Week 6 - Electronics Production

This week is a continuation of the EDA week.

PCB Making Training at the MIT Eletronics Mezzanine

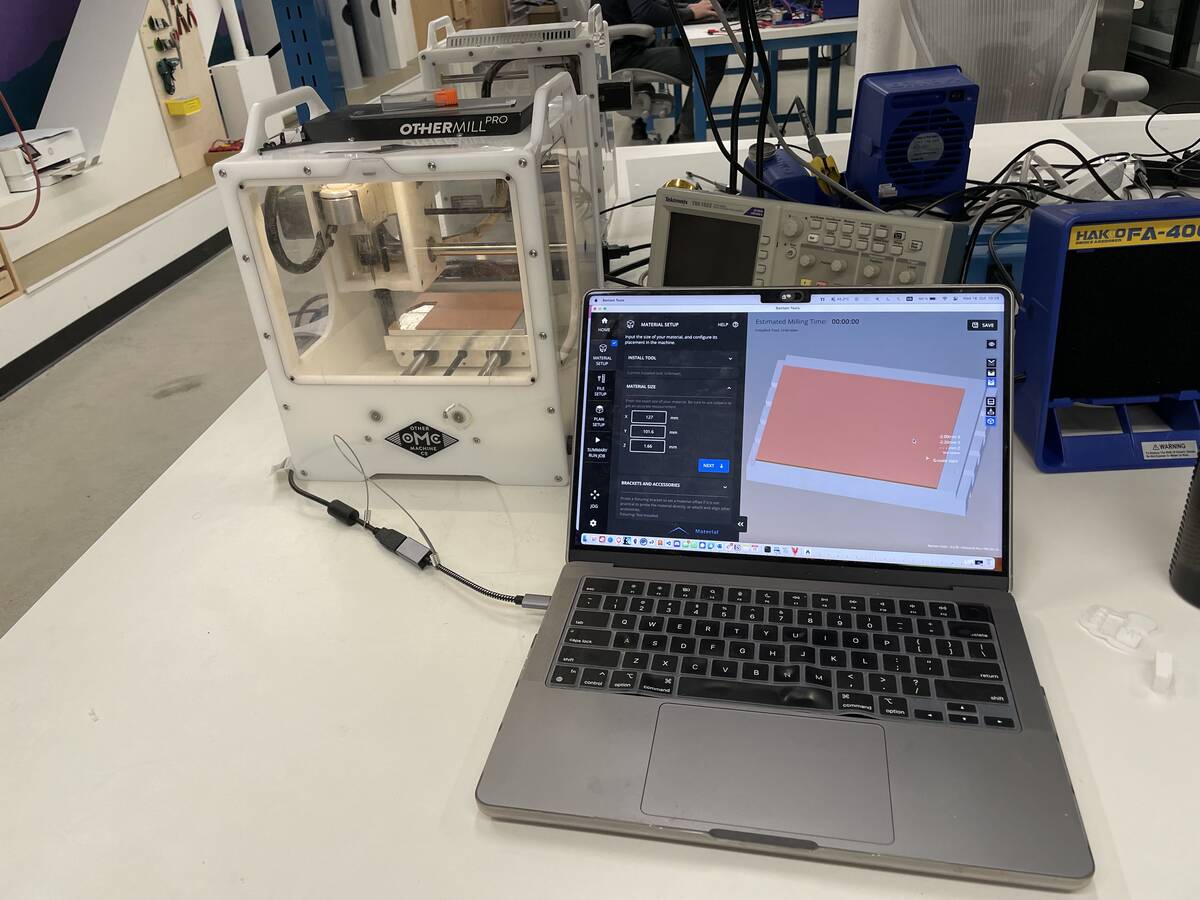

Milling with Bantham Tools

Project Manus is great. They have at least 4 working PCB Milling Machines at the Electronics workshop. They are all Bantam Tools Desktop PCB Milling Machines. They are very easy to use, and the software is very intuitive. You can find the instructions here.

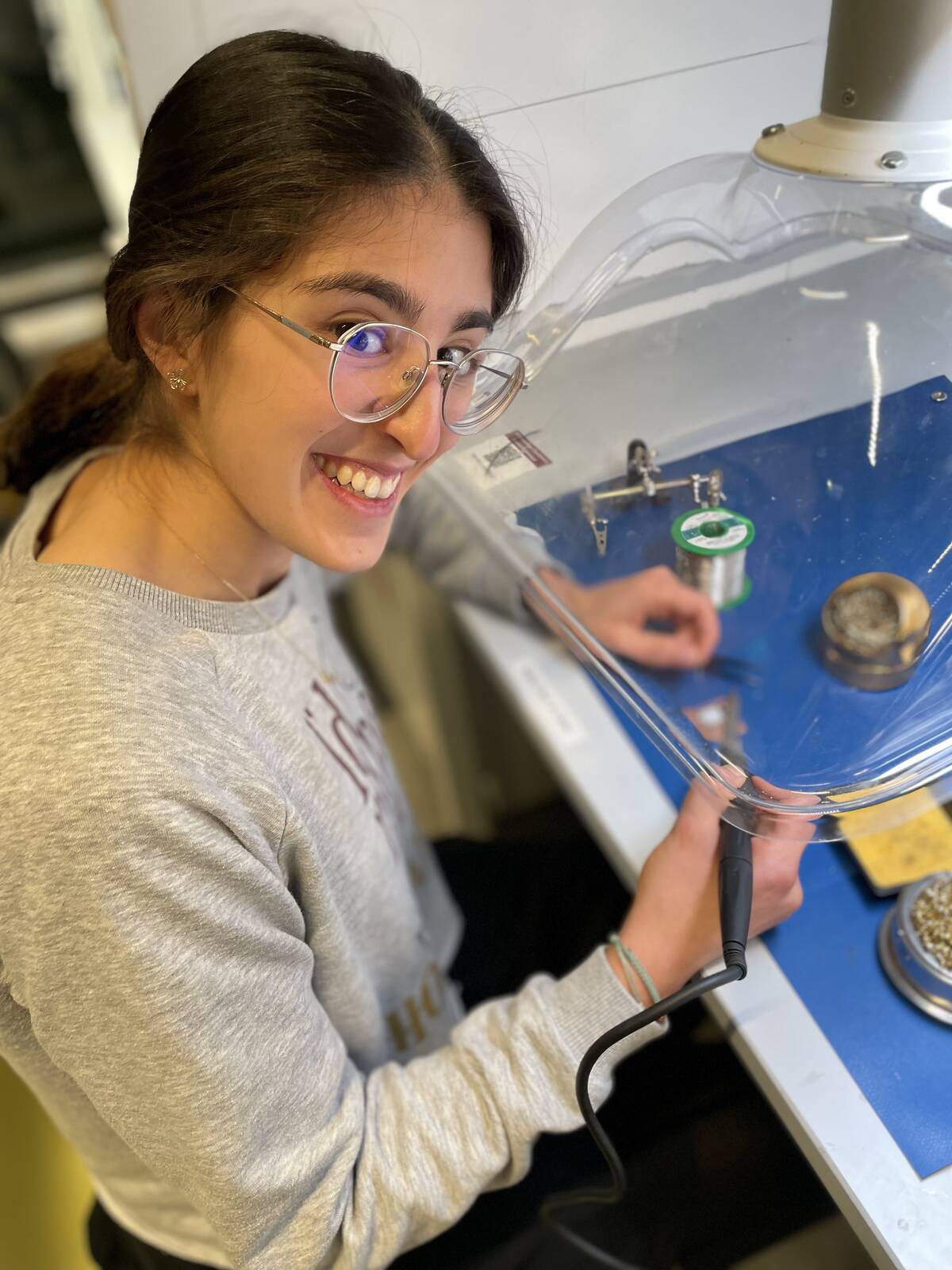

Soldering

Soldering my LED circuit proved a little difficult. Some components were so small, and my soldering iron tip wasn’t very fine. I messed up a couple of times (also due to my lack of skill - I didn’t know you should heat up both the component and the plate before applying solder) and had to unsolder parts. Well, practice makes perfect.

Assignment: Solving my MAX7219 LED Routing Problem with Hardware

As the queue for the Milling Machine at the CBA shop was too long, I went back to the Eletronics Mezzanine and worked with the Bantham. The machine and its software are great, I just messed up a couple of times and had to restart.

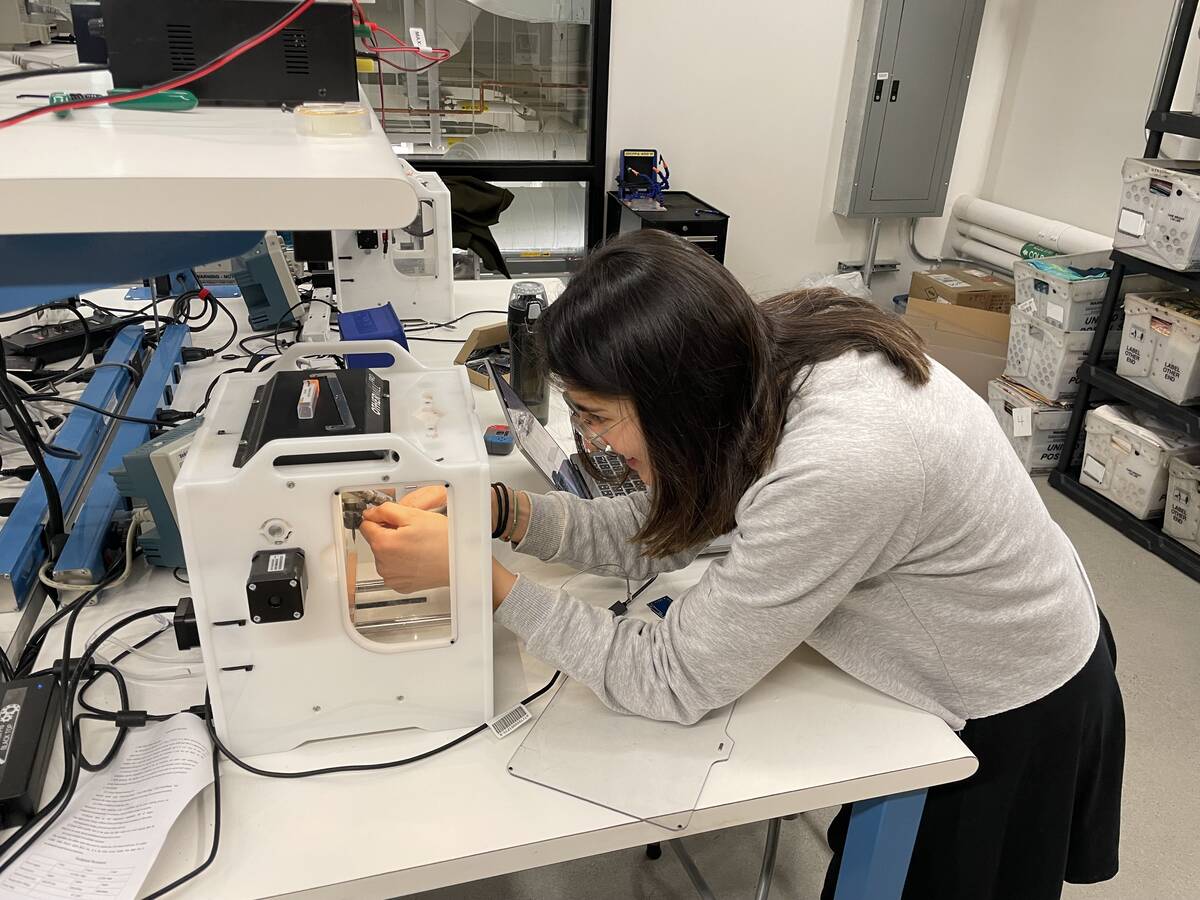

First, I forgot to measure the custom z-height of the copper plate. It failed multiple times, and the reason is that Bantham Tools is using electric current to tell the endmill when to stop. For that, you need to awkwardly use something that is electrically conductive and connect the copper plate to the mill while it’s auto-adjusting the z-height. The initial height it measured was too high, so the milling didn’t go deep enough - another restart. But eventually, I got to a good height.

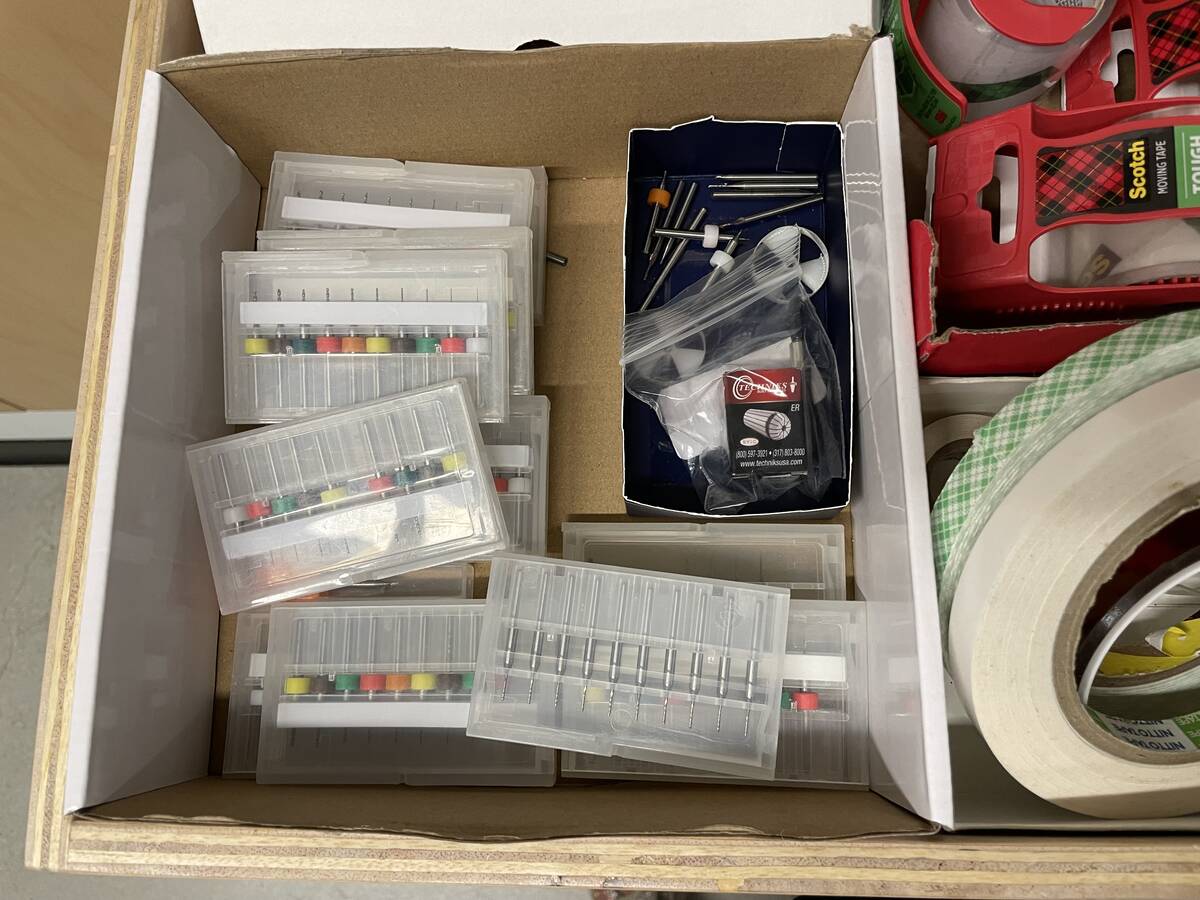

Second, I did break my 1/64" endmill. Oops. It worked great on the traces, and I knew we were supposed to use another one for the outline, and now I know why. The mentor from the Mezzanine told me it had something to do with the speed - a 1/64" endmill should technically be able to mill the outline, but it’s too slow, so it breaks. I had to restart again, and use a 1/32" endmill for the outline. {{ <video “./milling.mp4”>}}

Take Two: Remilling on the Roland

Unfortunately, I ended up ripping off my traces during soldering, so I had to make a new board.

Since I still wanted to learn how to use the Roland (and seriously, nobody but Metropolis from Project Manus and EECS has the nice Bantam machines), I used it for take two. A couple of quick points:

- The Roland doesn’t have an auto-z feature. So you need to first put in the end mill as high as you can and move to origin. Then you manually drop the end mill until it touches the copper plat and tighten it.

- The bed may not be level. Try to really press down the copper plate.

- You should always have a second layer underneath whatever you’re cutting. This way, if the mill happens to go too deep, you won’t damage the bed.

- The Roland goes into emergency mode when its lid is opened too soon after it has stopped moving. Always wait at least 5 sec before opening it. Once it’s in emergency mode, you’ll have start over setting up.

On MODS:

- TAKE A NOTE of your x and y positions in MODS. You’ll need them again later for the outline. Once MODS is refreshed, it deletes any values you put in.

- You can feed it a png or svg. Jake wrote a ULP, which is like a script, for Fusion, that lets you export your footprints as png. More here.

- The traces and outline need to be entered and milled separately.

- When you have throughholes like I do, you will need to enter a separate throughhole png, adapt the cut depth (the copper plates are 1/16 in thick), and mill again.

- Make sure you selected the correct tool in MODS. ❗️

- Always hit calculate again. It never hurts to hit it and you should definitely hit it before milling to avoid issues.

After realizing that MODS cannot specify throughholes, or I fail to set up that feature, I decide, after all, to give up on the Roland. Or so I thought. I learned from Anthony that MODS can indeed do throughholes but I had been overwriting the settings. So I finally got the board from the Roland.

Soldering

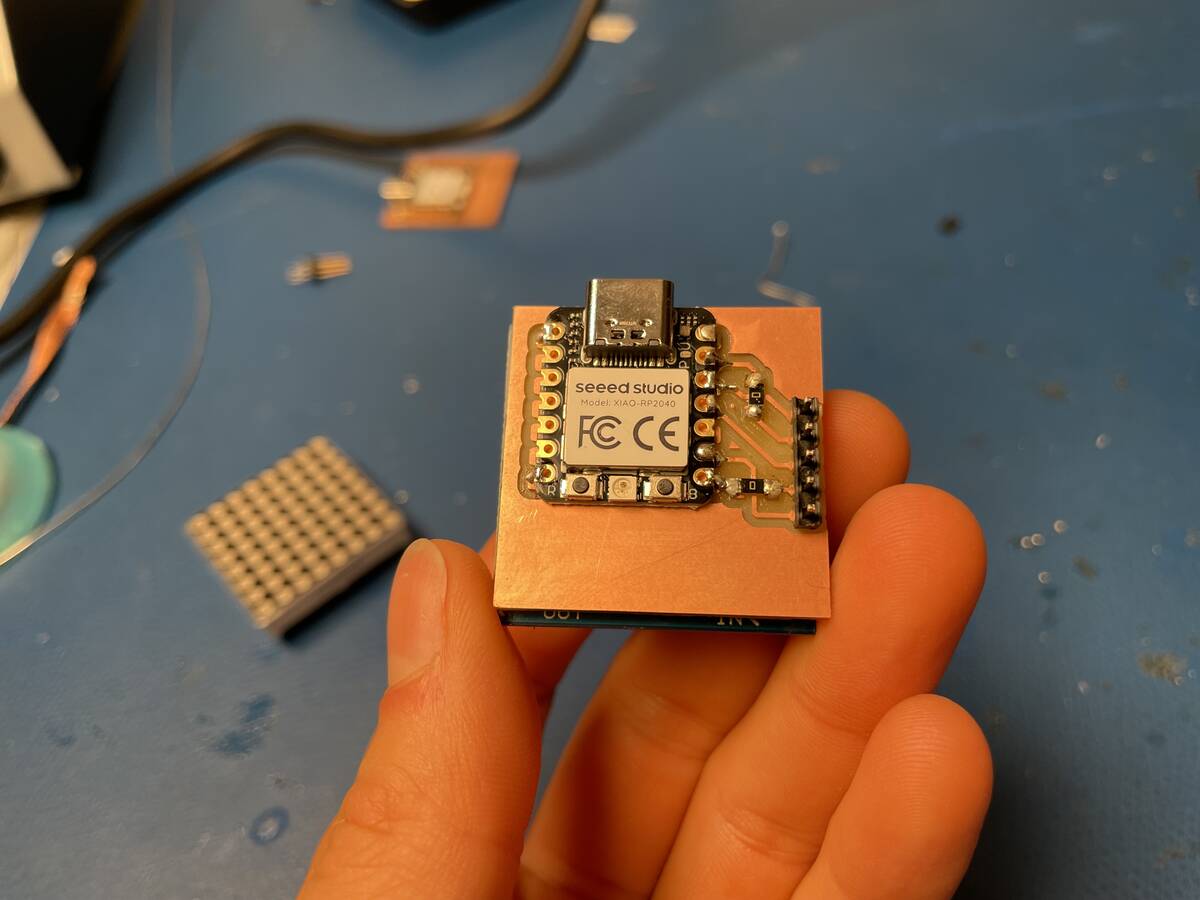

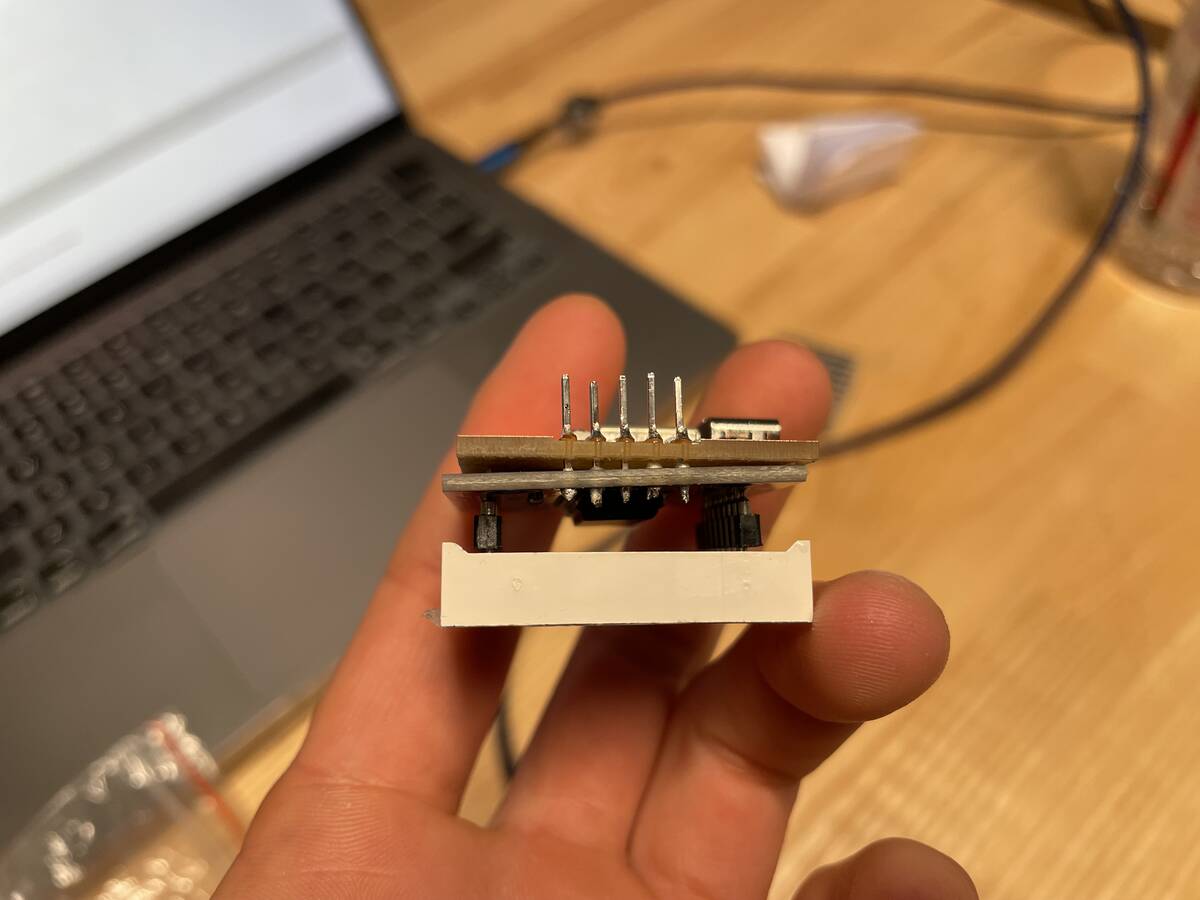

This is how it fit:

I guess it works.