assignment 6 how to use the equipment here [6] :: use the HASS milling machine :: - in this assignment, we were asked to "make a mold of anything that makes you happy" - then we will take this mold and inject it with ABS plastic in the injection machine.

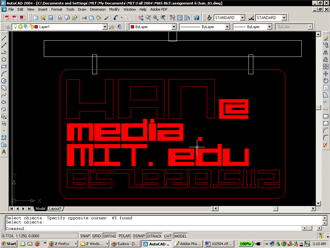

:: using AutoCAD to generate the DXF file ::

i decided to make a mold of my email address in order to create a template for my version of a business card.

i used AutoCAD and generated text. however, in FeaturCAM (the layout program that we're using to set up the milling),

it cannot register fonts as shapes, but rather only polylines or geometries. therefore, after i generated the text,

i outlined the shapes of the text with polylines and then export it as a dxf file.

i decided to make a mold of my email address in order to create a template for my version of a business card.

i used AutoCAD and generated text. however, in FeaturCAM (the layout program that we're using to set up the milling),

it cannot register fonts as shapes, but rather only polylines or geometries. therefore, after i generated the text,

i outlined the shapes of the text with polylines and then export it as a dxf file.

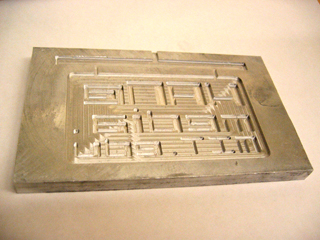

the FeatureCAM file is then sent to here to be mill.

the FeatureCAM file is then sent to here to be mill.

the final milled piece that will be use for the mold of my business cards.

the final milled piece that will be use for the mold of my business cards.

:: mold injection :: - here is the step by step process for the mold injection