We are testing different lengths of overhanging parts

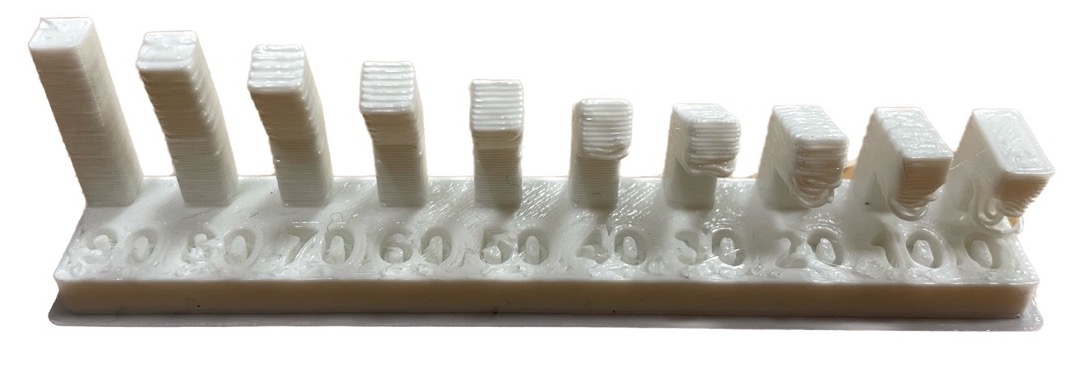

We are testing different lengths of overhanging partsIn this test we are determining how much unsupported material will successfully print on the 3D printers available in the shop. As expected, more overhangs results in more "stringy" filament that has fallen mid-print due to gravity.

To start, some tests on the Prusa i3 Mk3 printers. We are using 15% infill "draft" preset.

We are testing different lengths of overhanging parts

We are testing different lengths of overhanging parts

Demonstration of "too much" overhang

Demonstration of "too much" overhang

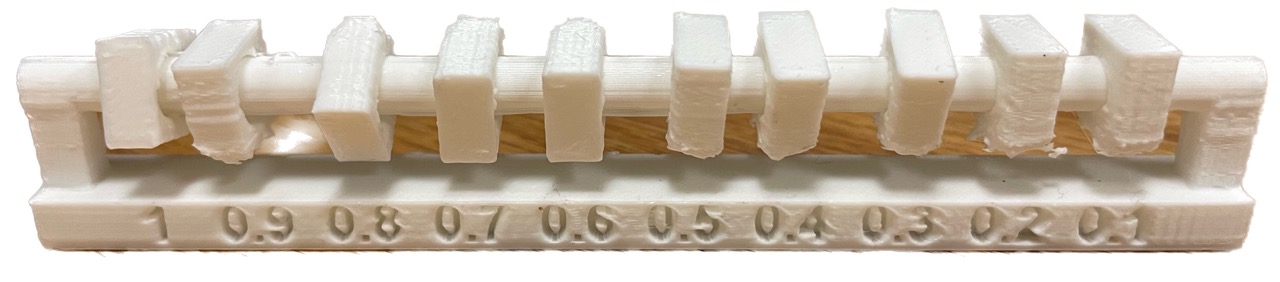

Similar idea to the previous test, we experiment with different angles of unsupported overhang.

Prusa:

Here is the setup

Here is the setup

The print "fails" more as we tend towards an unsupported right angle

The print "fails" more as we tend towards an unsupported right angle

In contrast, adding supports completely mitigates the "drooping" effect from before.

Here is the result from printing on the Sindoh 3DWOX1:

Even the right angle has no issue

Even the right angle has no issue

The surface finish is slightly worst where the supports were connected

The surface finish is slightly worst where the supports were connected

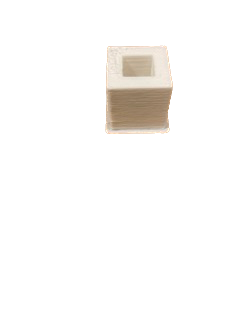

For this test, we examine the material strength of certain infill. We anticipate that more infill will result in stronger parts.

Here is the Prusa at 15%:

The target (victim) will be this solid block. Observe the differing surface finish on the sides versus the top face

The target (victim) will be this solid block. Observe the differing surface finish on the sides versus the top face

Pressing the top face (i.e. the "15" is facing up) is pretty much impossible by hand; it's really strong. But flipping it on its side, it's possible to completely buckle the "15" itself which kind of destroys it.

The negative space in the "15" is where the excess material went

The negative space in the "15" is where the excess material went

The result is more of a shear than an actual compression. Either way, the cube is destroyed but with a lot of effort

The result is more of a shear than an actual compression. Either way, the cube is destroyed but with a lot of effort

Overhanging bridge starts to sag after 2 mm and gets worse with non continuous sagging after 8 mm

Overhanging bridge starts to sag after 2 mm and gets worse with non continuous sagging after 8 mm

When constructing a sphere even though the step size is the same depending on where you’re on the steps become less smooth

When constructing a sphere even though the step size is the same depending on where you’re on the steps become less smooth

When constructing a sphere even though the step size is the same depending on where you’re on the steps become less smooth

When constructing a sphere even though the step size is the same depending on where you’re on the steps become less smooth

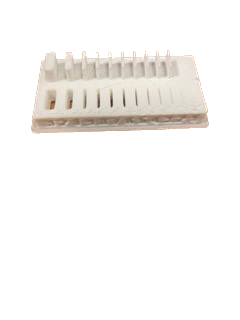

This test involves an abacus-like print where the pins have varying amounts of clearance to the rod.

Sindoh:

The picture doesn't convey much, but the pins get easier to move with more clearance

The picture doesn't convey much, but the pins get easier to move with more clearance

We found that 0.4mm clearance and above moves and rotates very easily (i.e. gravity alone displaces them). The 0.3mm can move with some effort, and 0.2mm and below will not budge without breaking things.

Prusa:

The error in the dimensions is the same size as the nozzle -.06mm

Smaller than .4 mm you don’t get a full length cut in the object. Walls can only get as small as .4 mm - not sure if having .4 mm nozzle will allow smaller