Re-configurable mold

for complex surfaces using shape memory alloys

When using molds for sheet stamping,

injection molding, or even thermoforming, custom molds for each unique component

must be fabricated for that component only. This works fine for high volume

fabrication of parts in which the cost benefit eventually balances itself out

after production of many parts. However, for fields such as architecture and

other applications that only require low volume or even one-time uses, this

process of creating hundreds of individual molds can be costly.

Therefore, creating a re-configurable

mold that can reform to any surface shape would be extremely beneficial:

Less prep time - an automated system

for the surface adjustment could save time from milling out a surface from

a block

Lower cost - not paying for fabrication

of each mold

No waste - after use, most mold

serve no other purpose and are discarded.

Depending on the mold properties, materials can be recycled, which still adds

on additional time and cost.

I am proposing to use shape memory

alloys as a template to create re-configurable molds. Shape memory alloys are

metals that exhibit two unique properties, pseudo-elasticity, and the shape

memory effect. These alloys experience solid state phase change in which the

crystalline structure undergoes parallel registry and flexes under stresses

instead of shearing, which is irreversible in solid state.

Because of these unique properties SMA's can be deformed into multiple shapes

yet always resume its original shape once heated to a certain temperature. I

would like to experiment creating a machine that deforms the SMA to a desired

complex double-curved surface, uses it a mold for a necessary number of applications,

then when finished heats the SMA to return it to its original flat shape, ready

to be used again.

Functional Requirement: Create any double curved sheet

Design Parameter:

- Best-fit curve and surface fitting

- Current induced heating

…or hot bath heating

- Clamp/Iron press for 2-D alloys

Analysis:

- "one way effect" also "shape memory effect"

- Transformation temps - Austenite and Martensite - phase transformation

References: http://herkules.oulu.fi/isbn9514252217/html/x317.html

http://www.cs.ualberta.ca/~database/MEMS/sma_mems/sma.html

http://www.memory-metalle.de/html/03_knowhow/04_glossay.asp

Risks: High temperatures or current may be a danger to user if not

properly shielded

Countermeasures: Enclosed and insulated components

Now the challenge that presents itself is how to manipulate

the shape memory alloy template to a desired shape. Depending on the type mold

(injection mold, thermoforming, or stamping) the can be reformed various ways….

The simplest crude approach eliminates any CNC type of application and requires

the "carpenter" to deform the alloy by hand.

The next step up could require the

user to place rods/blocks of various heights in a sequence that would simulate

a best-fit curve. Although the process is not automated the rod or block orientation

could be driven by a computer model, giving a stack-by-number template to the

user. This best fit stack serves as a pre-mold to deform the shape memory alloy

to. Given a thick enough sheet, the alloy serves as a buffer from the rough

best-fit surface to a smooth surface.

Another way to approach the problem

is to divide the surface into rollable strips. After digitally dividing the

sheet up and computing its curvature, this info would be translated to mechanical

metal rollers that would alter their orientation to output various curves. Each

SMA curved strip would then be reassembled to form a best-fit sheet. This surface

would not be a true uniform surface; however, depending on the material being

formed, the resulting ridges may not be prominent.

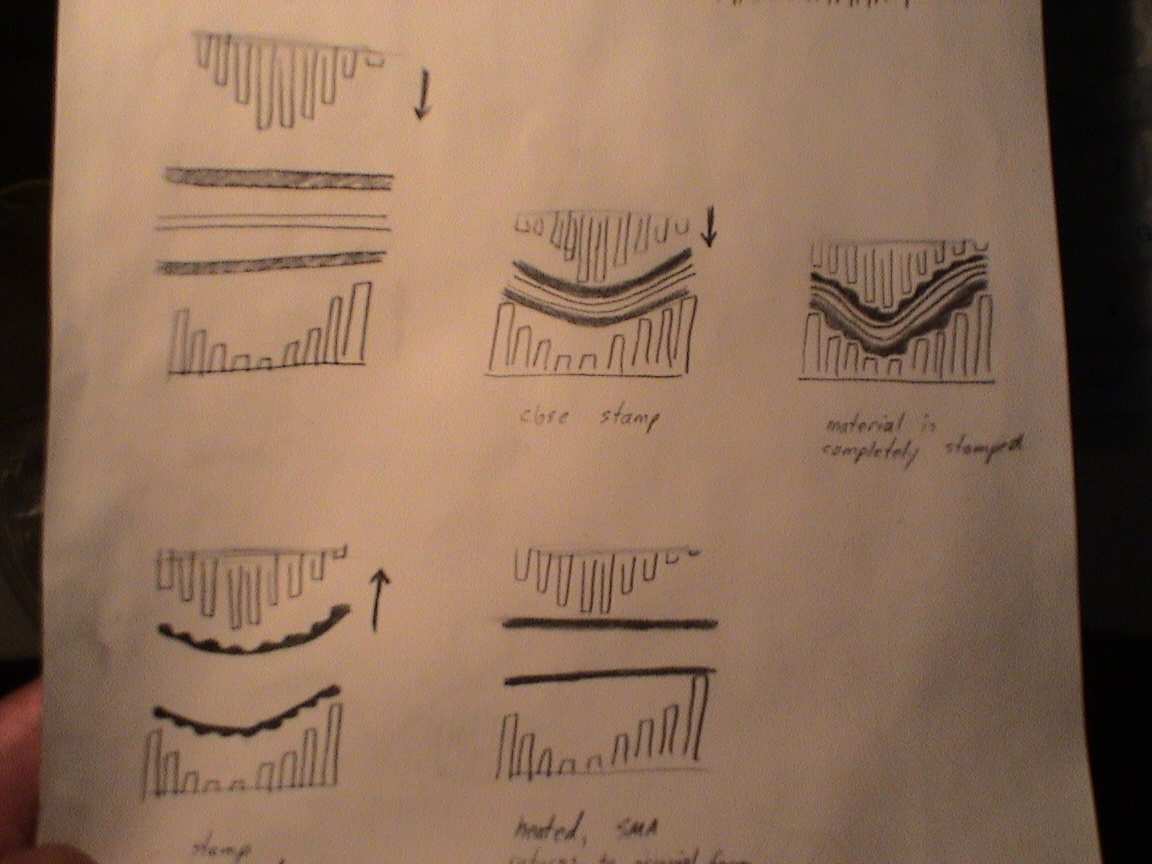

Adding more complexity, using threaded

rods (screws) to create a best-fit surface could also work. A SMA sheet could

be pressed down or rolled out on this screw/piston bed or stamped between two

beds. Using the later method the beds could also move in the X-Y direction while

synchronistically altering each screw/piston in the Z direction to "massage"

the shape memory alloy to the correct geometry.

One way to add some of the given

options together is to sandwich the desired material to be manufactured between

two SMA sheets. These three sheets would together be stamped by a best-fit re-configurable

mold. As mentioned before, the SMA would act as a buffer to translate a smooth

surface to the manufactured piece. Once the stamping is complete, the manufactured

sheet is removed and the SMA buffer sheets are heated, returning to their original

[flat] geometry.