Bioprinting: Leveraging 3D Printing for Biofabrication

April 18, 2019

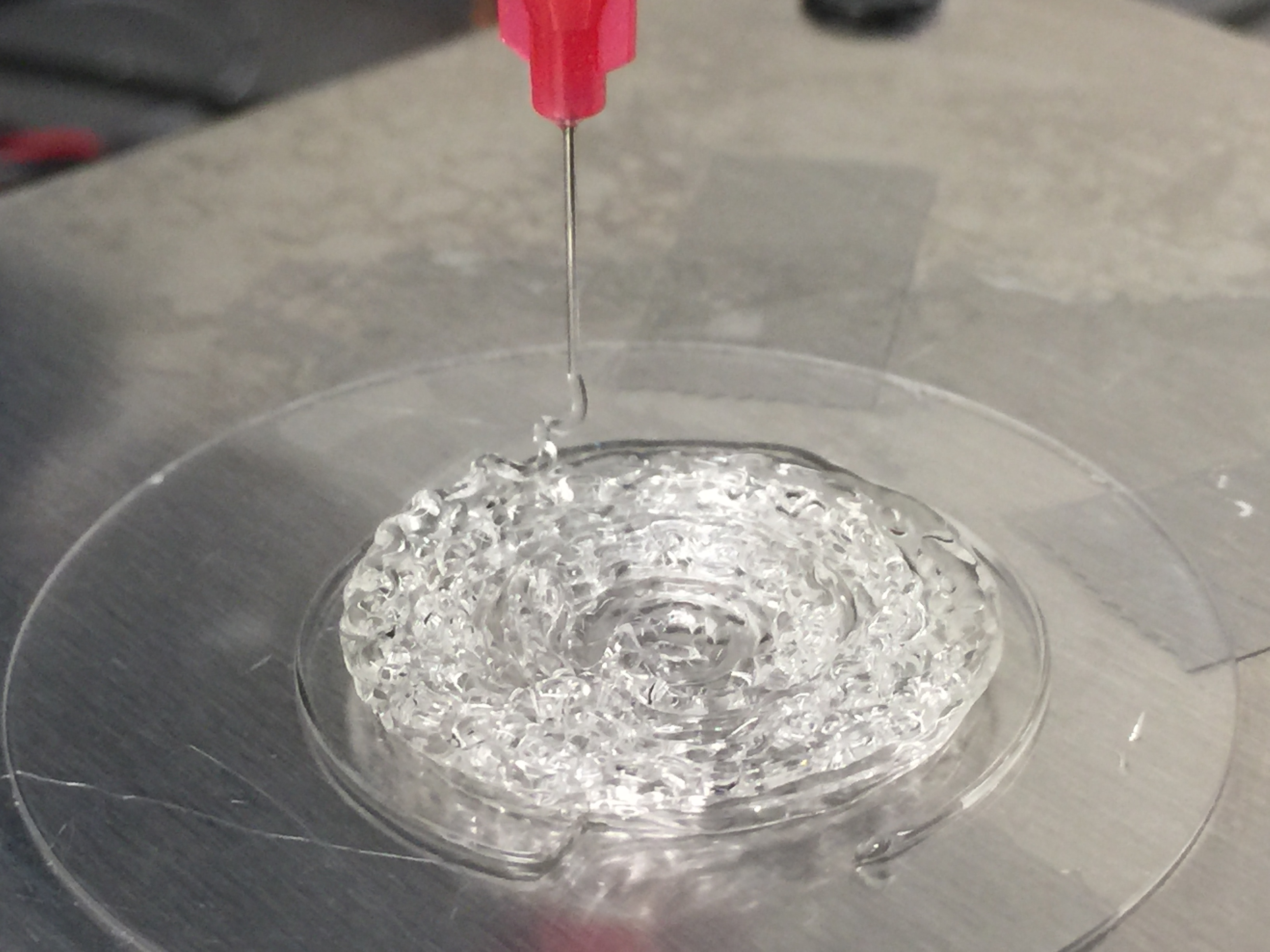

For this week, we made a bioink and then 3D printed that bioink in a shape of our choosing. We used a bioink that is a gel at room temperature and a liquid when cold. This allows us to mix the cells in easily but still be able to print structure. However, the bioink material is not as strong as traditional plastics (and the printer does not provide support material), so the geometries it can print are limited.

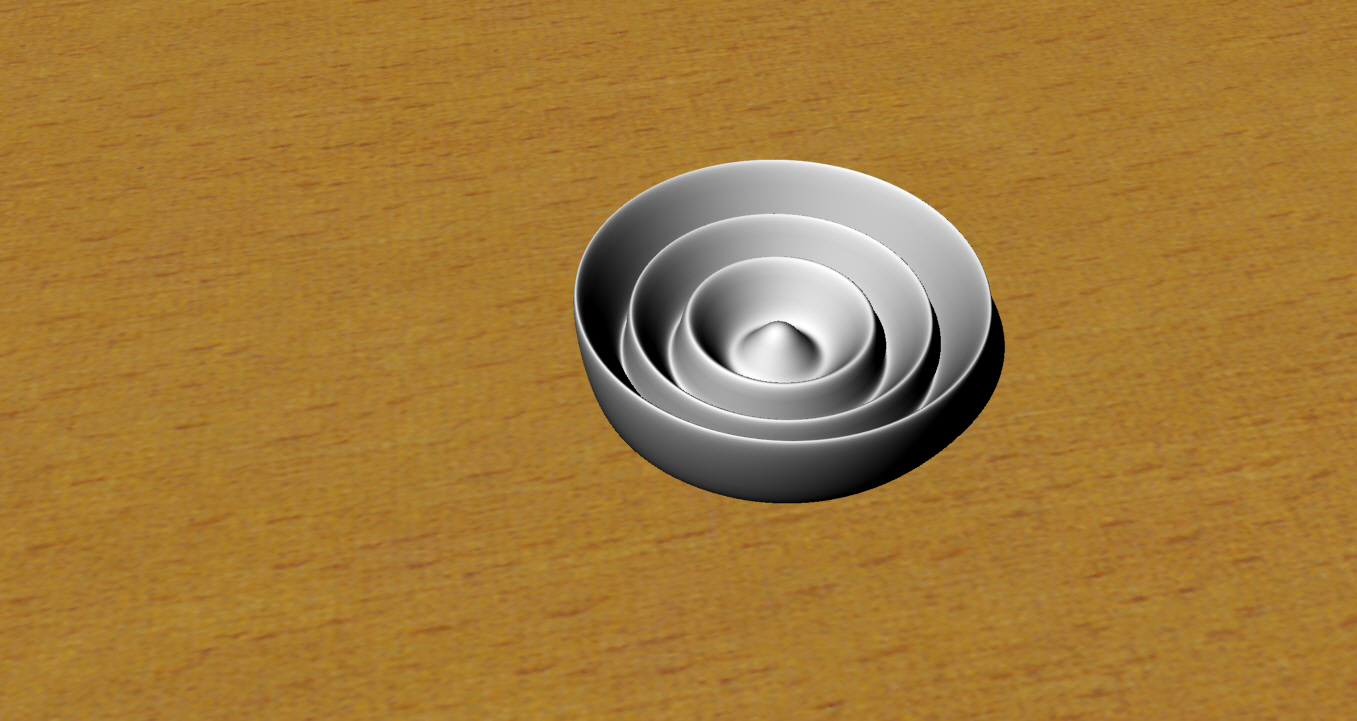

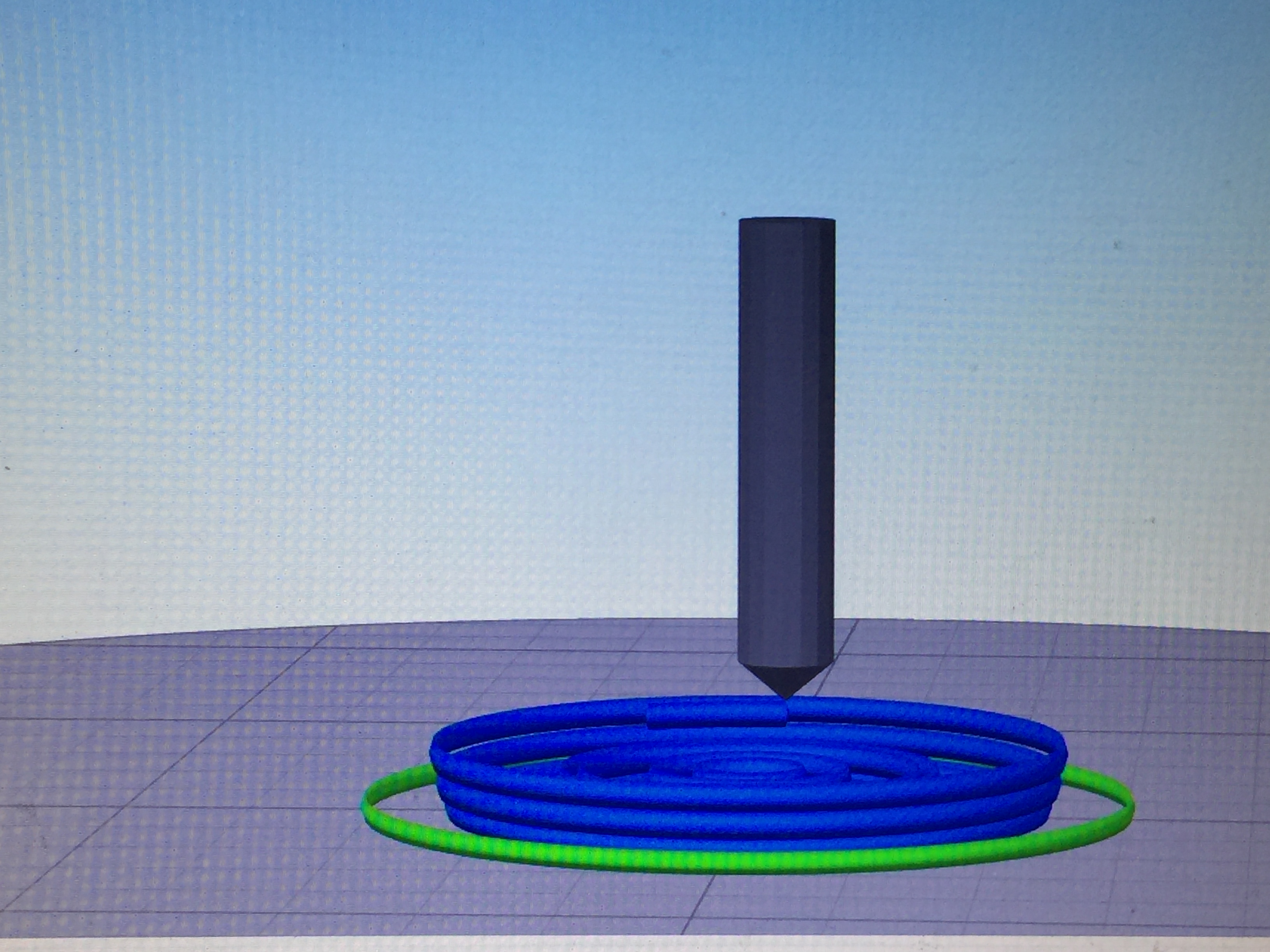

I created the above geometry by revolving a curve such that it only had a very minimal incline. However, at the scale of the bioprinter, the walls proved to be too thin to support themselves. The software was able to lay out a path that looked promising, but that collapsed over time.

This could potentially be fixed by using thicker walls with absolutely no incline.