assignment 3 - project description - [1] - A self-forming mold injection machine - [SFMIM]

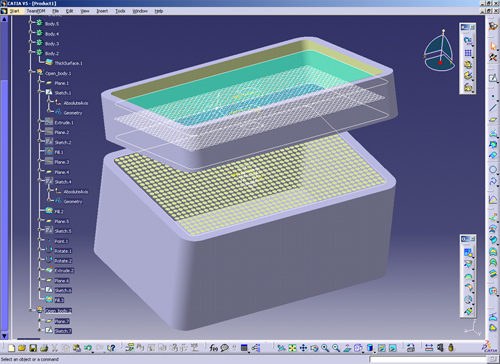

this machine uses reactor pins as a primary support to form the

mold for the injection. as an object with unique and exotic shape is

placed on the bed, the pins react and position themselves according to

the form. this can be use for only single-sided curves or

surfaces. since, objects of any material can be use as a

placement for the mold, this provides an infinite possibility to form

any type of surfaces. once the object is removed, the pins hold their

form and the injection takes place.

the overall size and dimensions are similar to the current laser cutter.

With the bed approximately at 40"x20" and the maximum height of a

forming curve or surface at 10". however, with a 3-dimensional

object, the overall height of the lower bed can be use as a mold, which

stands at 20".

for a 3-dimensional form, instead of reactor pins, this bed can

be full of tiny magnetic bearing balls. as the object is inserted

into the bed, the balls find their way to fill in all the open gaps and

curves that otherwise couldn't be reach by the pins. this final form is

then digitally recorded. the 3D object is then removed and with

the click of a button, the balls re-form themselves to the original

shape of the 3D object through the use of memory magnetic

contact. this version can possibly form single-sided as well

as double-sided curves and surfaces.

this machine uses reactor pins as a primary support to form the

mold for the injection. as an object with unique and exotic shape is

placed on the bed, the pins react and position themselves according to

the form. this can be use for only single-sided curves or

surfaces. since, objects of any material can be use as a

placement for the mold, this provides an infinite possibility to form

any type of surfaces. once the object is removed, the pins hold their

form and the injection takes place.

the overall size and dimensions are similar to the current laser cutter.

With the bed approximately at 40"x20" and the maximum height of a

forming curve or surface at 10". however, with a 3-dimensional

object, the overall height of the lower bed can be use as a mold, which

stands at 20".

for a 3-dimensional form, instead of reactor pins, this bed can

be full of tiny magnetic bearing balls. as the object is inserted

into the bed, the balls find their way to fill in all the open gaps and

curves that otherwise couldn't be reach by the pins. this final form is

then digitally recorded. the 3D object is then removed and with

the click of a button, the balls re-form themselves to the original

shape of the 3D object through the use of memory magnetic

contact. this version can possibly form single-sided as well

as double-sided curves and surfaces.