Making the serial cable (This is the tricky one!)

-

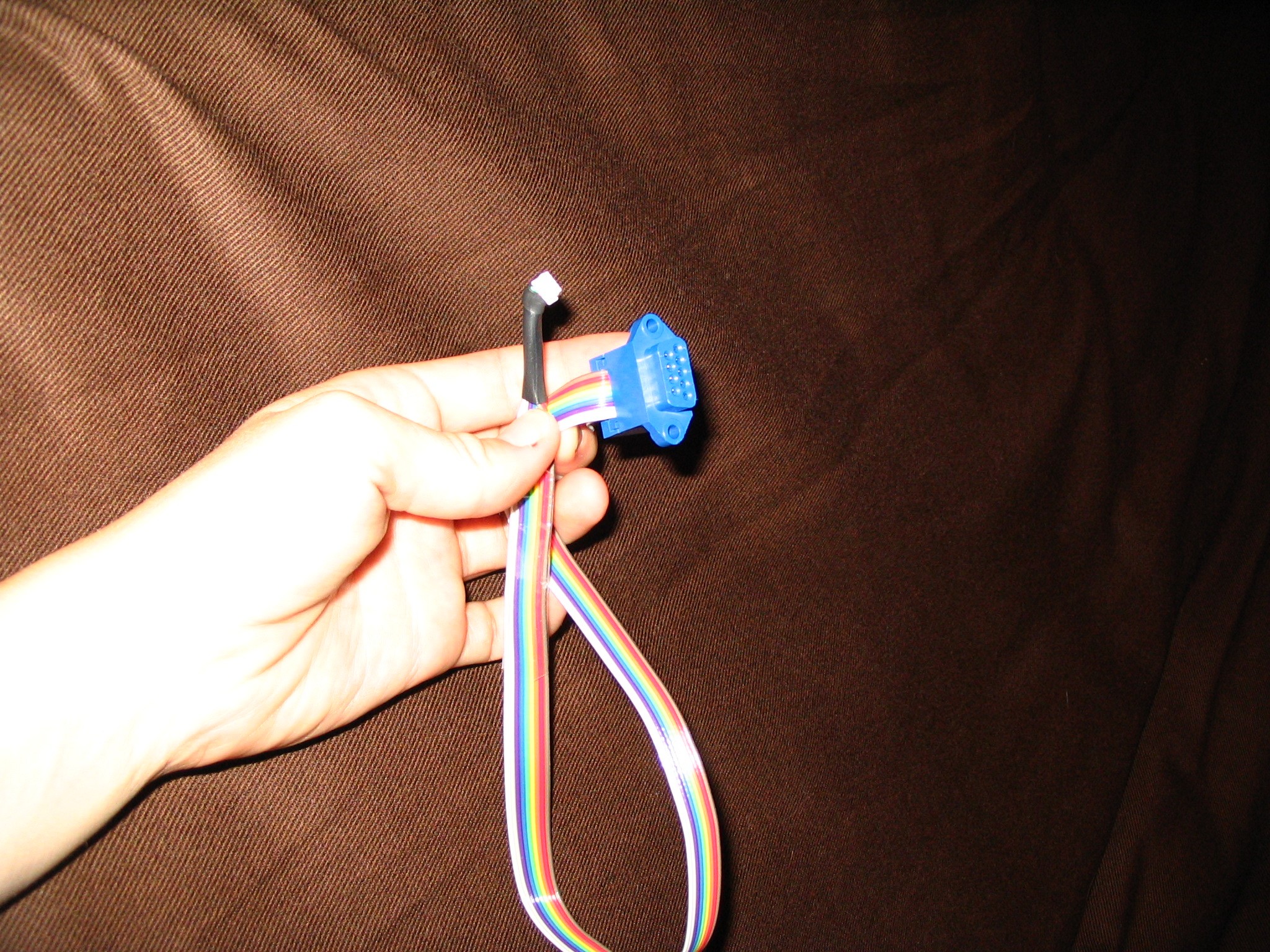

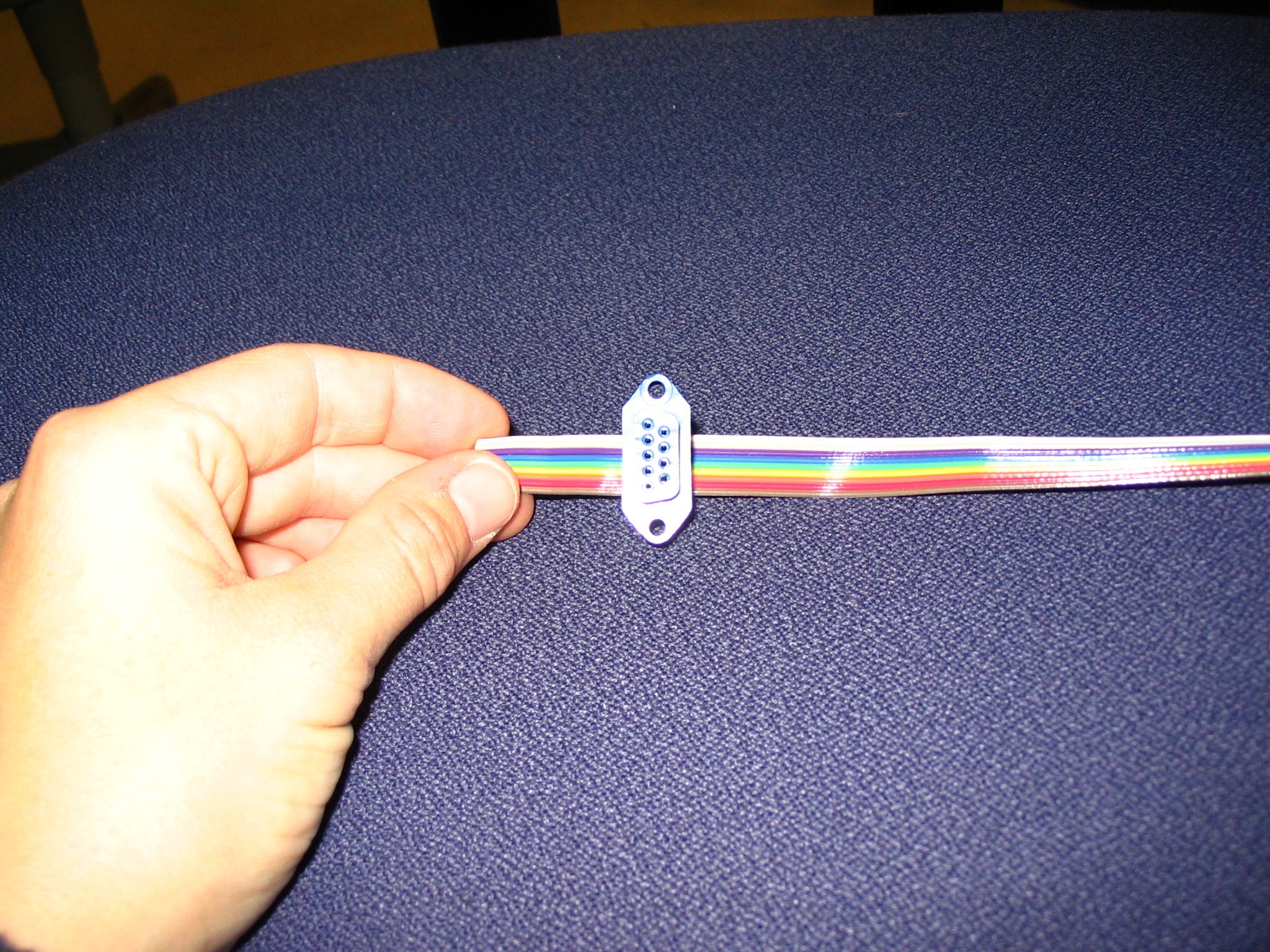

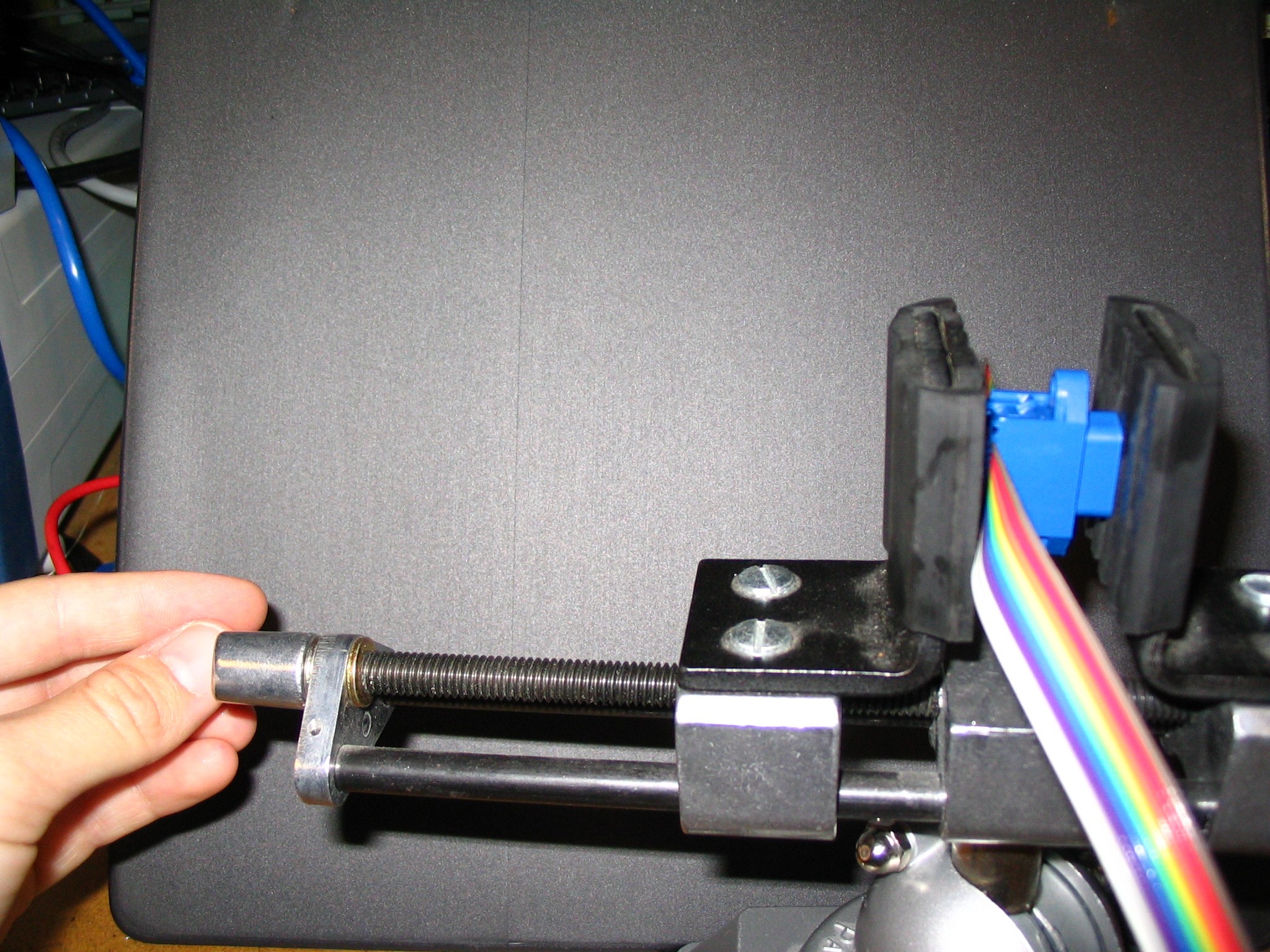

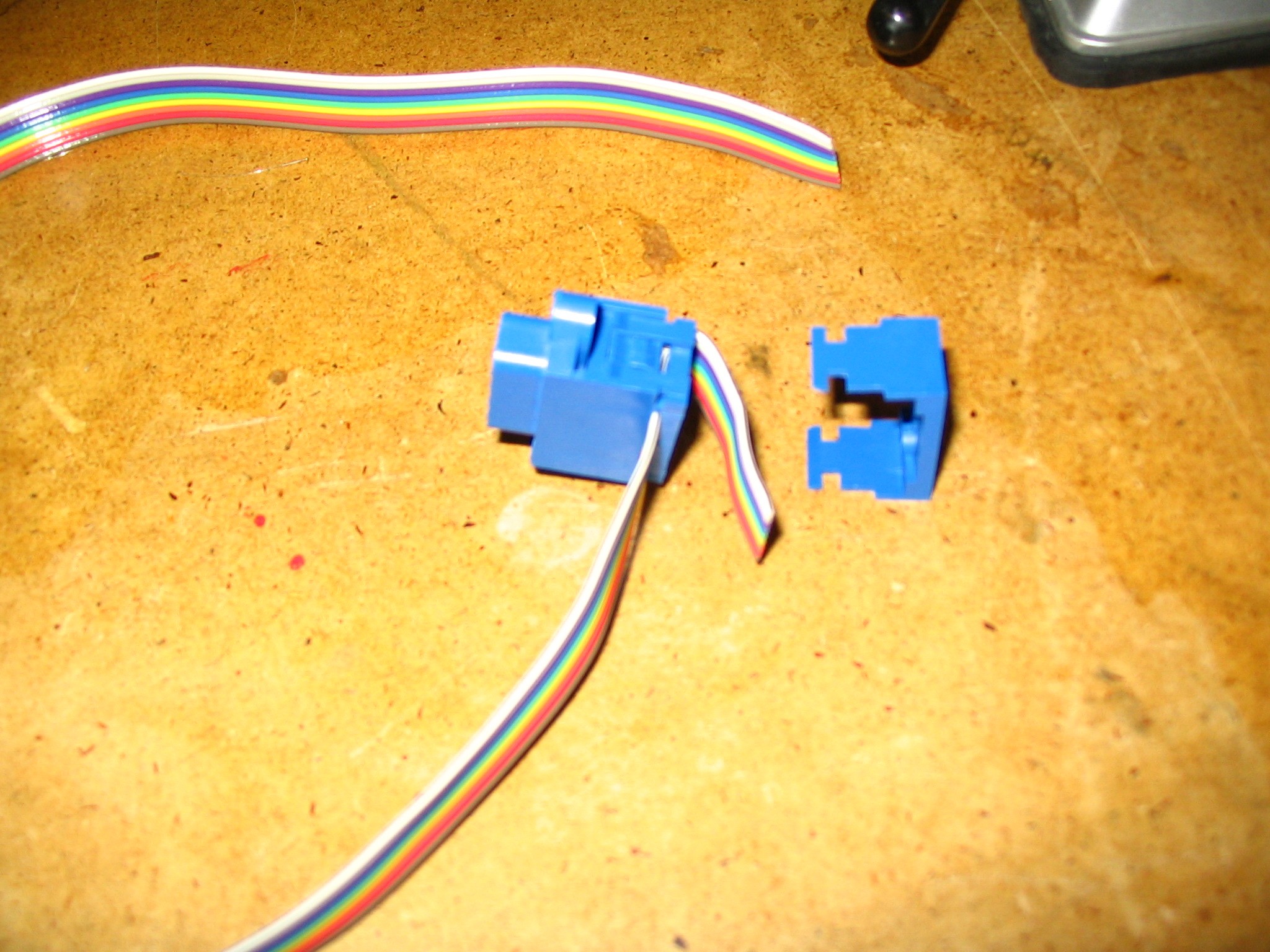

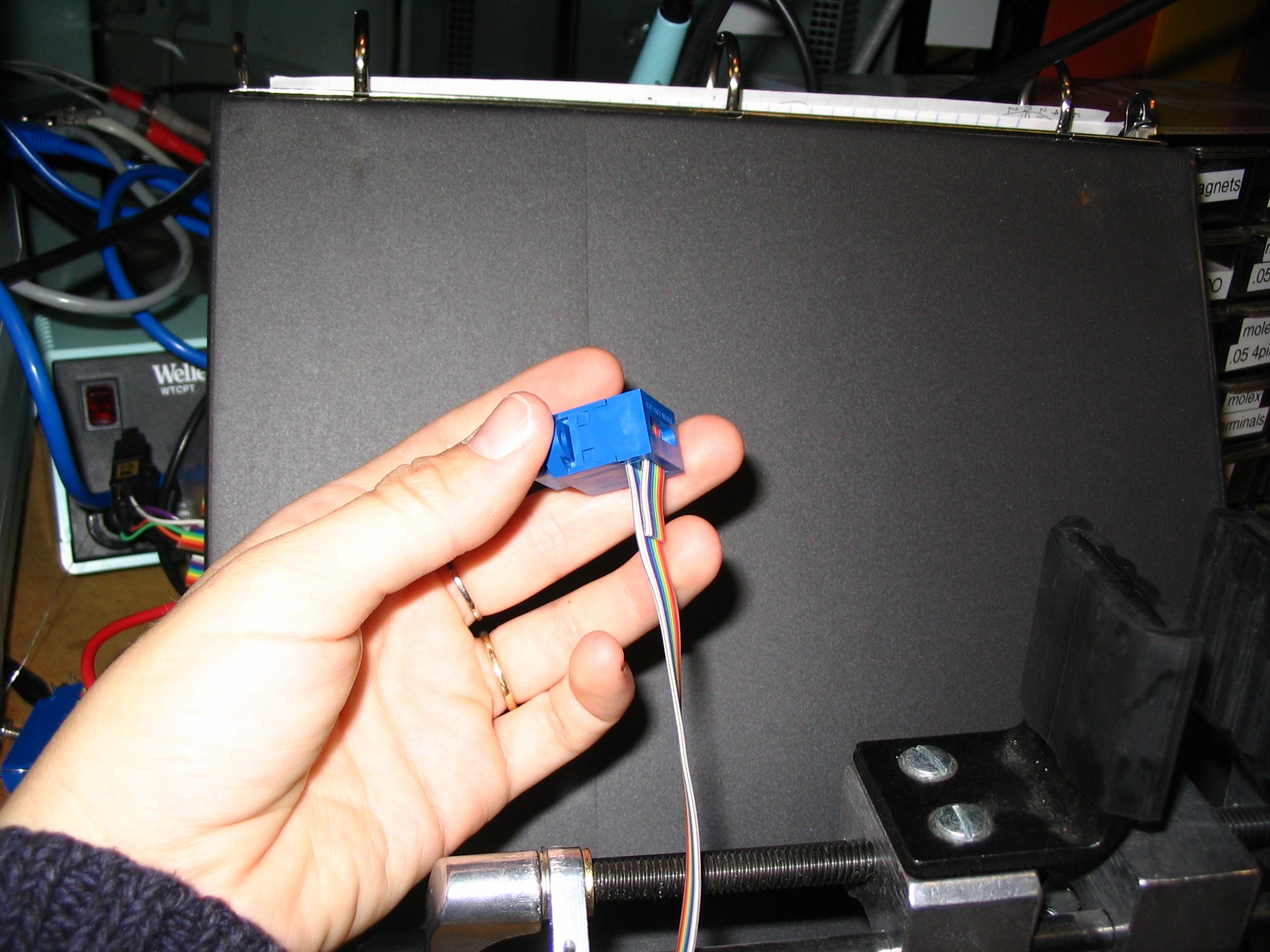

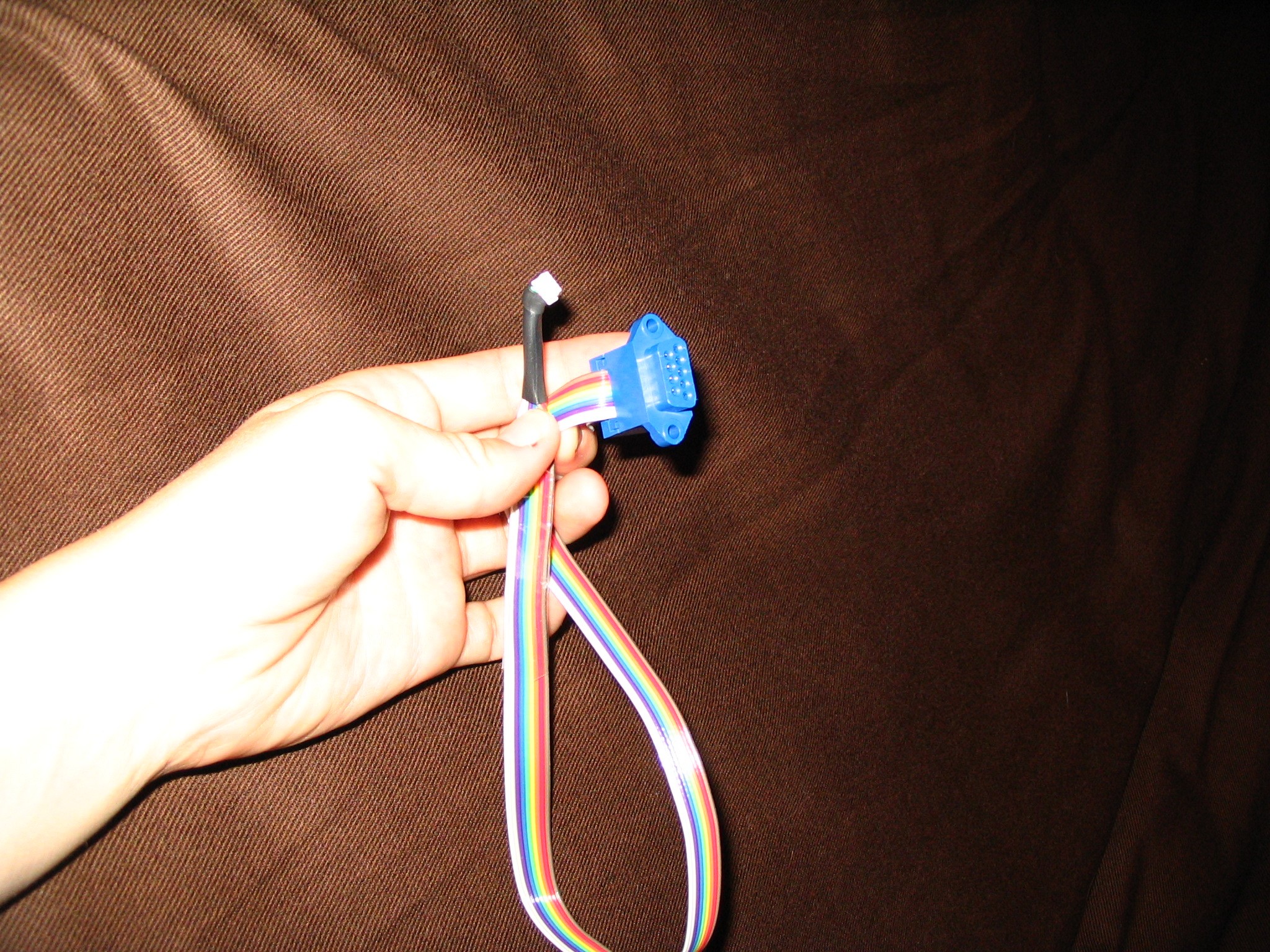

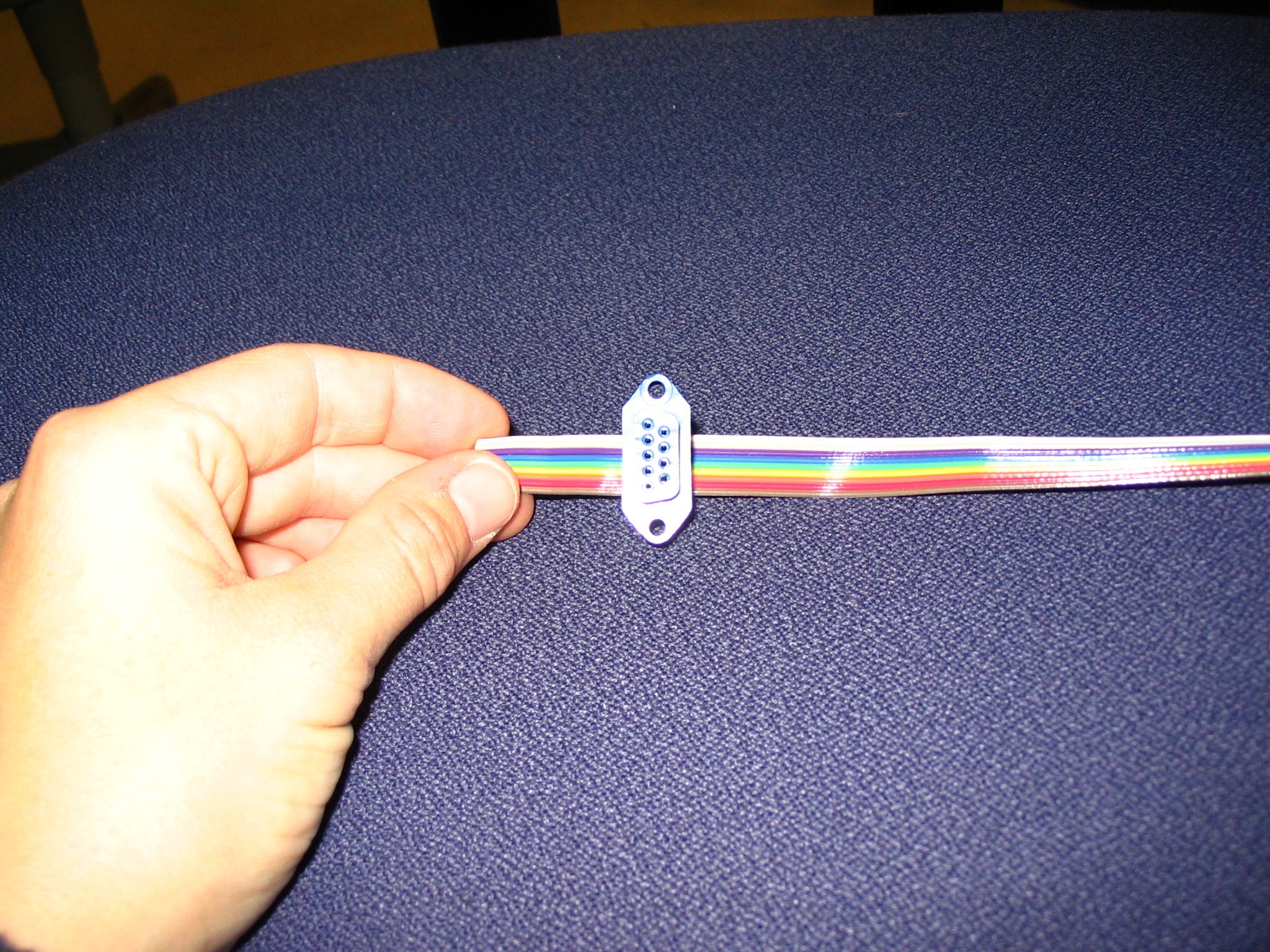

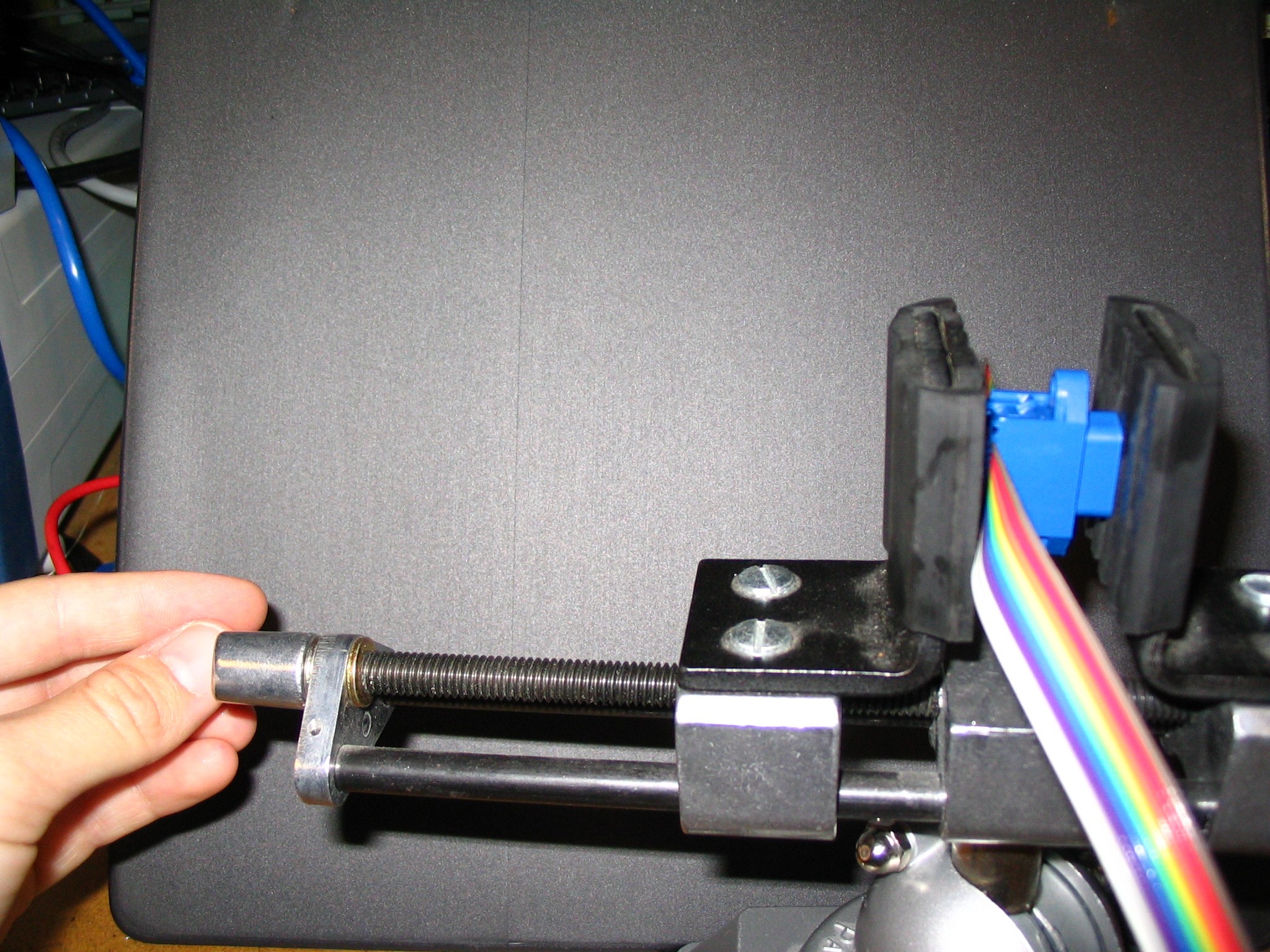

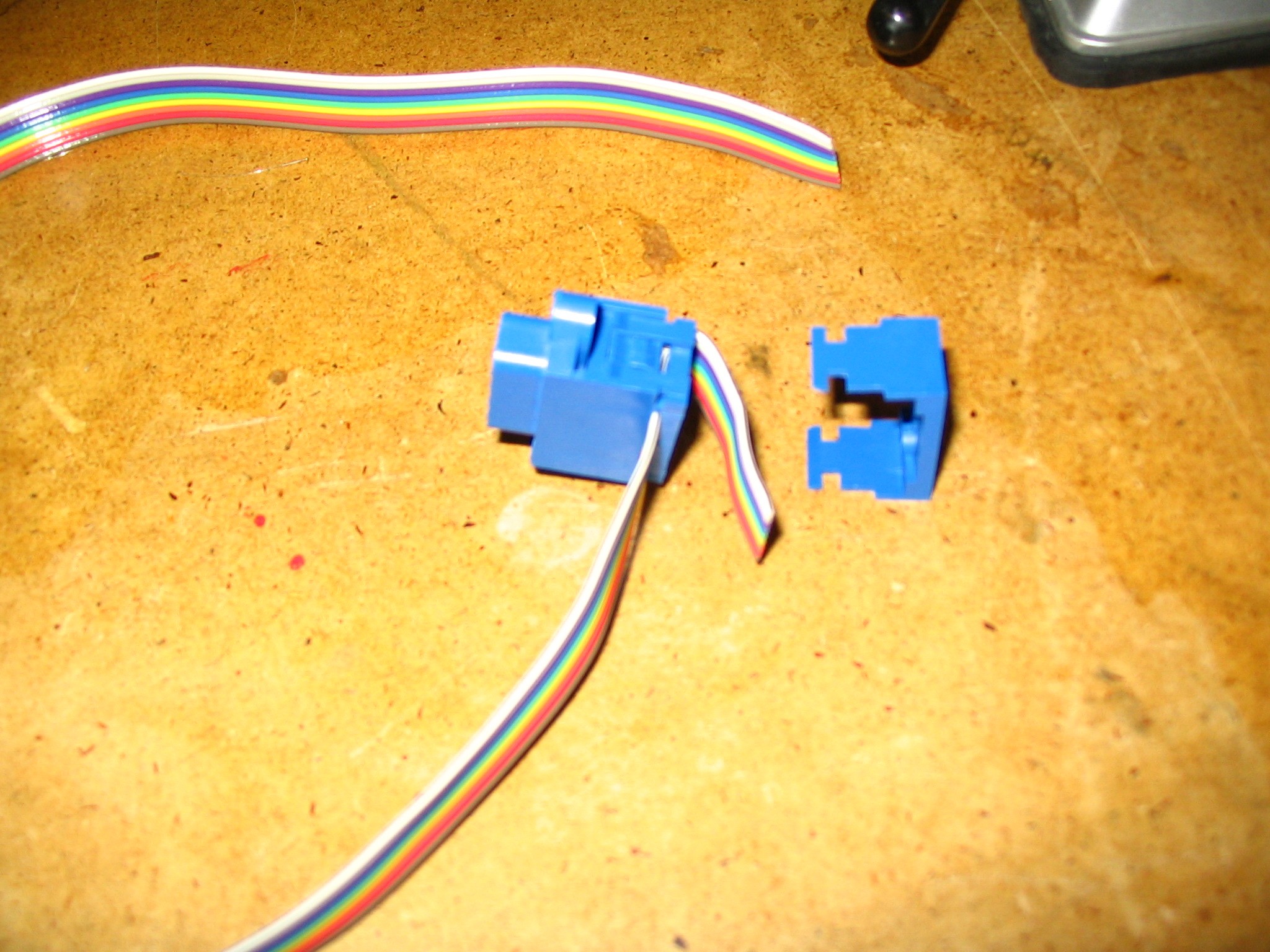

Get a length of rainbow-color-coded, 25-wire ribbon cable. Peel off a strip of 9 wires - that's all you'll need for this cable. Feed the wire through a blue DB9 female connector. Clamp the assembly in a vise and squeeze it (by tightening the vise) until you hear two faint clicks indicating that the connections are made between the connector and the wire. When you finish squeezing, put a strain-relieving blue 'cap' on the connector.

-

The pins on the connector and the wires in the cable are both numbered 1-9. Pins 1-5 are in the longer TOP row on the connector, and pins 6-9 are in the shorter BOTTOM row. If you are holding the cable/connector assembly so that you are looking at the pins (and pins 1-5 are in the longer, top row with 1 at the upper right), then wire 1 is the rightmost wire. The 9 wires are numbered from right to left.

-

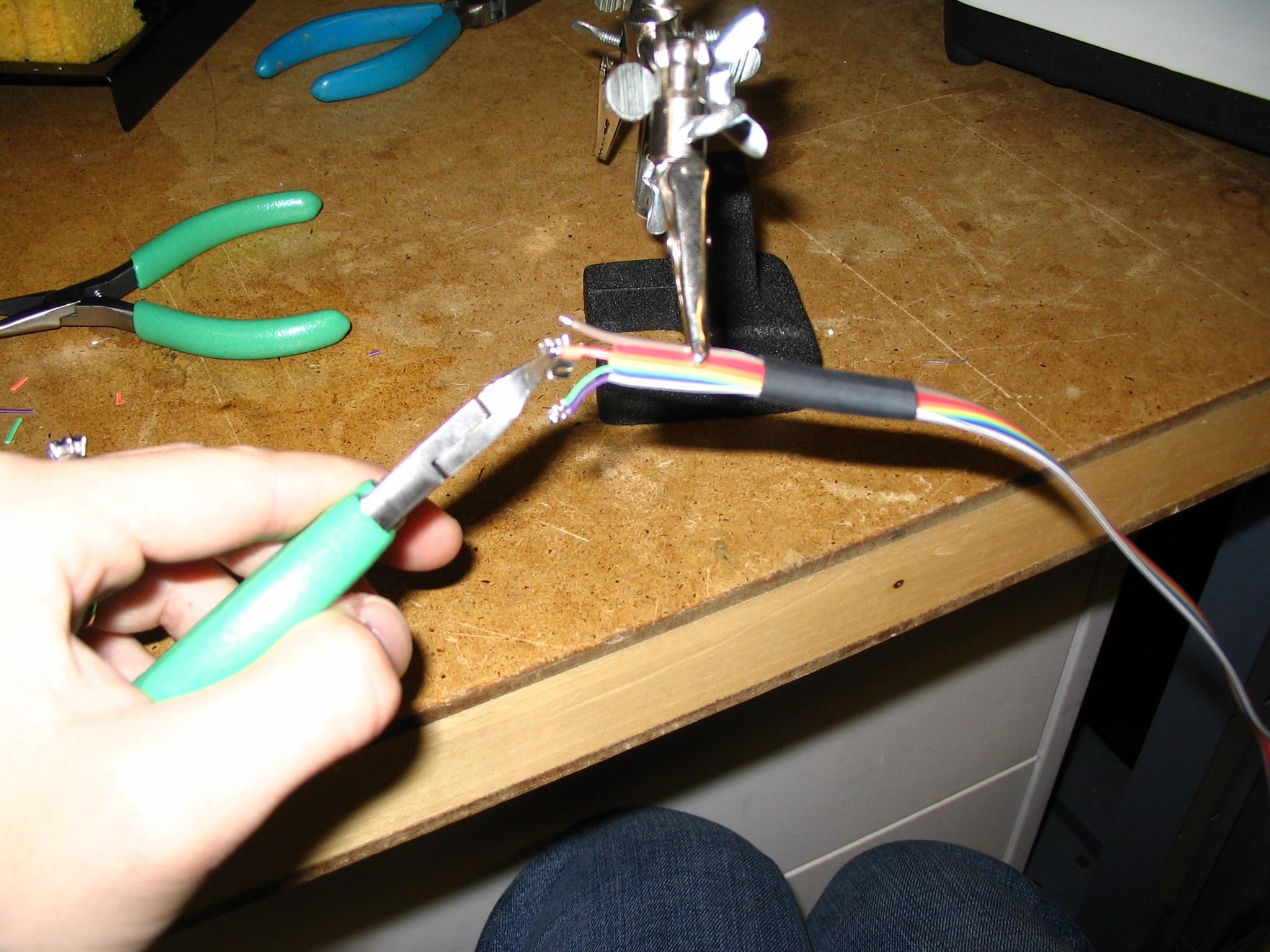

Use the cable layout (you can find one for 2005 hello world chips on this fab website) to figure out which 4 wires from the cable you will use. Separate a few inches of those wires from the rest of the cable (they peel apart easily) and cut off the wires you will not use.

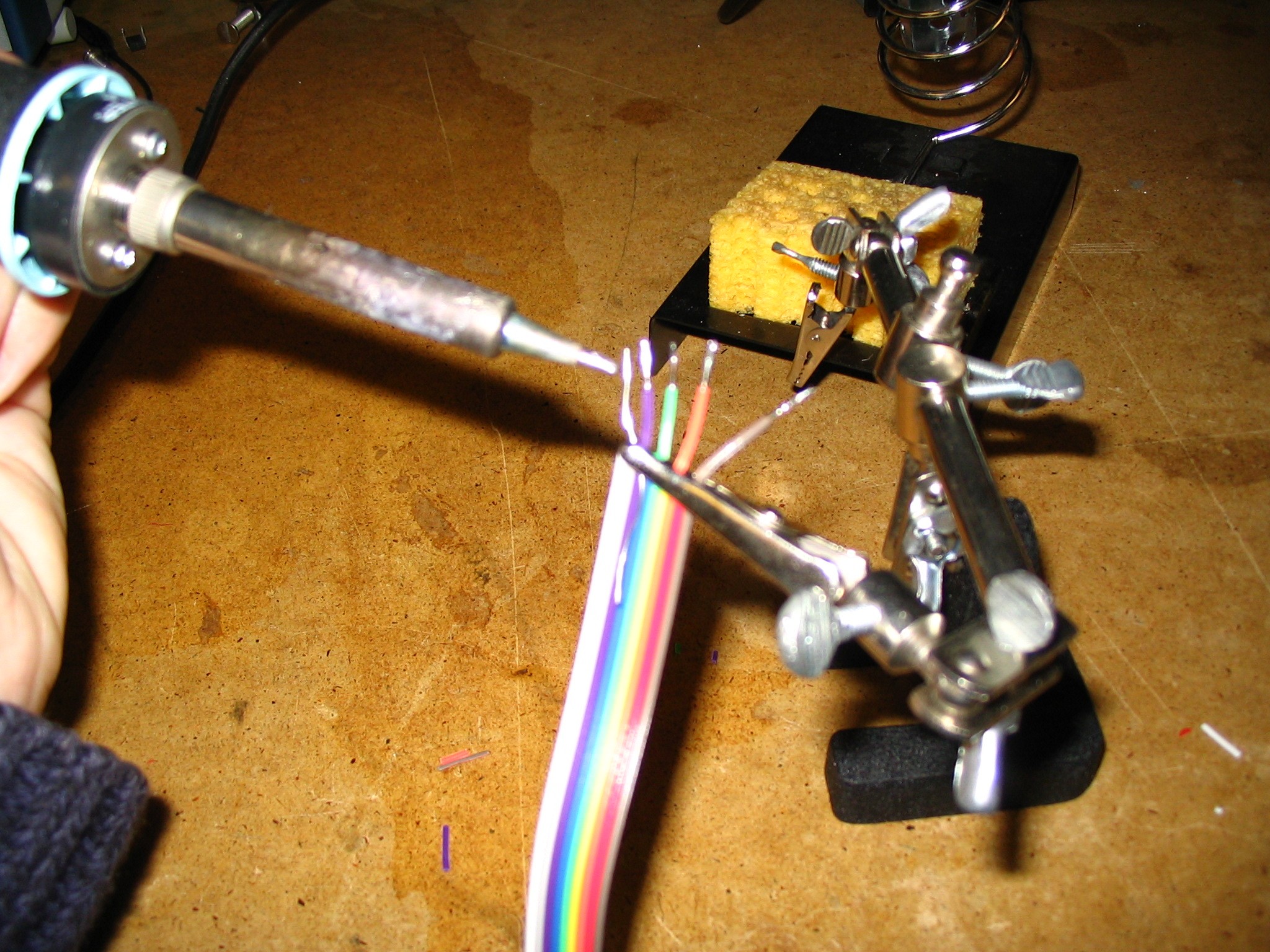

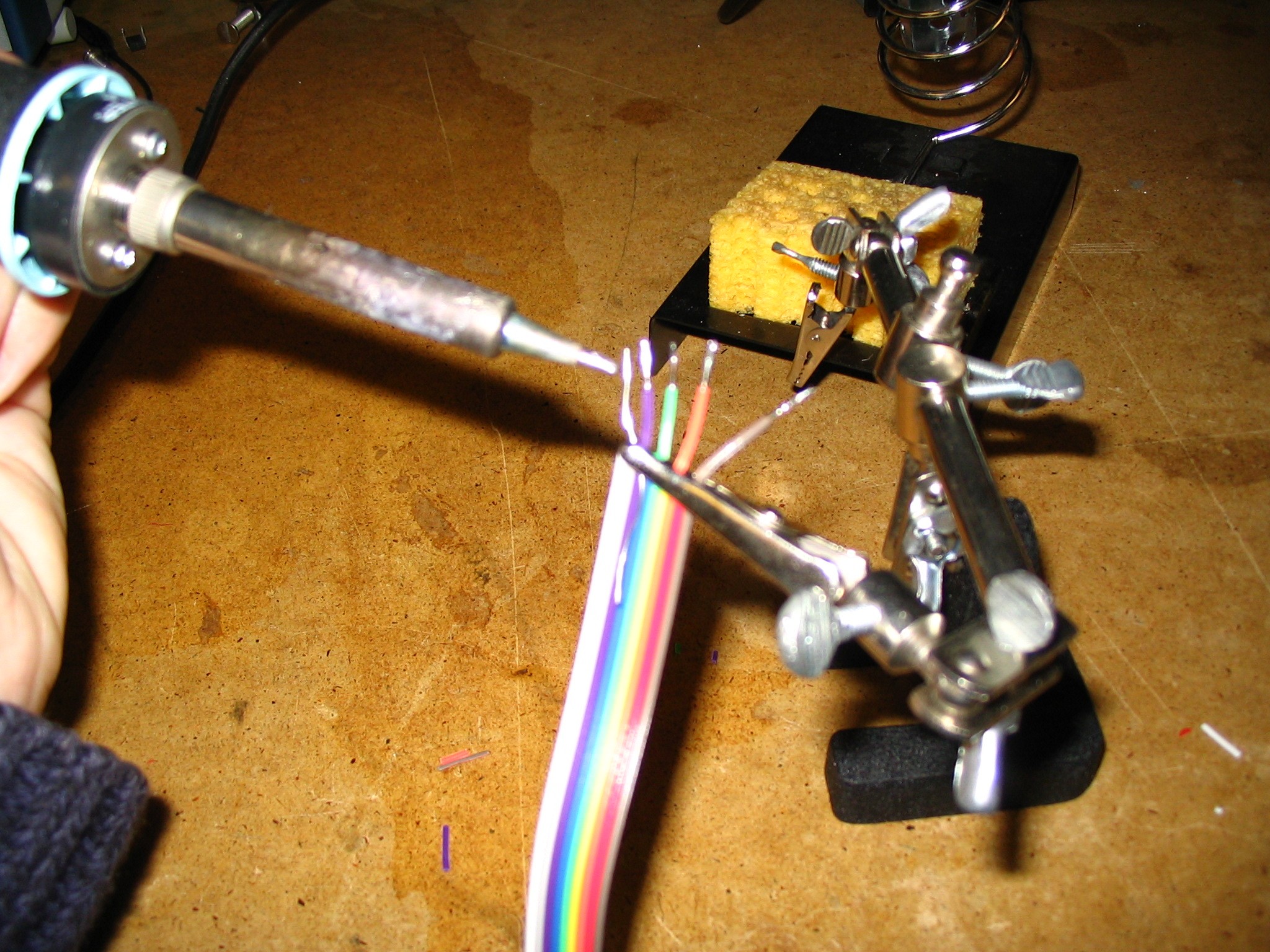

Strip about an inch of the ends of the wires you are using, and "tin" them with a little solder. Trim them to about 1/16" (about 2mm) so that just enough exposed wire is available to make the connections in the next step. NOTE - the later steps will be easier if all your wires are the same length.

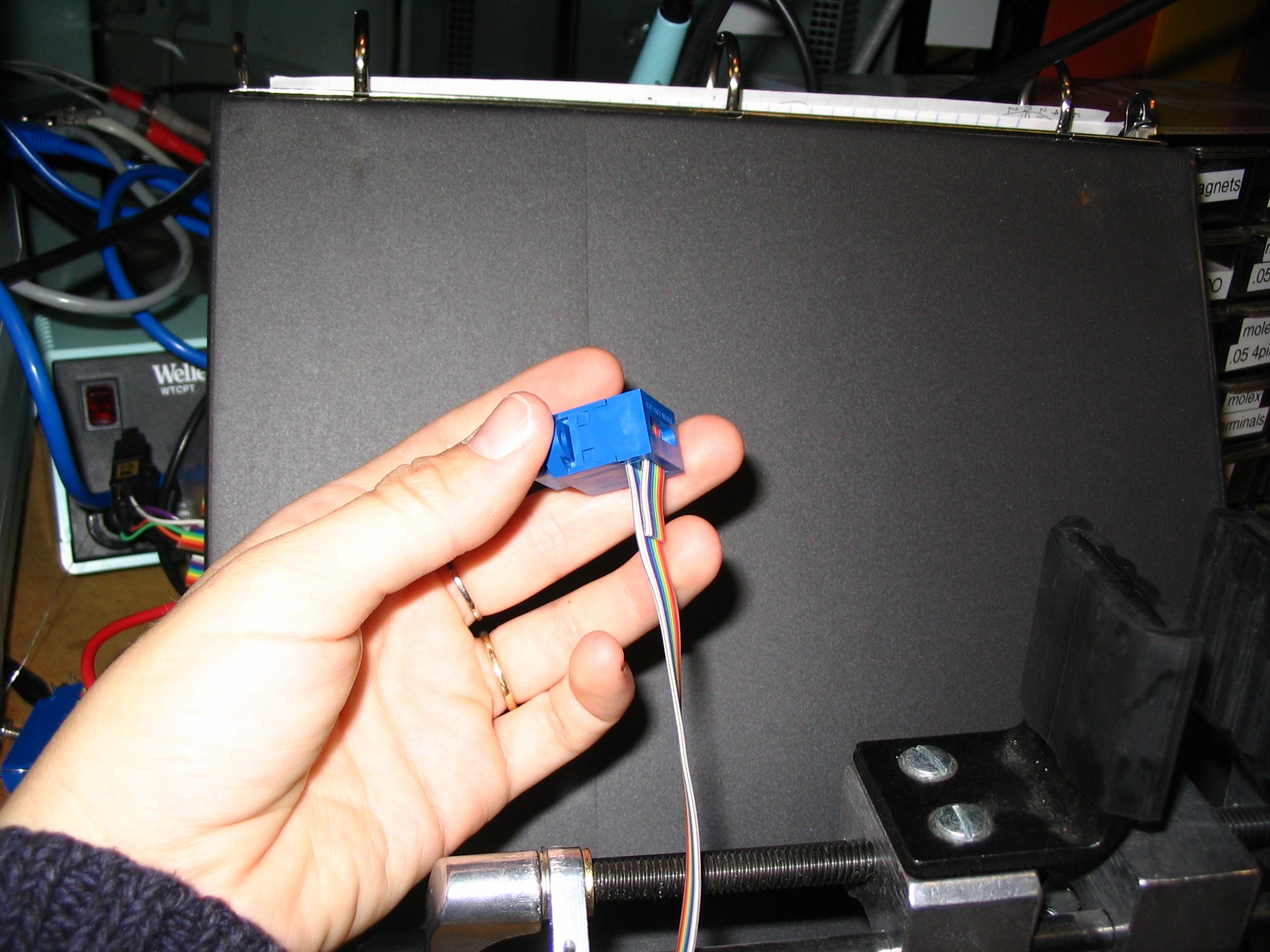

As shown in the picture, Put a piece of heat-shrink-wrap on the loose-wire end of the ribbon cable NOW - you won't be able to put it on after you solder on the connections! Having the shrink wrap there will help strengthen the final product, which is very desirable given the fragility of these cables.

-

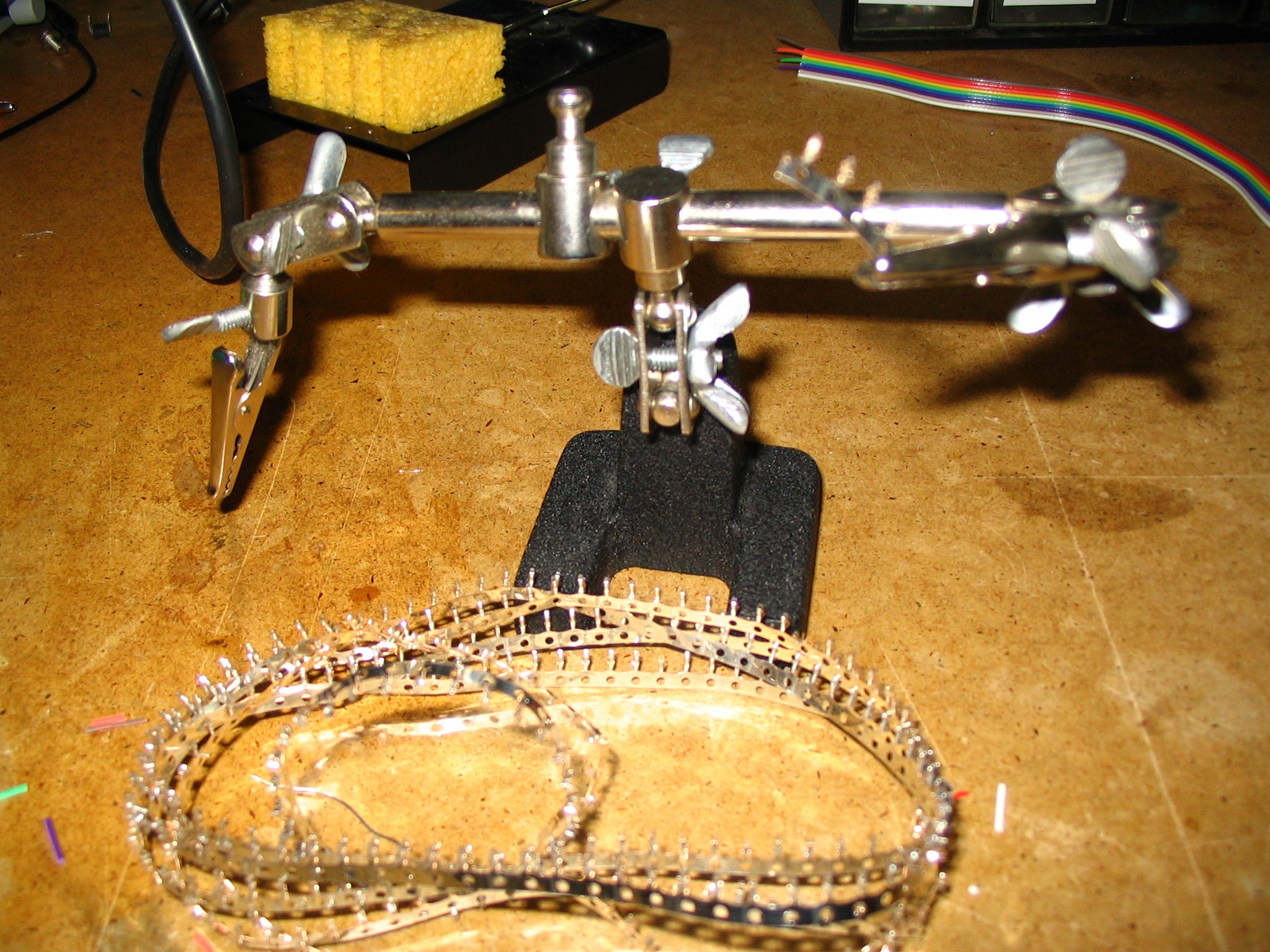

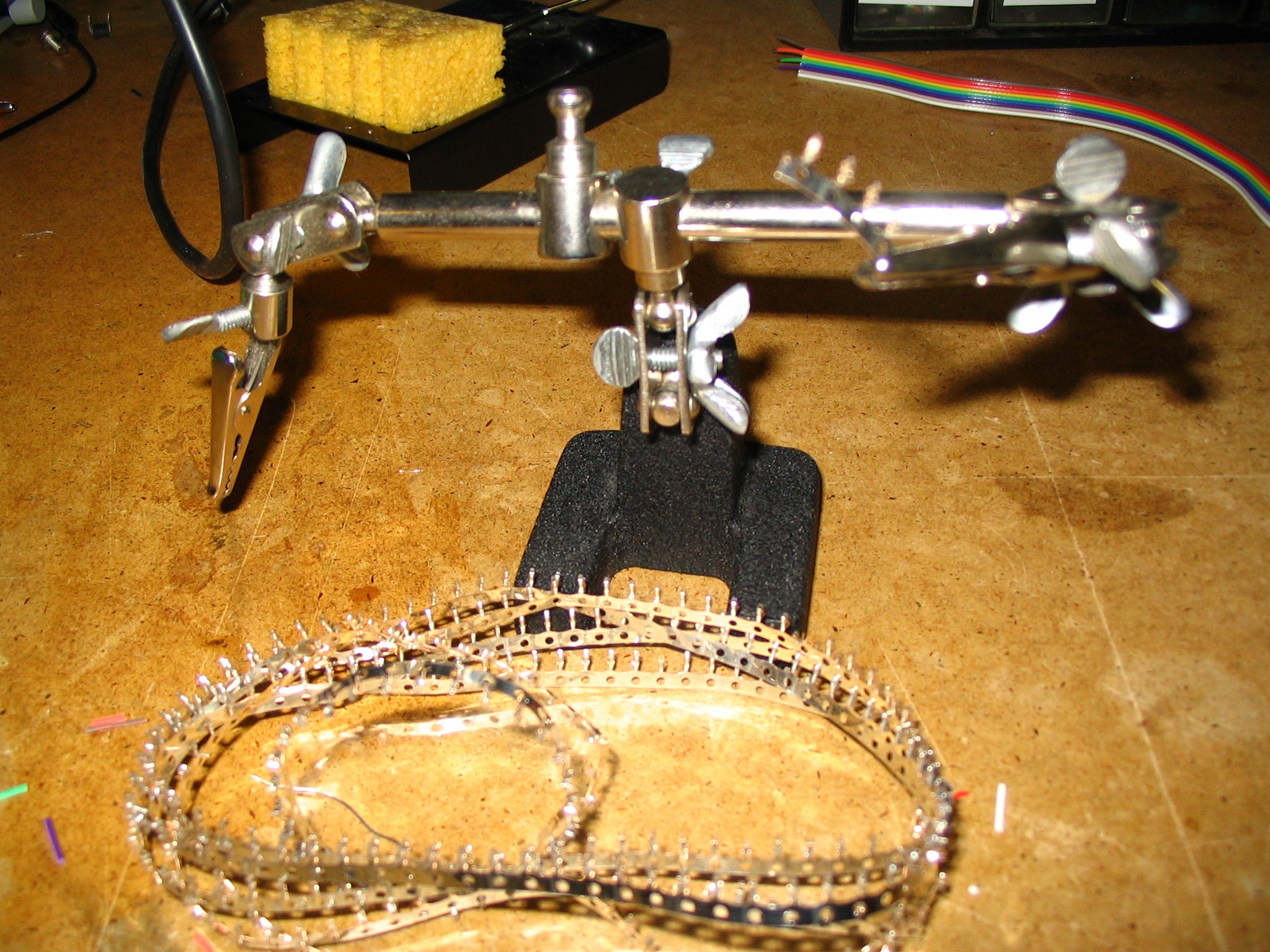

Get 4 little silver inserts for the serial header, leaving them attached in a strip. NOTE that the picture of the serial header shows a model with more ports than the one you are using, which has only 4.

On each metal thing, the side with three sets of "arms" reaching up around a central trough is the BOTTOM, and the side with one little finger/hook sticking out is the top. The end with the taller "arms" is the back (where you will insert wire), and the end with the shorter "arms" is the front (where the thing will insert into the white plastic serial header).

-

Clip the strip of metal things in a "helping hand" on your benchtop so they are facedown and the back is accessible to you. VERY IMPORTANT: These metal things will insert right-side-up into a little white serial header, which will insert right-side-up into the serial port on your chip. You need to be sure you do not connect the metal things upside down, so check your cable layout carefully and remember that the metal things are upside down as you are soldering them!

-

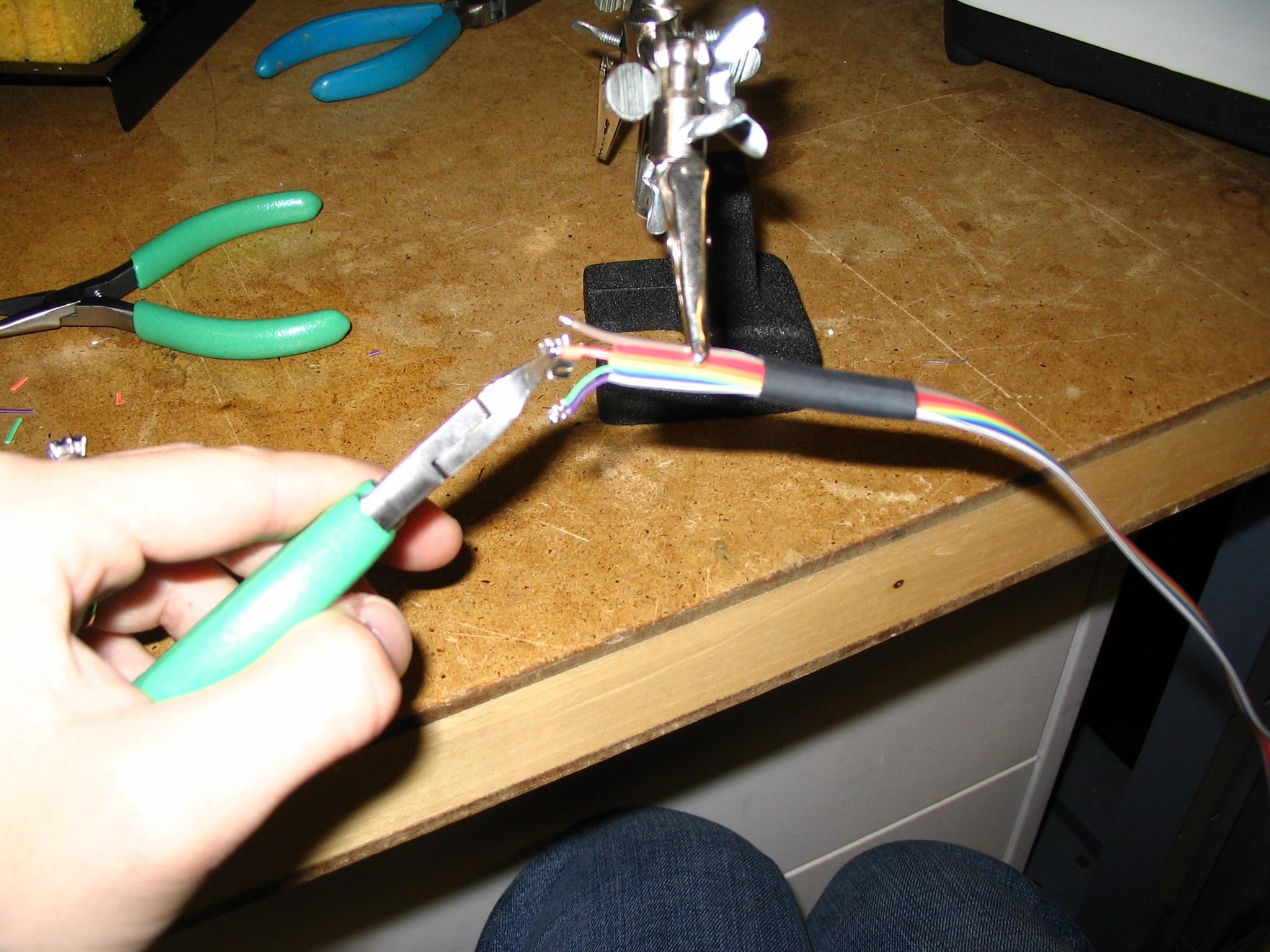

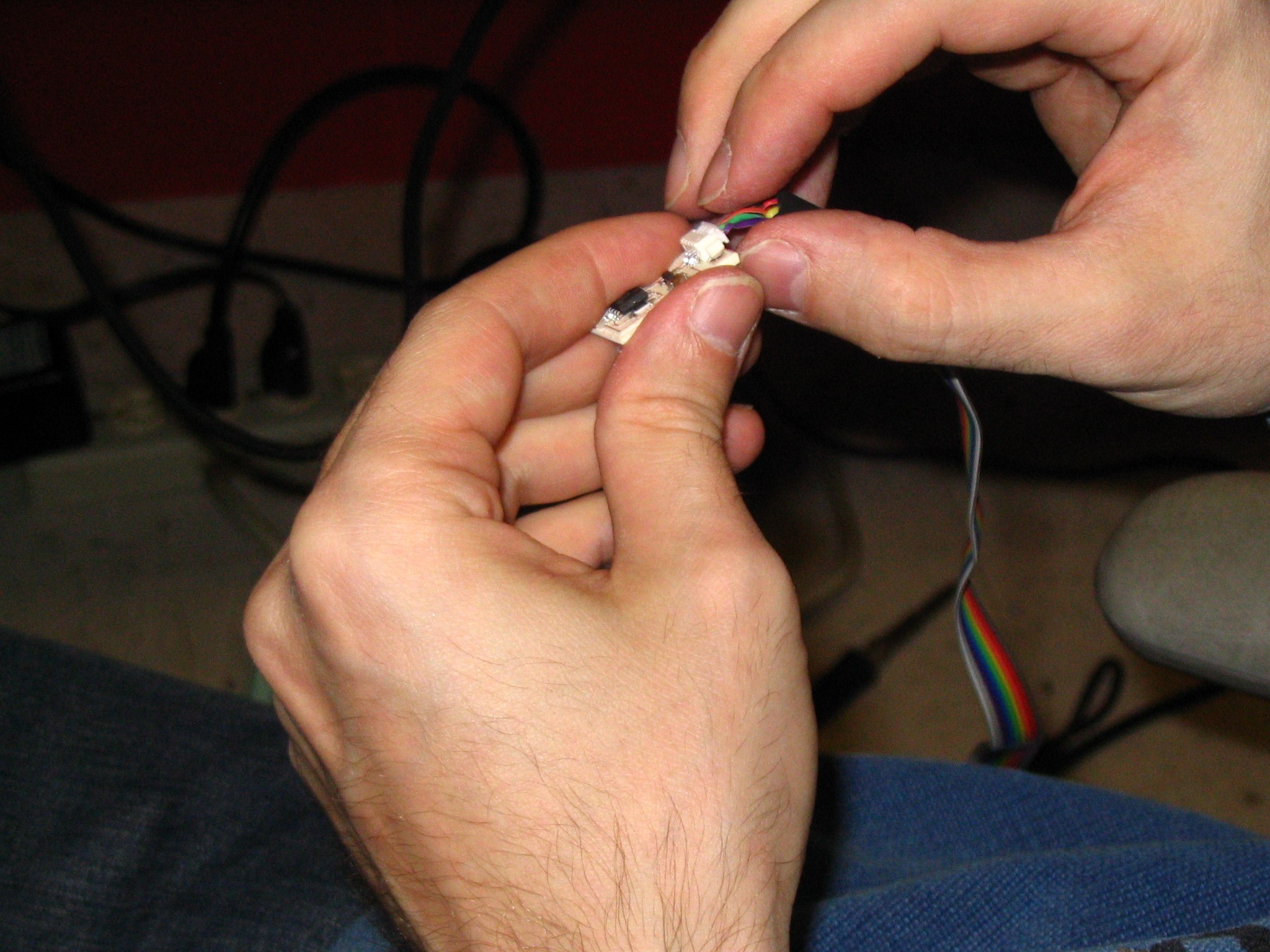

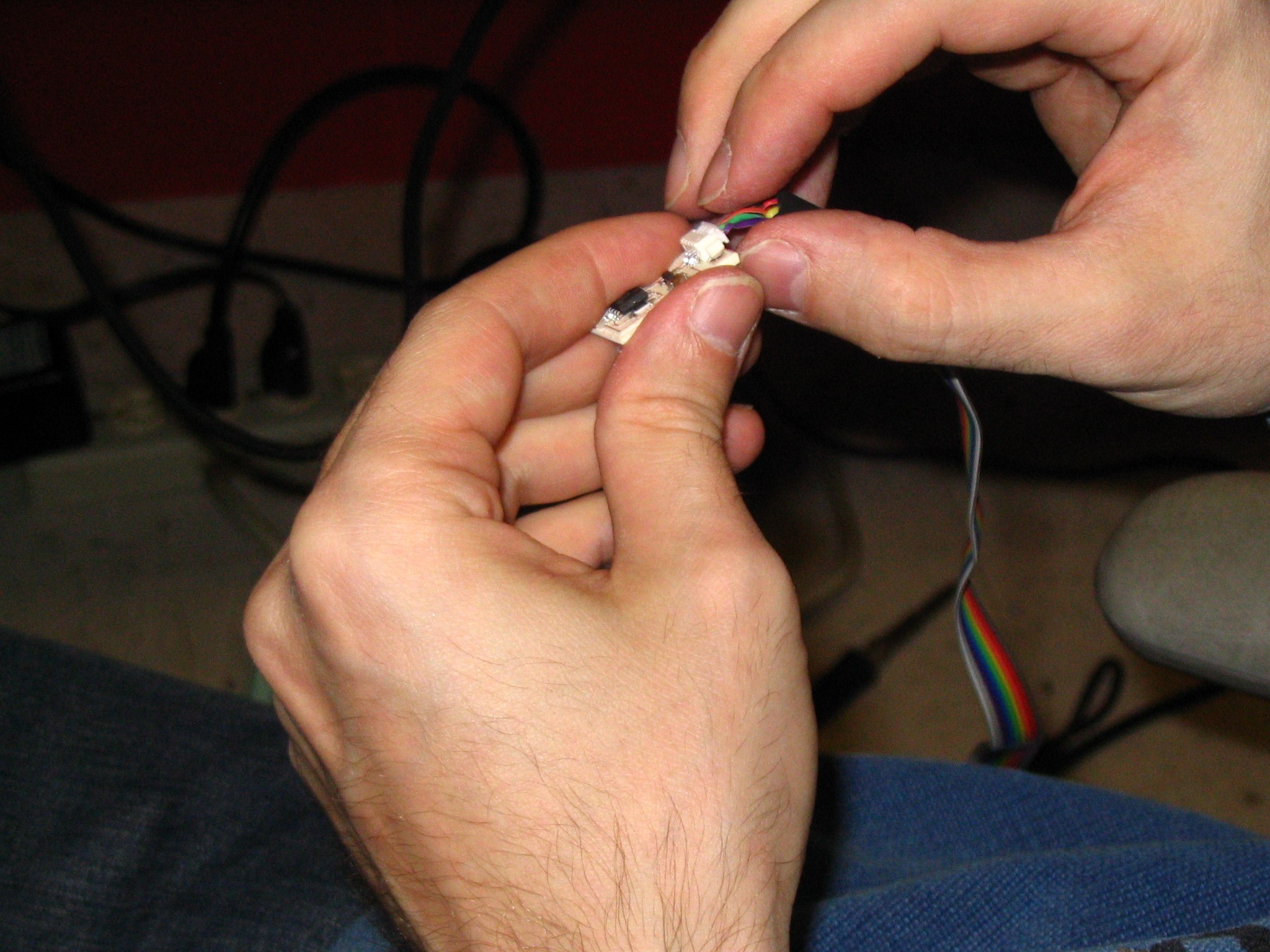

Insert a wire into the trough of the metal thing. It should reach to the second set of "arms," but NOT all the way to the third. The insulation on the wire should come right up to the back end of the metal thing - if it doesn't, cut your exposed wire shorter. Use a needlenose pliers to pinch the rear-most set of "arms" tight around the wire (this provides strain relief and helps hold the wire in place).

-

Solder the wire in place with a LITTLE bit of solder, making sure that the soldered joint does not reach all the way to the front-most "arms."

-

Repeat for all four wires, then use metal snips to cut all four wire/metal thing assemblies off the stip the metal things came on.

- Get a little white serial header, which will insert right-side-up into the serial port on your chip. The side with two square indentations on it is the bottom, and the opposite side with 4 rectangular holes is the top. Push your four wire/metal thing assemblies into the holes in the side of the serial header. Push them in far enough that you can see the little finger on the top of the metal thing peeking out the rectangular hole in the top of the serial header. You may want to push them in against the table/workbench, or you may need to use a pliers.

-

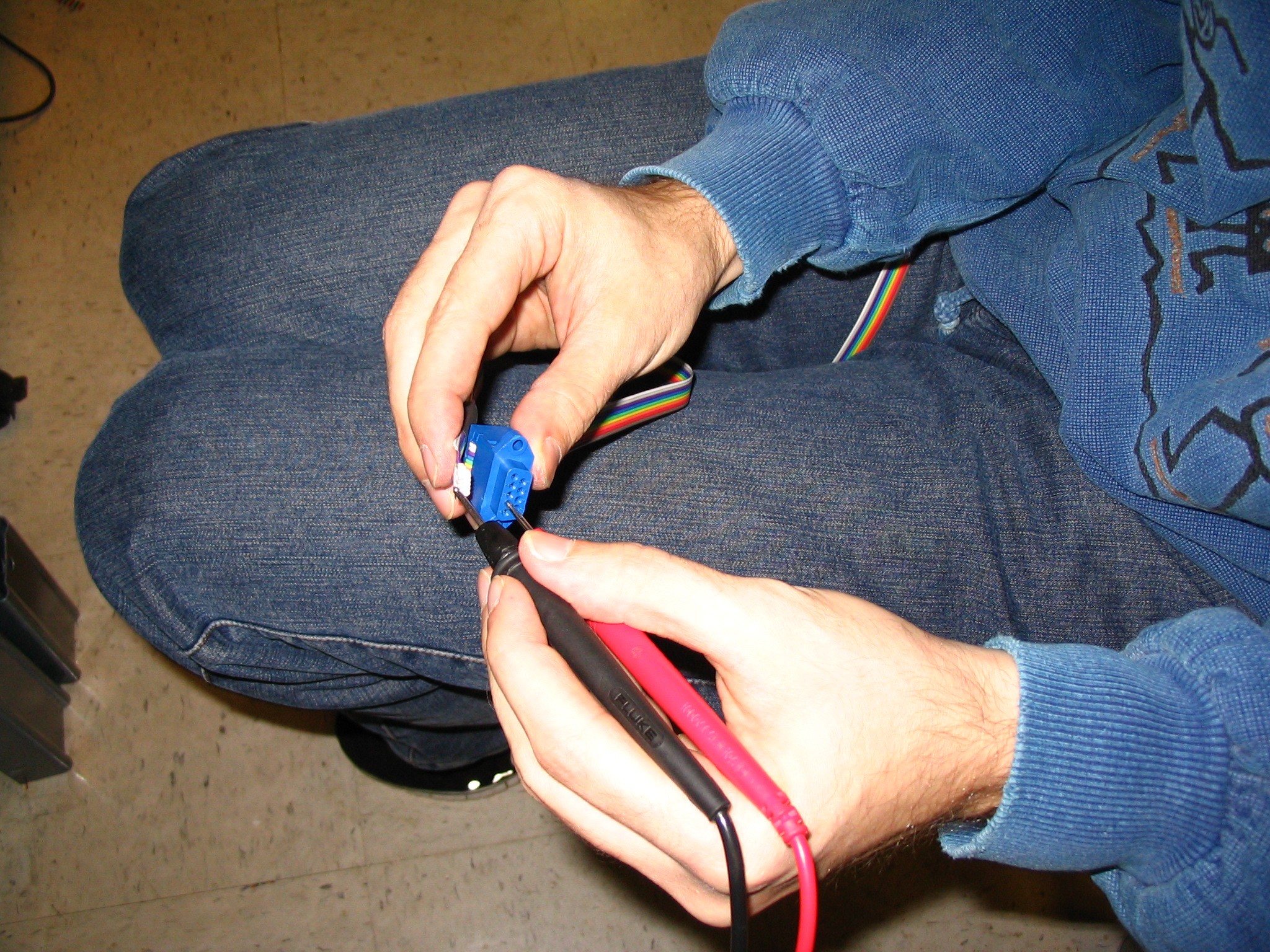

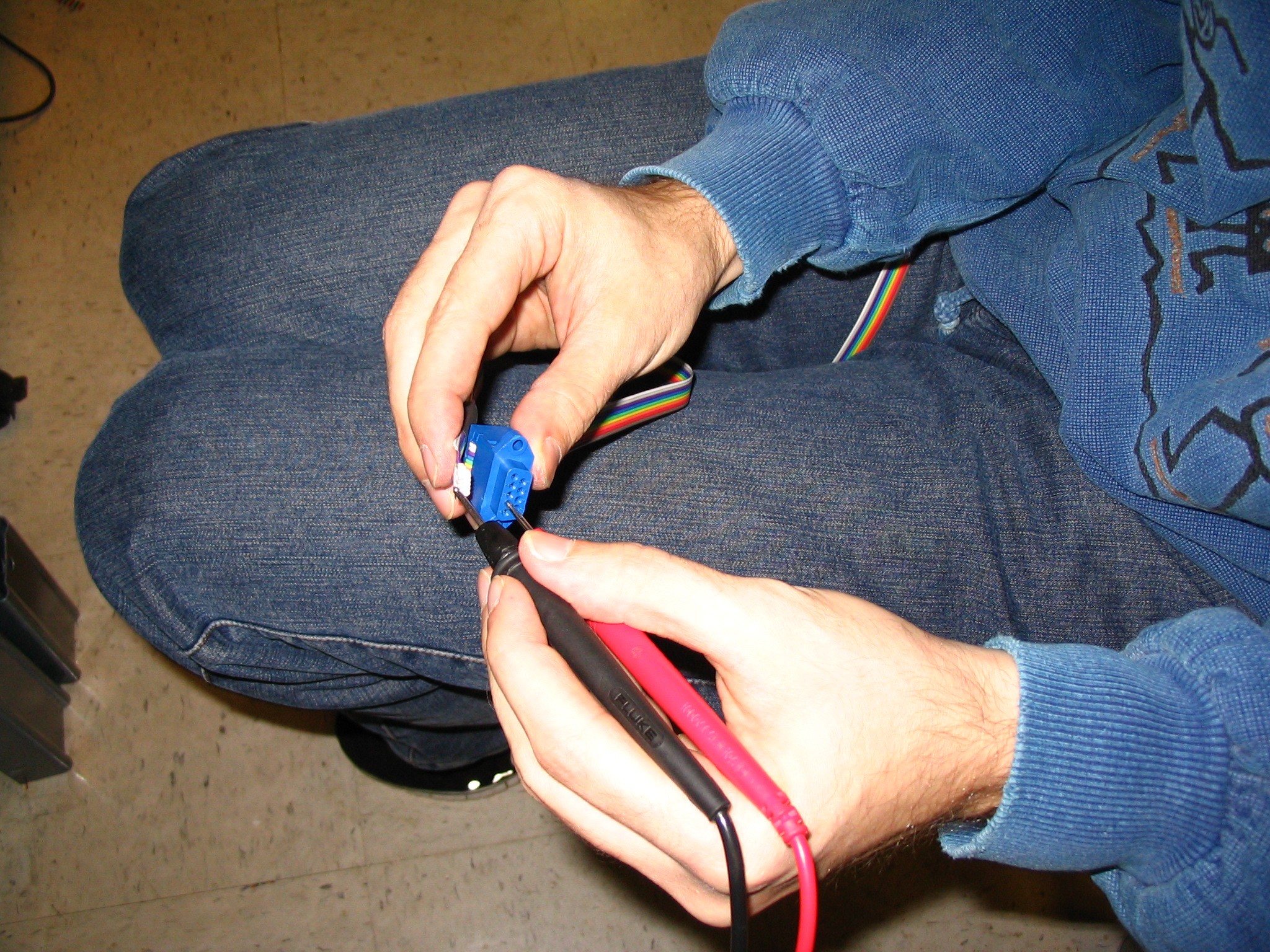

The cable is almost done! You can test the electrical connections using a multi-meter - do this if you think there's any small chance that you may have connected the wrong wires, or done a poor soldering job. (admit it, there's a chance.) Set the meter to beep when an electrical connection is made, connect the arms of the programming clip to the corresponding pins on the parallel connector, and hope for a beep. To make it possible to make a connection to the serial-header end of your cable, you will have to insert the header into a port (on a chip, or just a loose one).

-

Plug the cable into a chip, and then slide the heat-shrink-wrap down as far as possible toward the soldered connections between the wires and the serial header. (You are using the chip as a guide to know how close to the header you can put the shrink wrap without interfering with its ability to connect. If you don't have a chip, you have to guess where to put the shrink wrap.) Use the heat gun to shrink it into place. After it cools, pull the cable firmly from the chip (for some reason, it's important to use some force when pulling it out the first time to 'break it in.')

-

All done - test the cable by trying to power/communicate with a chip! (Note - to program a chip and verify that it worked, you'll need a parallel cable as well, in most cases. If you have a programmed chip, you can just plug it in with your new cable.)