Week 8: Computer controlled machining

Background

For this assignment, we were asked to make (design + mill + assemble) something big.

Materials

Creating the outline

This idea started when I thought about how I would store this project when it was completed. I only have so much space in my apartment, so I came up with the idea of creating a wooden sculpture that could later be burned. It wasn't until I was actually milling this that I realized OSB wood releases toxic fumes when burned, but I was deep enough into things that I didn’t care.

Once I was settled on the idea, I set out to find a design precedent. The only thing I could find was a decorative campfire centerpiece that I found on Amazon.

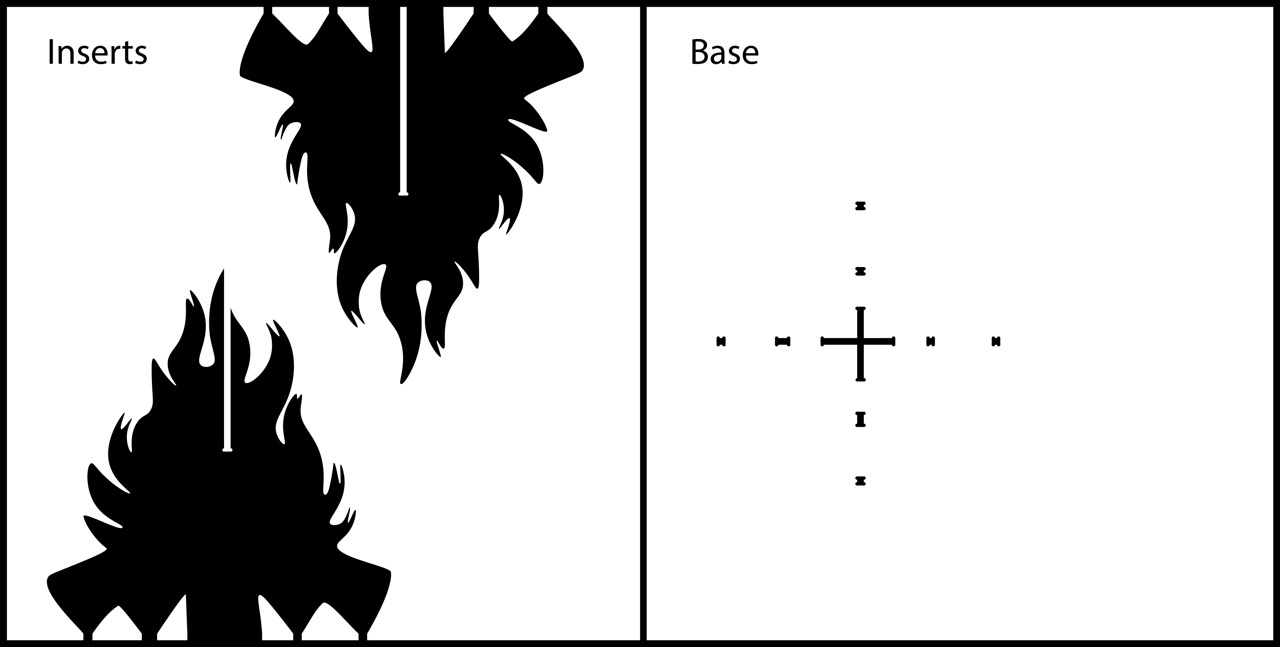

This turned out to be good enough, because I copied the photo into Illustrator and imaged traced the outline of the shape.

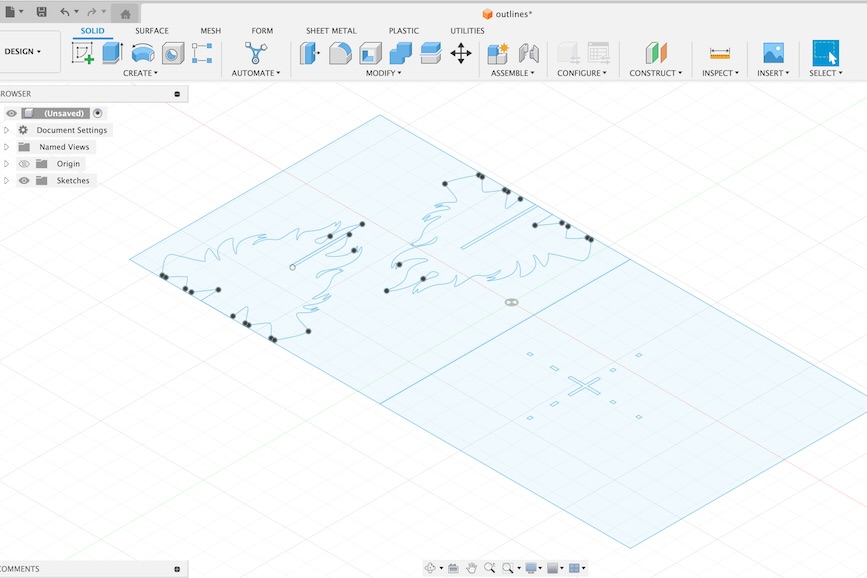

After that, I made two slits that help the two main pieces slide together and mapped out the holes on the base. Although this could all stand on its own, I still wanted to create a cohesive piece to test my understanding of kerf and tolerances.

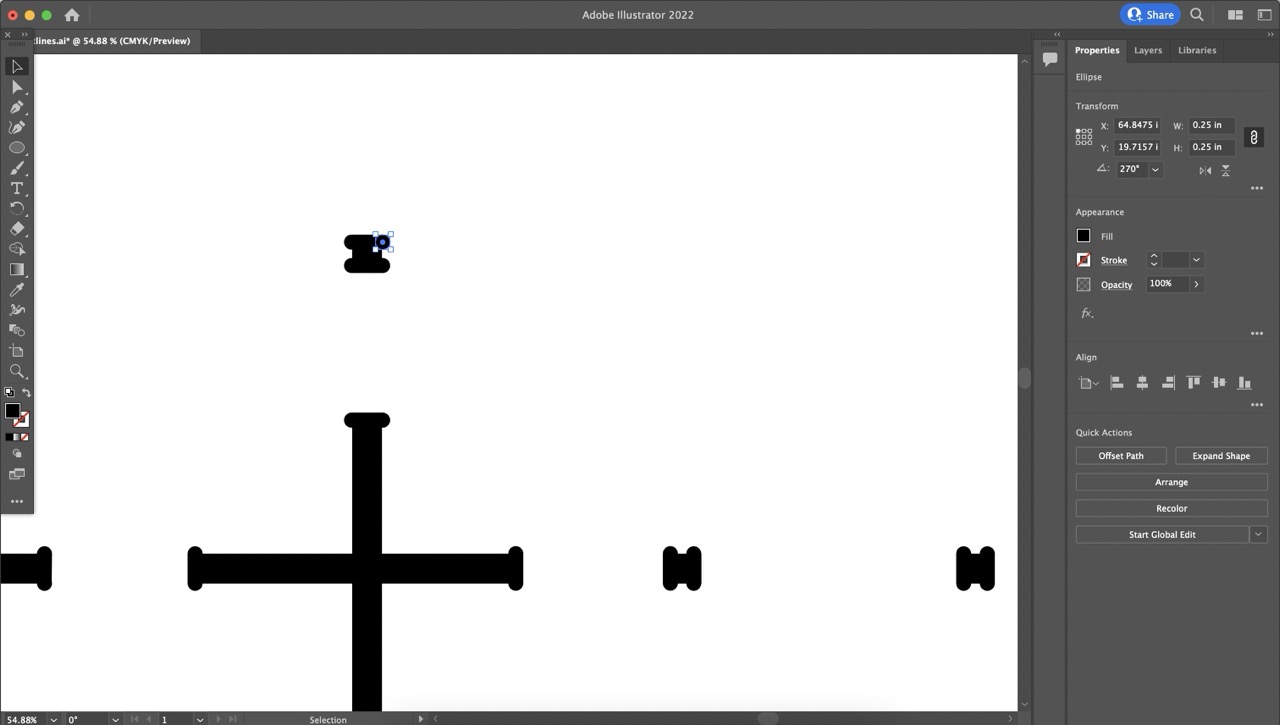

I added .25" circular (diameter) dogbones to all joints in order to make snapping the pieces together an easier process.

Milling something big

Once my design was mostly completed, I went through the steps below. If you don't want to use Carbide Create like I did and instead want to use Aspire, follow these steps. Otherwise, follow along:

- Export your design from Illustrator/Fusion 360 as an SVG (DXF wasn't working for any of the students in my section, but SVGs worked for some reason)

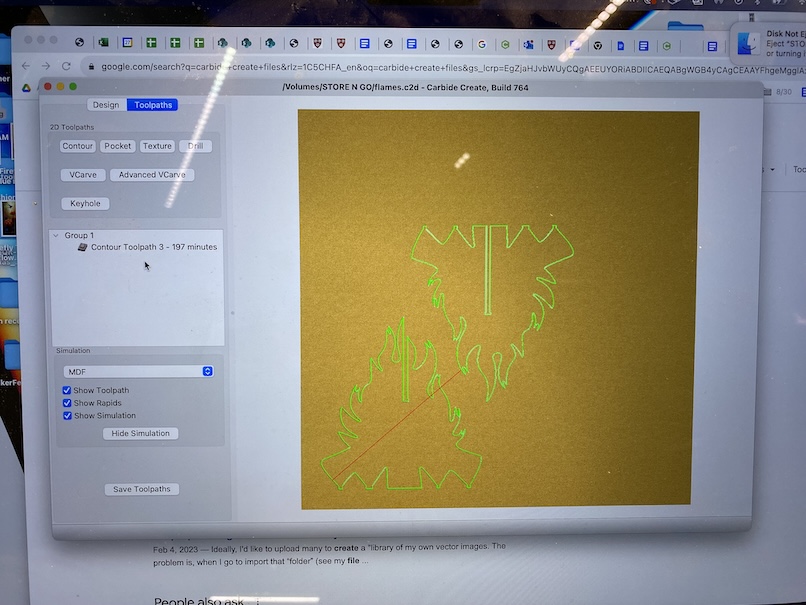

- Import SVG into Carbide Create - this is where you'll generate your toolpaths

- In Carbide Create, add tabs to keep your design steady as it's cut through, adjust your cutting material and its thickness, and select the endmill you'll be using (1/8" double flute upcut)

- Simulate your toolpath to make sure it looks right

- Export your file from Carbide Create as a .c2d - this is what Carbide Motion will be able to understand to actually translate everything into gcode

- Import into Carbide Motion

- Change endmill on ShopBot to 1/8"

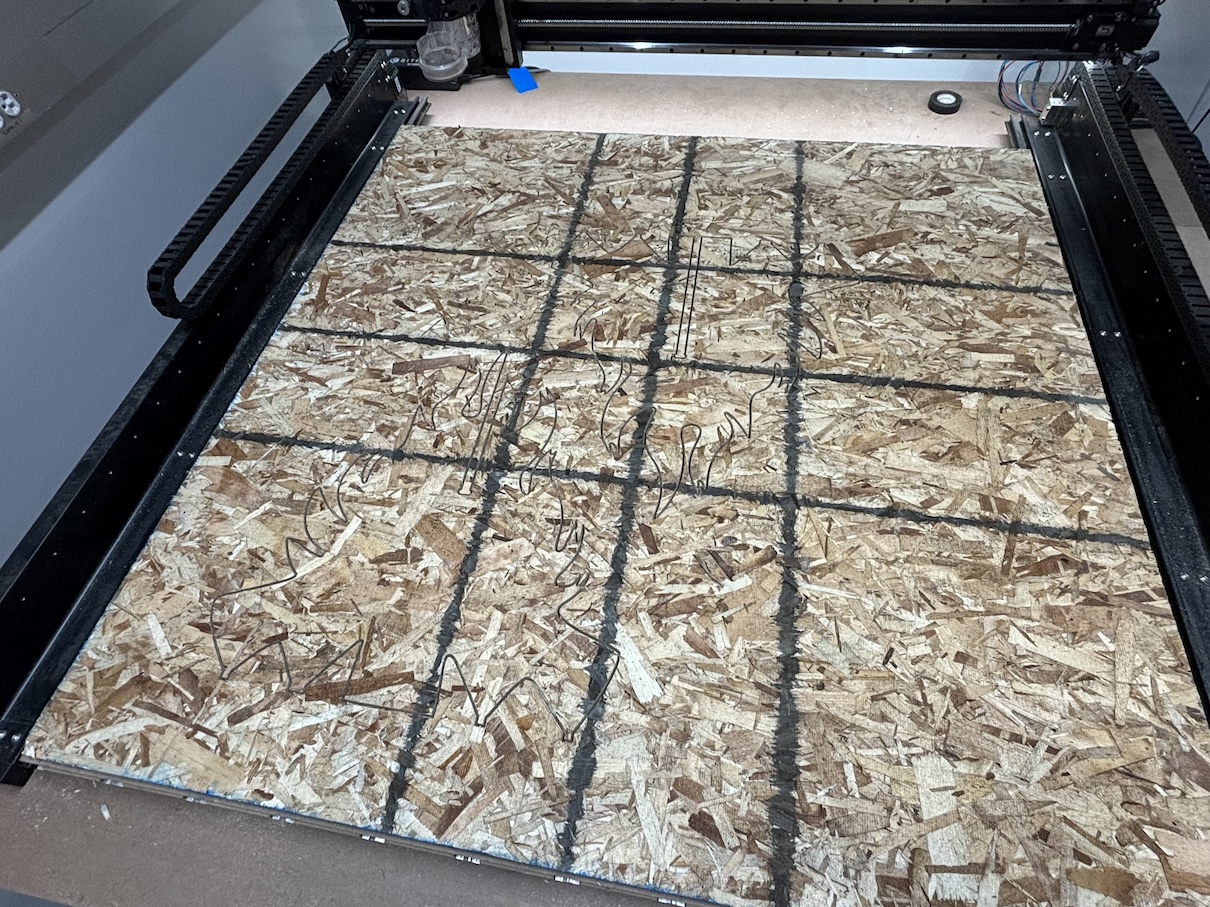

- Load your 4x4' OSB onto the ShopBot's bed

- Move the mill to the bottom left corner of your material then set the XYZ origin as you wish

- Remove OSB from bed

- Run a practice route so you can make sure your design won't run off the OSB sheet or hit any screws you plan on using to secure the material

- Load in material again

- Use a screw on each corner of the bed to secure your material onto the sacrificial layer

- Put in earplugs, glasses, and a mask you squid

- Start the vacuum attachment that will suck up the shavings

- Start the spindle using the "Engage Spindle" button next to the e-stop

- Start your job on Carbide Motion

- Once the job has completed, wait for ShopBot to move to the upper right of bed

- Remove screws

- Remove material from bed

- Vacuum

Assembling something big

- Saw through tabs and any remaining OSB to finish cutting out your design. I didn't cut through enough, but only by a little, so I had a little bit of sawing to do.

- Assemble (my tolerances and dogbones made for a perfect fit!)

- Cry about the fact that you are unable to mill the base for your design due to resource constraints

- Done!

Final thoughts

Overall, another... cool... week. It was unfortunate that the Harvard section couldn't mill for 4-5 weeks past when everyone else had finished, but I'm grateful we got the chance to at all!

This wasn't an easy process to figure out the first time, but I can imagine with a few more iterations it'd seem much, much easier. There's so much potential for really cool creations with the ShopBot!

If you'd like to recreate this project, you can download my SVG files here.