Week 7 - How to CNC (almost) Anything Big

For this week's project, I wanted to build a piece of furniture that I could keep or use in the long term, but my house is already pretty full of furniture, and I didn't want to make something that I would have to throw away, so I decided to make a stick rack for the club hockey team. I started by sketching it out on paper, and then I went to design each of the faces that I would need to cut out (also on paper).

I probably would have been better off designing straight in fusion since the boards were not in fact 1/2 inch thick, and they were much closer to 5/8ths. My paper and pencil sketch, unfortunately, was not paraparametric, and so I had to go back and redesign each of the faces to have cut depths 5/8ths of an inch thick. I also had to add a few more press-fit joints than I initially drew after seeing how it came together.

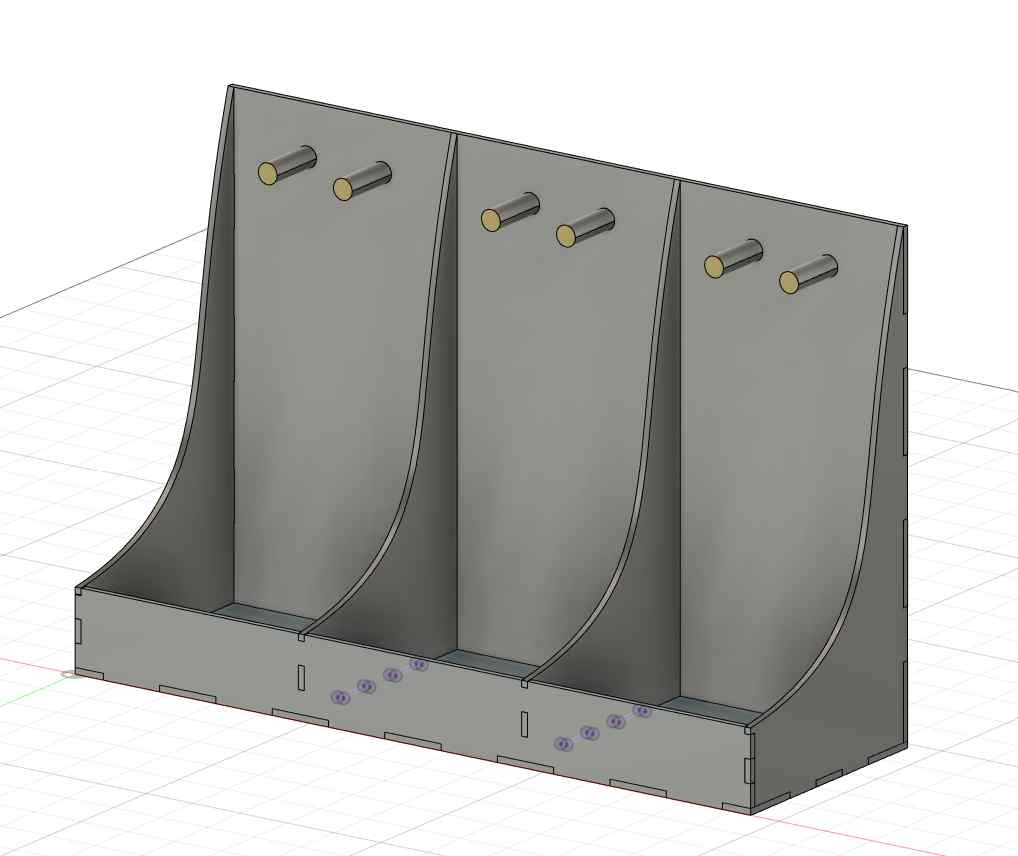

I began in fusion by drawing the base. I cut out press fit sockets for the front and back panels, as well as a set of sockets for the four vertical dividers that would also serve as the left and right walls.

I then designed the front lip which bears some of the weight of the sticks as they rest against it at an angle, but more significantly it contains a critical vertical support socket for the four dividers. I also added a small lip to the back of the base to prevent the dividers from sliding on the back wall.

I then designed the back panel, which has a set of sockets for the dividers, as well as a set of sockets for the connection to the base. I also added a set of 2 inch holes to allow for wooden dowels to provide vertical support for the sticks so that they did not all rest on the dividers. The pegs also allow for the sticks to be removed and replaced easily without having them pile up in the rack.

Last, I designed the dividers, which each have two press fit joints for the base, one the front lip, and three in the the back panel. Initially I had a simpler design with triangular dividers, but I didnt like the look of them, so I revised it to be a semicircular cutout, but this also didn't seem quite right, so I ended up with a more complex curve that mimicked a hockey stick which I liked the look of.

TODO: As of this time the CNC for the Harvard section has still not been set up so I am not yet able to cut and assemble this piece. I will update this section with photos of the final product when I am able to do so.