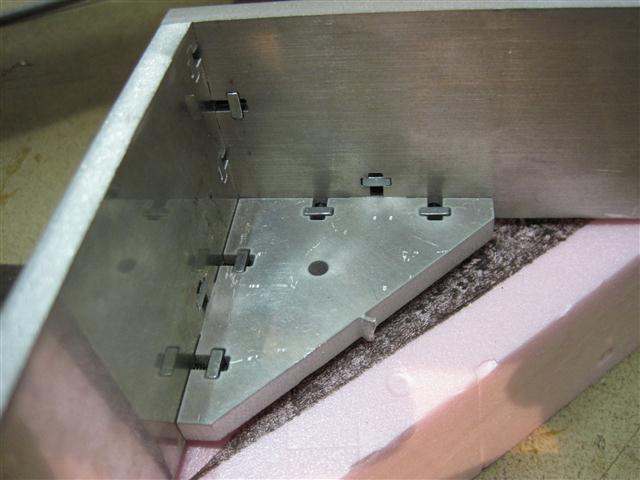

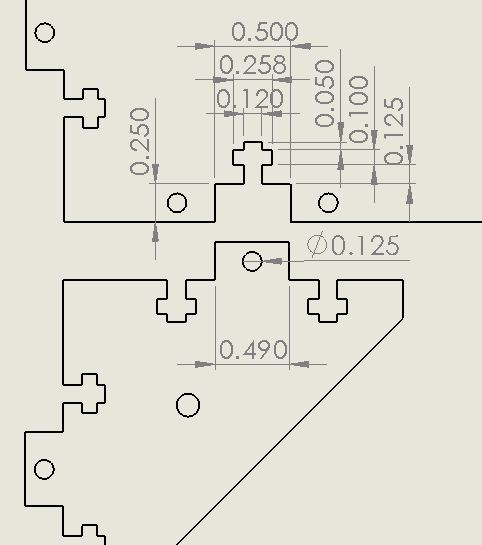

Captive T-nuts, or t-nuts (as termed by Charles Guan, who popularized their use at MIT), are great for rapid assembly of machines and also allow for easy disassembly and interchangeability. T-nuts are usually the name given to nuts with anchoring spikes that are pressed into wood to provided a threaded fastening point. However, t-nuts in this case likely derive their name from the distinctive shape that the nut slot makes in the stock material. One t-nut conists of a regular screw (usually a hex socket head), a square nut, and a distinctive slot geometry in the stock. T-nut fasteners can really only be made on rapid fabrication machines like a laser cutter, a 3D printer, or a waterjet cutter. T-nuts fully leverage the capabilities of these machines by allowing fasteners to be embedded in materials without much effort. In essence, the nut slides into the slot in one piece (which keeps it from rotating) and the screw goes through a hole in the other piece and into the nut, securing the two pieces together. The image and drawing below are dimensions for a 4-40 screw, 4-40 square nut, and 1/4" Al stock.

Part components can be attached in a couple ways with t-nuts. As above, they are most often attached at a right angle at a corner. In this configuration, it is important that screws start from both components in order to preserve rigidity in each direction. Two parts in a slot and tenon configuration can also be secured with a t-nut assembly.

page started by Daniel Fourie, MAS.863 Fall '10