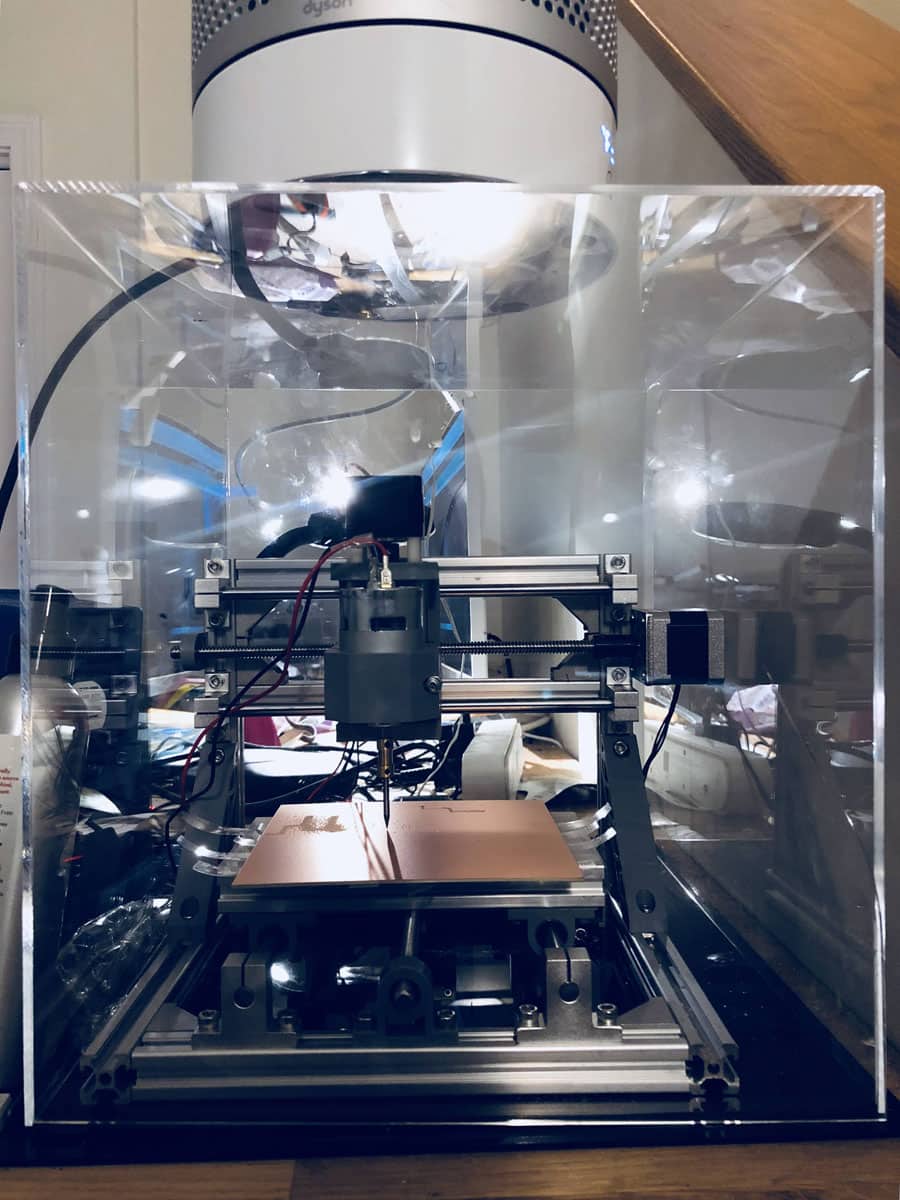

Noname Shenzhen PCB mill

|

|

Noname $200 PCB

(Setup Time 4 hours)

|

| bed size: 150mm * 75mm |

|

Software: Grbl Control

Workflow: CAD software (PNG)-> mods (gcode) -> GRBL control to drive the machine

|

|

Things Could Go Wrong:

1. Hand-assmbled machine with extremely uneven z level

2. blindly controlled without any feedback

3. screws are unfastened over time

|

|

Silhouette Cameo Vinly Cutter

Supporting Devices

Home-brew Vent for lasercutters

Material List:

1. Airpurifier

Hepa filter remove particles that have a size of 0.3 µm.

2. Duct In-line Fan

Increase air flow. Create vortex in carbon filter.

3. Carbon Filter

Chemical Obsorption of organic particals.

Resin Print Post-processing Units

|

a cheap solution could be sanding sponge + sterilizer

|

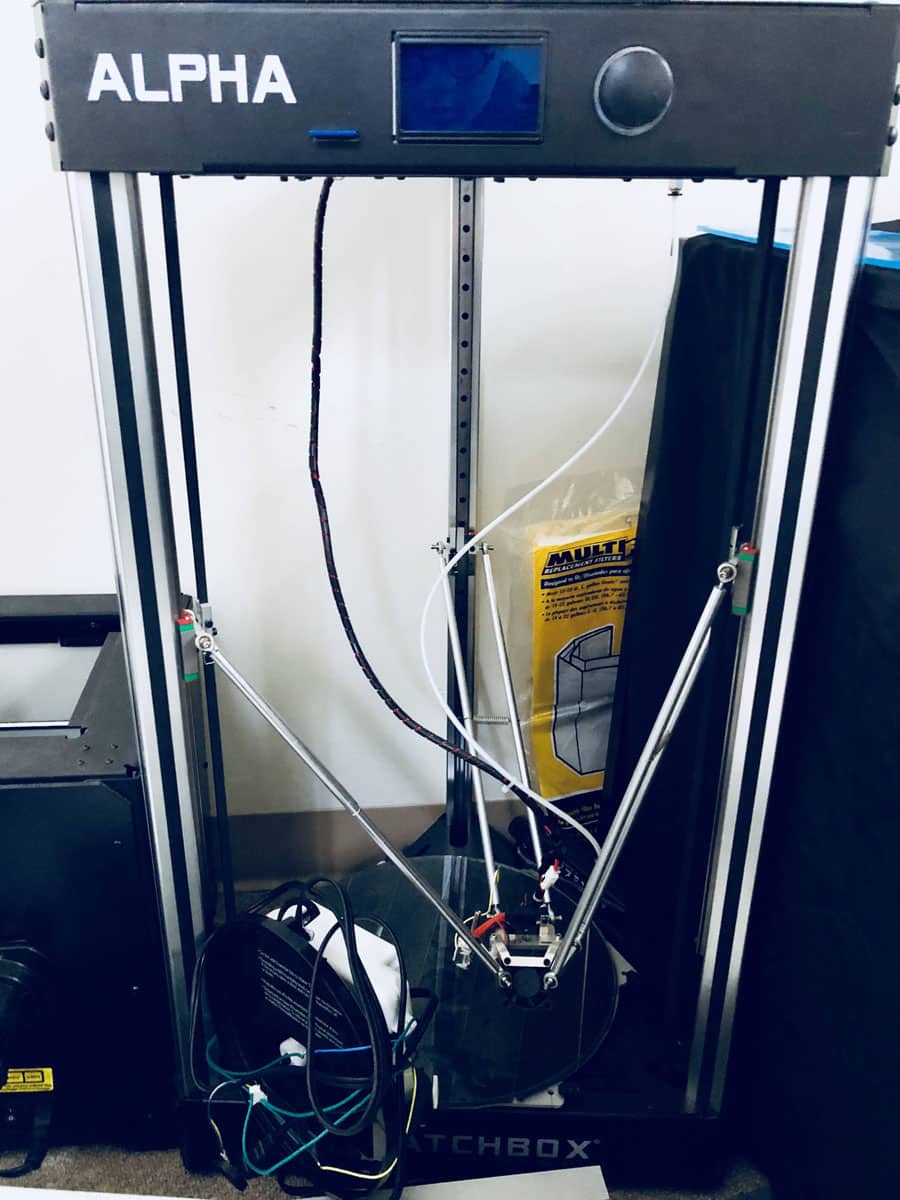

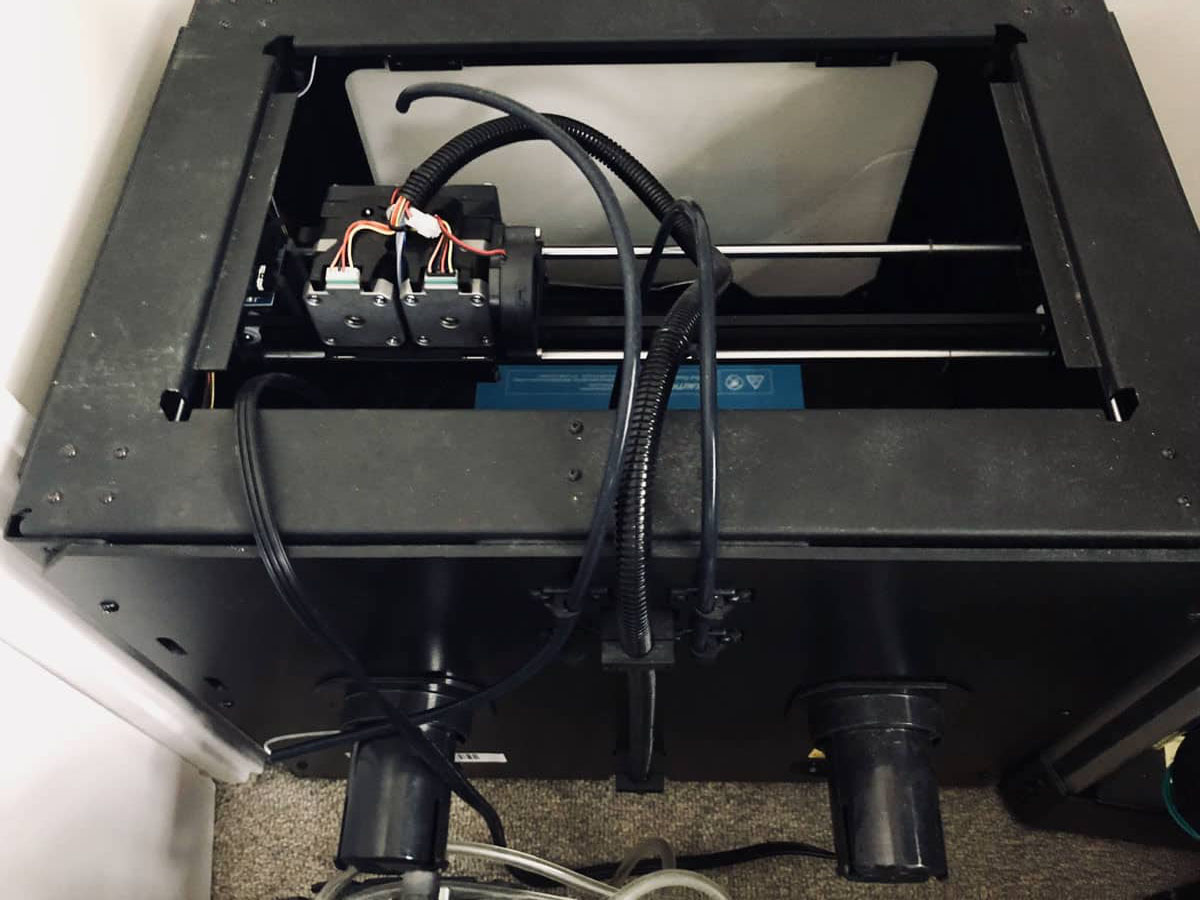

Corpes

|

Cause of Death: Water Pipe Leaking

|

|

Cause of Death: Nozzle Jammed, and broken inside when being replaced

|

|

|

Cause of Death:

2 nozzles not exactly at same height. Uneven Z platform.

|

Cause of Death:

Board Dead

|

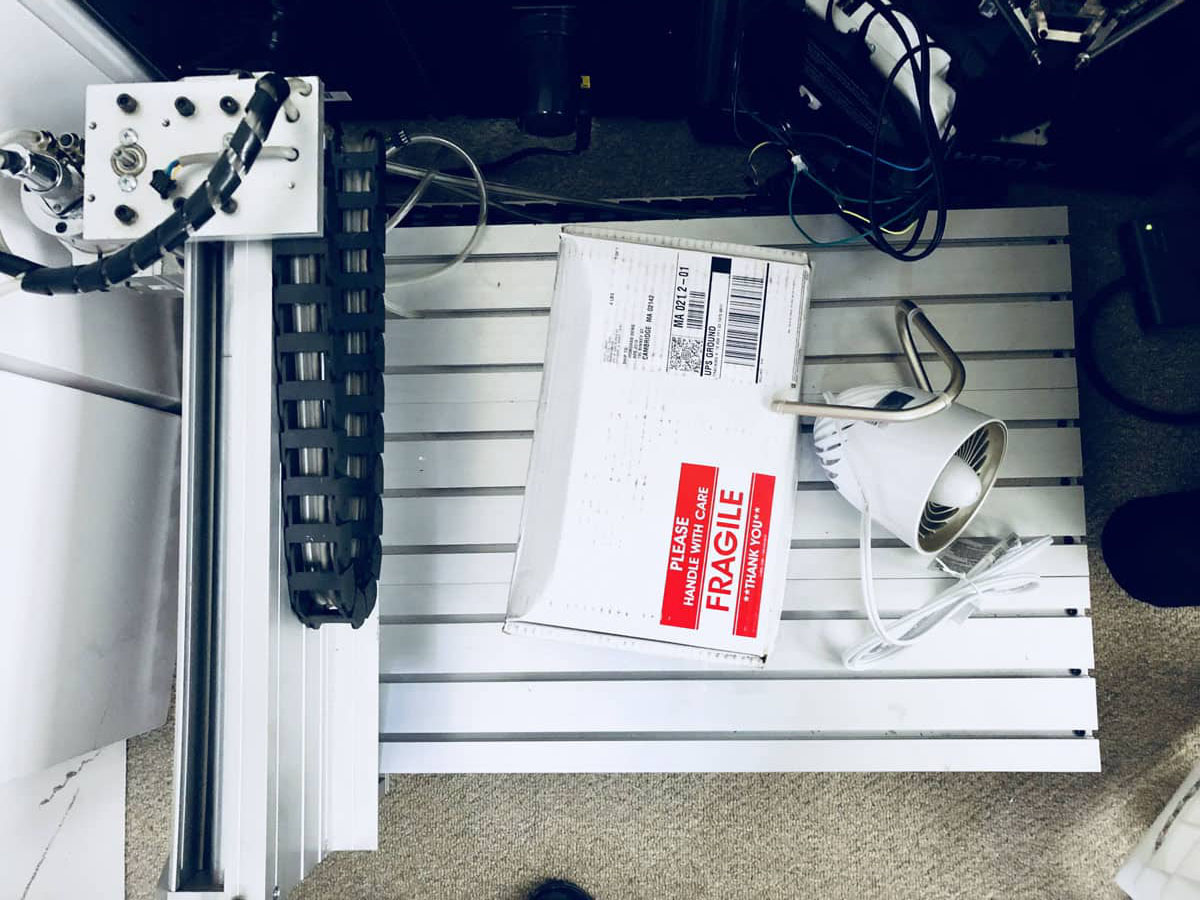

What's Amazon Prime Delivery?

How to become a prime seller? Ask WhiteBox

Fullfilled by Amazon (FBA service) Pricing

What's happening in Shenzhen's Machine to make business

Customized machines modified from models in OEM and open-source machines are slowly migerate to U.S. through ebay and amazon.

taobao (en)

Alibaba

Ebay

Amazon

extra fun

fake form1 by form1 OEM

form1 to laser engraver

now selling in U.S.

same thing another company

What are the things Shenzhen Machines Needs to Work on

1. supporting software, supporting devices

lasercutters are all still using corelDraw 6.0 plugins

filters, vent solutions for lasercutter

dust collection for CNC

2. Documentation (shouldn't be just Chinese)

3. slow-kill factors, long term reliability