3D Bio Printing & Biofabrication

Week 9

3D Bio Printing & Biofabrication

Background of this Experiment (HTTGA)

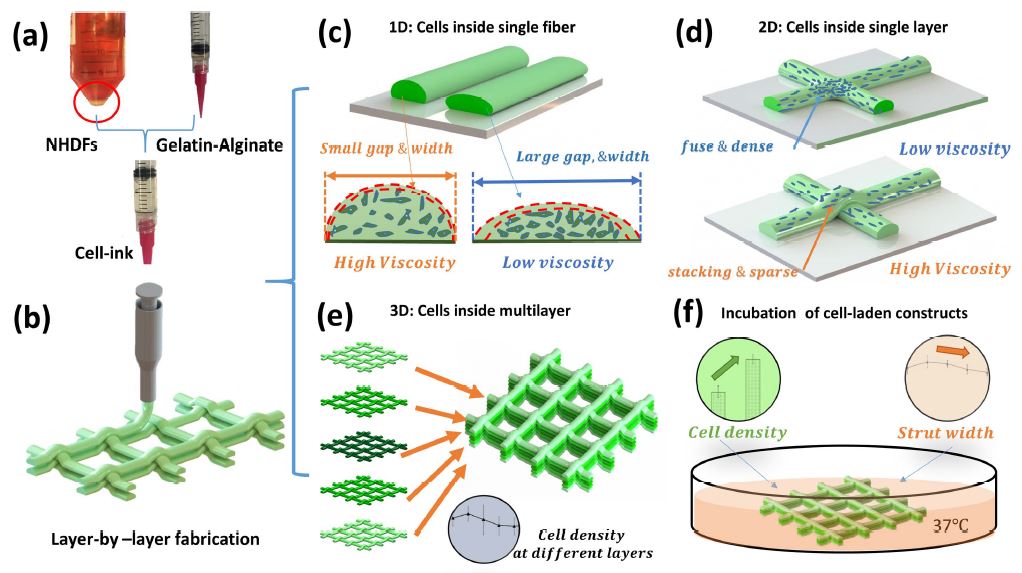

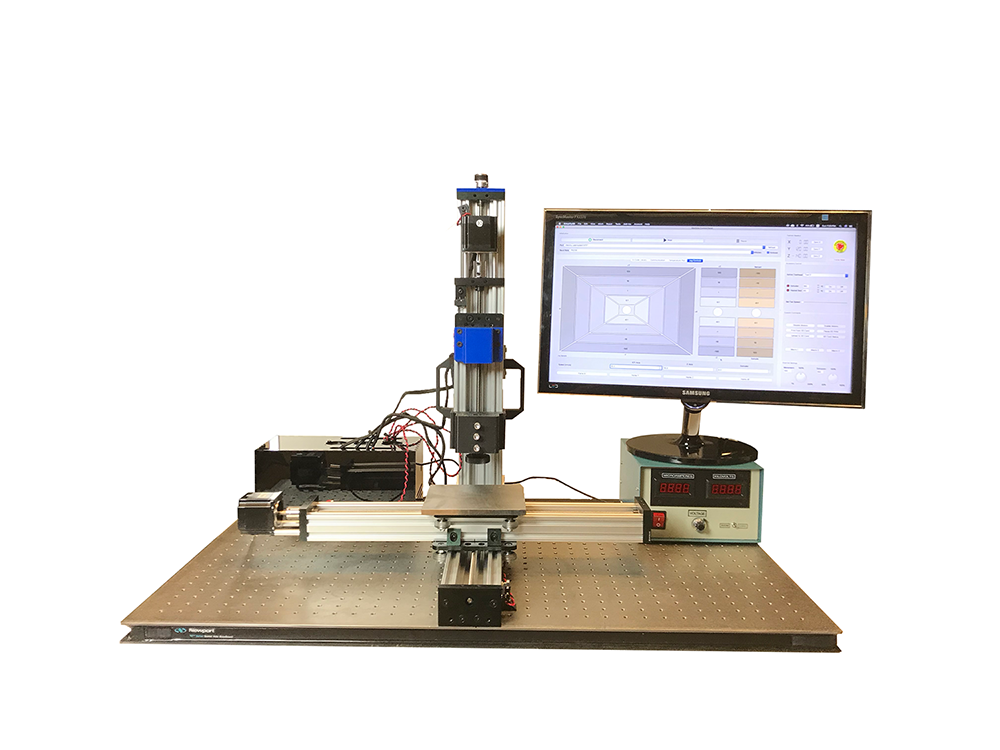

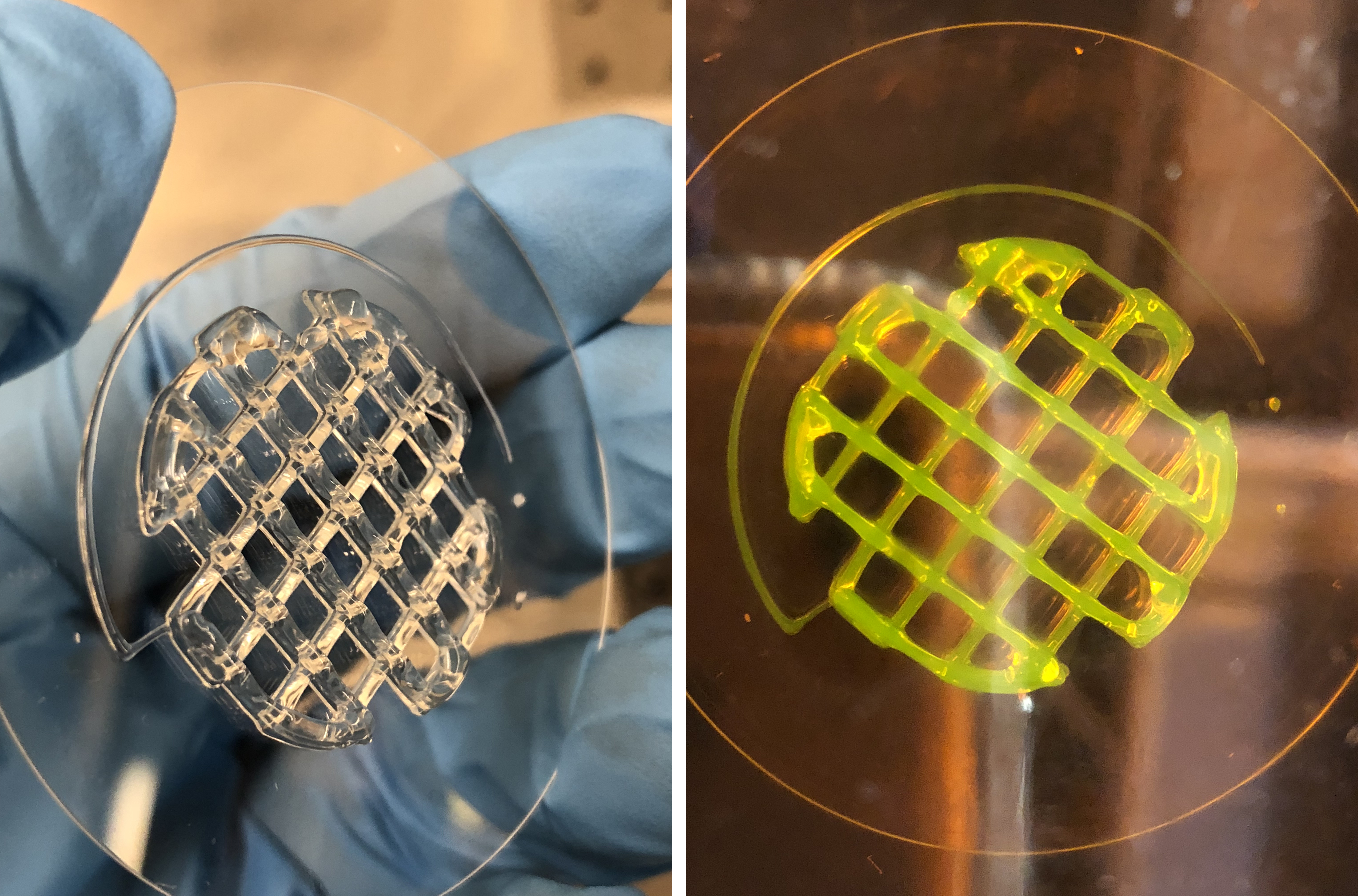

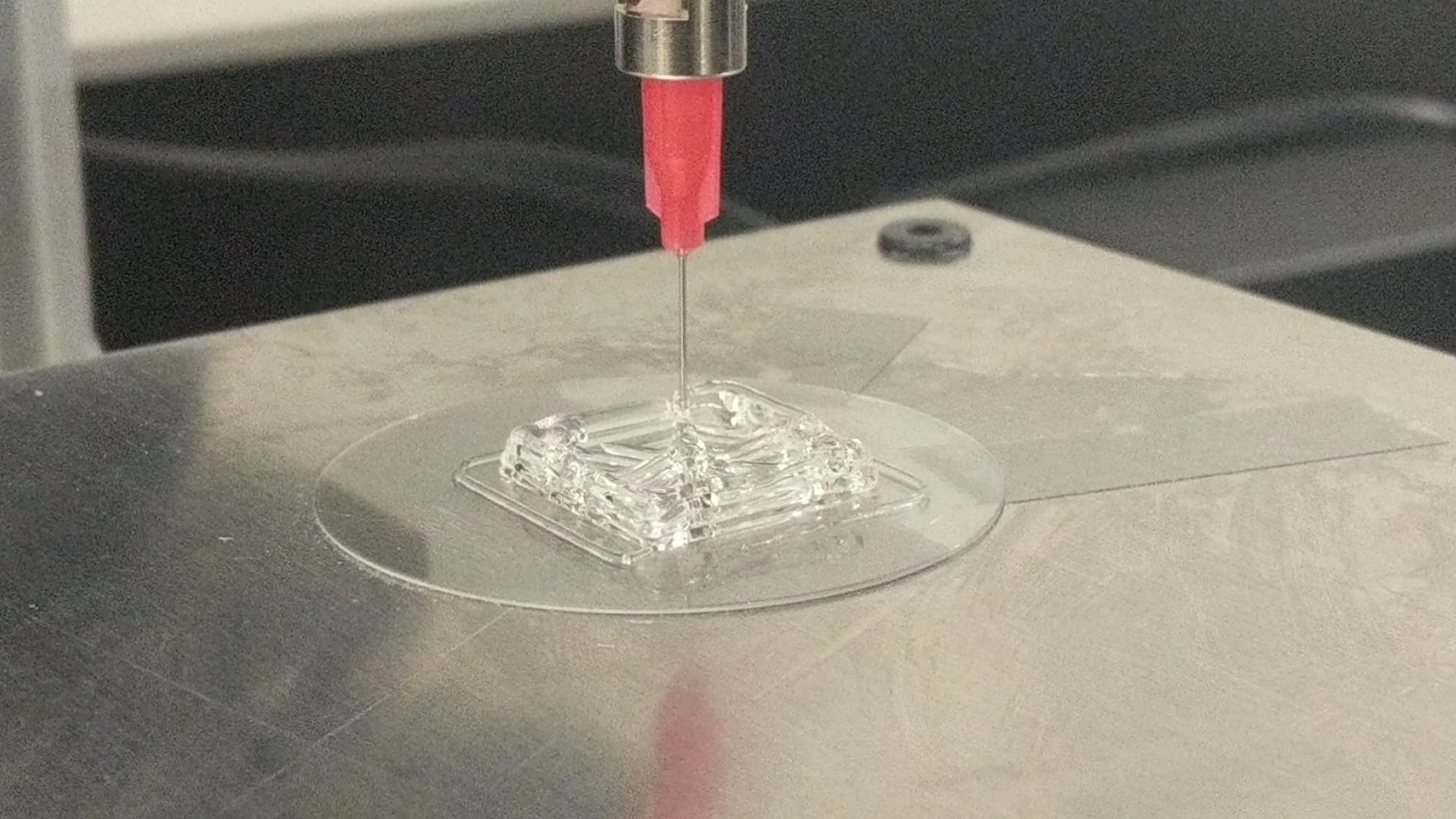

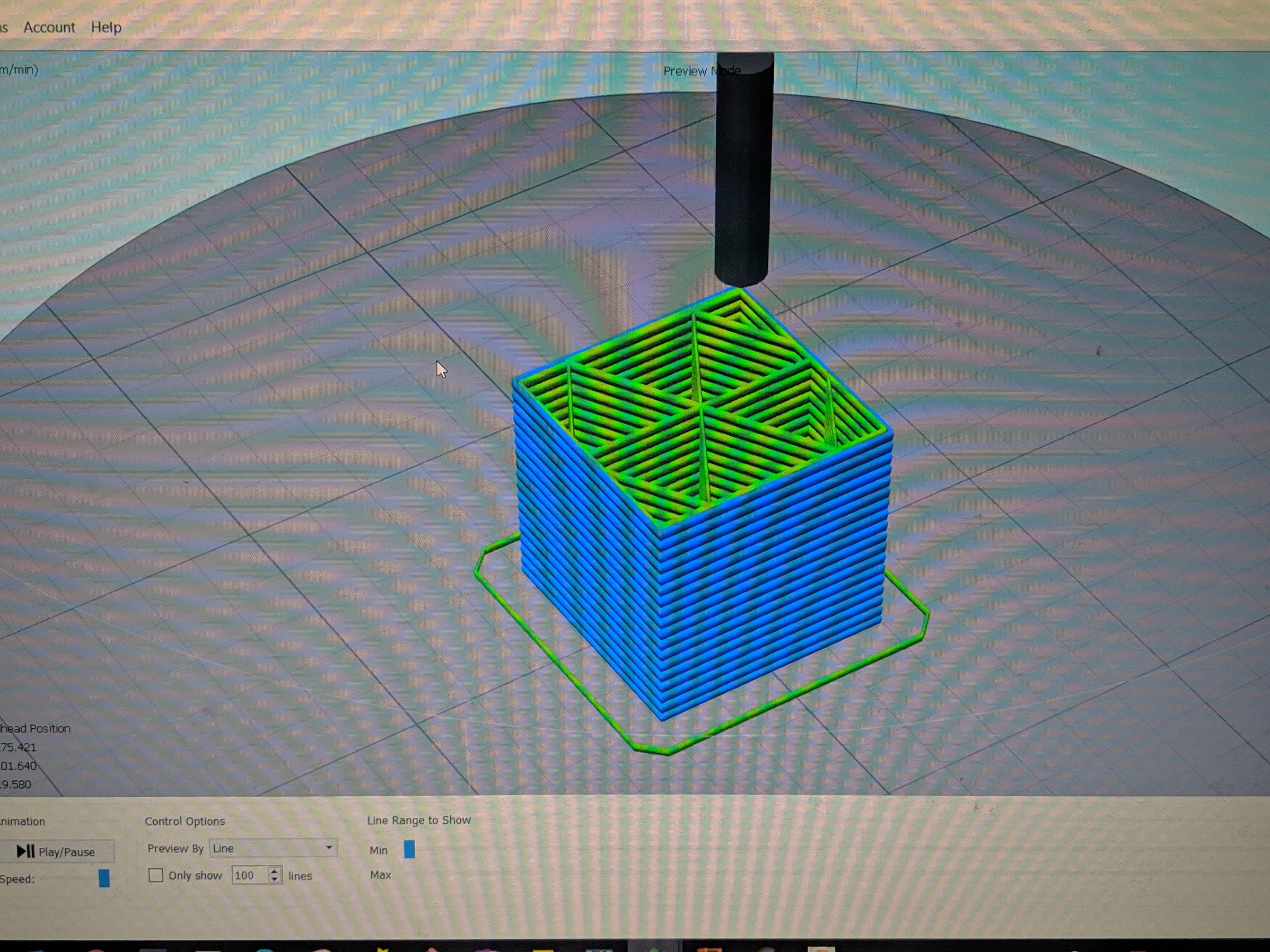

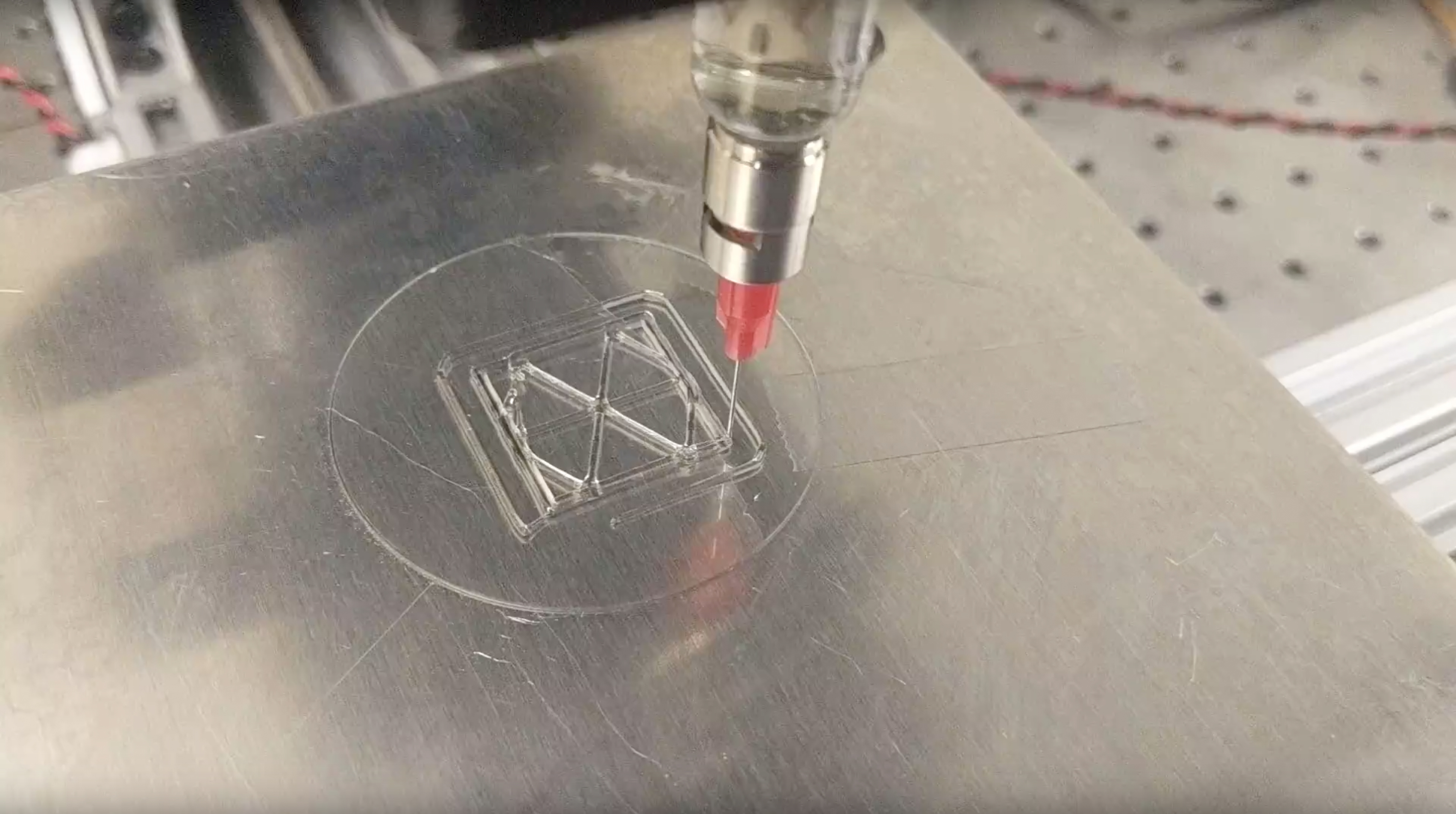

http://fab.cba.mit.edu/classes/S66.19/S66.19/assignments/bioprinting.htmlCell printing process could be devided in to 3 major steps : cell engineering, bioink formulation, and digital fabrication. In this experiment, we performed a transformation protocol in order to produce Ecoli bacteria that express GFP. We used a thermoresponsive gel called Pluronic . Here the task is to learn how to optimize its rheological properties for optimum printability with and without cells. After having optimized the bioink formulation, we can design and print using a custom-made bioprinter. Printing 3D soft matter structures with well defined geometrical features requires a careful parametric study of the independent process parameters (extrusion rate, tranlational stage speed are the most important ones considering the ink's rheological properties).