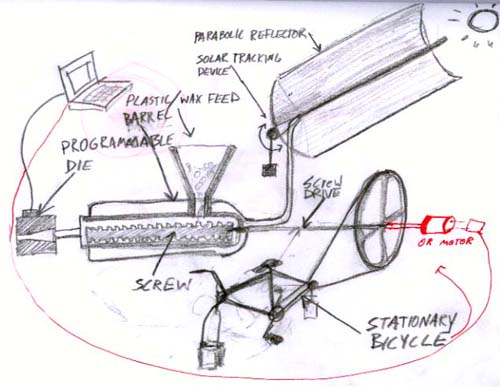

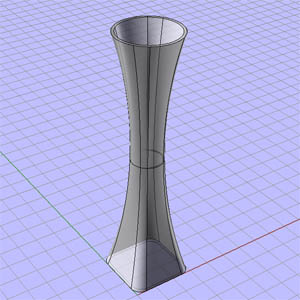

solar extrusion machine with programmable die

- what process(es) will it use?

solar thermal collection

extrusion process

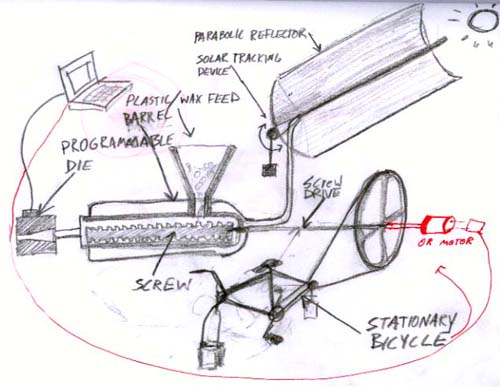

CNC controlled transforming die

- what will (and won't) it be able to do?

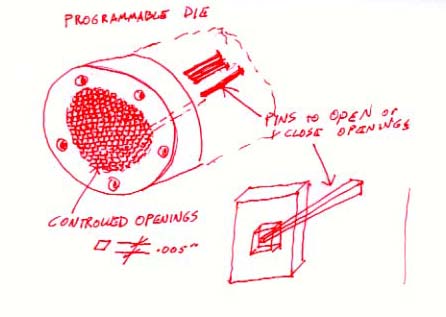

it will be able to melt plastic/wax or other materials and extrude them into structural components or shapes with variable cross sections

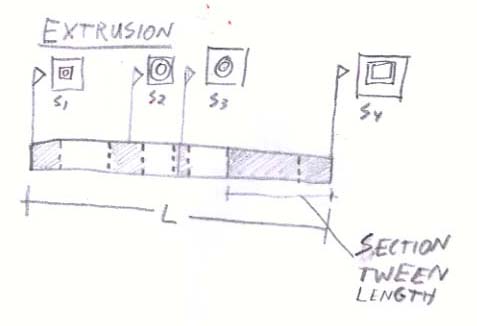

the die will be able to change as the extrusion operation is being performed, so the cross-section can change throughout the part.

- what are the benefits (and disadvantages) over current practice?

pros: makes large custom parts requires no or very little electricity creates little waste when compared to injection molding requires less pressure than injection molding creates extrusions with varying cross sections (varying within one part)

cons:

may not be as precise

could take longer than industrial extrusion process

can't use it at night

- what are the system components?

parabolic reflector

sun tracking device

thermocouple

plastic extrusion machine

stationary bicycle or motor

transformable die and die controller

- which parts exist, and which will require development?

all of the parts will need development

1) parabolic trough and thermal system to transfer enough heat to melt plastics (about 400-500 degrees F)

2) sun tracking device and temperature/pressure control

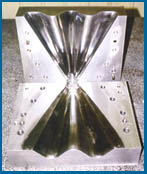

3)design mechanical parts for die

4)software/interface for programming die

- what will the workflow be from design to output?

The operator can specify the shape of the die at any point on an extrusion length and the die will transform between those shapes. The operator will also be able to control tween lengths.

- how much will it cost?

initial small prototype would be approximately $275

-reflective film $50

-pipes $50

-stainless steel $100

-metal for mechanical parts $50

-microcontrollers/electrical $25

the reflector film and the machining of the screw for the extrusion process will be the most expensive parts.

the initial prototype would be small, so the major purchases would only require reflective film, aluminum and some plywood for the parabolic mirror and some stainless steel to mill the screw and extruding barrel.

Parts:

Mirror Film

http://www.reflectechsolar.com/

$3.00/ft2

Stainless Steel

-for the prototype would only need a small portion, so could buy scrap material.

transition plate

- how fast will it be?

There will be setup time and it will depend on the amount of sunlight, but it should produce parts quickly

- what consumables will it need?

lubricants

mecanical parts

water to clean mirror

heat transfer fluid

custom candy canes