Beam Dynamics Laser Cutter Tutorial

Beam Dynamics

laser cutter.

Creating a

Drawing

1. Create the

pattern you are going to cut using a drawing program like

CorelDraw

2. Export

your drawing as a dxf or in HPGL (.plt) format

The Beam's LaserLink software can import HPGL

files (.plt), and Drawing Exchange Format files (.dxf).

If having problems opening dxf file in Laserlink open in Rhino

and save as default dxf this should work.

Some have had more success with HPGL files. CorelDraw11 lets

you export drawings as .plt files. An HPGL file is

also easy to generate programmatically--it's a list of x,y

coordinates that are preceded by either Pen Up (PU) or Pen

Down (PD) commands. A PU command moves the plotter to

the specified point without cutting/drawing and a PD command

moves the head while cutting or drawing.

If you must

use .dxf files, make sure all of the lines in your drawing are

on the same layer and that your drawing contains no groups.

Nested groups especially cause all sorts of problems in the

LaserLink software.

Laser Link

Software

LaserLink

software manual

3. Open the

LaserLink software

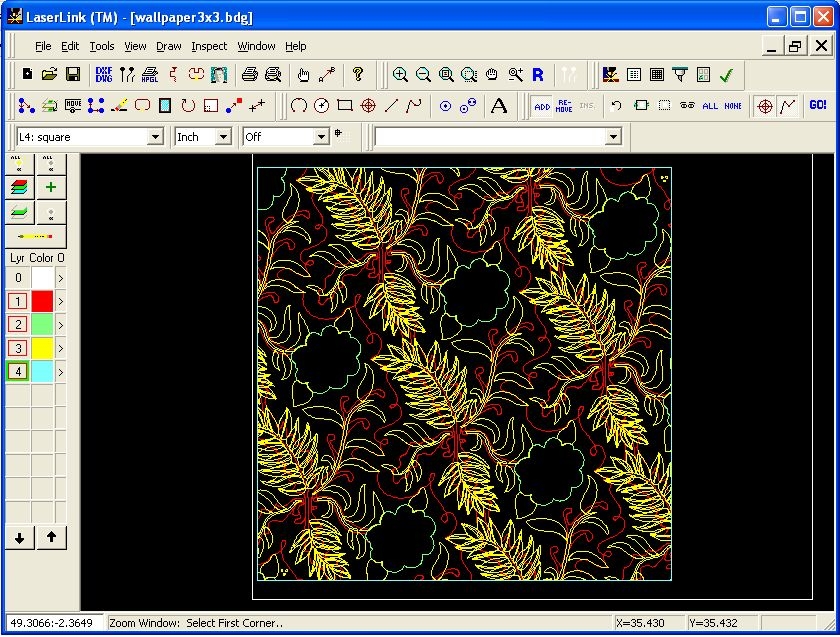

Here's what

the software looks like with a 4 layer drawing. (Each layer was

imported as a separate HPGL file.)

4. Import

your drawing

Go to

File/Import and select the appropriate file format

5. Editing

your drawing

The LaserLink

software is not terribly user friendly. To accomplish any

action:

a) left mouse

click

b) select the

area of the drawing you want to modify

c) left mouse

click again

d) right

mouse click

e) left mouse

click to begin your action (moving, copying, etc.)

6. Save your

drawing.

If you don't

save your drawing, edits that you made may not be reflected in

the toolpaths.

7. Create the

toolpaths for your drawing

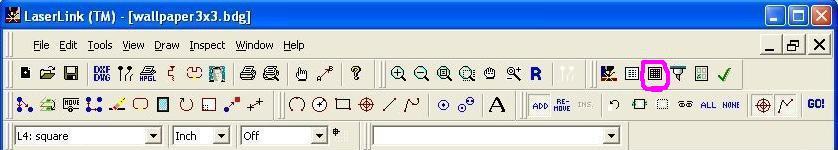

a) Create a new material entry in the "database

table" with the speed and power settings appropriate for your

material. Click on the "database table" icon and fill in the

entries for your material.

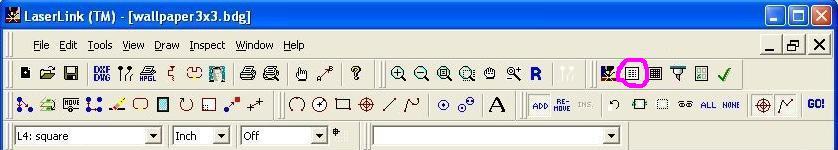

b) Define the

"process table", the laser cutter toolpath, for your drawing.

Click on the "process table" icon. For each layer in your

drawing, select the appropriate material.

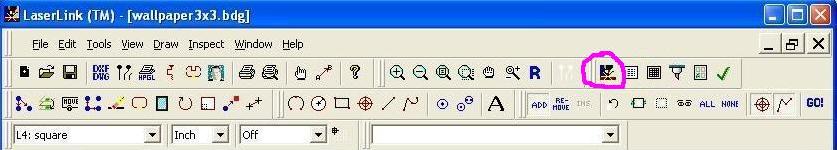

c)

Create the "process" by clicking the "process" icon or by

clicking "process" after you've created the process table. Save

the process file to: C:/BeamDynamics/JOBS.

8.Open the

Beam HMI software

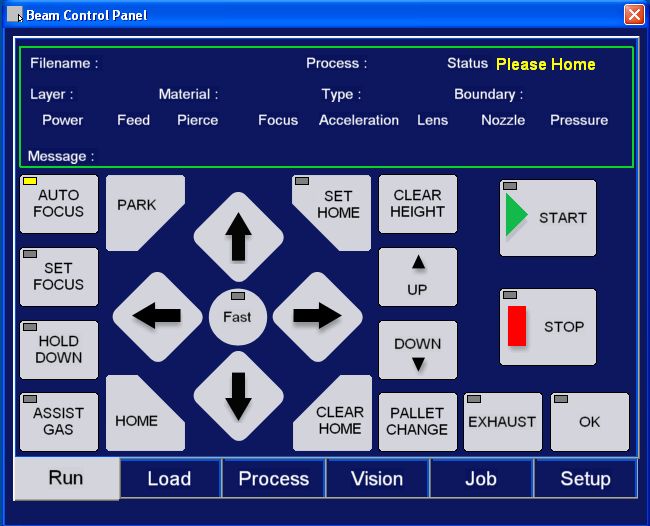

This is the

control interface to the machine. This is what the main window

looks like.

9. Home the

machine

If you get a

motor fault message (which I sometimes get the first time I try

to home the machine), turn the machine off with the key and with

your hand move the head around a bit in the x and y directions.

Turn the machine back on & rehome.

10. Load your

job

Click on the

Load button and browse to your file.

11. Press

start to begin cutting.

Troubleshooting

Note: the

machine and software are pretty buggy, frequently exhibiting

inexplicable behavior and errors. I've listed a few of the

problems (& solutions) I've encountered below, but the list

is by no means exhaustive. When in doubt, home the machine. If

that doesn't work, cycle power. If that doesn't work, restart

the software.

Problem: I

press Start in the Beam HMI software, but nothing happens.

Solution: Home the

machine and try again.

Problem: I

press Start, and the head moves, but it doesn't cut.

Solution: Make sure

the laser cooler is turned on and try again. If that doesn't

work...

Home the

machine and try again.

Problem:

Motor head fault.

Solution: Turn off the

machine, manually move the head around with your hands. Turn the

machine back on. Home.

Problem:

Focusing error/fault.

Solution: Home the

machine and try again. If that doesn't work...

Move the Z

axis up or down a bit using the controls in Beam HMI (Be careful

not to crash the table into the head of the laser!). Home the

machine & try again.

Problem:

Laser head keeps "crashing" into loose material on the table.

This tends to be a problem with soft/light materials that are

blown around by the ventilation system.

Solution: To help fix

the problem, temporarily remove the bottom cone nozzle from the

laser head.