<br>

[MAS.865](../index.html) > [subtractive](index.html)

## Machining processes

###Milling

[End mill terminology](http://www.endmill.com/pages/training/design.html)

[Roughing end mill](https://www.travers.com/roughing-end-mills/c/297804/)

<ul>

<li>Chip loading</li>

For 1/8" tool travelling 50mm/s at 300 RPS<br>

Chip Load = feed rate (m/s) / (flutes x rev) = (.05m/s) / (1 flute x 300 1/s) = 0.13 mm<br>

chip thickness / tool radius = 0.13mm/1.5mm = 13%<br>

<li>Chip thickness: recommended chip 5-20% of tool radius.</li>

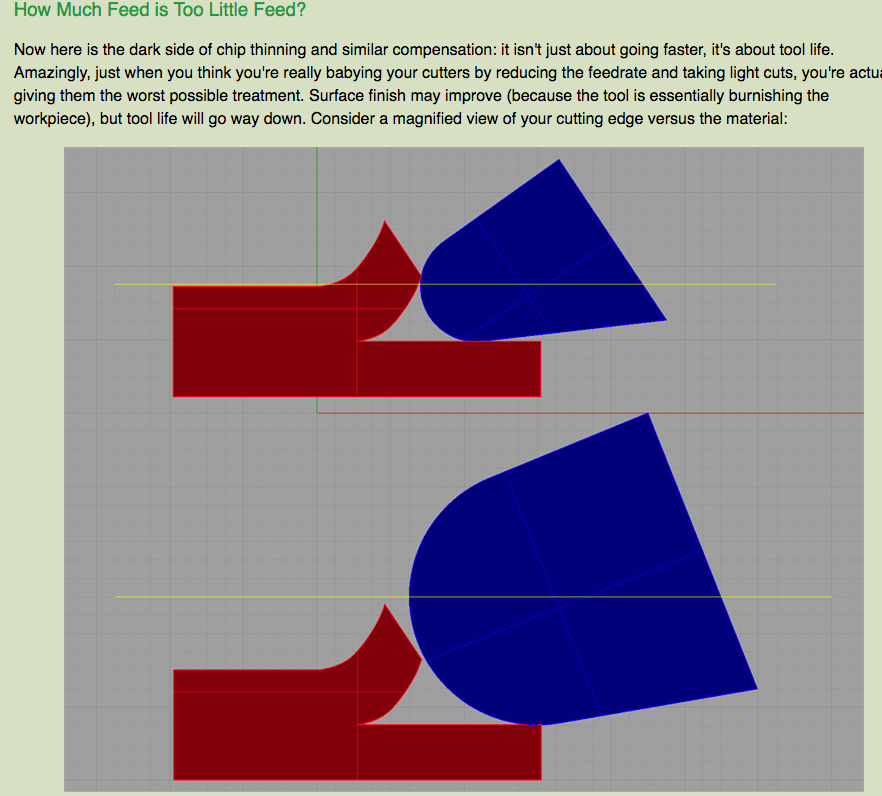

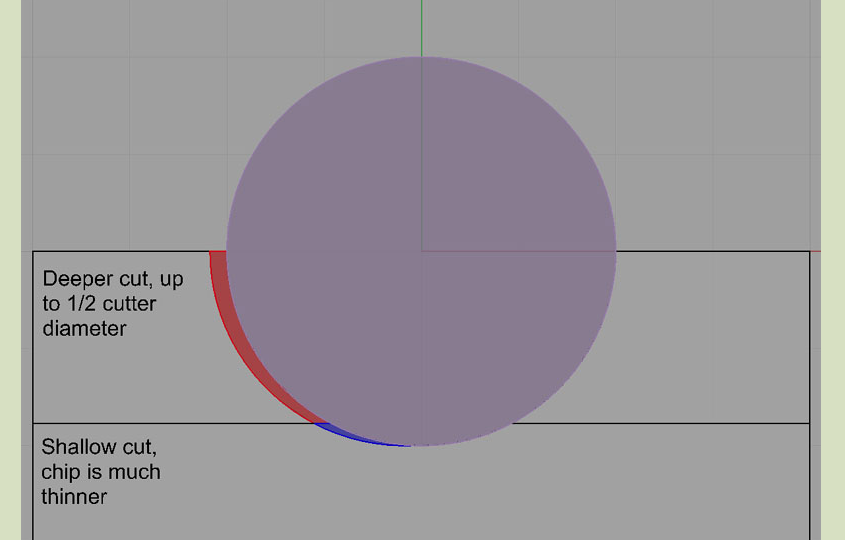

<li>Chip thinning.</li>

<li>[From CNC Cookbook on feeds and speeds](https://www.cnccookbook.com/high-speed-machining-trochoidal-milling-hsm-speeds-and-feeds/)</li>

</ul>

####High Speed Toolpaths

<ul>

<li>[Tool Path Strategies For High Speed Machining](https://www.mmsonline.com/articles/tool-path-strategies-for-high-speed-machining)</li>

<ul>

<li>Small stepover.</li>

<li>High feed rate.</li>

<li>No sharp turns.</li>

</ul>

<li>Trochoidal toolpaths </li>

<ul>

<li>Longer length of side-cutting flutes</li>

<li>Smaller radial engagement</li>

<li>More constant load on tool.</li>

<li></li>

</ul>

<li>[Jens Dyvik website](https://github.com/fellesverkstedet/fabricatable-machines)</li>

<li>Fusion 360 Cam for adaptive clearing.</li>

<li></li>

</ul>

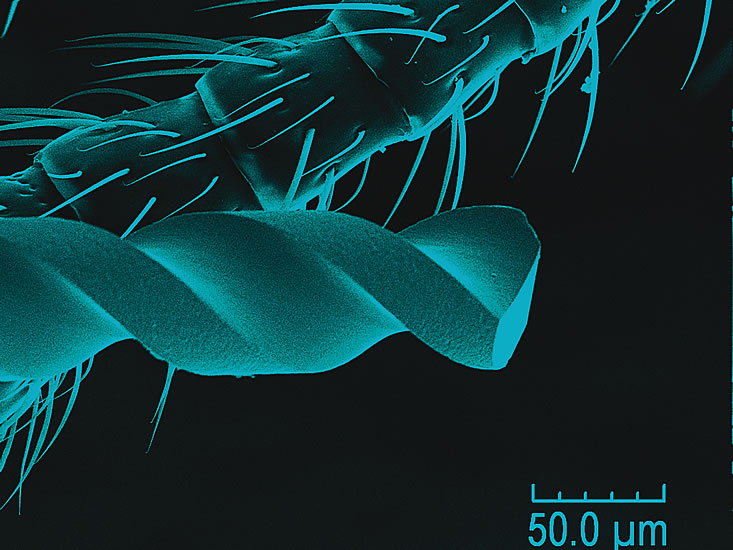

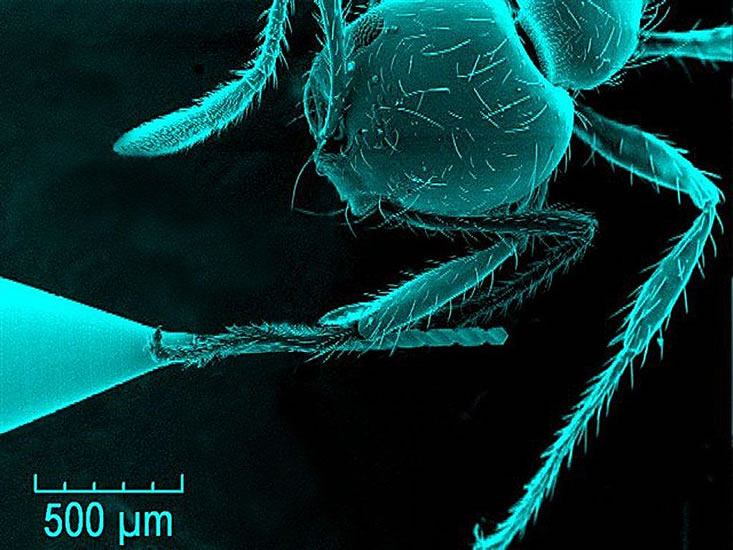

####[micro-milling](http://www.pmtnow.com/nano)

End mills smaller than 0.001"

[Challenges with micro-machining](https://www.moldmakingtechnology.com/articles/micro-milling-opportunities-and-challenges)

* Building machines with micron precision

* need really high spindle speeds (50k RPM)

* "The software should support toolpath calculation with tolerances down to 0.01 micron while considering the constraints of the machine used. Such tight tolerances require special toolpath algorithms with greater accuracy and better point distribution in order to achieve a polish-free surface."

###[Turning](https://www.youtube.com/watch?v=cEBOeLHQKZE)

[Spindle speed variation (SSV)](https://www.youtube.com/watch?v=dXR2wDDFFm4)

<ul>

<li>[High speed machining in regards to turning](https://www.mmsonline.com/articles/basic-questions-on-high-speed-machining)</li>

<ul>

<li>Material Removal Rate [MRR] is a function of speed, tool engagement and cutting force</li>

<li>limited by spindle speed</li>

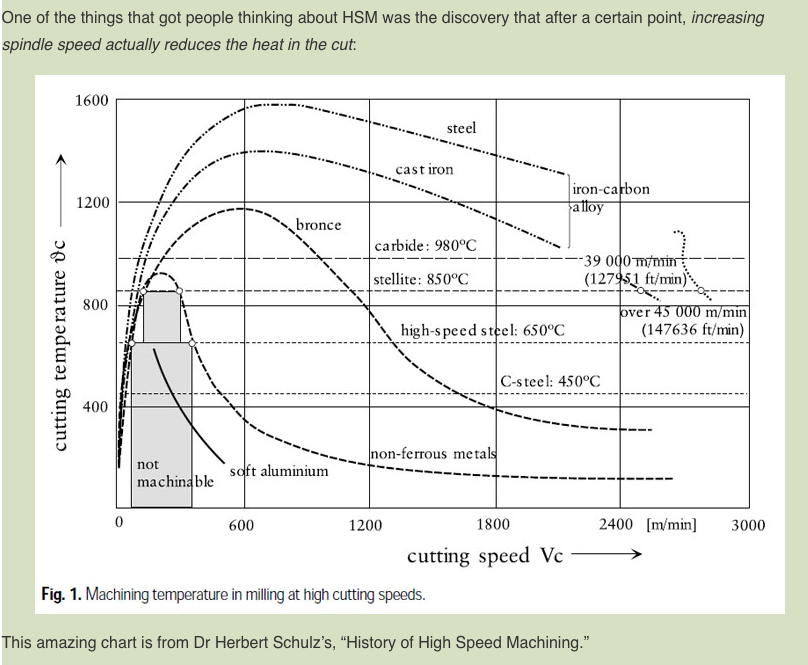

<li>heats are generally higher with HSM, but the heating profile is different because at higher speeds you can have less tool engagment and acheive the same MRR</li>

</ul>

</ul>

[Wood turning](https://www.youtube.com/watch?v=3Bk-K_Ativs)

[CNC wood turning](https://www.youtube.com/watch?v=VrUFLVBDock)

###[Band saw](https://www.youtube.com/watch?v=ZwNa6JPVbk0)

[Historical bandsaw designs](http://wiki.vintagemachinery.org/Pre%20History%20Of%20Band%20Saws.ashx)

[CNC Bandsaw](https://www.doallsaws.com/s-320cnc)

###Drill press

Designed for vertical loads and lower spindle speeds than a mill.

###Fixturing

* [sine plate](https://openoregon.pressbooks.pub/manufacturingprocesses45/chapter/unit-3-sine-bar/)

* [collet blocks](https://www.google.com/search?q=collet+blocks&client=firefox-b-1-ab&source=lnms&tbm=isch&sa=X&ved=0ahUKEwj356e-1sbaAhUNMt8KHZNcDXYQ_AUICygC&biw=1280&bih=623)

* [get creative and DIY](https://www.google.com/search?client=firefox-b-1-ab&biw=1280&bih=623&tbm=isch&sa=1&ei=_LjYWu3TKo3H_Qa4yrOABA&q=machining+fixturing&oq=machining+fixturing&gs_l=psy-ab.3..0i8i30k1.6900.8838.0.9220.11.11.0.0.0.0.124.970.8j3.11.0....0...1c.1.64.psy-ab..2.9.760...0i7i5i30k1j0i7i30k1j0i8i7i30k1j0i13k1.0.owmNLyswqoA)