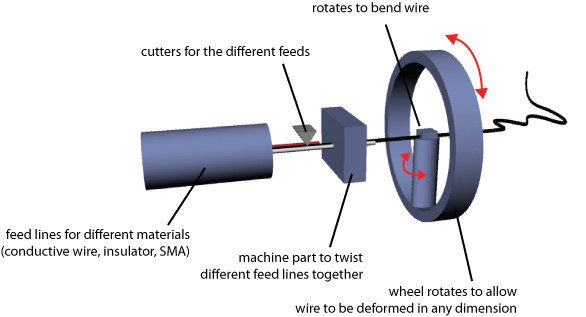

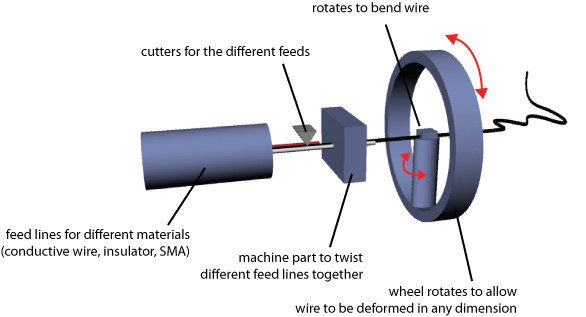

Marcelo Coelho Assignment 2. Fab Machine For this machine, I tried to create a fabricator similar to the self-assembler from the previous assignment, but where different active and passive materials could be combined to achieve different material properties and mechanisms. The machine I designed is basically a wire bending machine with the additional capability of twisting different kinds of wires together. |

what process(es) will it use? It will need to cut, twist, bend and rotate wires or rods of different materials. what will (and won't) it be able to do? Fabricating actuators seems somewhat feasible, but fairly complex since it will require a high degree of precision and resolution. what are the benefits (and disadvantages) over current practice? Benefits:

Disadvantages:

what are the system components?

which parts exist, and which will require development? Wire bending machines already exist. They could be adapted to include the possibility of combining different materials. what will the workflow be from design to output? It would need software to convert a 3D model into a single curved line. how much will it cost? Probably not very cheap, since it would require at least 5 motors. how fast will it be? Based on the speed of today's wire bending machines, probably very fast; however speed would depend on the number of curves in a design. what consumables will it need? Wire. |